Patents

Literature

57 results about "Pressure Tubing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The tubing head pressure was 16 kilograms per square centimeter. This apparently low pressure is accounted for by the large size of the orifice at the surface. The tubing head pressure is the pressure on the tubing, which is measured at the wellhead.

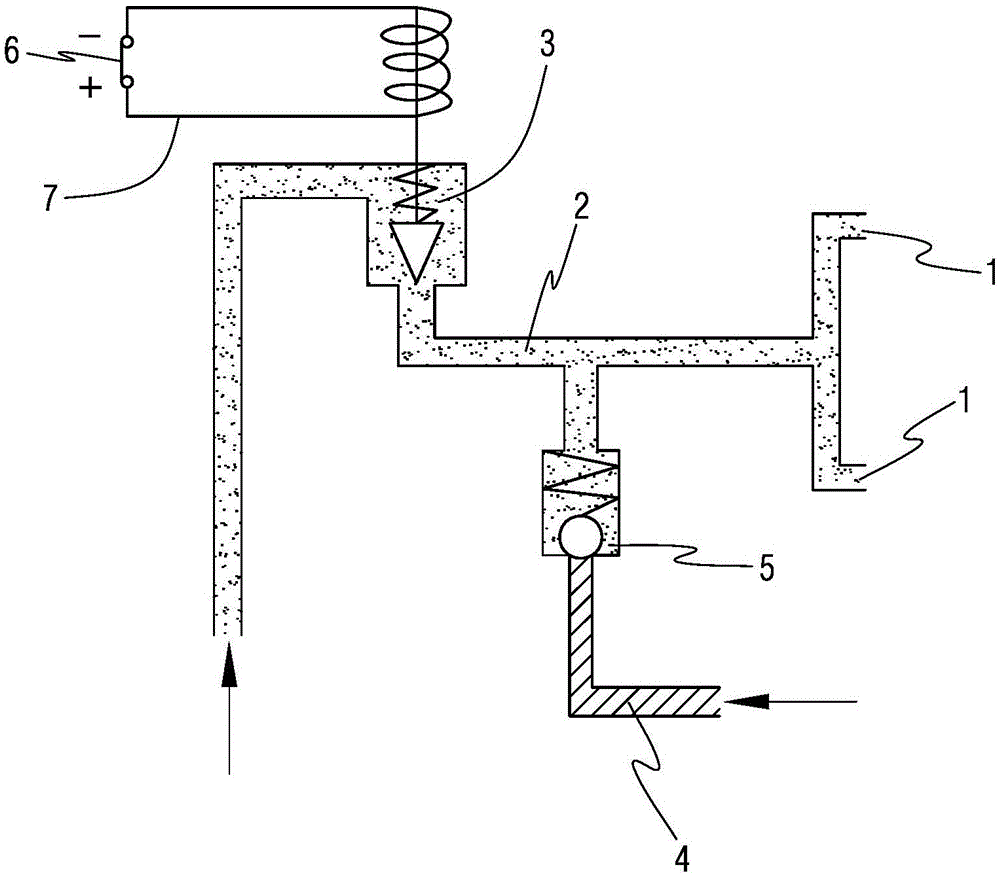

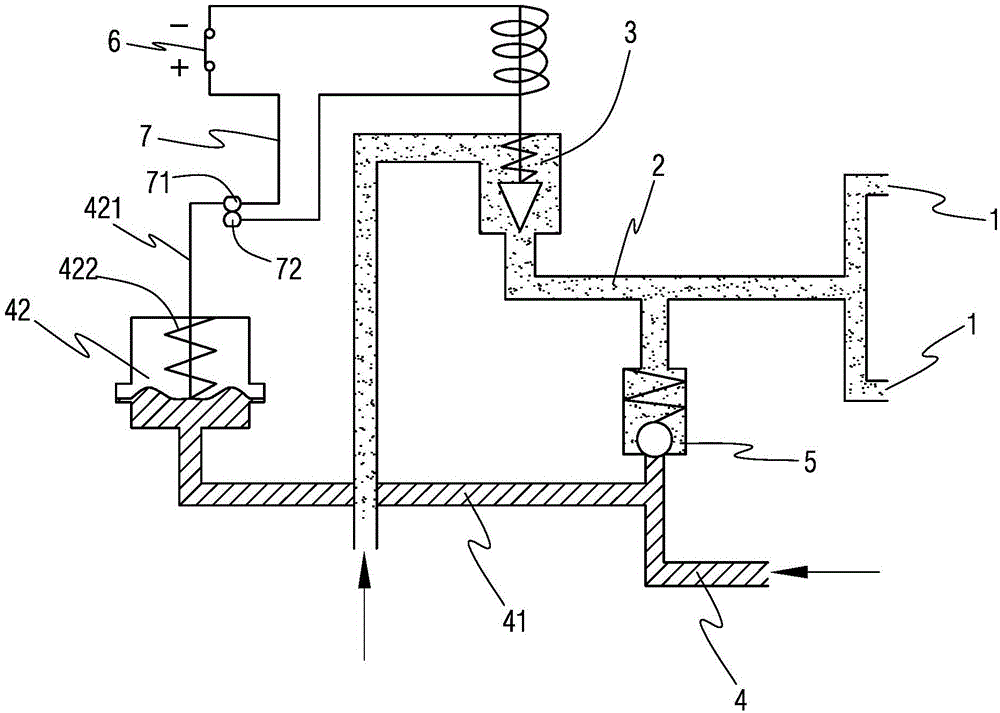

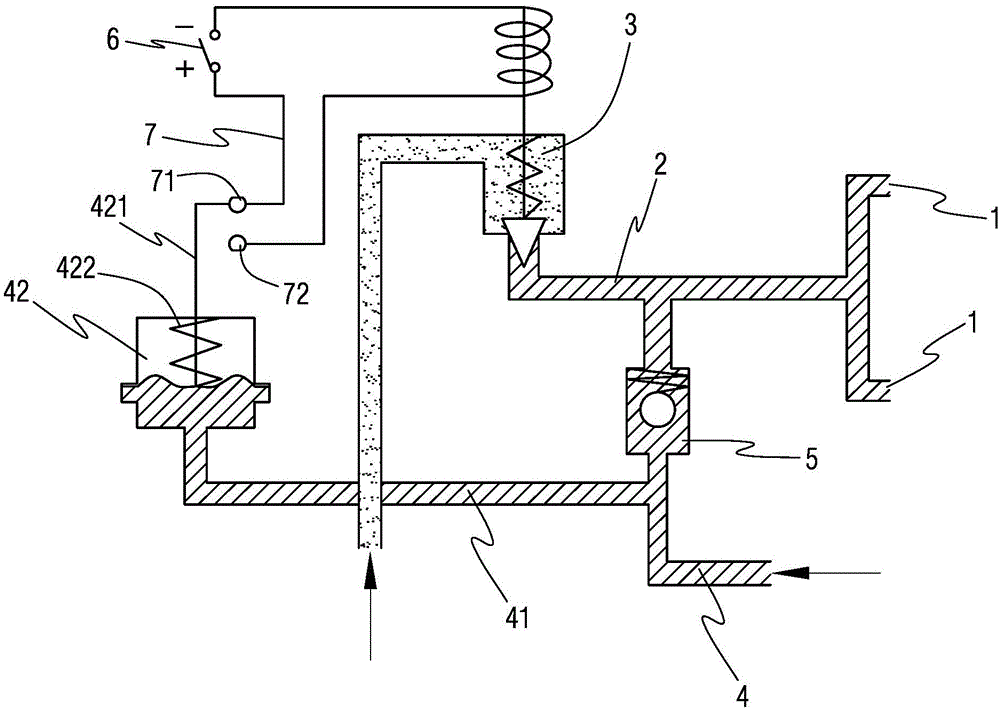

On-board engine using compressed air as power

InactiveCN1851260ASimple structureSafety/regulatory devicesReciprocating piston enginesOn boardElectric machinery

The invention relates to car carried engine used compressed air as power. It includes engine body, crank shaft, gear box, and belt sheave. The end of the crank shaft is connected with piston in cylinder. The cylinder cover is set intake pressure pipe and exhaust pipe. The engine body is set engine speed, dead point-distinguishing signal generator, and engine crank shaft dish rotating electric machinery. The crank shaft is set one way overrunning clutch. Compared with the existing technique, it has the advantages of environmental protection and simple structure.

