Method for processing main cable saddle of suspension bridge

A processing method and technology of the main cable saddle, applied in the processing field of mechanical parts, can solve the problems of high requirements on processing equipment, difficult to guarantee precision, low processing efficiency, etc., and achieve high docking precision, ensure consistency, and shorten the manufacturing period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

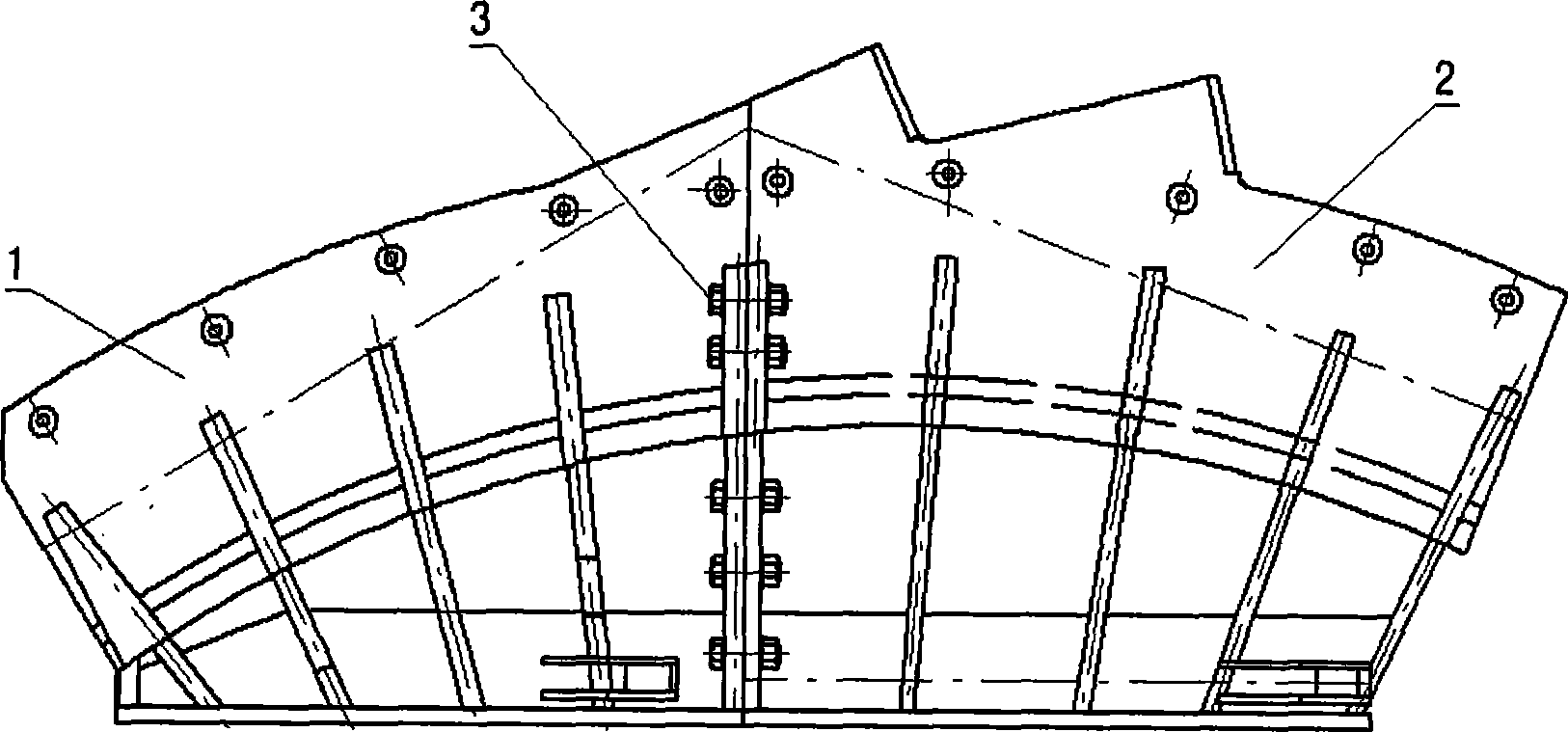

