Slender hole glass-sealing multi-pin electrical connector and preparation method of slender hole glass-sealing multi-pin electrical connector

A technology for electrical connectors and glass seals, applied in the manufacture of contact boxes/bases, fixing/insulating contact components, etc., can solve the problem of reducing the sealing density of the glass insulator in the inner hole of the seal, affecting the appearance of the seal, The problem of the height of the glass climbing column is to achieve the effect of good shape and size consistency, consistent size and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

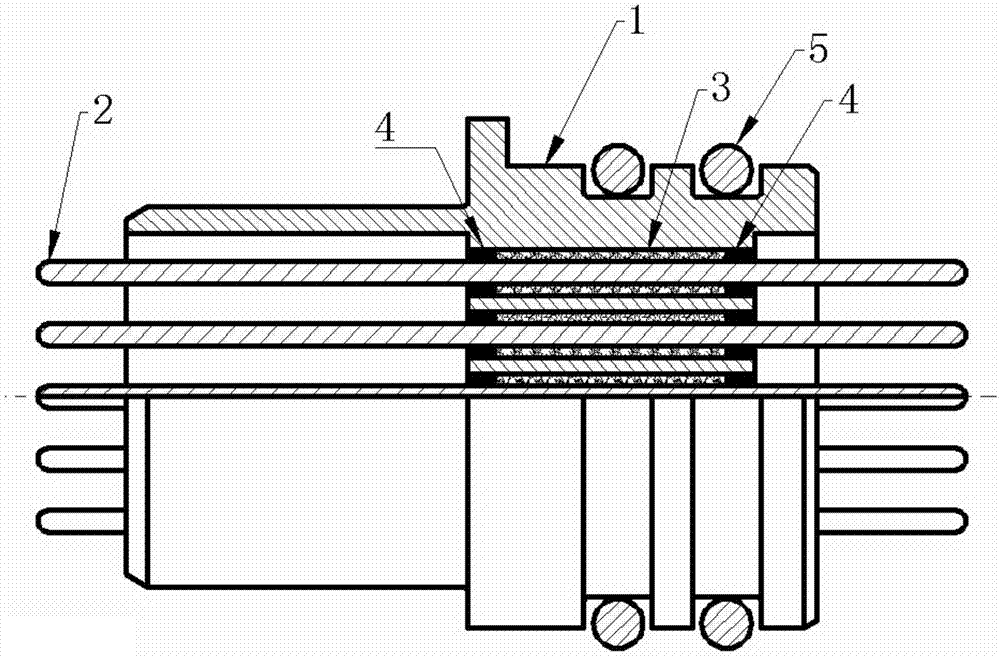

[0036] Such as figure 1 As shown, a glass-sealed multi-pin electrical connector with elongated holes includes a metal shell 1 with several sealing holes in the axial direction. The axial sealing holes of the metal shell 1 are through holes, and the sealing holes are equipped with Conductor pin 2, glass insulator 3 is sandwiched between conductor pin 2 and the wall of the sealing hole of metal shell 1, wherein glass insulator 3 is a single slender glass tube; There is an epoxy cured layer 4, a plurality of O-rings 5 are arranged on the outer side of the metal shell 1, grooves are arranged at both ends of the sealing hole of the metal shell 1, and the epoxy cured layer 4 is placed in the grooves.

[0037] The outer diameter of the glass insulator 3 is smaller than the inner diameter of the sealing hole, and the inner diameter of the glass insulator 3 is larger than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com