Owner:陈志新

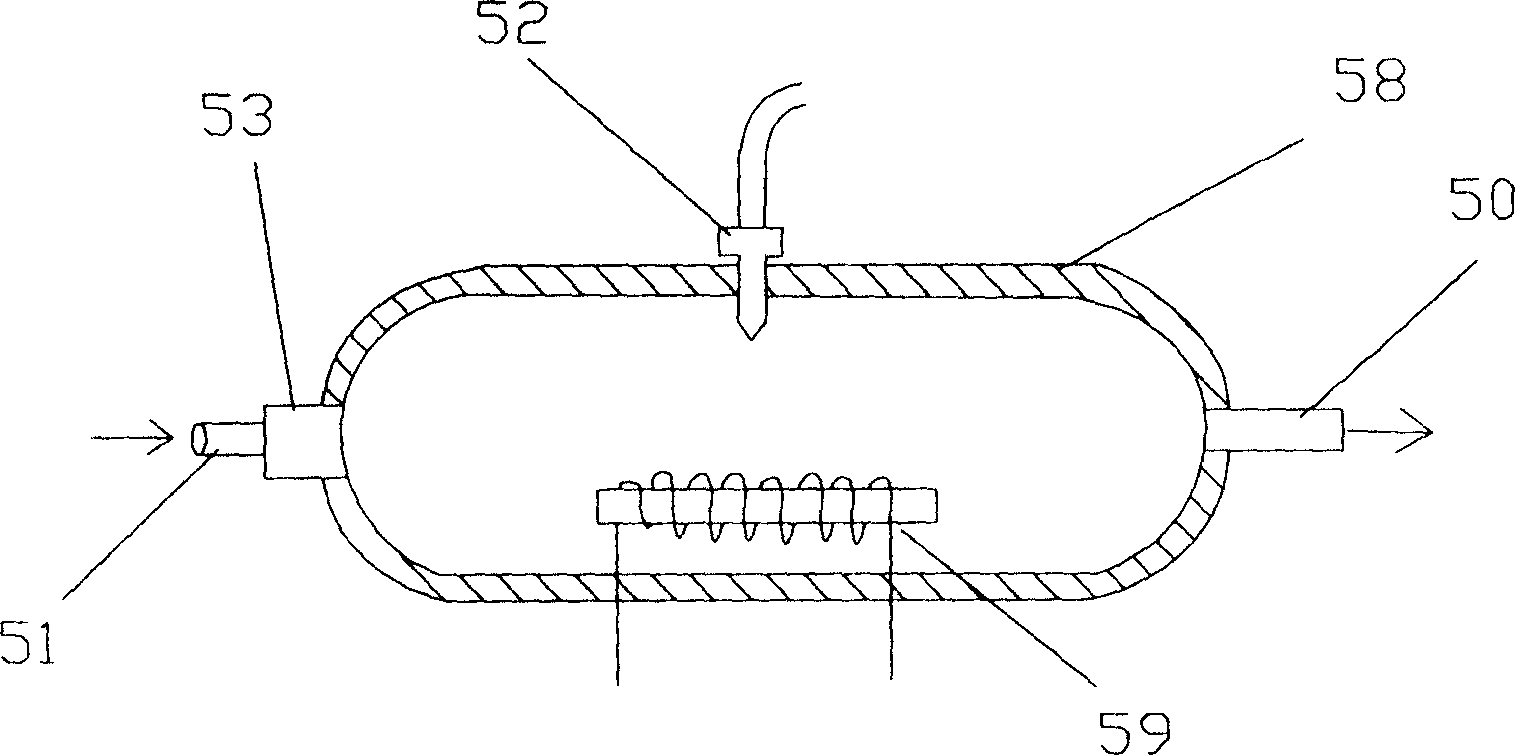

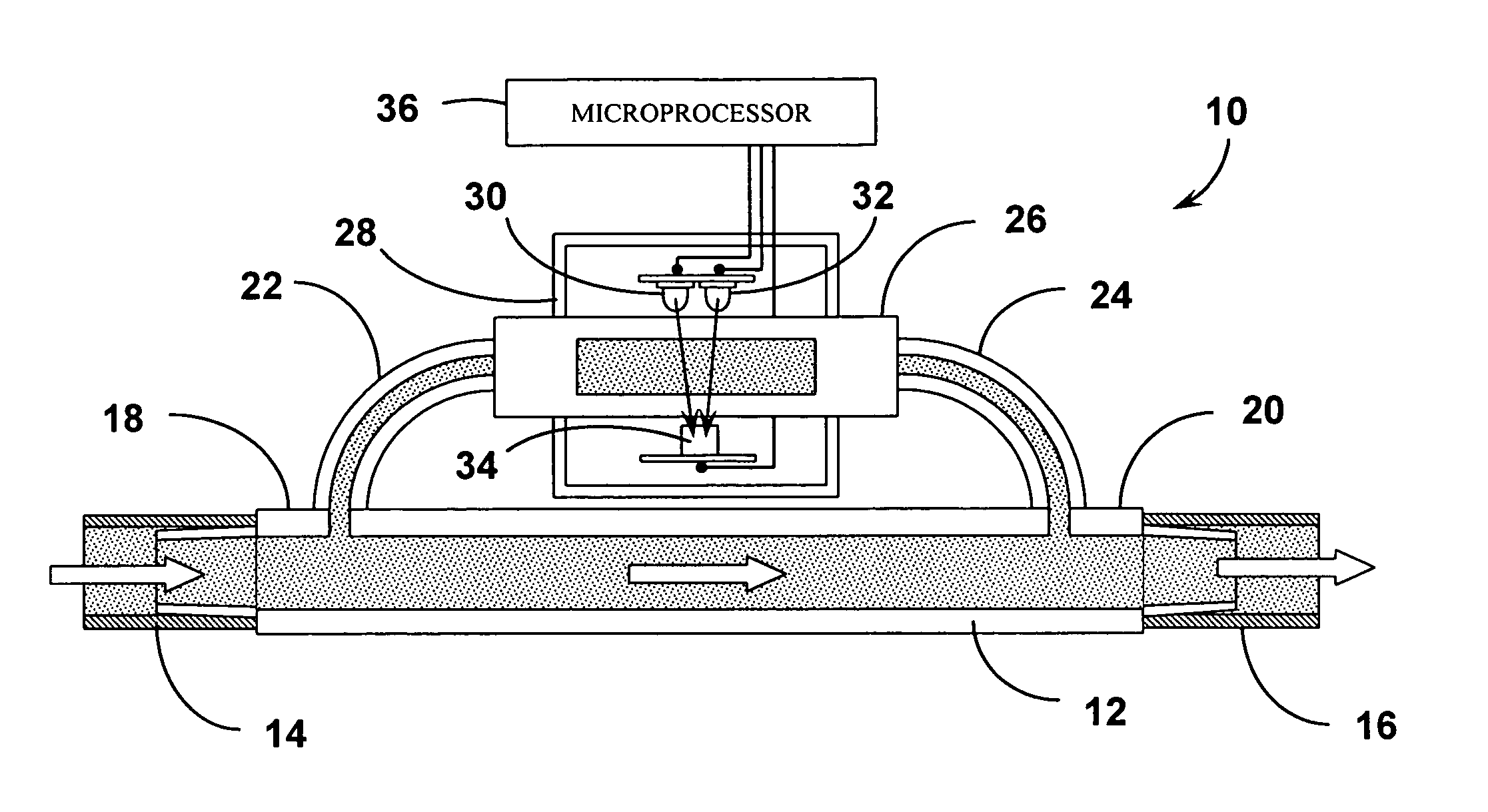

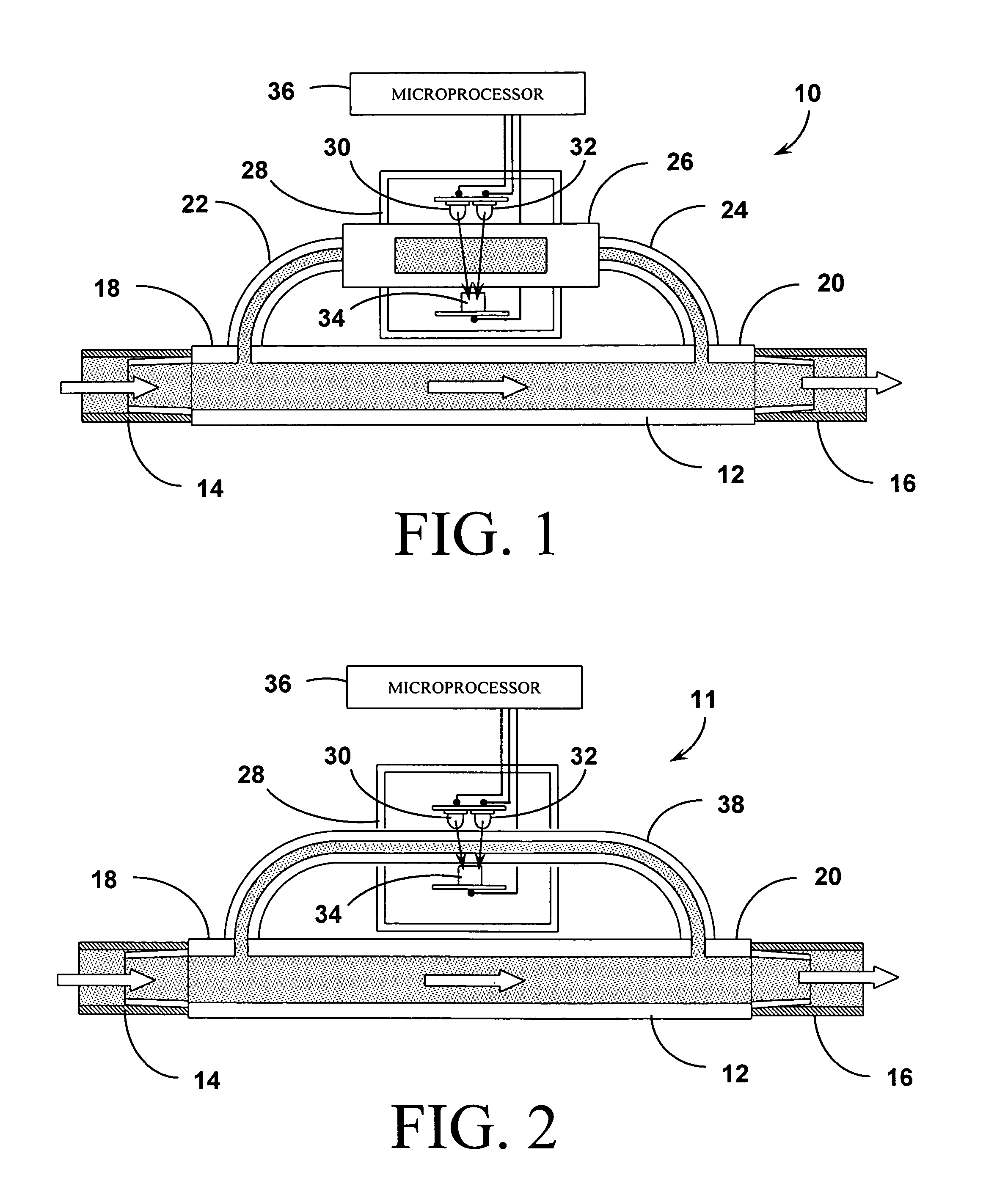

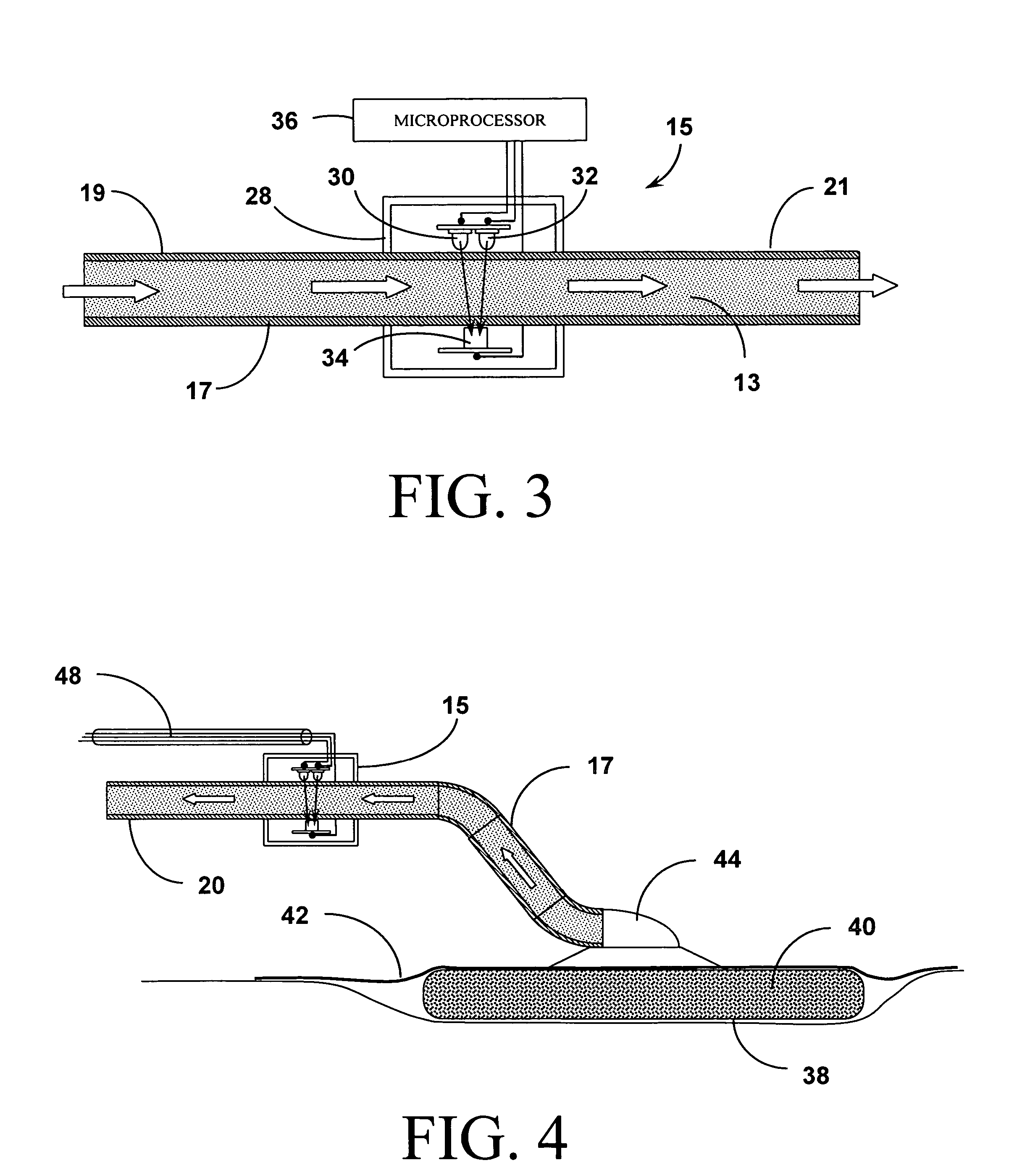

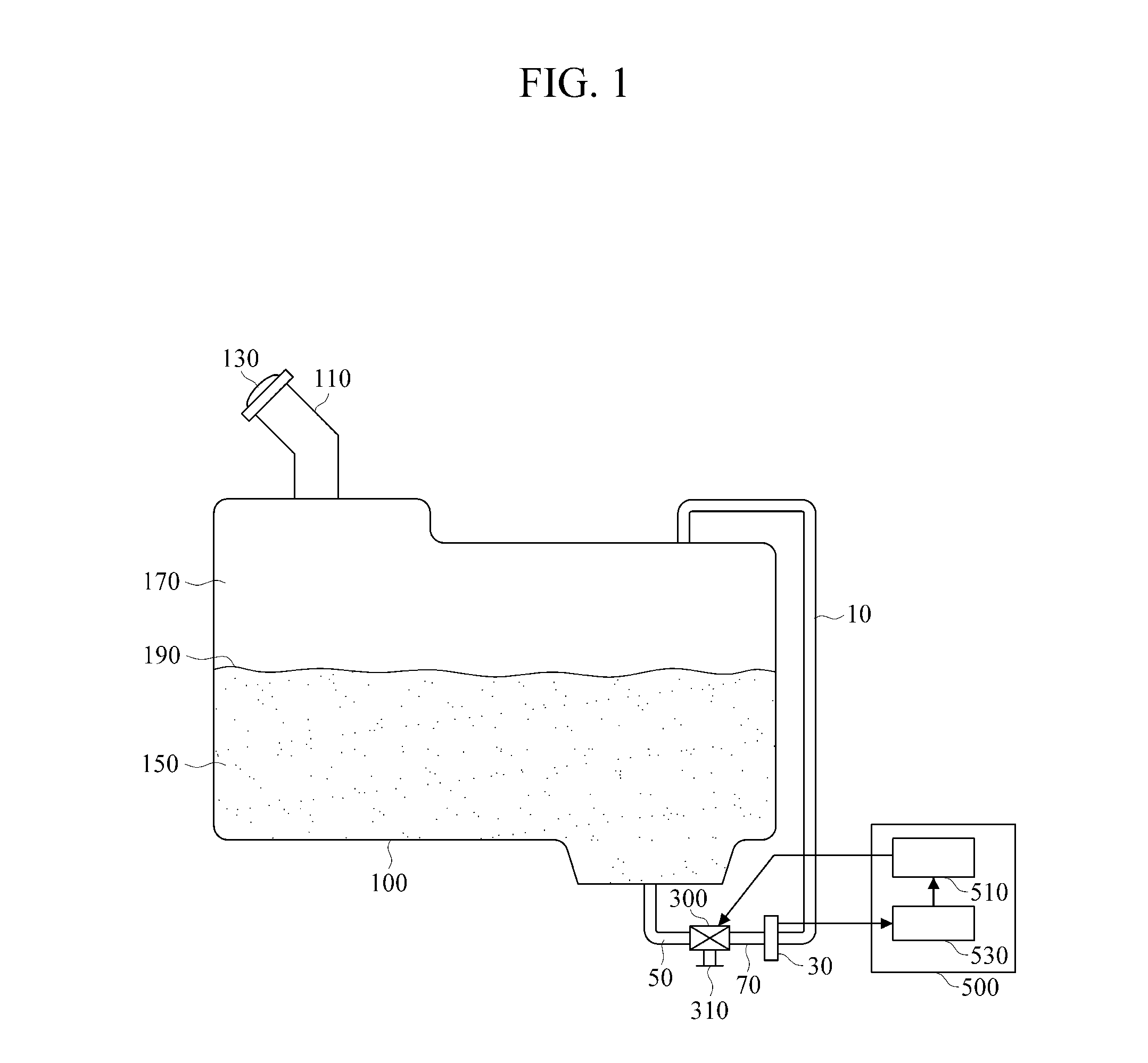

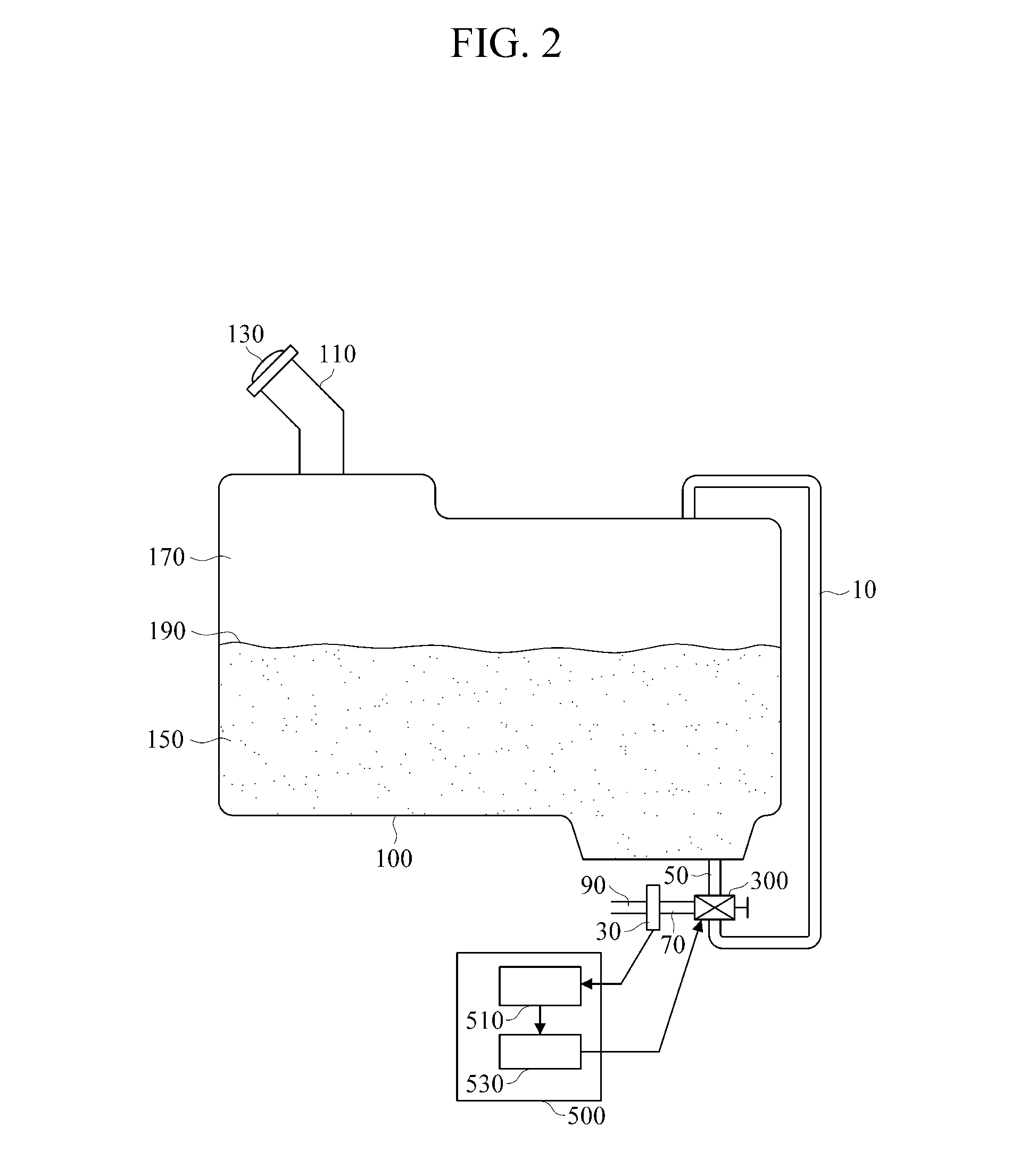

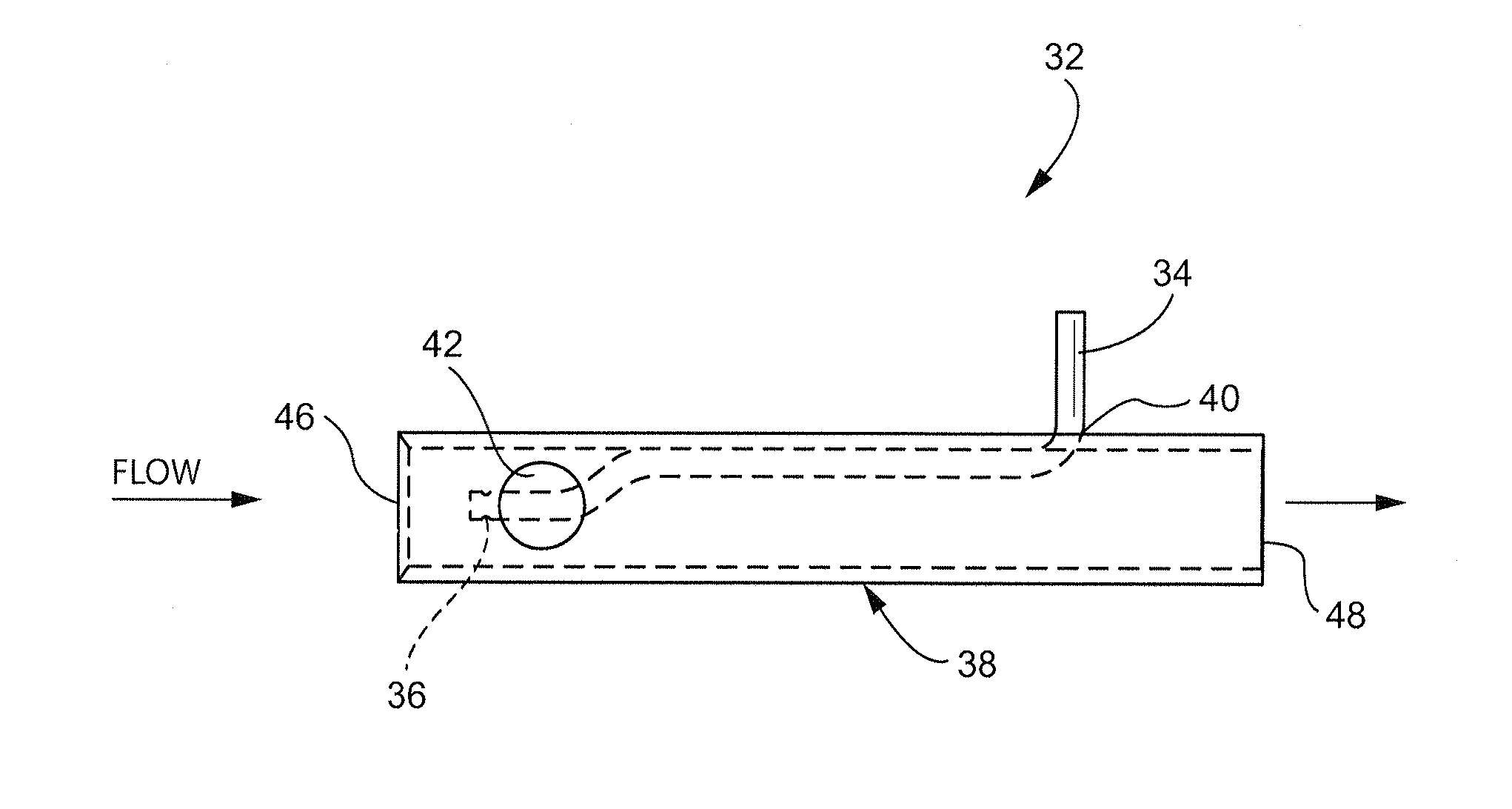

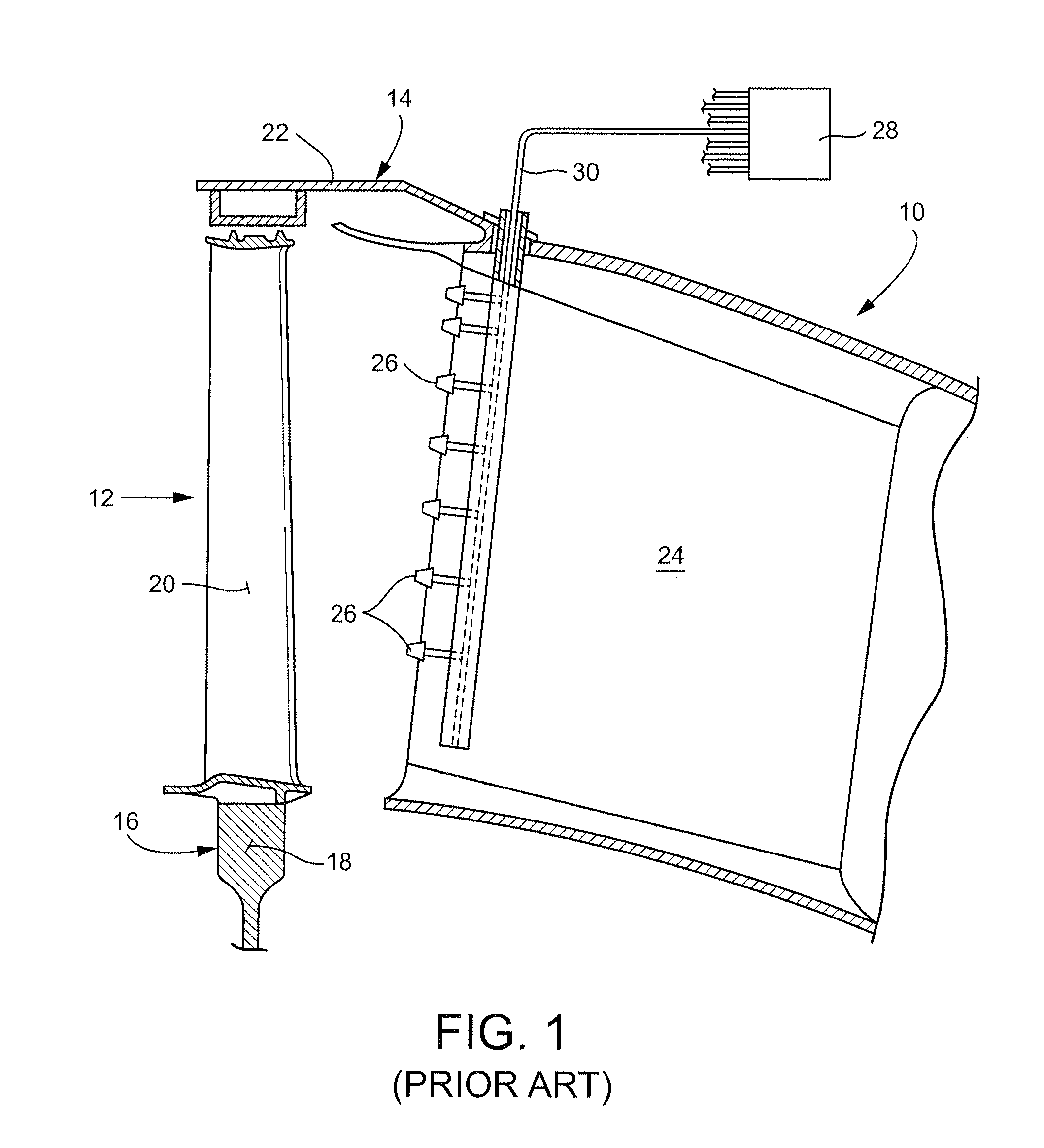

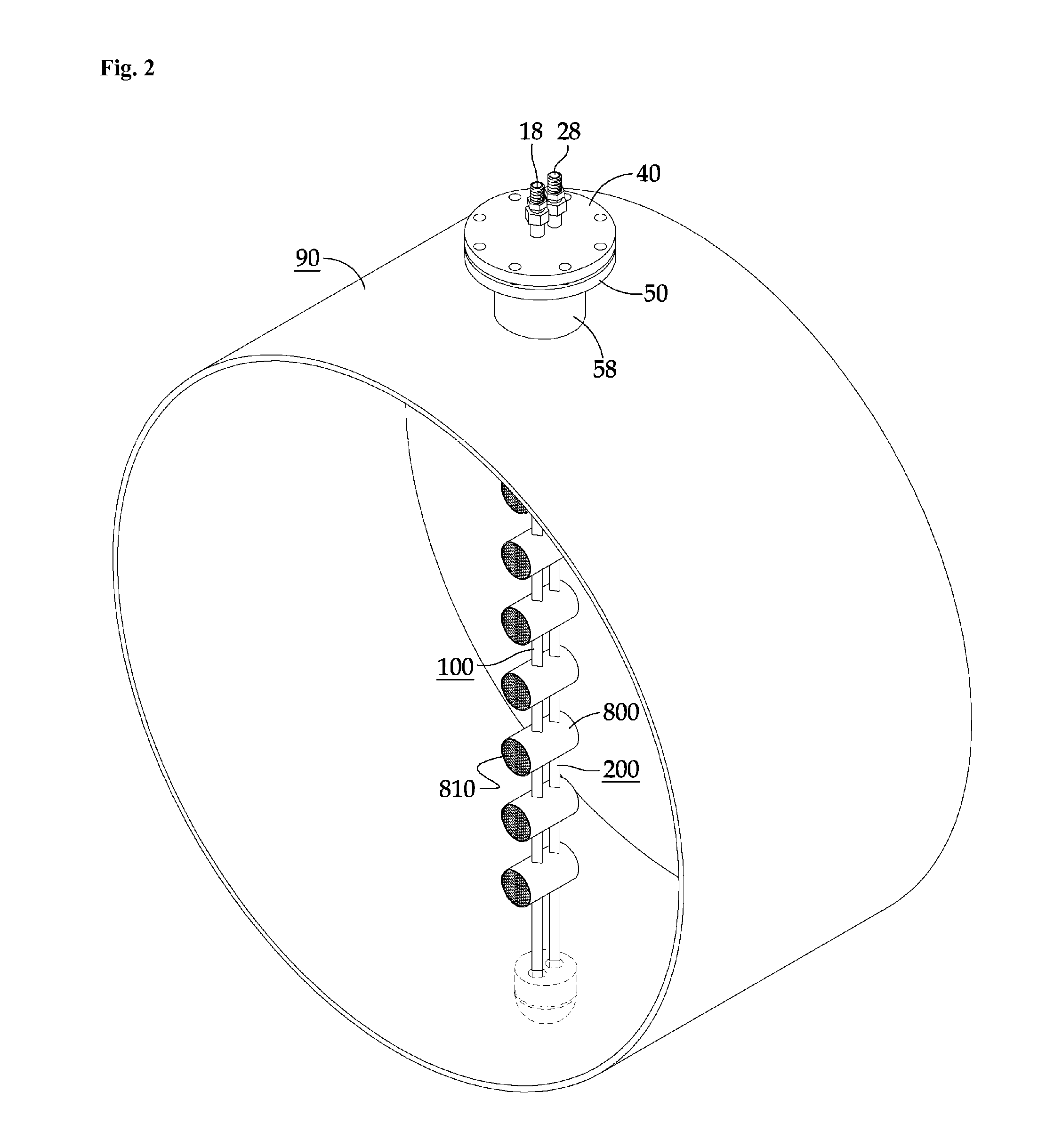

Systems and methods for detection of wound fluid blood and application of phototherapy in conjunction with reduced pressure wound treatment system

InactiveUS7947033B2Improve the level ofCut woundDiagnostics using lightWound drainsWound dressingLight treatment

Wound fluid blood detection systems and methods are described that are operable in conjunction with reduced pressure wound treatment (RPWT) systems, as well as ancillary therapy and monitoring systems applied concurrently with RPWT systems. The blood detection monitor operates by optically characterizing the content of wound fluids to the extent of identifying percentage blood content. This identification relies upon the transmission of select wavelengths of light across a volume of wound fluid to a photo detector (connected to signal processing instrumentation) capable of quantifying the absorption characteristics of the fluid. The detection components may be implemented in conjunction with either a fluid flow conduit (i.e. the reduced pressure tubing directing fluid away from the wound dressing) or more directly in association with the materials that comprise the wound dressing positioned within the wound bed itself. In addition, the present invention is configured to operate in conjunction with blood gas monitoring systems operating with the RPWT. Finally, the components of the systems that serve to illuminate the wound bed, lend themselves to use in conjunction with illumination in discreet electromagnetic wave wavelengths suitable for the application of phototherapy.

Owner:KCI LICENSING INC

PIV high pressure infusion set

InactiveUS20060259012A1Easy to produceCost-effectiveAdhesive processesCatheterInfusion setEngineering

A high-pressure tubing set includes a fitting and tubing having an end. The fitting has opposing ends and an aperture extending from one of the ends to the other end. The aperture has a tapered portion extending inwardly from one of the ends. The tubing end is received in the tapered portion and is chemically bonded thereto on an inner surface of the tapered portion, and defines a bonded portion, at a distance spaced from an end of the fitting, the end defining a beginning of the tapered portion. Fluid pressure within the tubing urges the tubing between the beginning of the tapered portion and the bonded portion outwardly, increasing the strength of the connection between the fitting and the tubing.