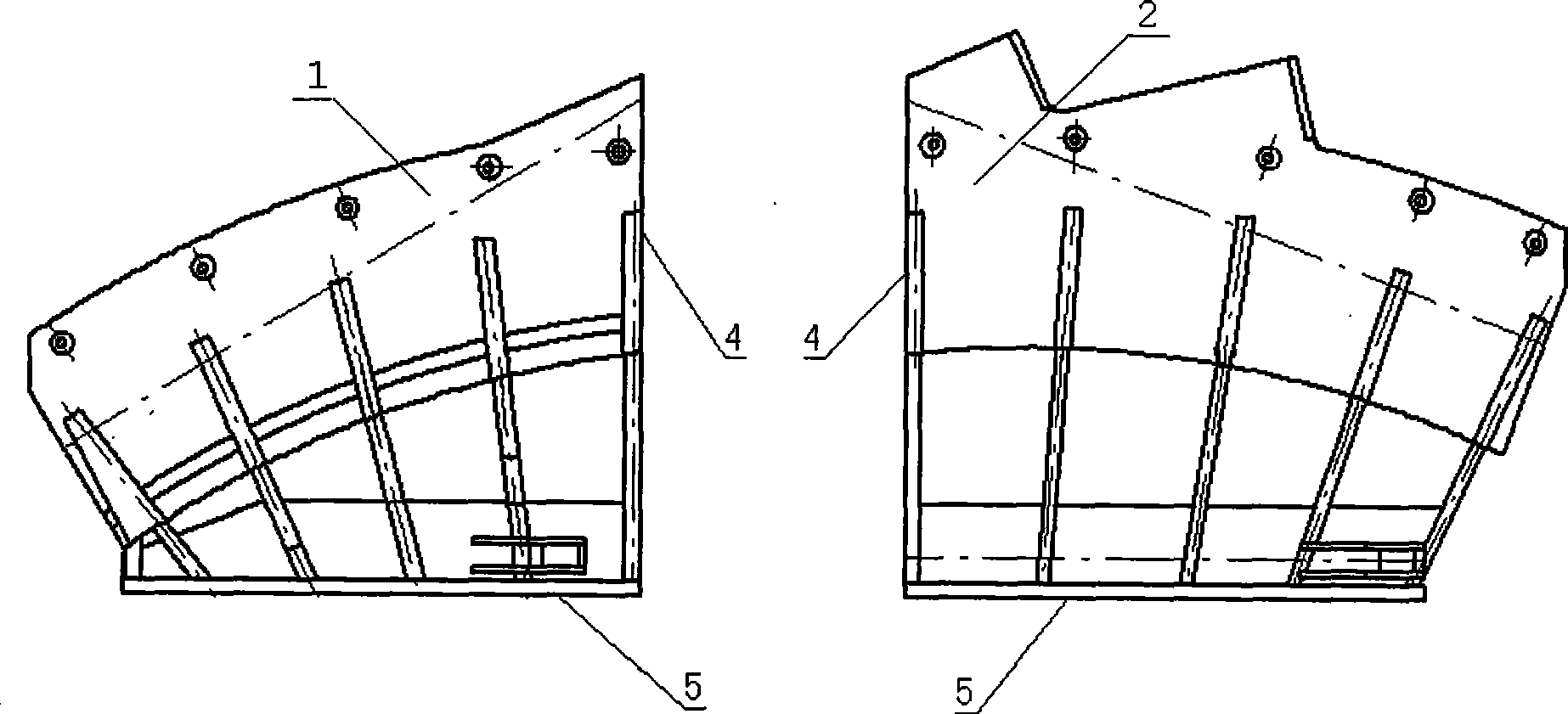

[0037] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , a method for processing the main cable saddle of a suspension bridge, respectively machining the side span 1 and the middle span 2 of the main cable saddle, and then connecting them with bolts 3, comprising the following steps:

[0038] A. Check the machining allowance of side span 1 and middle span 2 respectively, and mark the machining line on the joint surface 4 and bottom plane 5 of side span 1 and middle span 2;