Owner:TRI STATE HOSPITAL SUPPLY

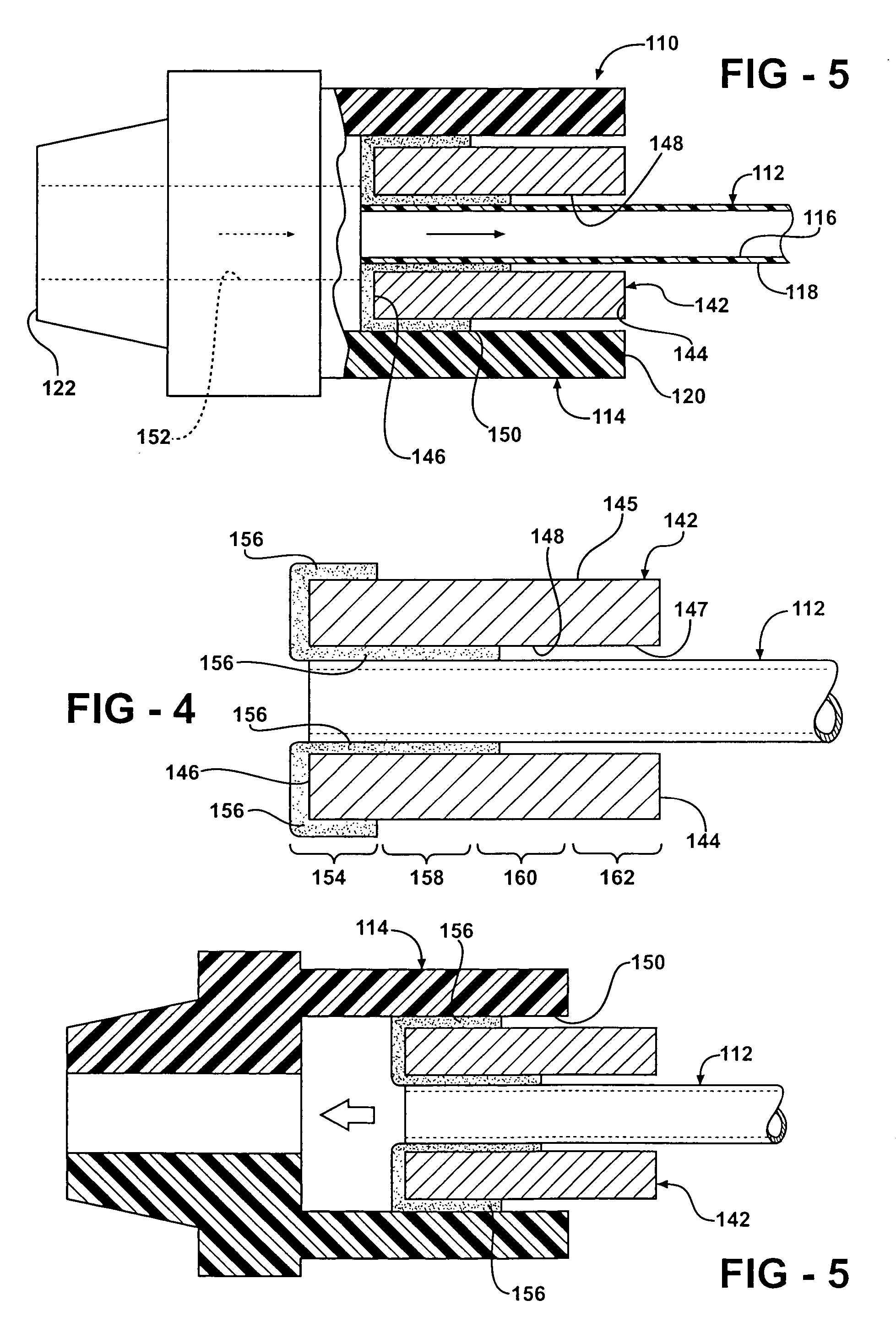

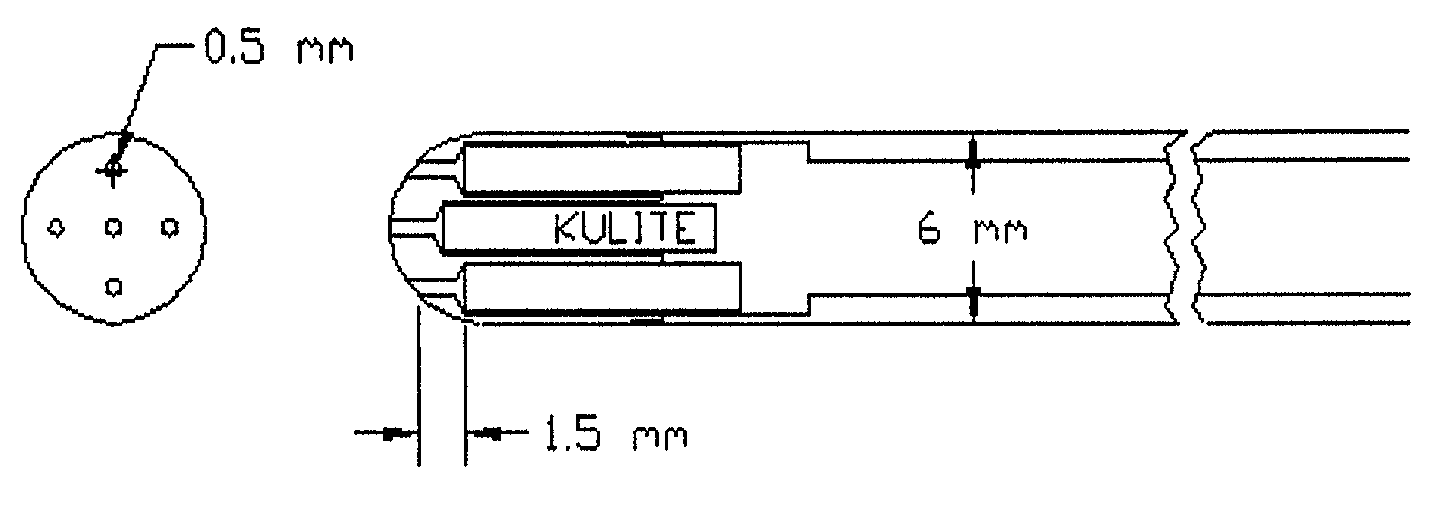

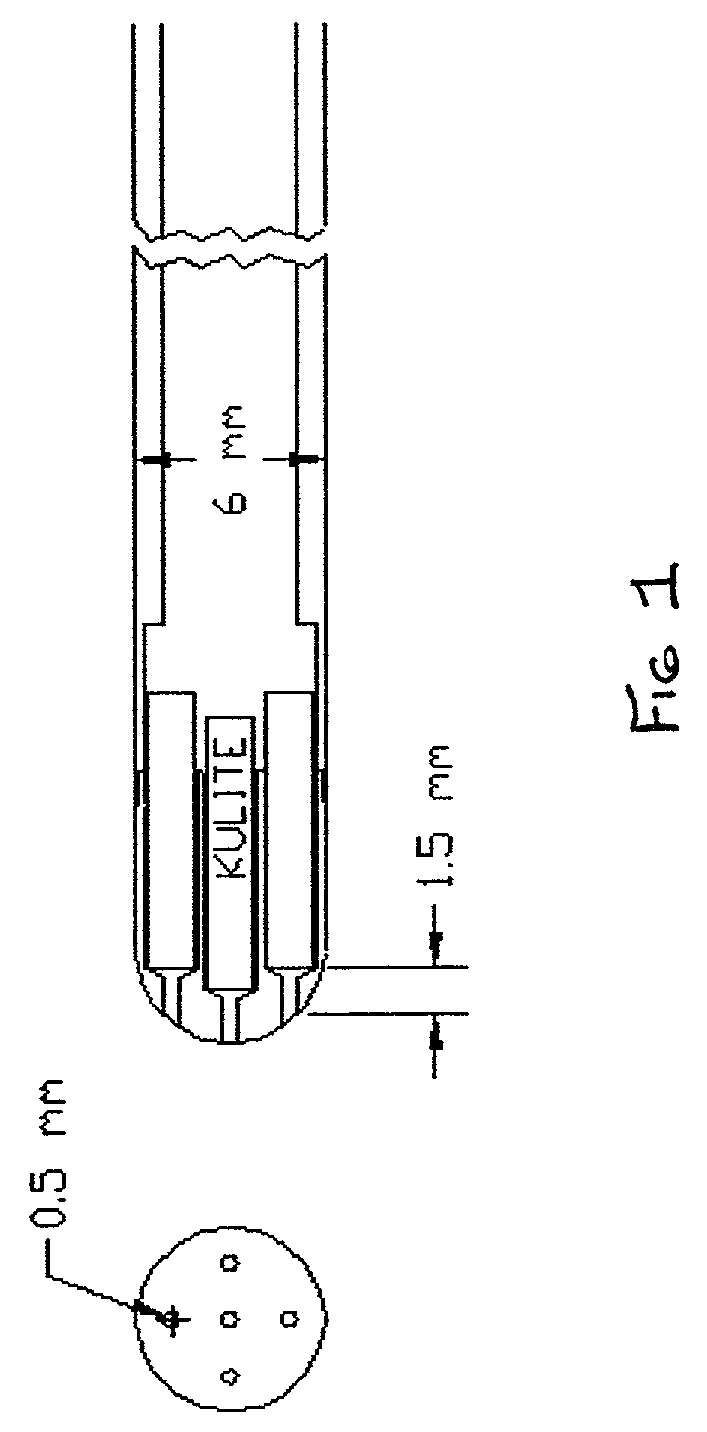

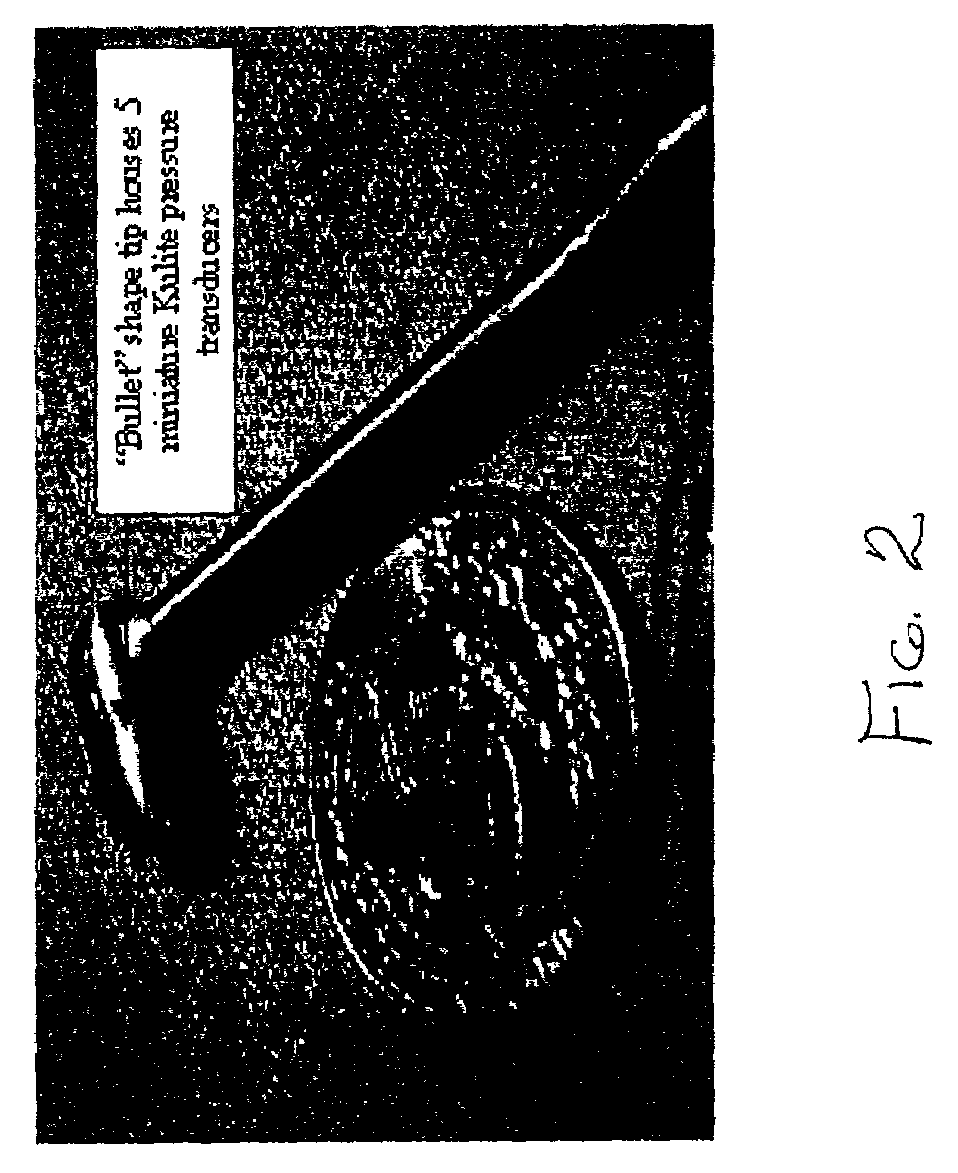

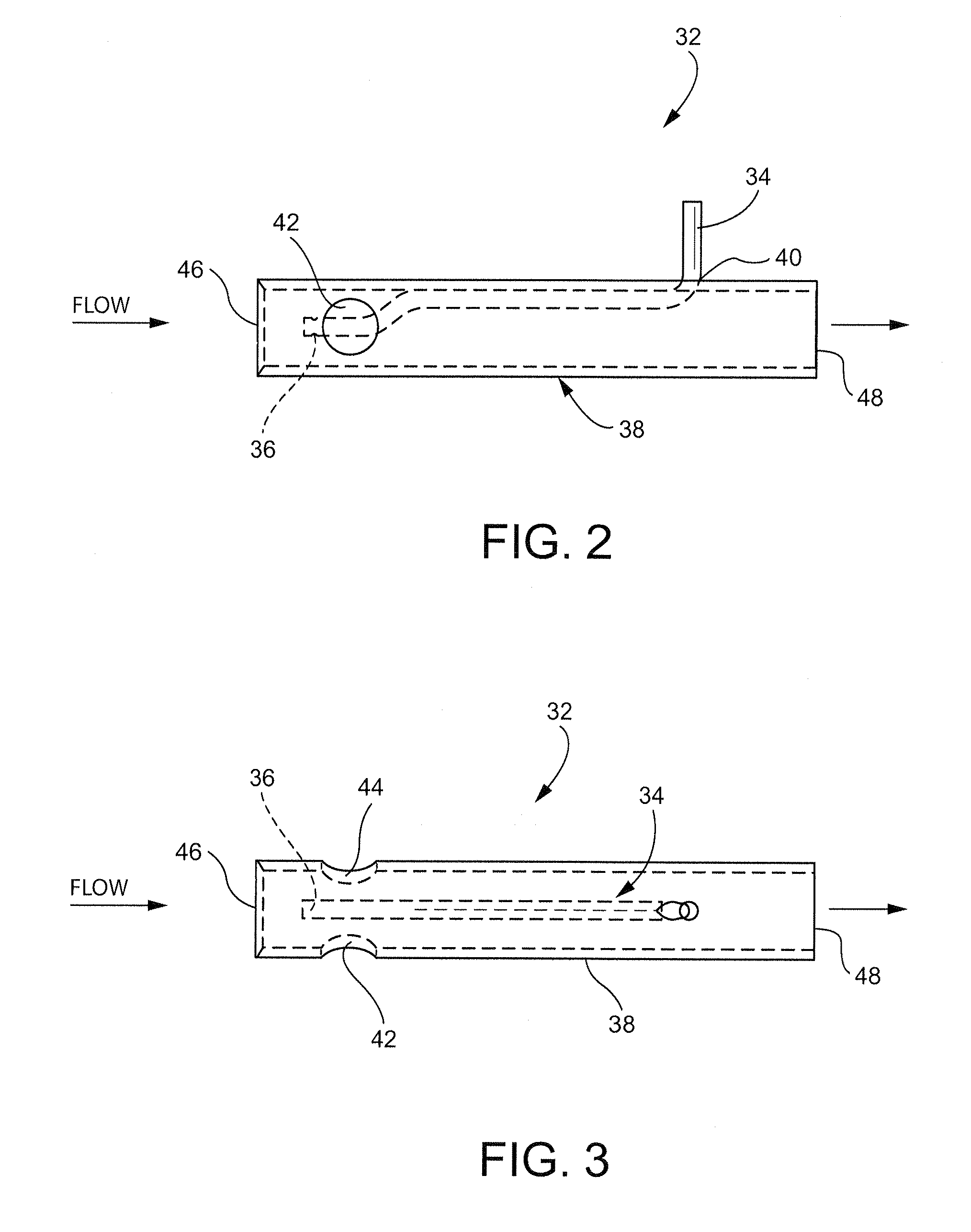

Embedded-sensor multi-hole probes

InactiveUS7010970B2Eliminate needVolume measurement and fluid deliveryIndication/recording movementEngineeringPressure measurement

A high-performance, fast-response, multi-sensor pressure probe for velocity and pressure measurement applications in unsteady and turbulent flowfields. The invention includes both 5 and 7-sensor probes, hemispherical-tip probes and conical-tip probes of various diameters. The present invention eliminates the need for long pressure tubing in such probes by placing the sensors adjacent the flow apertures which leads to a dramatic response in probe measurement frequency response which extends the use of the invention to unsteady and turbulent flows.

Owner:AEROPROBE CORP

Method for detecting leaks in a brake pressure line, under braking pressure, of a rail vehicle

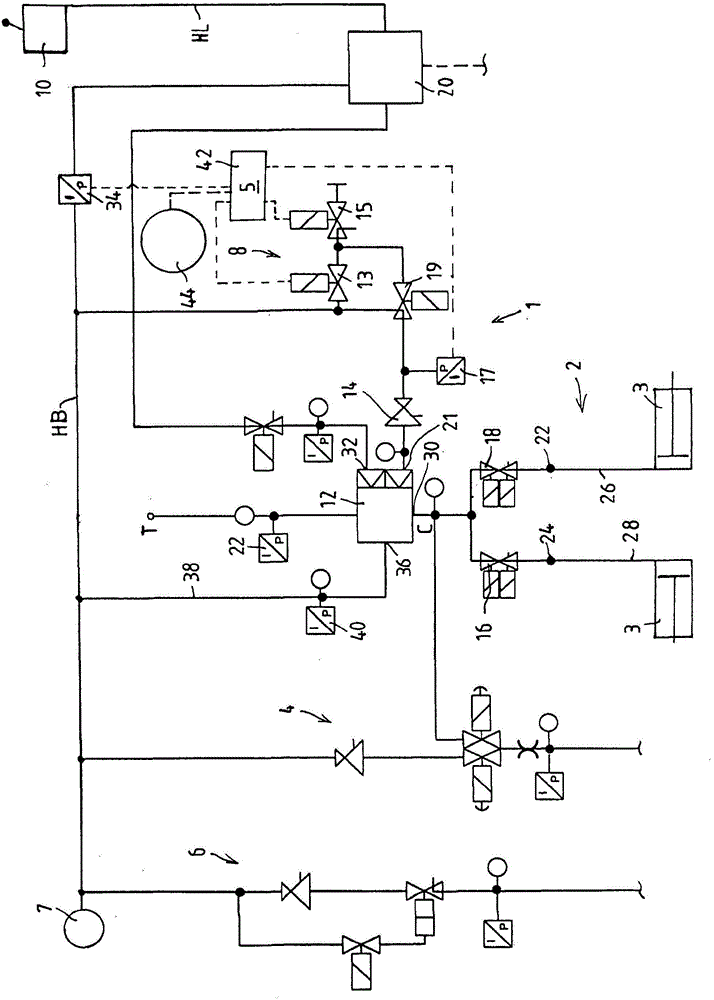

ActiveCN104411552ARelieve pressureEarly leakMeasurement of fluid loss/gain rateVehicle sub-unit featuresElectricityActuator

The invention relates to a method for detecting leaks in at least one brake pressure line (26, 28), under braking pressure (C), of a compressed air brake device (1) of a rail vehicle comprising an indirect electro-pneumatic brake, wherein the indirect electro-pneumatic brake has a master air vessel line (HB) to hold a master air vessel line pressure, and a compressed air source (7) supplying the master air vessel line (HB) with compressed air and is controlled by the master air line pressure in a master air line (HL), wherein the at least one brake pressure line (26, 28) under braking pressure (C) extends between a valve device (12), which controls the braking pressure (C) in dependence upon the master air line pressure in the master air line (HL), and at least one brake actuator (3), and wherein the method comprises a braking test carried out when the rail vehicle is stationary, having at least the following steps: a) checking whether, in the event of replenishment of compressed air from the compressed air source (7) into the master air vessel line (HB) being cut off, the master air vessel line pressure exceeds a preset limit value; and if so, b) controlling the master air line pressure in the master air line (HL) to apply the at least one brake actuator (3). According to the invention, within the framework of the braking test, the following further steps are carried out: c) monitoring the master air vessel line pressure to see whether c1) the value of the master air vessel line pressure arising after application of the at least one brake actuator (3) deviates by more than a preset difference from a preset plausible value for the master air vessel line pressure, and / or c2) in the period between the beginning and the end of the application of the at least one brake actuator (3), the pressure gradient of the master air vessel line pressure exceeds a preset pressure gradient; and d) if c1) and / or c2) applies, generating an error message that there is a leak in the at least one brake pressure line (26, 28).

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

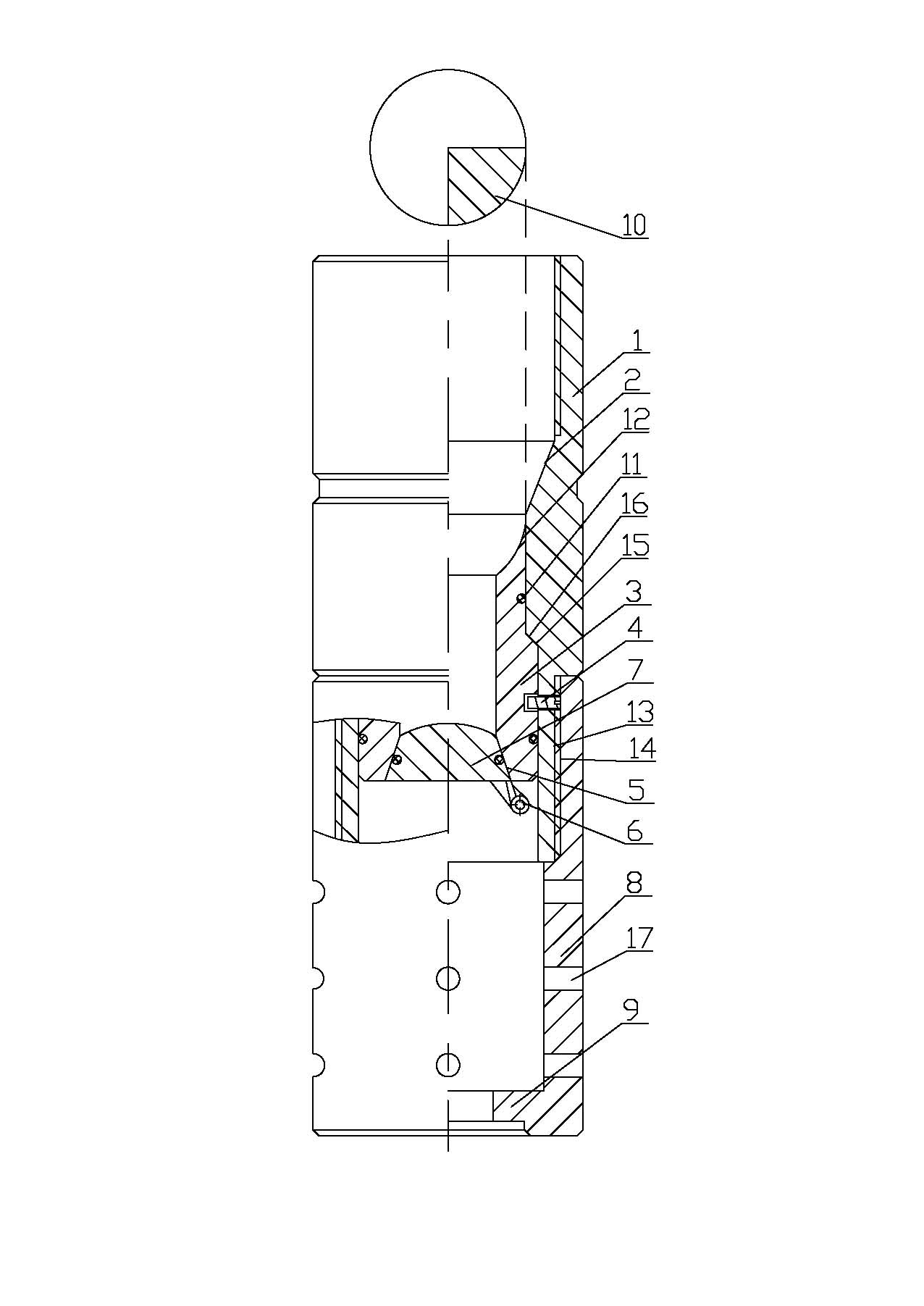

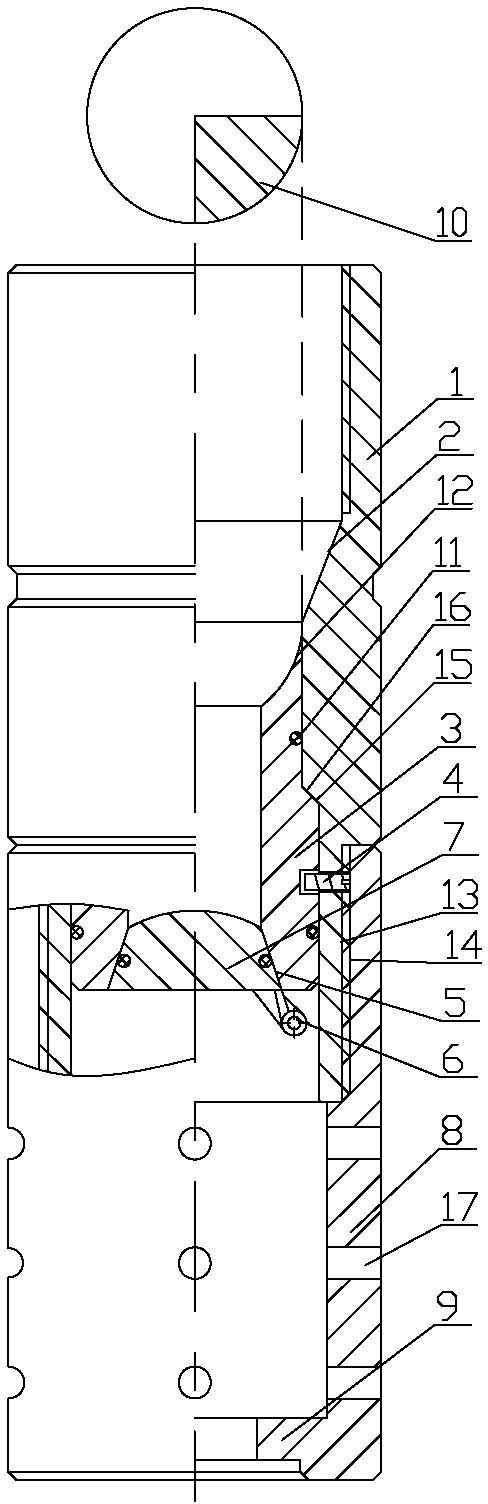

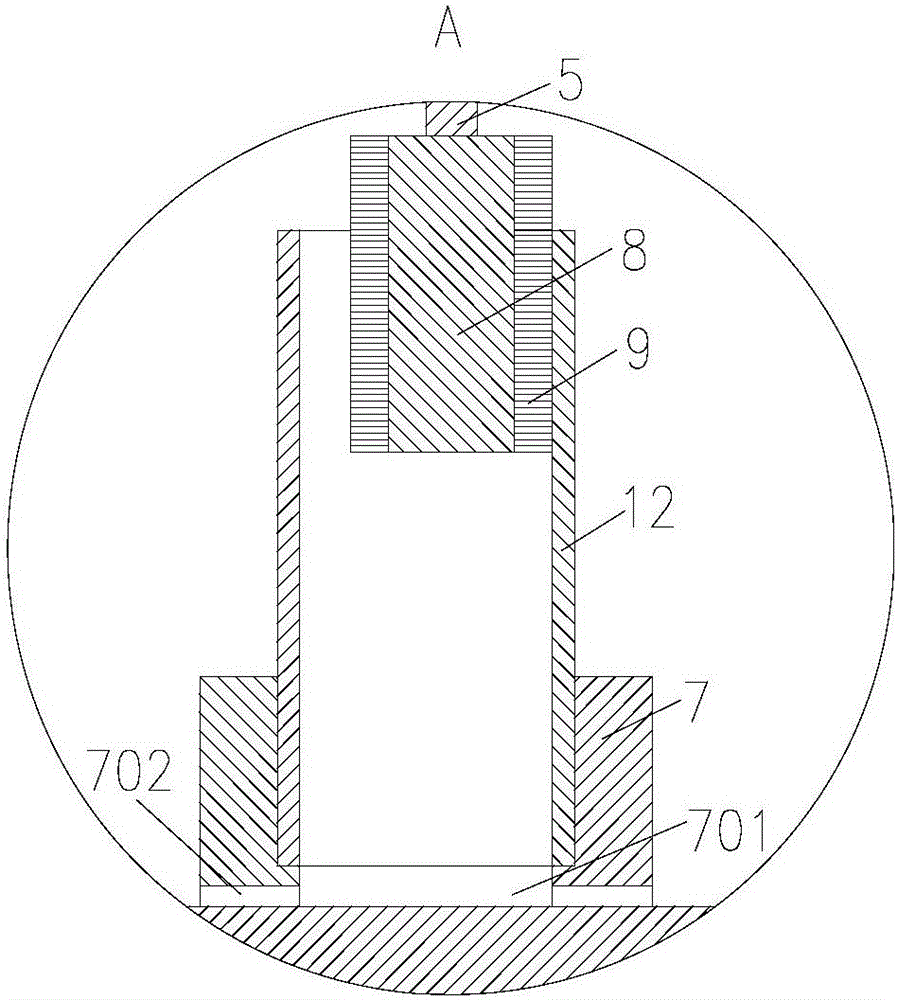

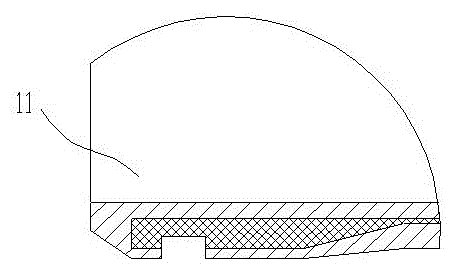

Pitching pressure-out opening oil tube constant-pressure floating valve

ActiveCN102606108APrevent sprayingCompact and reasonable structureWell/borehole valve arrangementsSealing/packingBlowout preventerTorsion spring

The invention relates to the technical field of blowout preventers in oil tubes in underbalance well completion tubing operation, in particular to a pitching pressure-out opening oil tube constant-pressure floating valve, which comprises a body, a valve spool, a torsion spring, a valve and a bucket. A concave platform is arranged on the lower portion of the body, a convex platform matched with the concave platform is arranged on the upper portion of the bucket, the outer wall of the concave platform and the inner wall of the convex platform are fixedly mounted together, the valve spool is fixedly mounted inside the concave platform through a grooving flat end constant-pressure locking nail, and the outer diameter of the valve spool is matched with the inner diameter of the body. The floating valve is reasonable and compact in structure and convenient in use, high-pressure oil and gas flow is effectively prevented from blowing out through an oil tube by the aid of the valve, possible well control accidents in the underbalance tubing operation are decreased, a blowout prevention tool in a pressure tubing is improved, and the floating valve achieves the purposes of simple operation procedures, convenience in use, low cost, safety and reliability.

Owner:CNPC XIBU DRILLING ENG

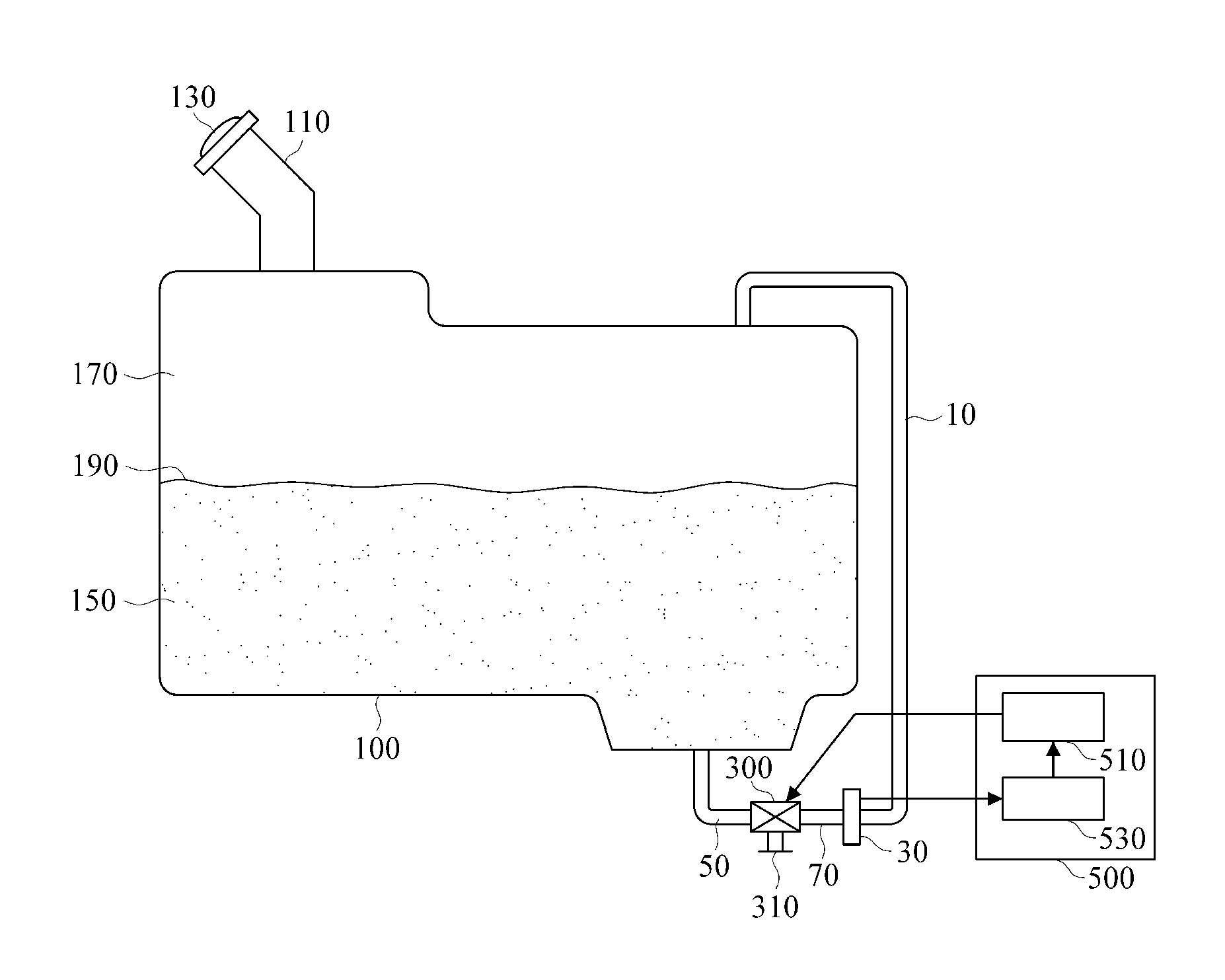

Integrated measuring apparatus for measuring vapor pressure and liquid level of liquid tank

InactiveUS20140196537A1Increase freedomIncreased durabilityMachines/enginesLubrication indication devicesDifferential pressureLiquid tank

A technique for measuring vapor pressure and liquid level of a volatile liquid contained in a tank. An integrated measuring apparatus sequentially measures vapor pressure and differential pressure by use of a single pressure sensor and a switching valve which switches between paths for measurement of the vapor pressure and the differential pressure. In addition, the integrated measuring apparatus includes a pressure sensor configured to sequentially measure vapor pressure and total pressure or the combination of the vapor pressure and liquid pressure; and a switching valve configured to be connected to a vapor pressure tube and a liquid pressure tube and switch between connection paths with at least one input port of the pressure sensor, wherein the vapor pressure tube is connected to an upper part of the tank and the liquid pressure tube is connected to a lower part of the tank.

Owner:AUTO IND

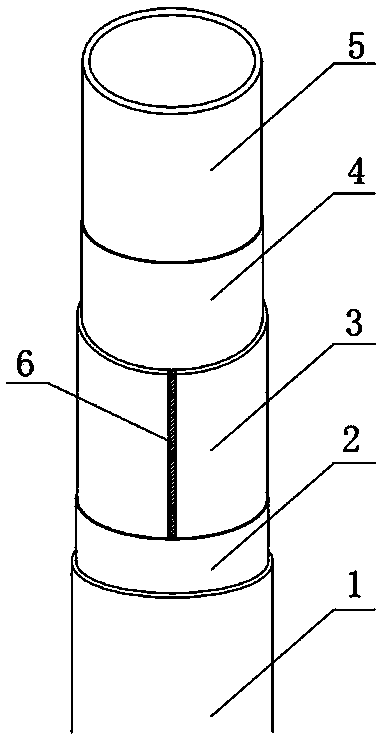

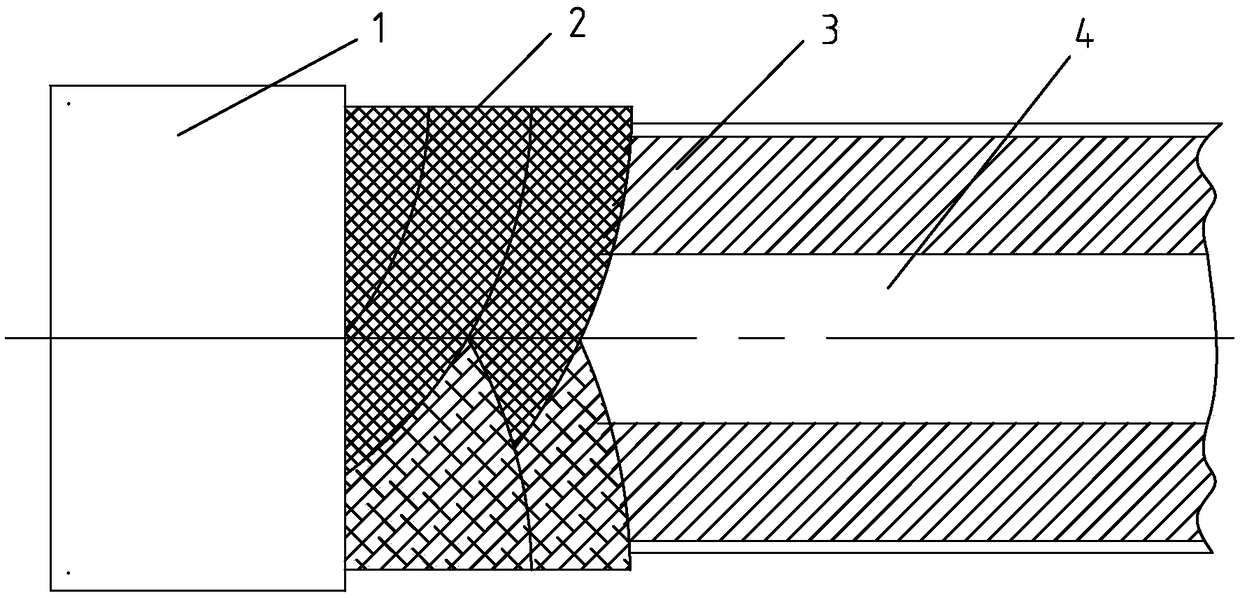

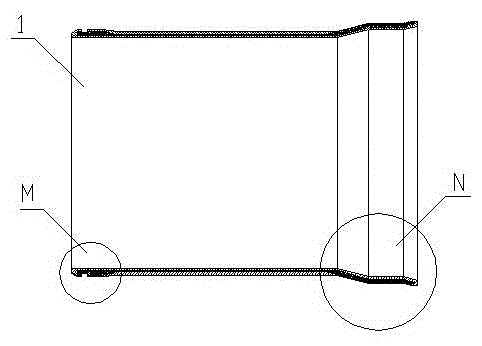

Composite steel-plastic pressure tube and manufacturing method thereof

InactiveCN103759080AIncrease the effective bonding areaHigh bonding strengthRigid pipesTubular articlesButt weldingAdhesion strength

The invention discloses a composite steel-plastic pressure tube and a manufacturing method thereof, and belongs to the technical field of composite steel-plastic tubes. The composite steel-plastic pressure tube comprises an outer plastic layer, an outer glue layer, an inner glue layer and an inner plastic layer. A steel tube with the rough surface is arranged between the outer glue layer and the inner glue layer. In the manufacturing process of the composite steel-plastic pressure tube, a laser texturing roller carries out rolling and texturing on an adopted steel plate, so that a rough surface is formed on the steel plate, and then the steel plate is processed into steel belts with required widths; the steel belts are rolled to be of tubular shapes under the extrusion state, and an inner plastic layer tube coated with hot melt glue is inserted synchronously; the tungsten electrode argon arc butt welding process is adopted for welding of welding lines, and a steel tube is formed; through a high frequency heater, adhesion of the inner plastic layer tube and the steel tube is achieved; the hot melt glue coats the steel tube, and the outer plastic layer is arranged outside the steel tube. According to the composite steel-plastic pressure tube, the adhesion strength between the outer plastic layer and the steel tube is high, the pressure-bearing capacity is high, and the production cost is low.

Owner:XINXING DUCTILE IRON PIPES CO LTD

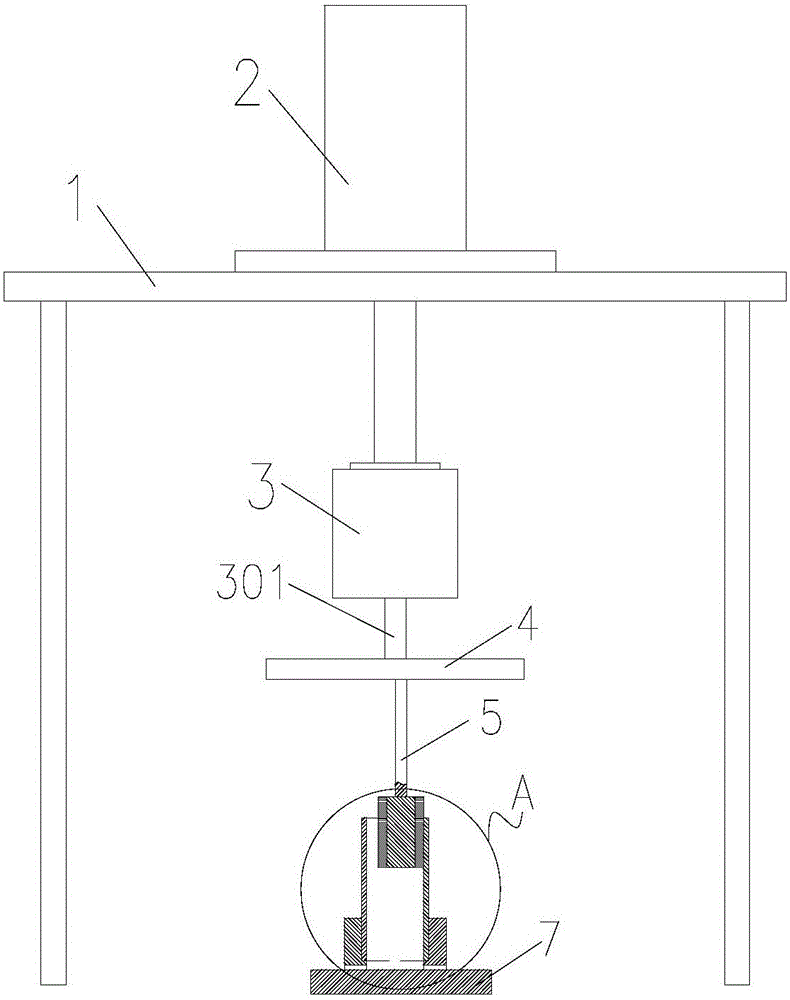

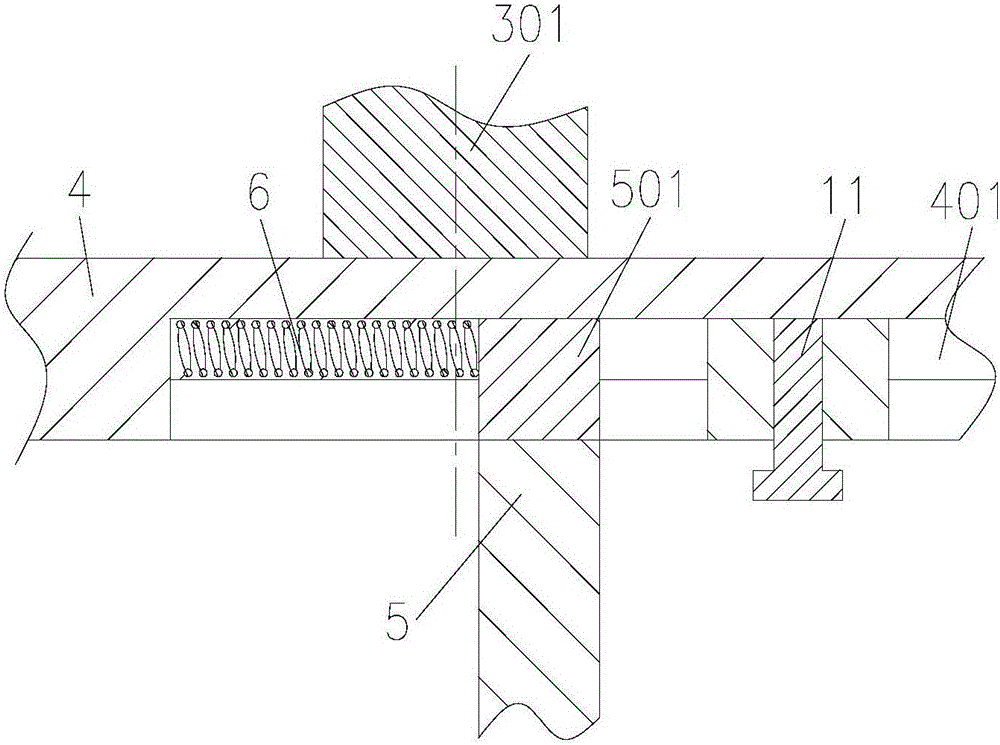

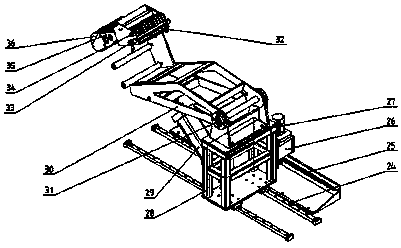

Cleaning machine for gas spring pressure pipe

InactiveCN105689343AEasy to cleanImprove cleaning qualityHollow article cleaningHydraulic cylinderBristle

The invention relates to the technical field of gas spring manufacturing, in particular to a cleaning machine for a gas spring pressure pipe. The cleaning machine comprises a rack and a hydraulic cylinder arranged on the rack, and the extending end of the hydraulic cylinder faces downwards. A motor is arranged at the extending end of the hydraulic cylinder. A rotary plate is fixedly connected to a main shaft of the motor. A rotary shaft is arranged on the rotary plate. A T-shaped protrusion is arranged at the upper end of the rotary shaft. A bristle brush assembly is arranged at the lower end of the rotary shaft. A T-shaped groove matched with the T-shaped protrusion is formed in the lower surface of the rotary plate. A spring is arranged between the T-shaped groove and the T-shaped protrusion. A fixing base is arranged under the bristle brush assembly. A positioning hole matched with the pressure pipe is formed in the fixing base. The positioning hole and the rotary plate are coaxial. The bristle brush assembly is placed in the positioning hole by transversely moving the rotary shaft, the spring is in a compressed state at the moment, and one side of the bristle brush assembly is tightly attached to the inner wall of the pressure pipe under the action of the spring so that the inner wall of the pressure pipe can be better cleaned by the bristle brush assembly. The cleaning effect on the pressure pipe is improved, and the cleaning efficiency is high.

Owner:CHANGZHOU GAS SPRING

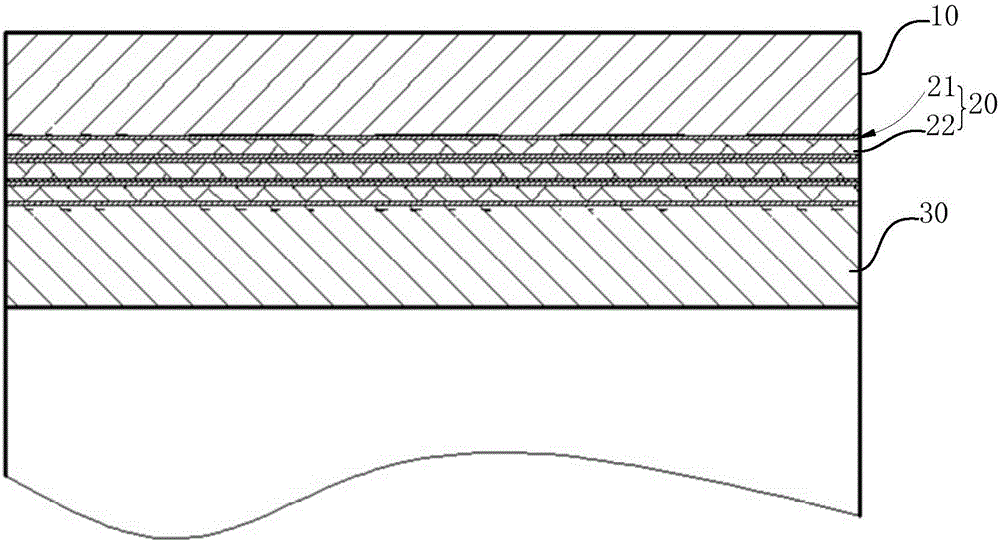

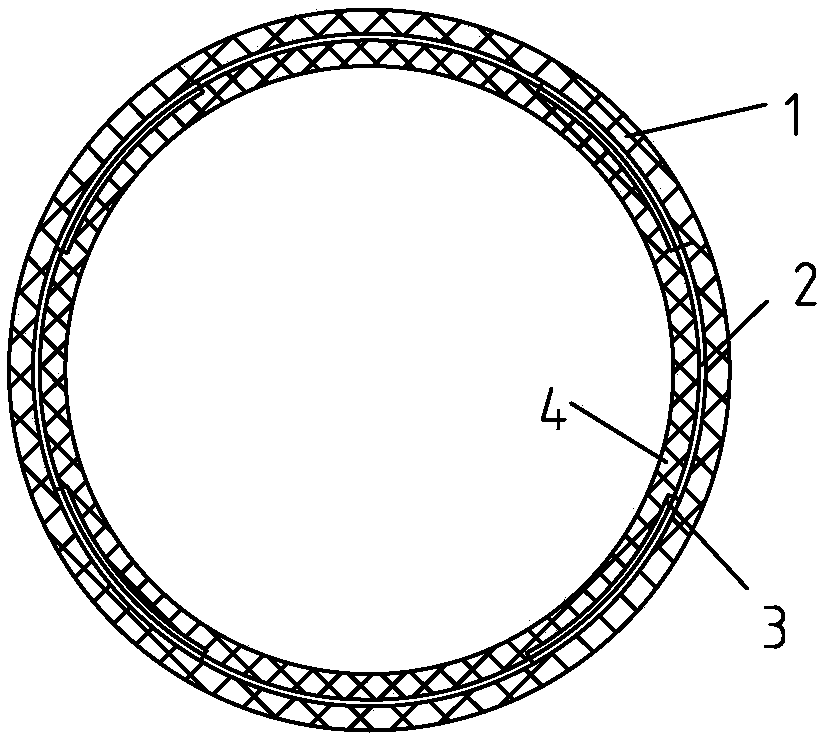

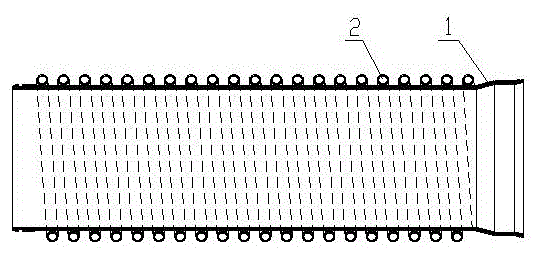

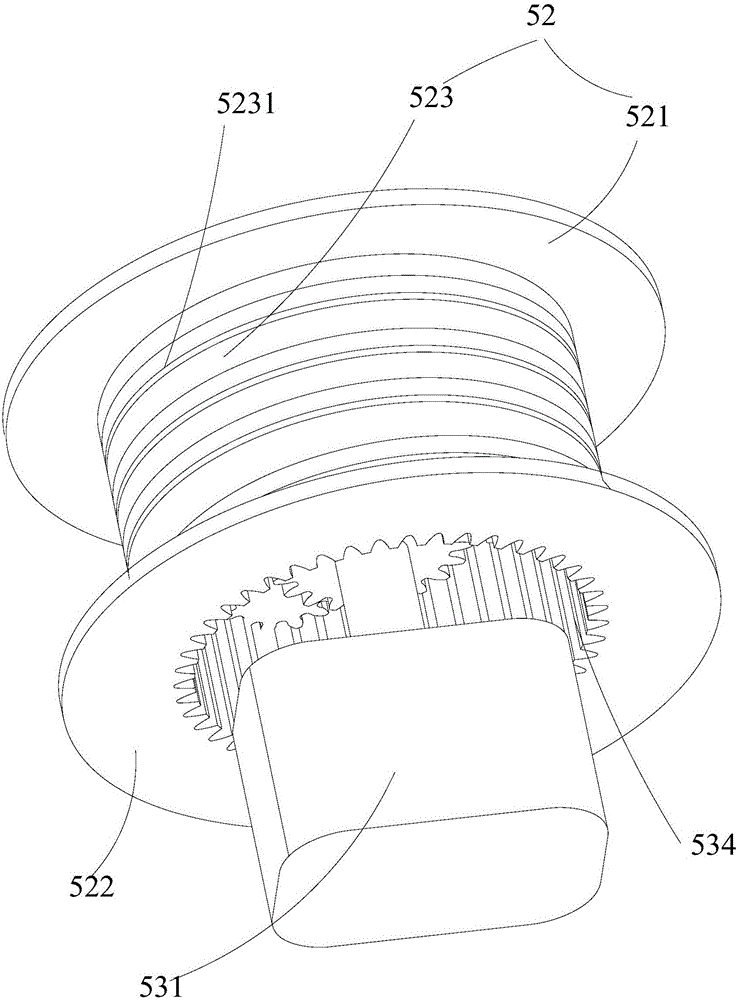

Composite reinforced winding-type pressure pipe and forming method thereof

InactiveCN105128323AEnhancement effect is goodSimple molding processSynthetic resin layered productsGlass/slag layered productsGlass fiberFiber

The invention relates to the technical field of plastic pressure pipes, in particular to a composite reinforced winding-type pressure pipe. The composite reinforced winding-type pressure pipe comprises an outer plastic layer, an inner plastic layer and a long glass fiber sheet reinforced plastic layer arranged between the outer plastic layer and the inner plastic layer. The long glass fiber sheet reinforced plastic layer comprises a long glass fiber sheet and a plastic composite layer wrapping the long glass fiber sheet, and the long glass fiber sheet is wound on the outer surface of the inner plastic layer through the wrapping plastic composite layer to form the long glass fiber sheet reinforced plastic layer; the long glass fiber sheet is composed of regularly-distributed long glass fibers, and the long glass fibers are flaky. The invention further discloses a forming method of the composite reinforced winding-type pressure pipe. Through the composite reinforced winding-type pressure pipe and the forming method of the composite reinforced winding-type pressure pipe, the process that the long glass fiber sheet is wrapped by the plastic composite layer and then wound on the outer surface of the inner plastic layer is simple, the production cost is low, and the yield is high. The pressure resistance is high, and the process stability is good. In addition, the long glass fibers are regularly distributed, so that the strength of the formed pressure pipe is uniform.