[0039] B. Rough boring

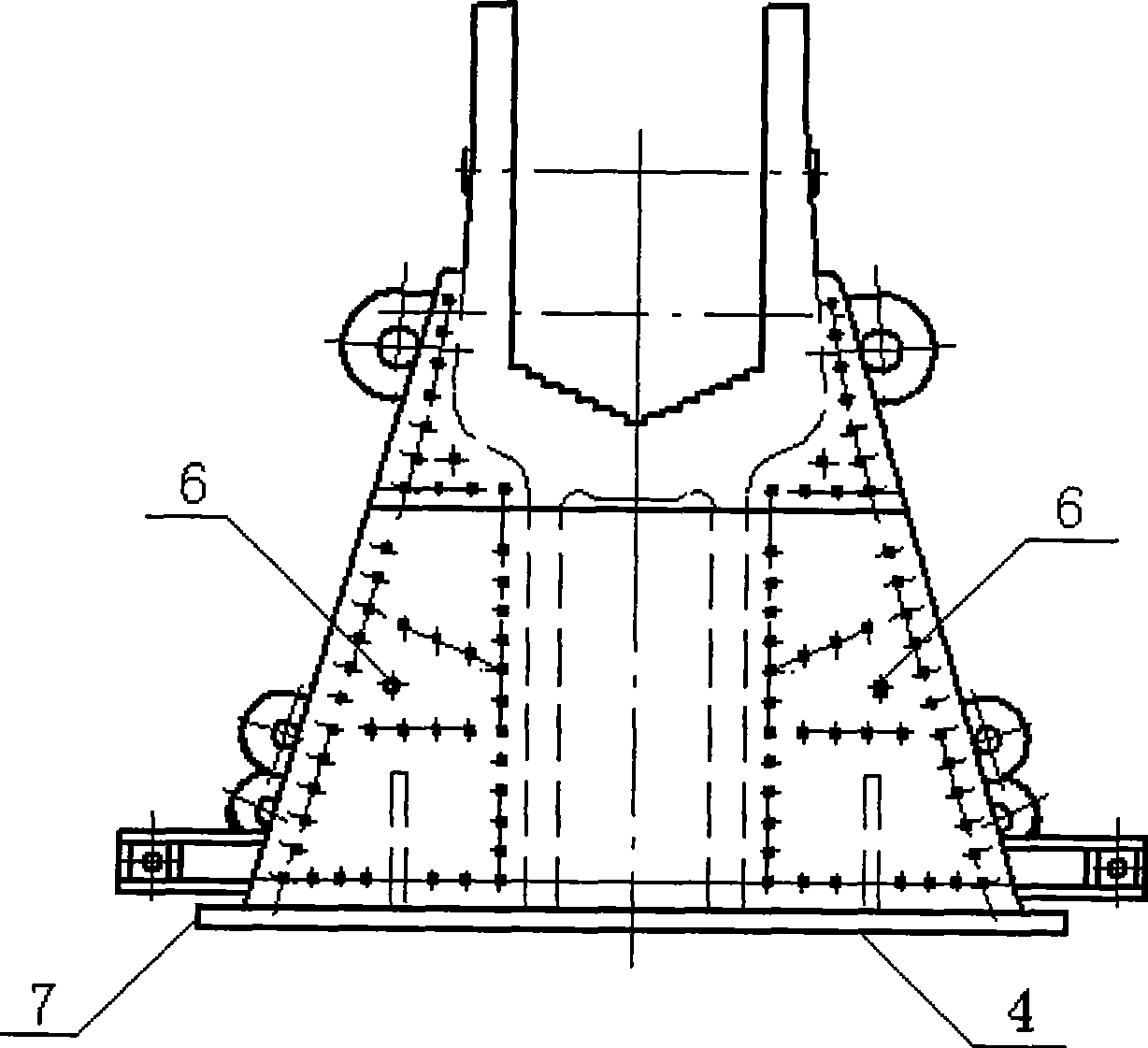

[0040] B1. Clamp the side span 1 or middle span 2 on the TK6925 CNC machine tool, align according to the marking line, rough-machine the bottom plane 5, the bottom side 7 and other sides of the bottom, and leave 5mm for finishing allowance;

[0041] B2. The worktable rotates 90° clockwise, taking the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com