Owner:深圳市华瀚科技控股有限公司

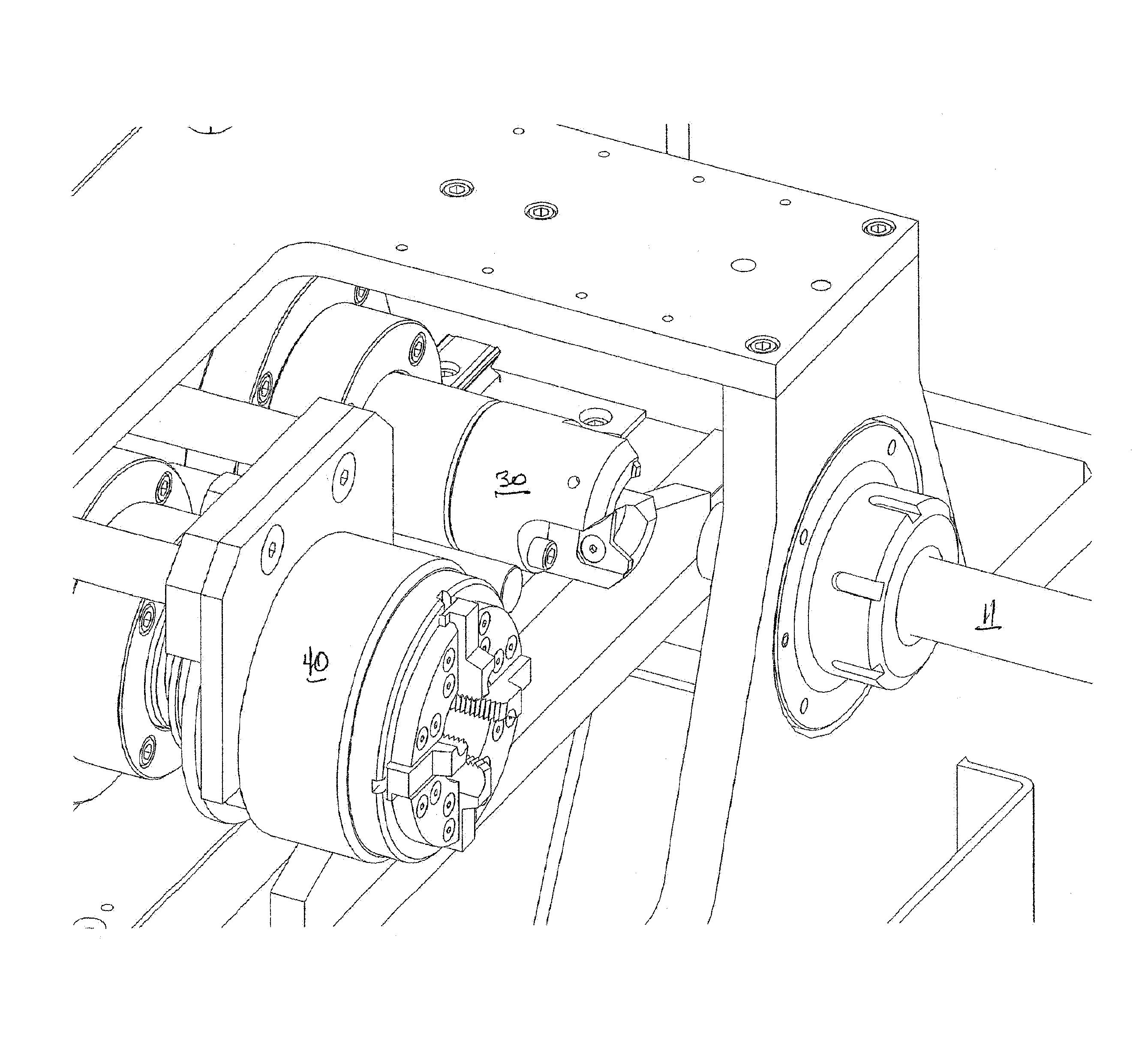

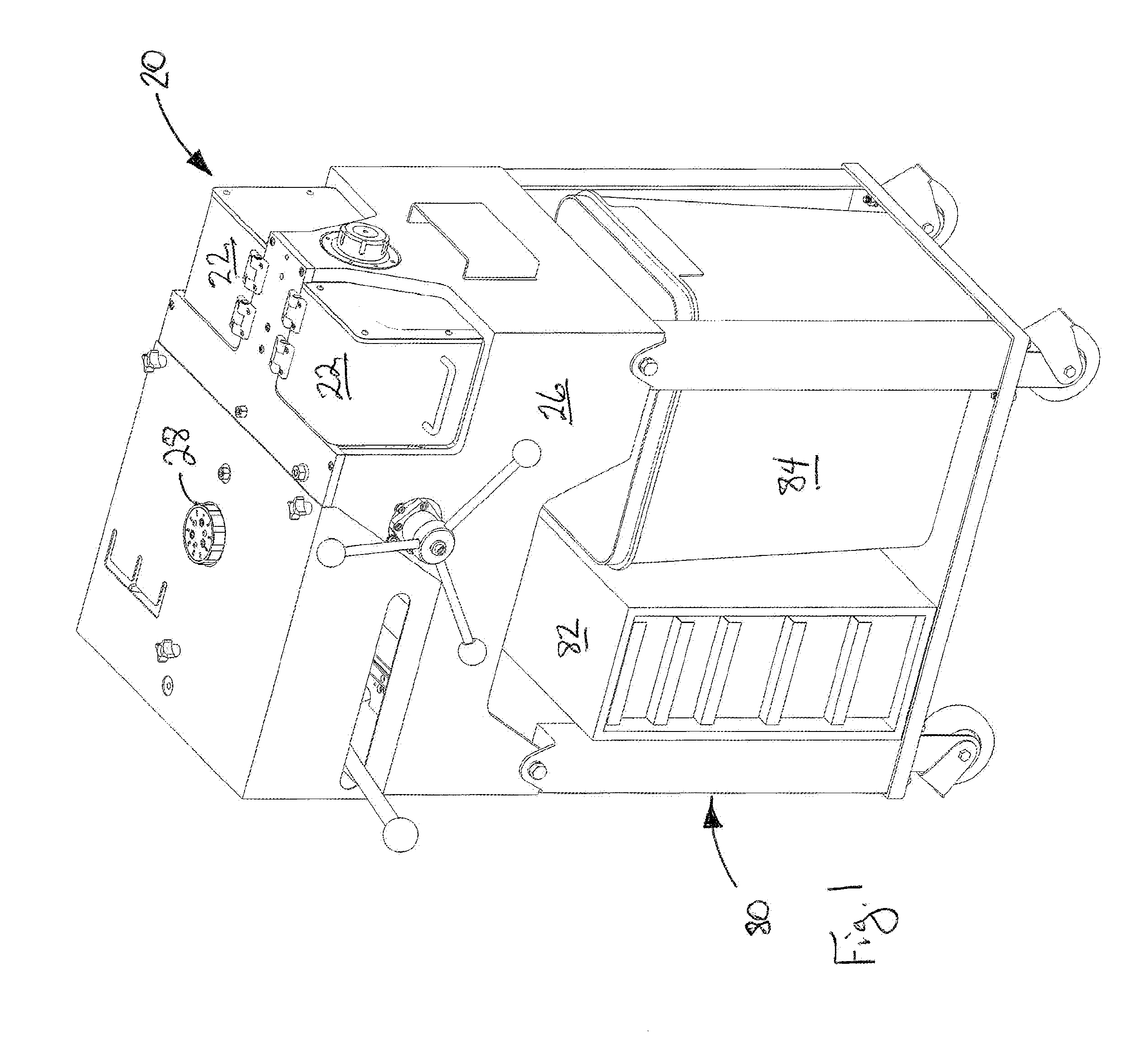

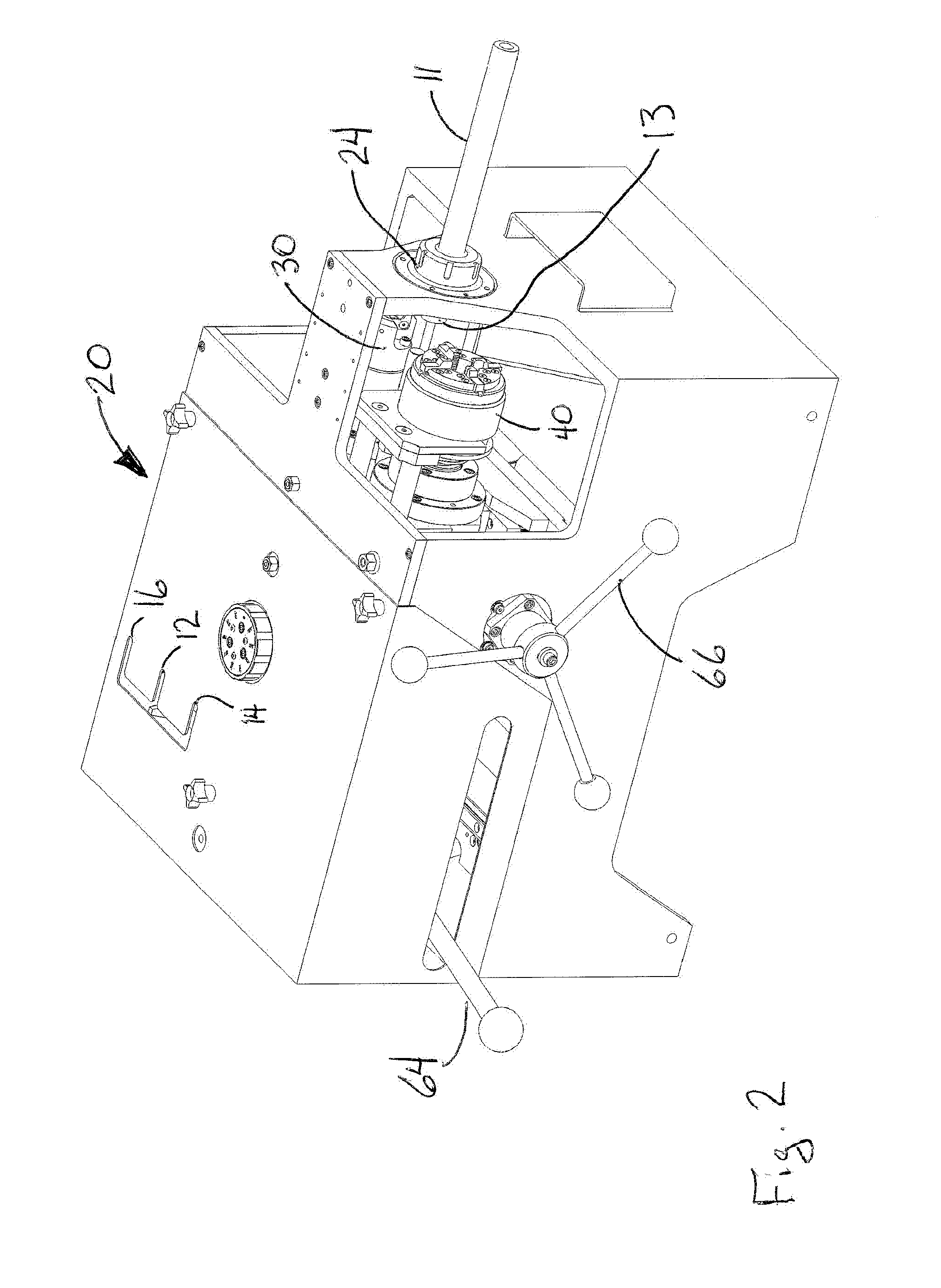

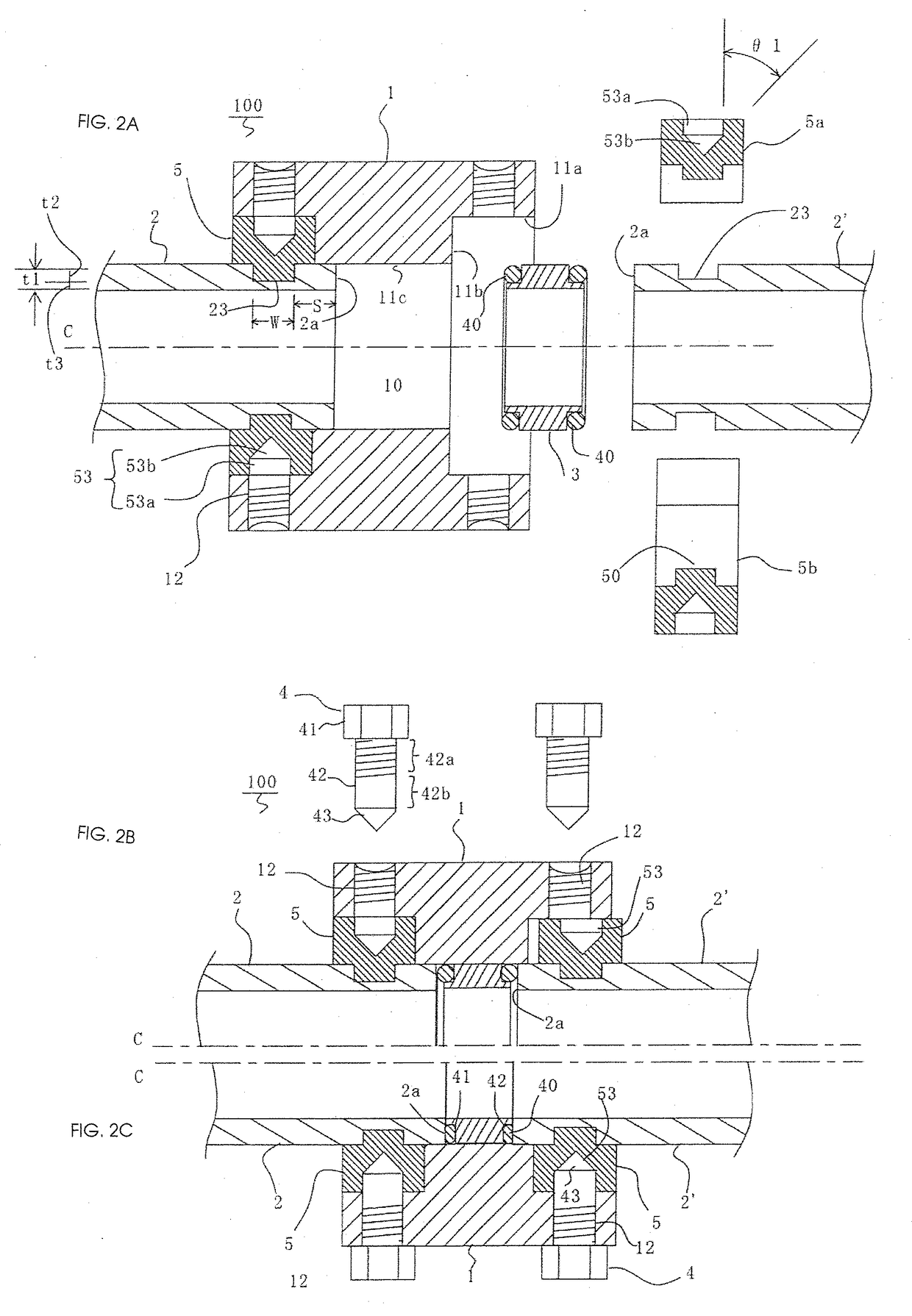

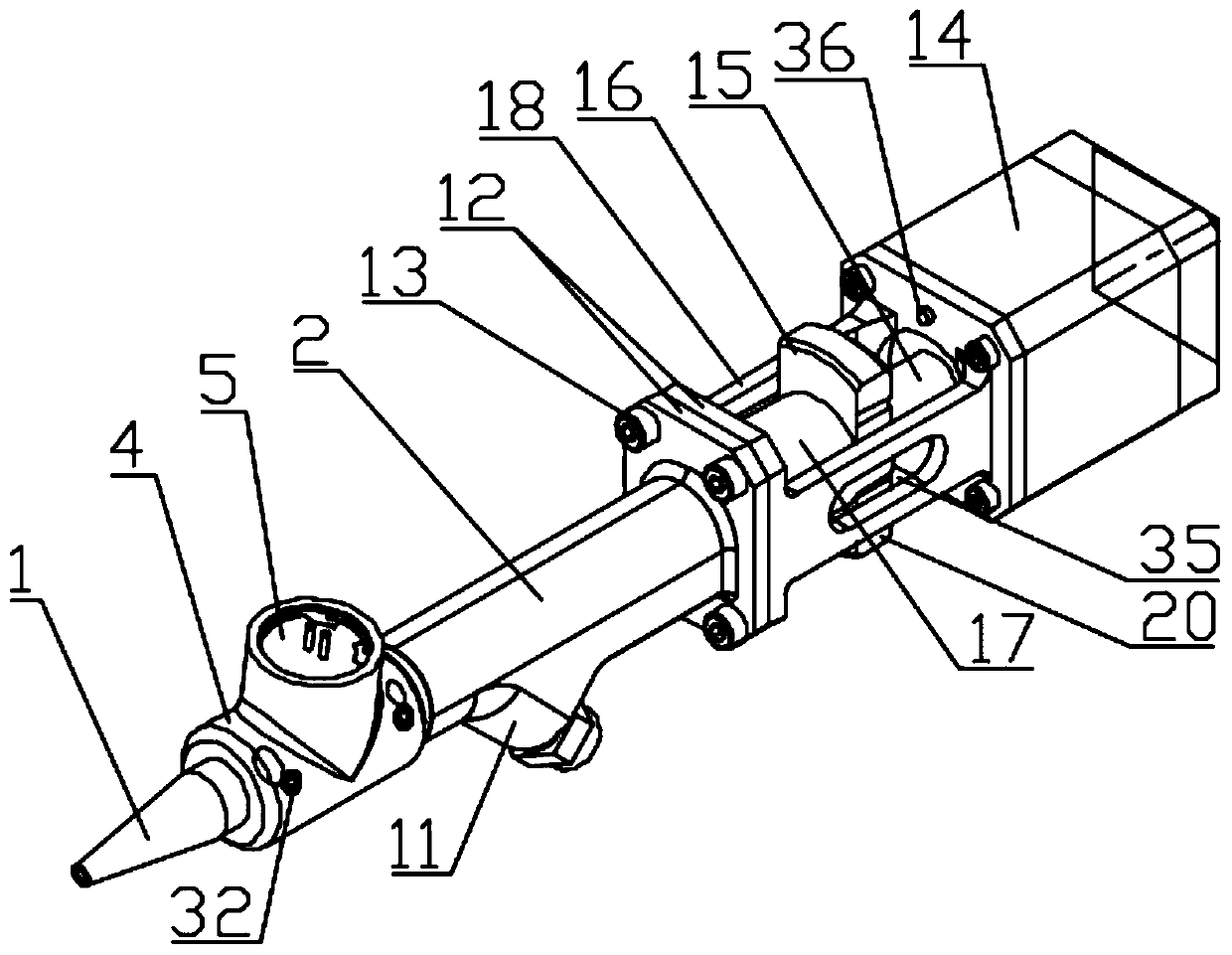

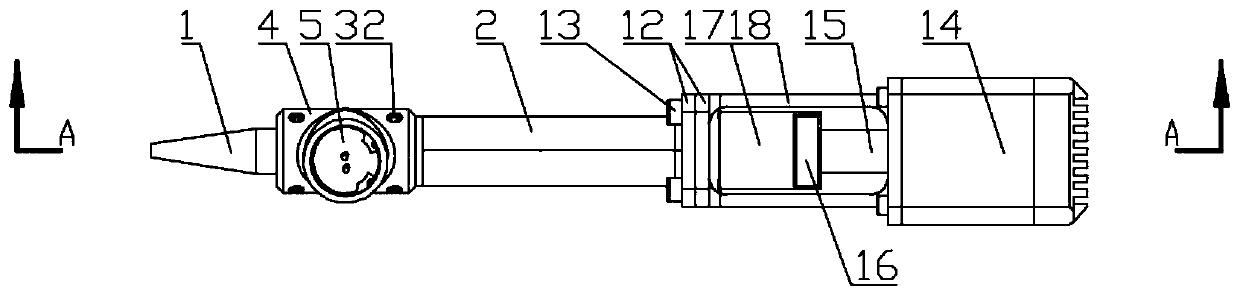

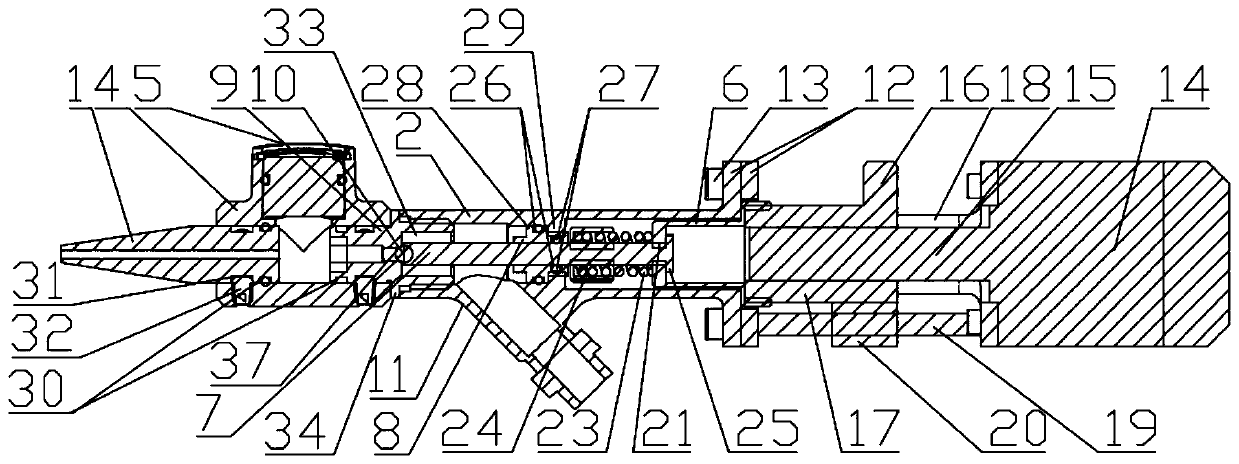

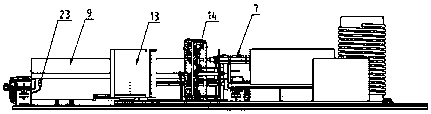

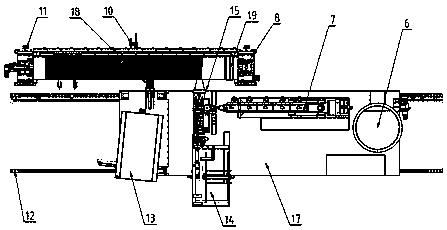

Coning and threading machine for high-pressure tubing

A machine permits an end of a thick-walled, high-pressure tubing to be chucked in a collet one time, coned, faced and threaded, using a coning head and threading head which are mounted on a carriage which can be translated laterally between three positions and the coning and threading heads parallel to the longitudinal axis of the workpiece to complete the coning and threading operations.

Owner:MAXPRO TECH

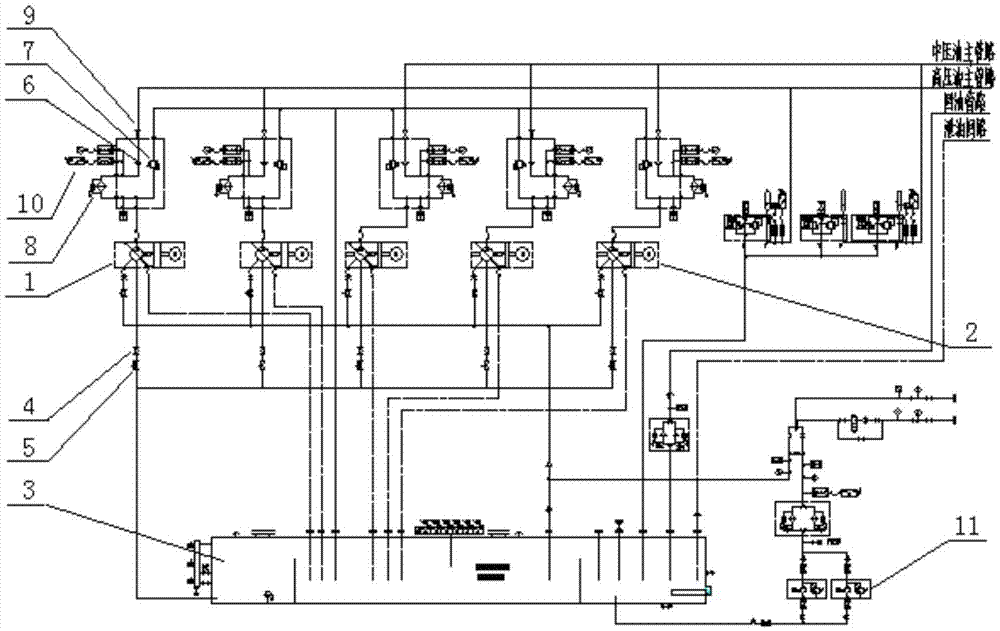

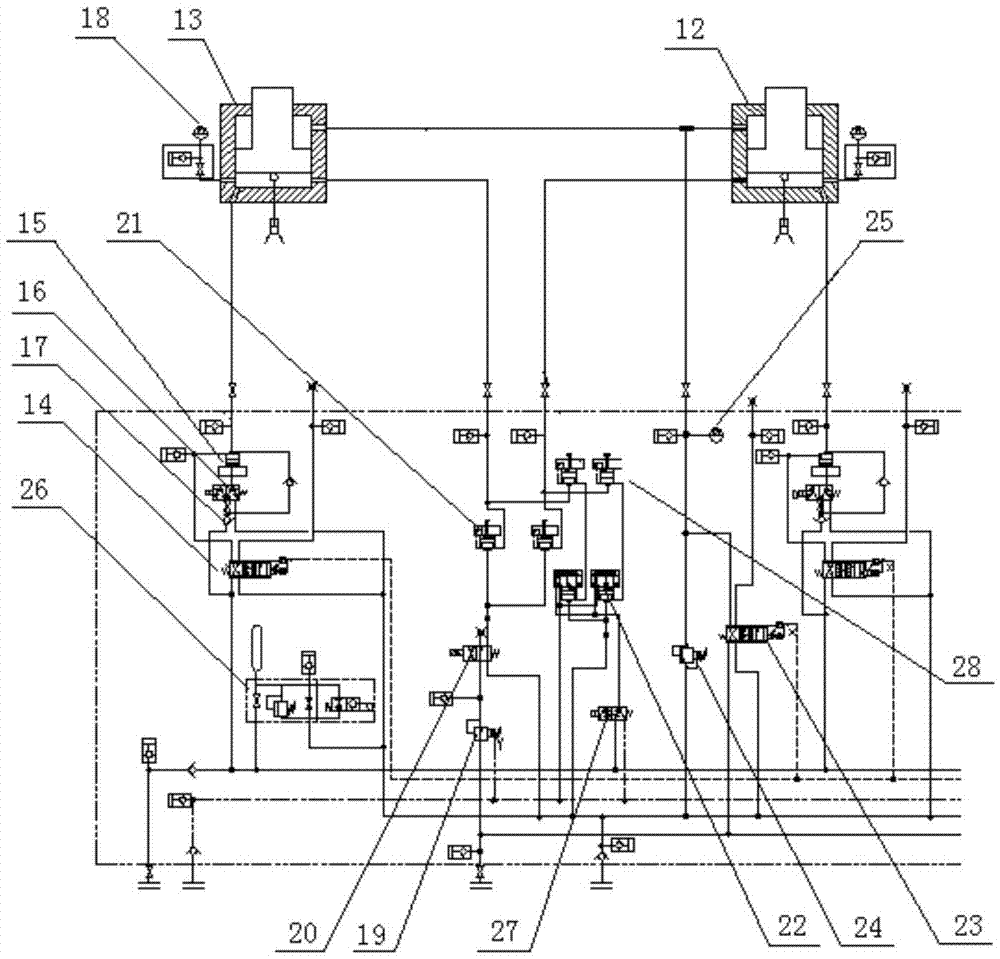

Hydraulic screwup control device and method of skin-pass mill

InactiveCN107013518ALow running costSimple designServomotorsProfile control deviceClosed loopHydraulic pump

The invention provides a control device and method for hydraulic pressure on a skin pass machine. The control device is composed of a hydraulic pump station and a hydraulic control valve table; the hydraulic pump station is equipped with 2 high-pressure pumps and 3 medium-pressure pumps; the high-pressure pump and the medium-pressure pump The inlet side is connected to the suction pipe in series through a stop valve and damping throat, and the outlet side is equipped with a check valve, overflow valve, filter, stop valve and pressure switch. The hydraulic control valve table includes a dynamic control adjustment circuit for the upper cylinder, a quick opening or closing control circuit for the upper cylinder, and a rod cavity control circuit for the upper cylinder. The high-pressure oil pipeline of the hydraulic control valve table is connected to the oil circuit of the high-pressure pump station to form a dynamic control adjustment of the upper cylinder; the medium-pressure oil pipeline of the hydraulic control valve table to quickly open and quickly close the circuit is connected to the medium-pressure pump station to form a pressure upper cylinder Quick action. The invention can save a hydraulic pump, correspondingly reduce the working energy consumption of the hydraulic pump and related hydraulic components, and reduce the consumption of spare parts and the operation cost of the skin-passing machine.

Owner:ANGANG STEEL CO LTD

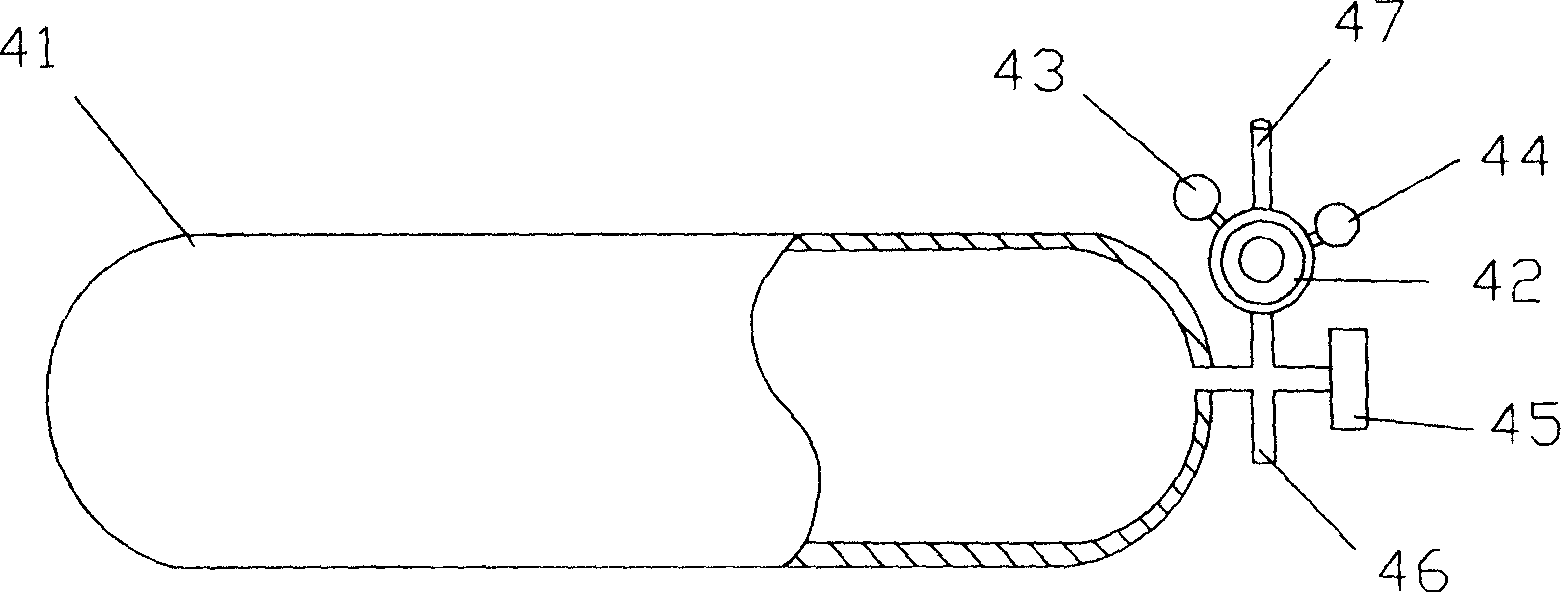

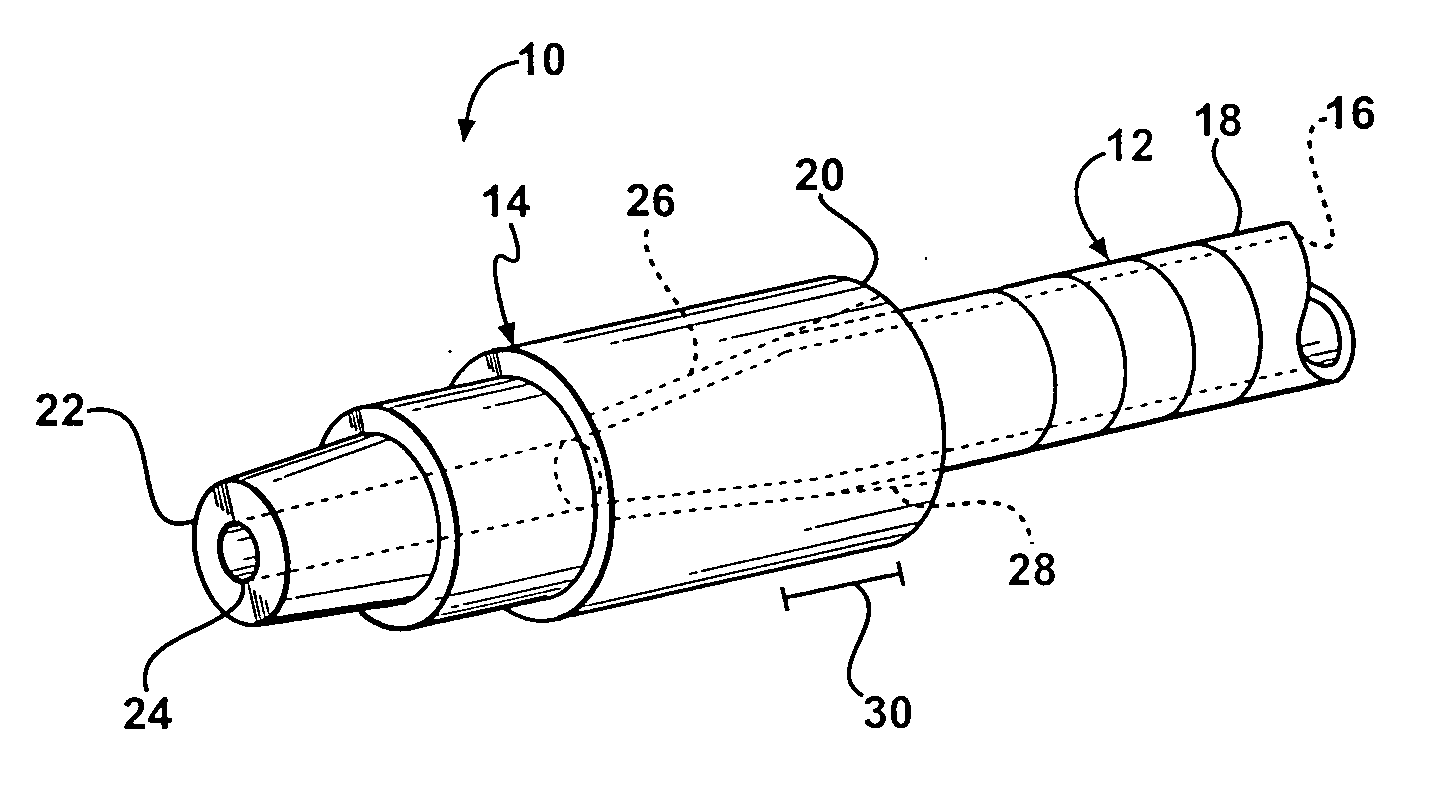

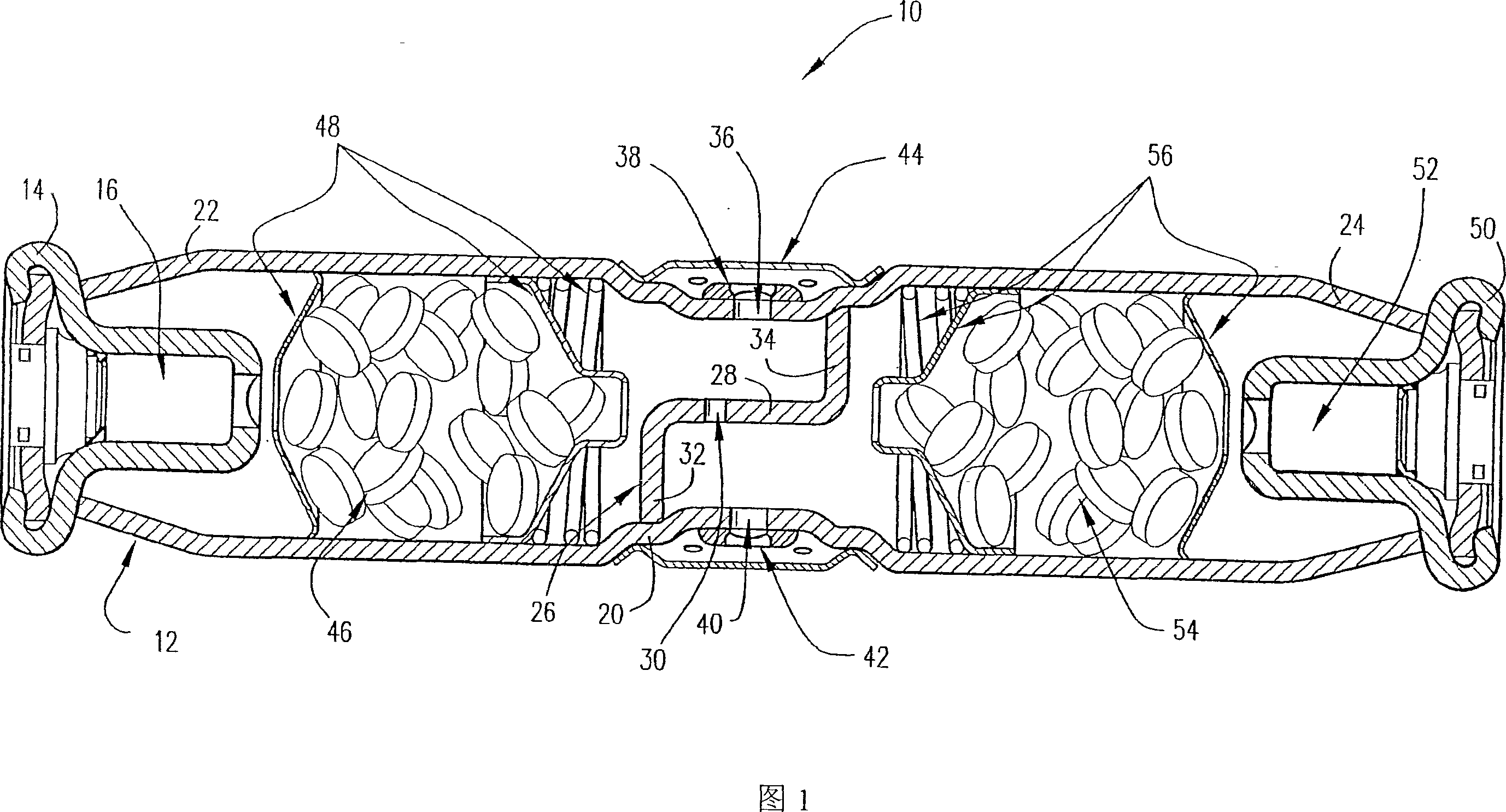

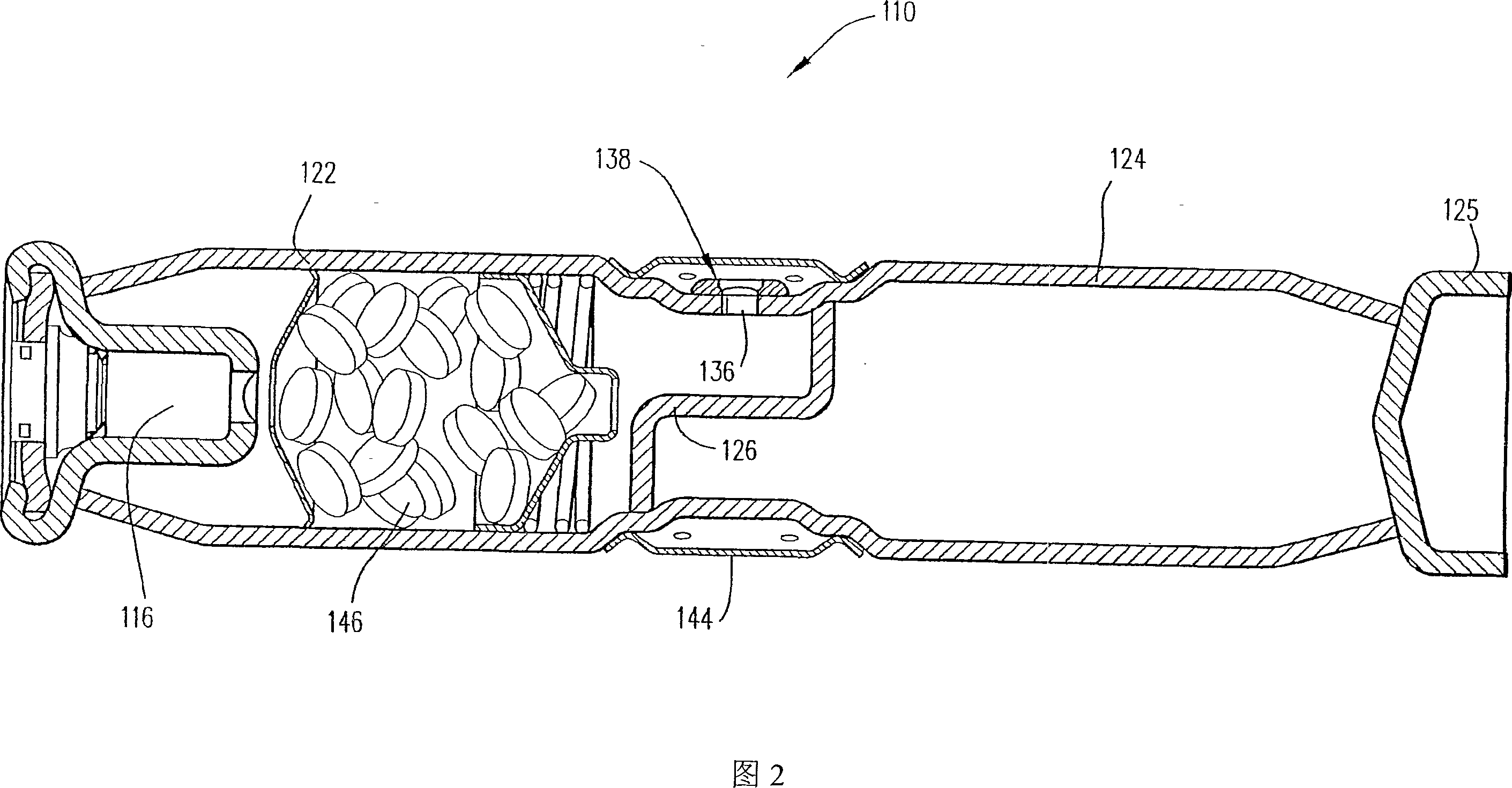

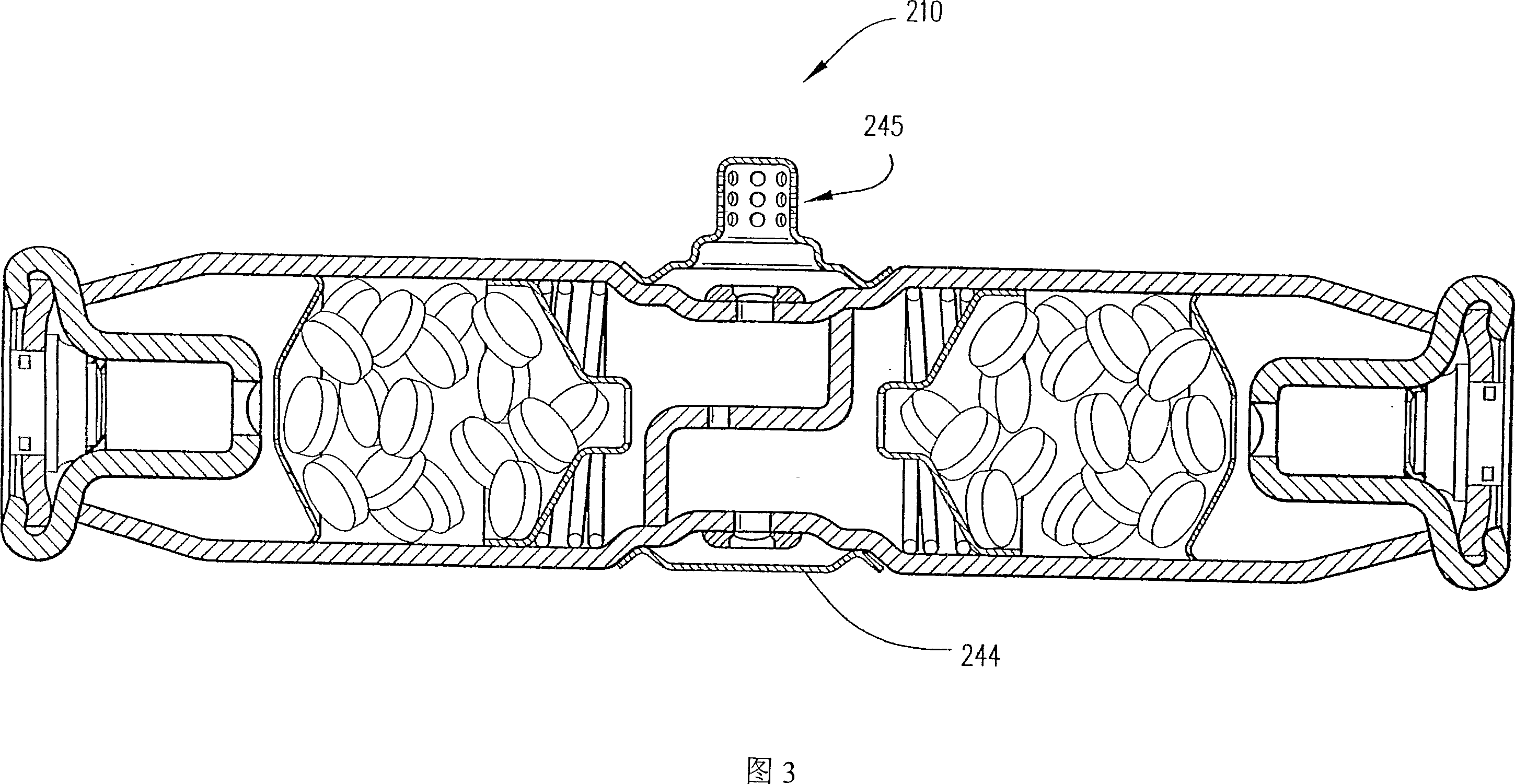

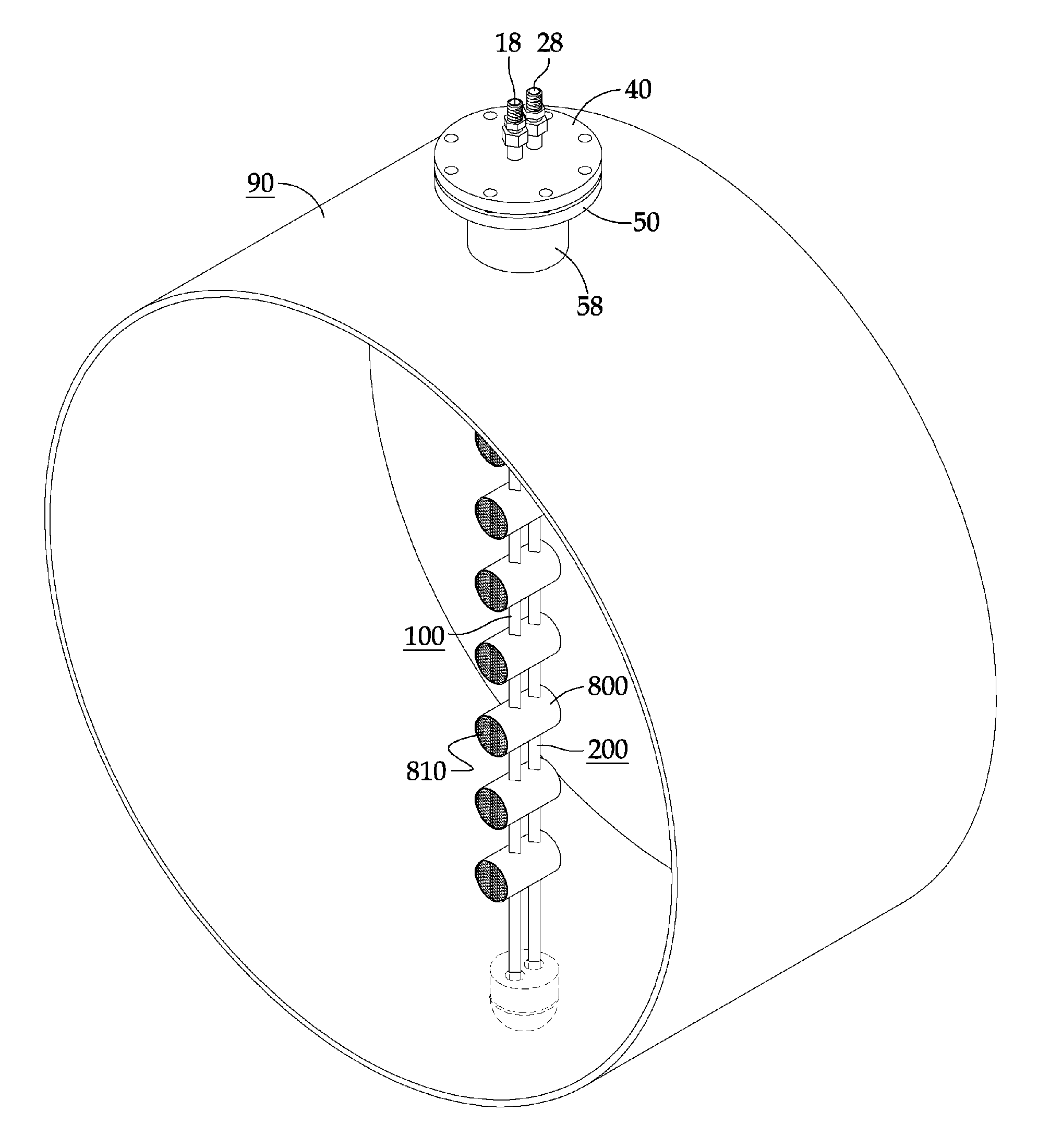

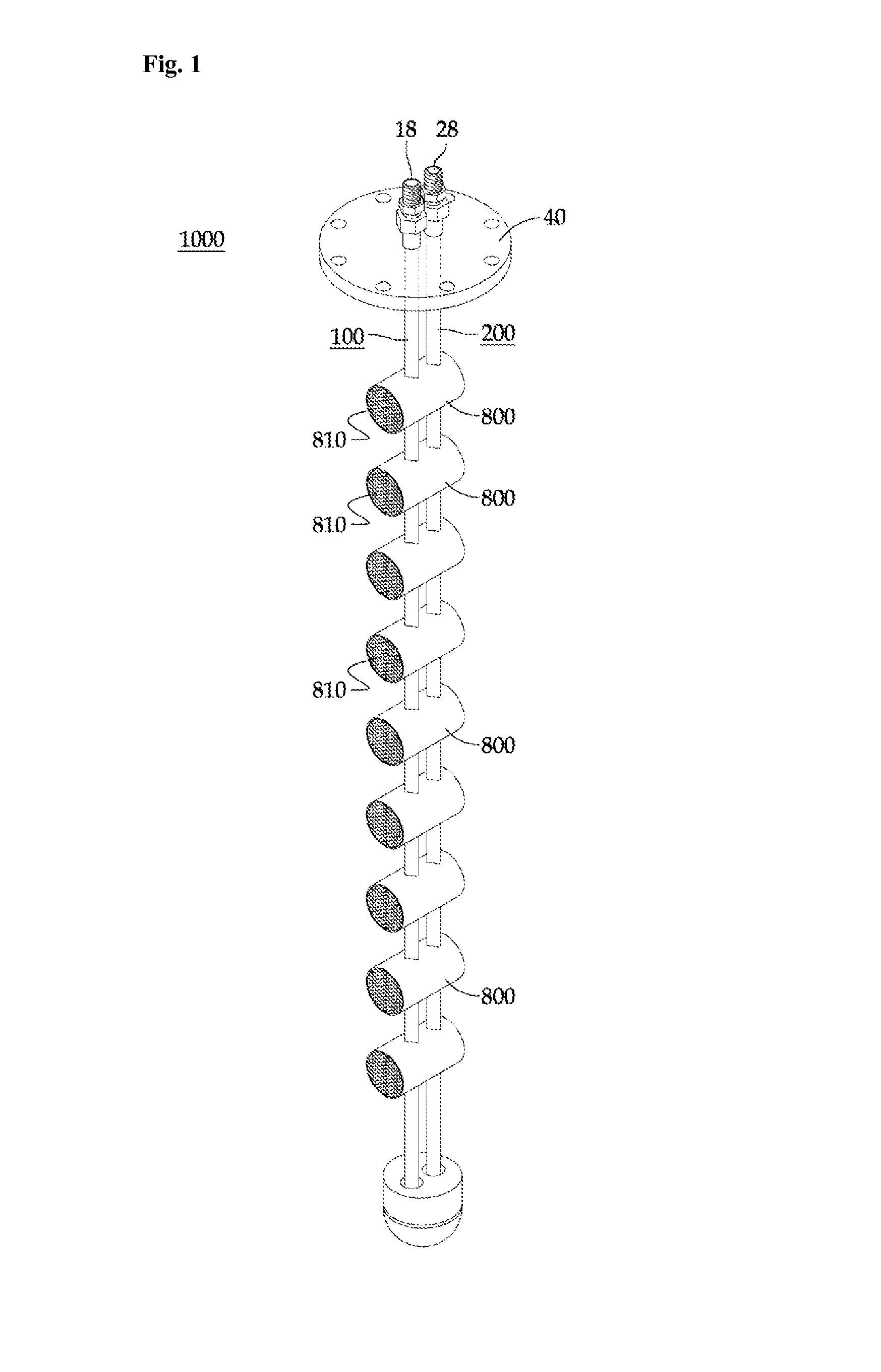

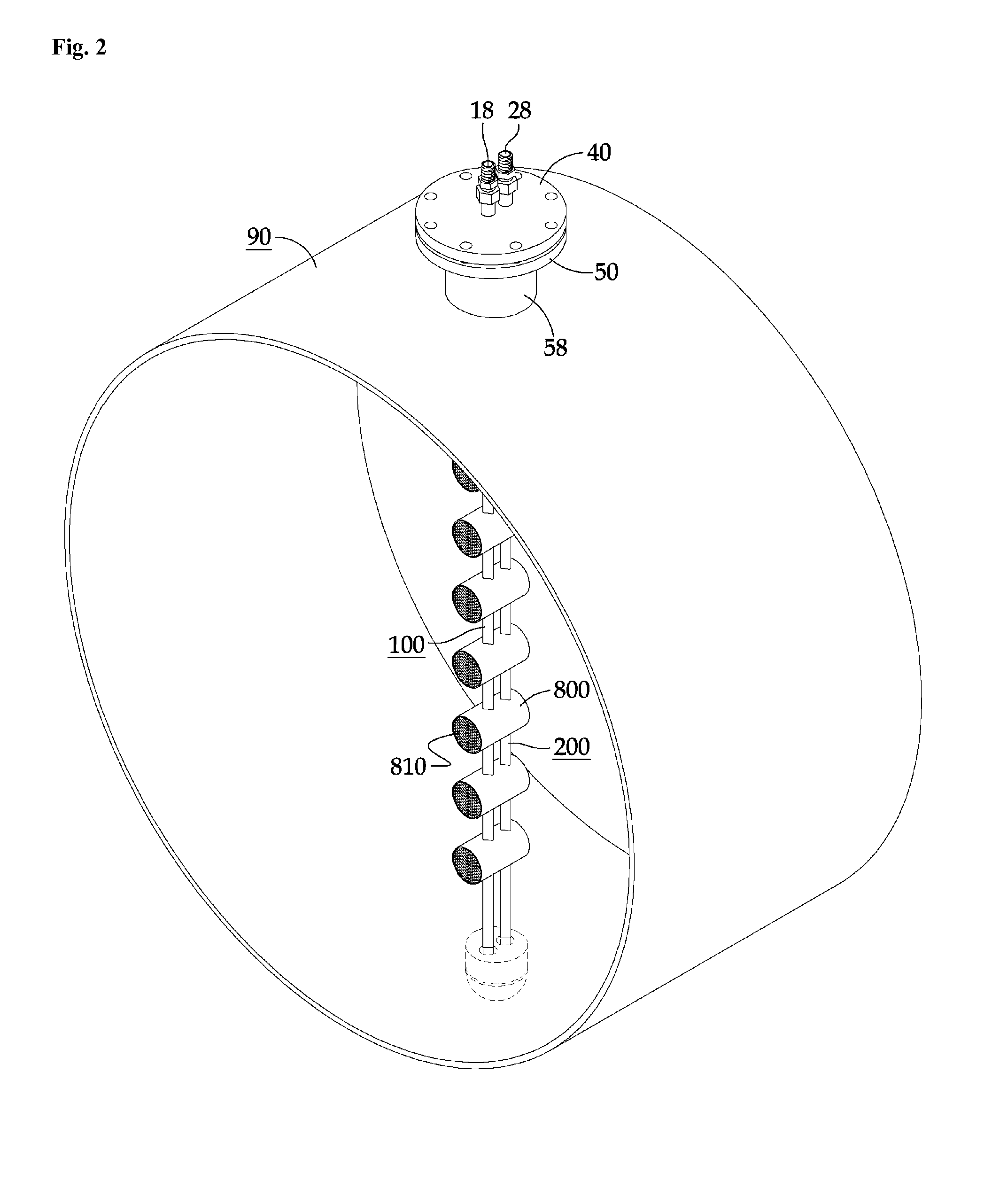

Compact multi-level output hybrid gas generator

InactiveCN101137525ASmall sizeSimple structurePedestrian/occupant safety arrangementVehicle design optimisationHybrid typeEnergetics

A multi-level gas inflator for an air bag or other safety device, comprising an elongated pressure vessel having a primary gas generant portion with a first open end and a secondary gas generant portion with a second open end. The primary gas generant portion has a primary ignition device and primary gas generating energetics disposed therein. The primary ignition device is mounted on and closes the pressure vessel at the first open end thereof. The secondary gas generant portion has a secondary ignition device and secondary gas generating energetics disposed therein. The secondary ignition device is mounted on and closes the pressure vessel at the second open end thereof. A suitable gas under a predetermined pressure is present in the primary and secondary gas generant portions. One or more dividers or divider walls are disposed within the midportion of the pressure vessel to separate the primary and secondary gas generant portions. The pressure vessel has a primary exit orifice in the midportion thereof that is in communication with the primary gas generant portion, and a secondary exit orifice in the midportion thereof that is in communication with the secondary gas generant portion. A primary rupture disk is disposed over the primary exit orifice, and a secondary rupture disk is disposed over the secondary exit orifice. A diffuser is mounted on and surrounds the pressure vessel midportion and the primary and secondary exit orifices. The diffuser is in communication with the air bag for the inflation thereof. The inflator can be easily converted to a single level output inflator by omitting the secondary ignition device and the secondary gas generating energetics.

Owner:ARC AUTOMOTIVE

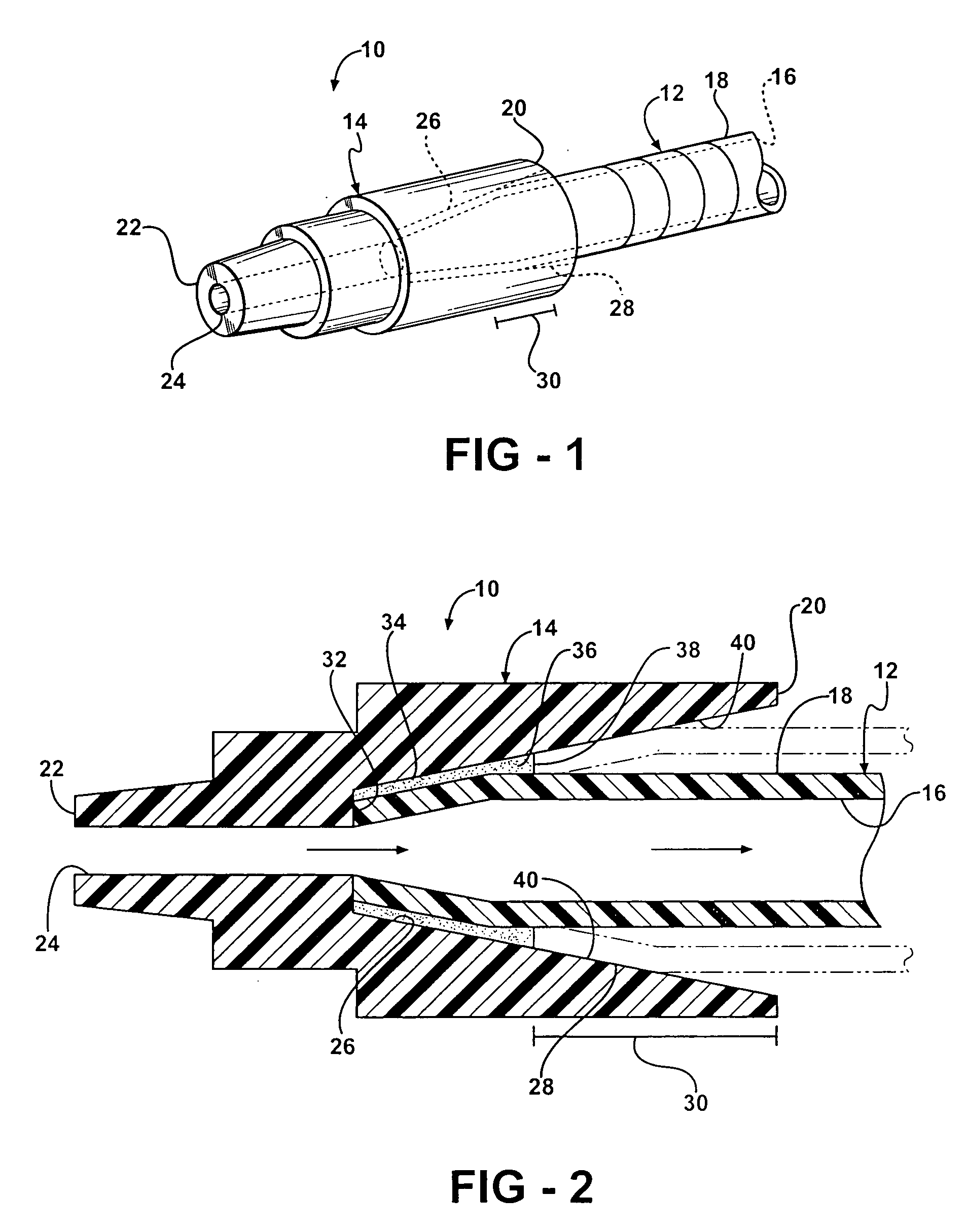

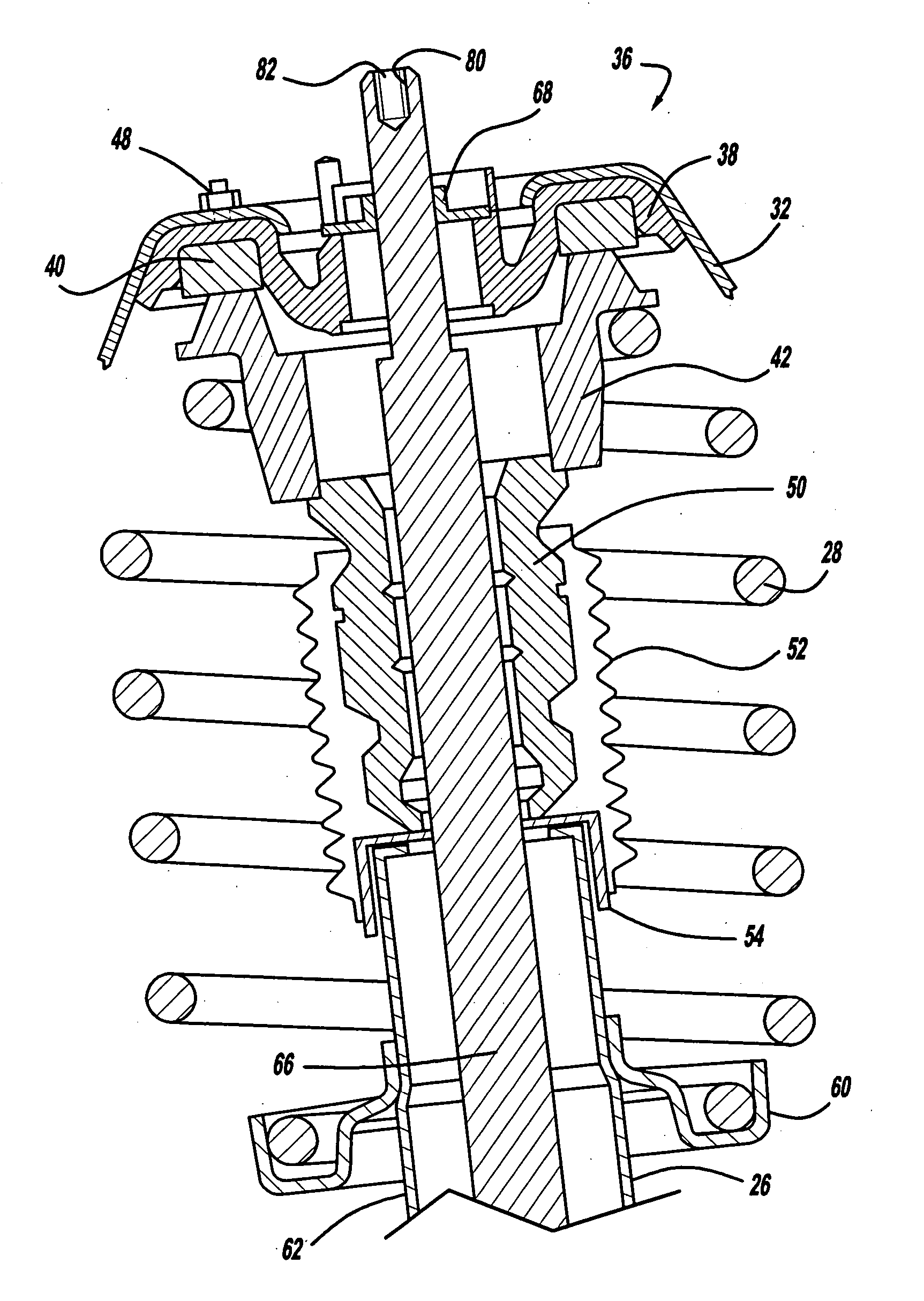

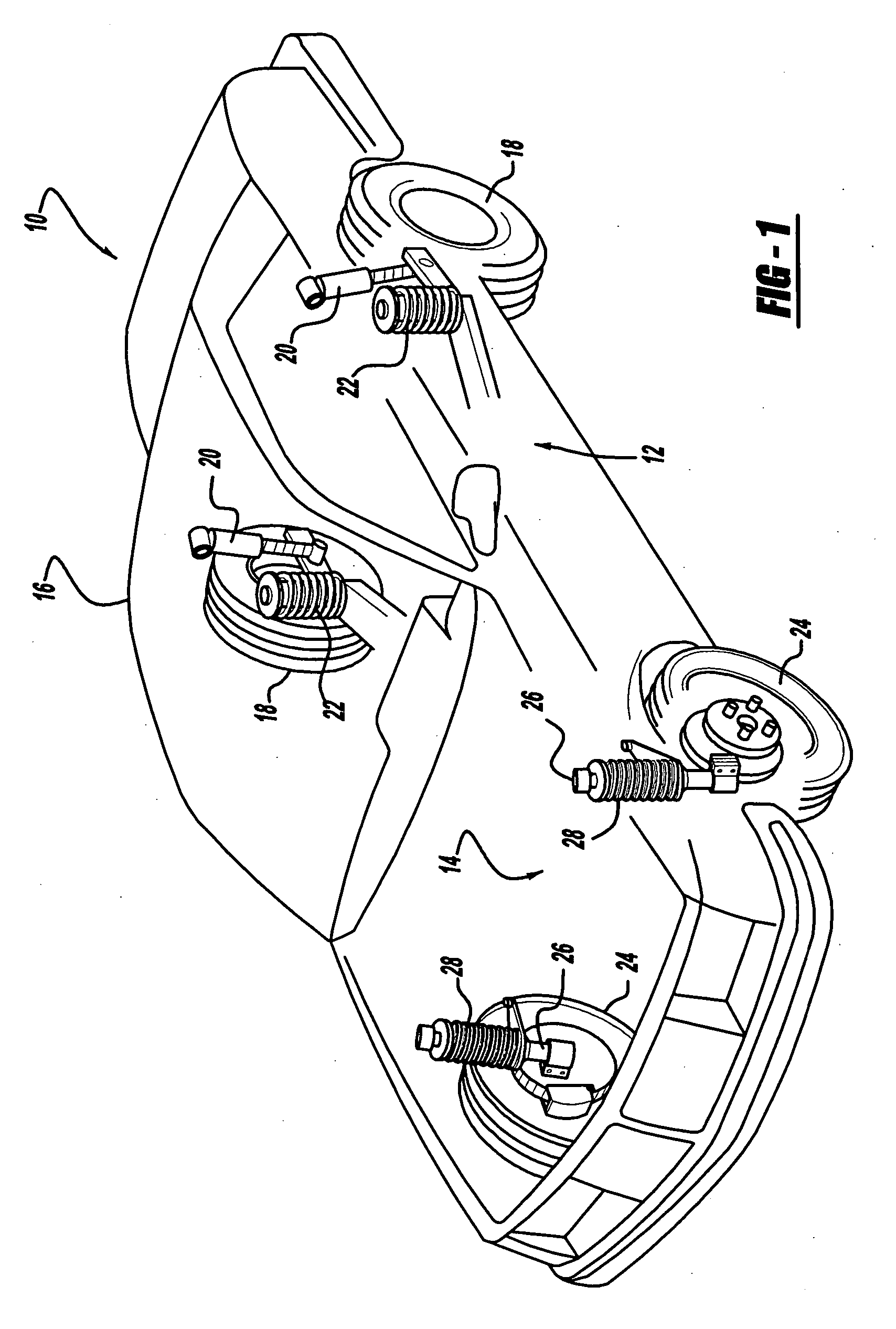

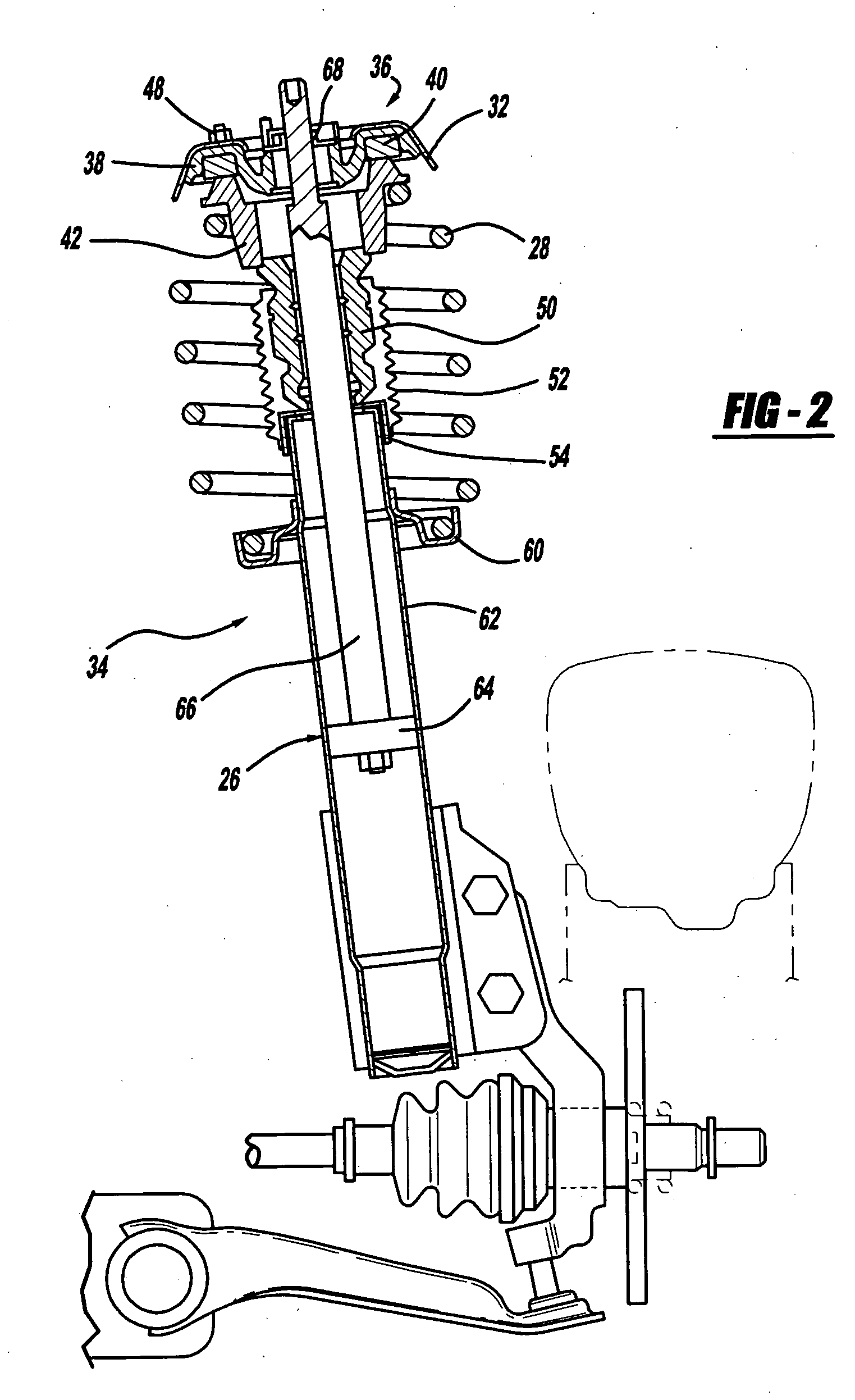

Automatic nut running to torque without the possibility of slip

A shock absorber has a pressure tube, a piston slidably disposed in the pressure tube and a piston rod attached to the piston and extending out of the pressure tube. The end of the piston rod extending out of the pressure tube defines a contoured surface which can be engaged to prohibit rotation of the piston rod. In one embodiment the contoured surface is defined by an inner surface of a bore. In another embodiment, the contoured surface is defined by an exterior surface of an extension to the piston rod.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Large diameter flow-through kiel-style probe for high moisture applications

ActiveUS20130247686A1Fluid pressure measurement by mechanical elementsVolume/mass flow by differential pressureEngineeringMoisture

A Kiel-style pressure probe includes pressure tubing having a remote sending end, the pressure tubing extending through an open-ended shroud, wherein the shroud has a diameter of at least about 0.375 to 0.50 inch and wherein a forward end of the shroud is formed with at least two drainage apertures in proximity to the remote sensing tip of the pressure tubing.

Owner:GENERAL ELECTRIC CO

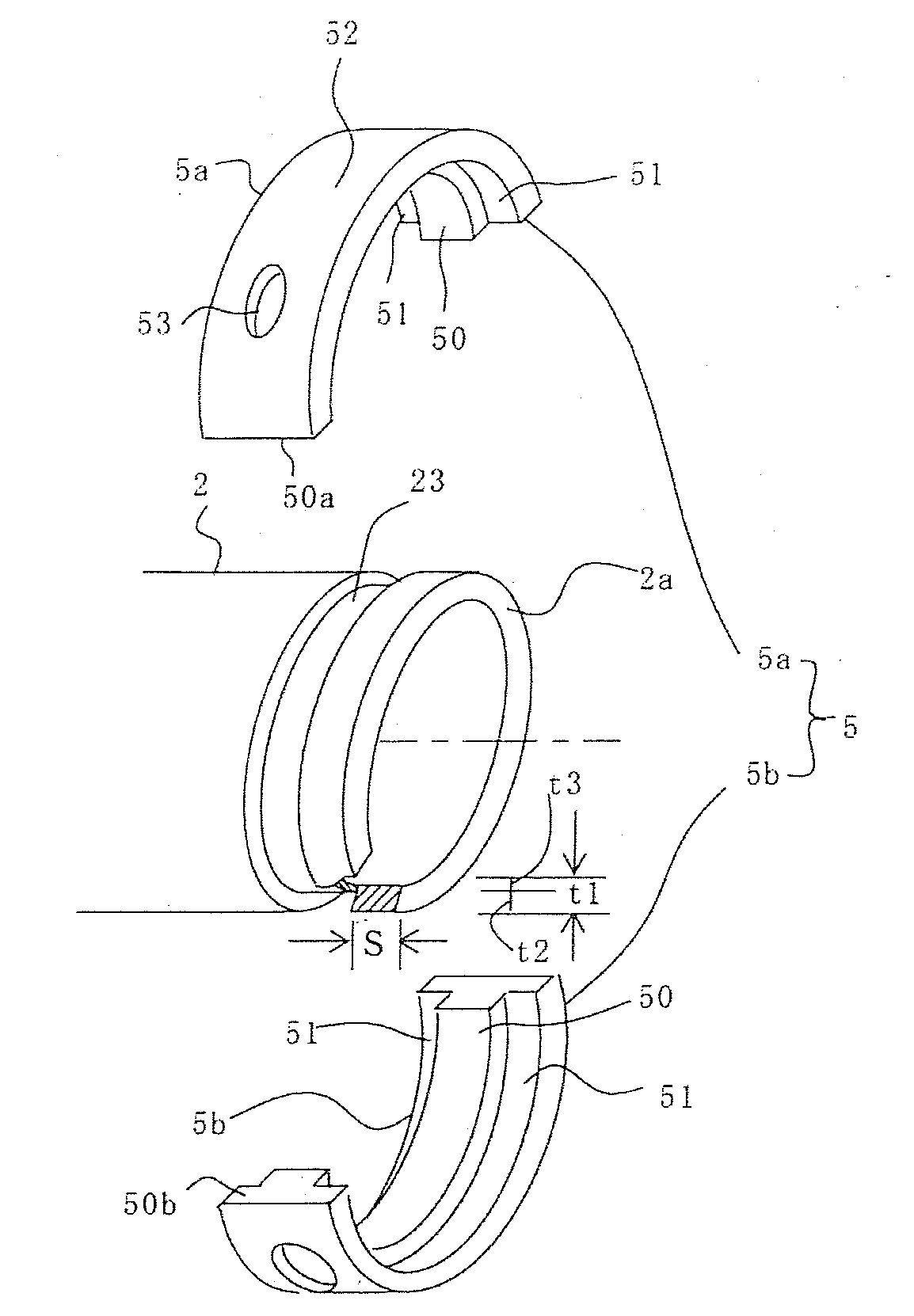

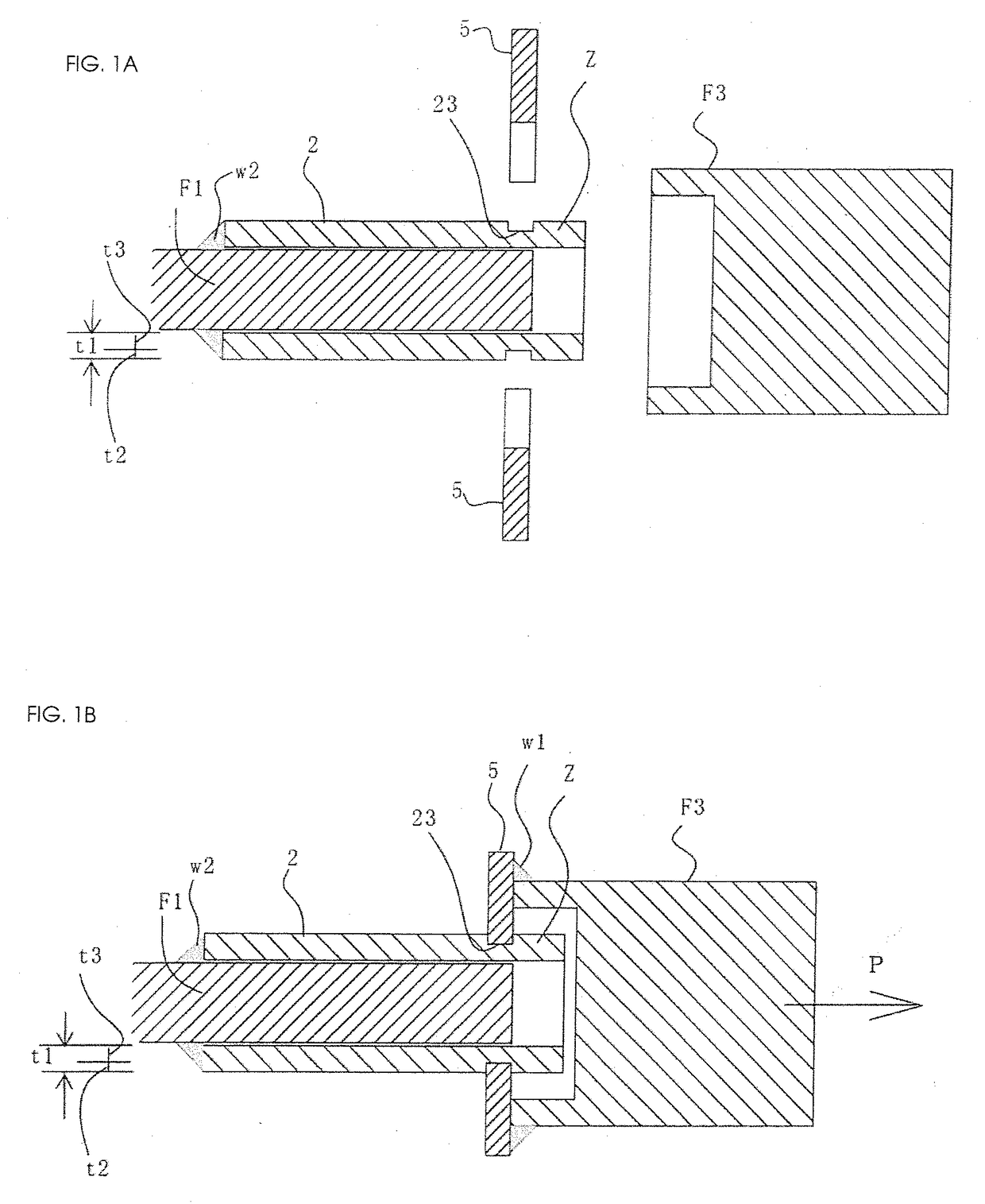

Pressure Pipe Connection Method and Method for Constructing Pressure Pipe with Flange

InactiveUS20180328524A1Reduce processing timeHigh machining skillSleeve/socket jointsFlanged jointsMan-hourEngineering

Provided is a pressure pipe connection structure that reduces man-hours for machining one or more pressure pipes and does not require high machining precision. Multiple arc members form a ring shape that makes a circle by matching the end faces thereof to each other. Non-penetrating holes may be provided on the outer circumference of the arc members. The ring formed by the multiple arc members has an inner diameter that is smaller than the outer diameter and larger than the inner diameter of a pressure pipe. A cylindrical sleeve has an inner cylindrical surface inside which the entire outer circumferences of arc members are fitted into a hollow internal space, into which respective one or more pressure pipes are inserted from one or more opposing entrances; and multiple through holes, which penetrate from the outside and are provided with female thread ridges. The one or more pressure pipes are cut to a certain length that is suited to the placement site and a groove is grooves cut in the corresponding pressure pipe. The arc members are fitted into the groove, and the arc members are positioned on an inner cylindrical surface by inserting the one or more pressure pipes into a sleeve, the respective through holes and non-penetrating holes are made to communicate with each other, and the one or more pressure pipes are fixed using bolts.

Owner:NIPPON KANSEN INDS

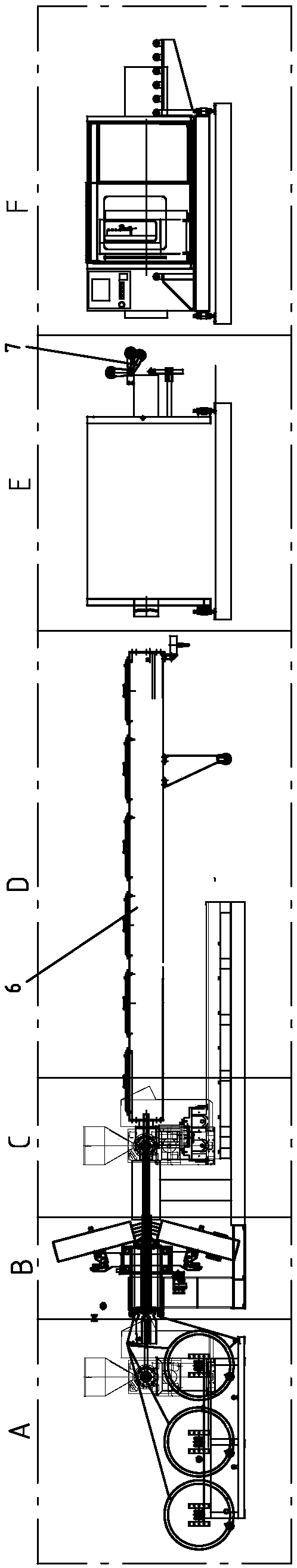

Continuous fiber reinforced plastic pressure pipe and manufacturing method and device thereof

PendingCN108426104AHigh axial mechanical propertiesSolve problemsRigid pipesTubular articlesEngineeringPlastic fiber

The invention relates to a continuous fiber reinforced plastic pressure pipe. The invention aims to provide a continuous fiber reinforced plastic pressure pipe which has the characteristics of high mechanical strength and material saving. The invention also aims to provide a manufacturing method and a production device of the continuous fiber reinforced plastic pressure pipe. The continuous fiberreinforced plastic pressure pipe is characterized in that an intermediate reinforcing layer of the pressure pipe consists of at least one axially laid inner prepreg plastic fiber band and at least one spirally wrapped outer prepreg plastic fiber band in the circumferential direction, and the two surfaces of the intermediate reinforcing layer are respectively a plastic inner wall layer and a plastic outer wall layer which are connected with the intermediate reinforcing layer into a whole through extrusion molding.

Owner:谈刚强

Continuous fiber reinforced pressure pipe and forming process thereof

The invention relates to a continuous fiber reinforced pressure pipe and a forming process thereof. In order to solve the problems that pipeline mechanical property is affected by layering due to insufficient fusion between a fiber layer and a plastic layer in a current pipeline, an outer reinforcing rib and a base pipe are delaminated, and the reinforcing rib is unreasonable in structure, is incapable of continuously winding, is high in manufacturing cost and is low in ring stiffness, the continuous fiber reinforced pressure pipe comprises the base pipe which is composed of the plastic layer and the fiber layer. The continuous fiber reinforced pressure pipe is characterized in that a spiral tubular reinforcing rib is wound and fused on the outer surface of the base pipe. An integral product is obtained by continuous base pipe winding and forming, tubular reinforcing rib winding and base pipe fusing. The continuous fiber reinforced pressure pipe is relatively light in mass, and is high in ring stiffness, and solves the transportation problem of large-caliber pipes.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

Connection structure and connection method for non-pressure tubes between modularized upper floor and lower floor

ActiveCN107419780APrevent infiltrationPlay a limiting roleDomestic plumbingBranching pipesPipe fittingExpansion joint

The invention relates to a connection structure for non-pressure tubes between modularized upper floors and lower floors. The structure includes a vent stack and a drainage stack between an upper floor module and a lower floor module. A first direct-connecting pipe fitting is arranged on the top of the vent stack, a first expansion joint is arranged on the middle-upper part and a first four-way built-in fitting is arranged on the lower part. A first fire-retardant collar sleeves the first four-way built-in fitting. The bottom of the first four-way built-in fitting is sleeved with a first built-in pedestal. A second direct-connecting pipe fitting is arranged on the top of the drainage stack, a second expansion joint is arranged on the middle-upper part, a six-way pipe fitting is arranged on the middle-lower part, and a second four-way built-in fitting is arranged on the lower part. The second four-way built-in fitting is sleeved with a second fire-retardant collar. The bottom of the second four-way built-in fitting is sleeved with a second built-in pedestal. A distance is reserved between the two direct-connecting pipe fittings and the upper floor module. The two four-way built-in fittings are located at the same horizontal plane of the lower floor module. With the structure, the connection structure is convenient to construct and low in cost.

Owner:优积建筑科技发展(上海)有限公司

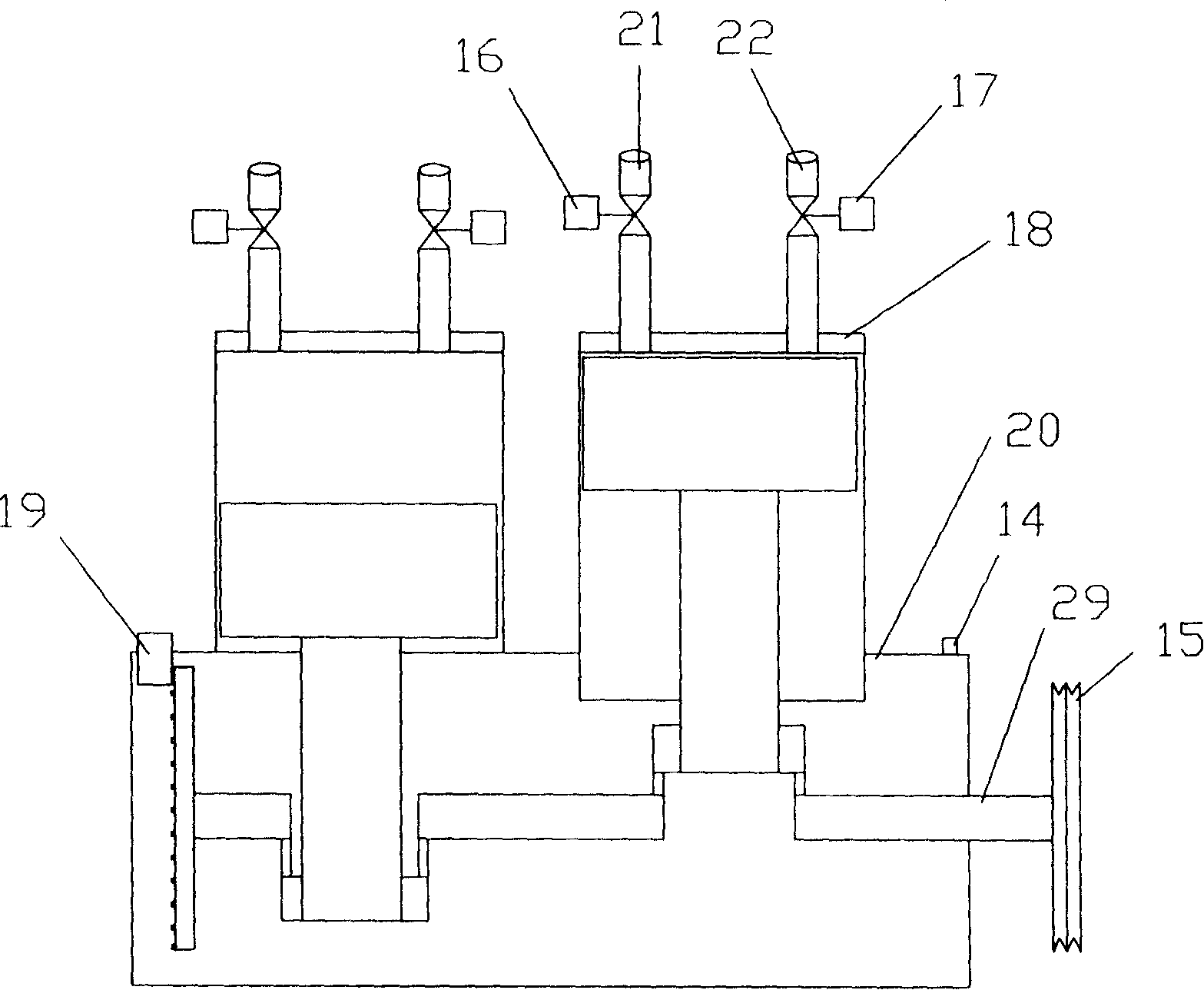

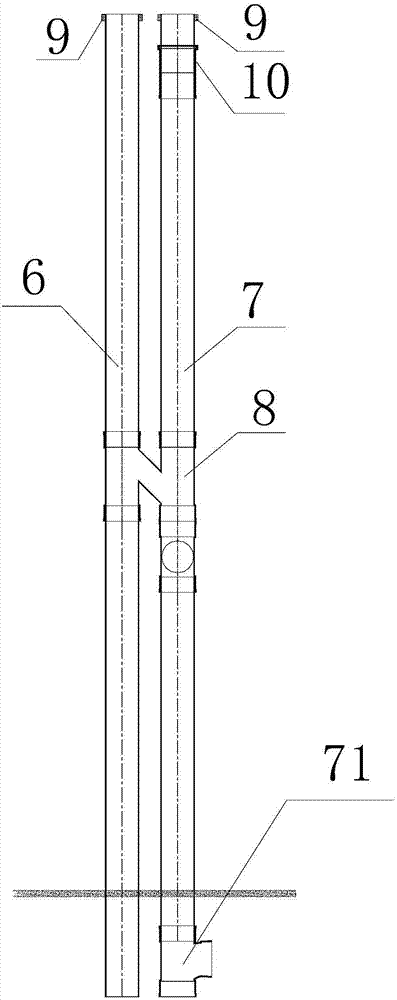

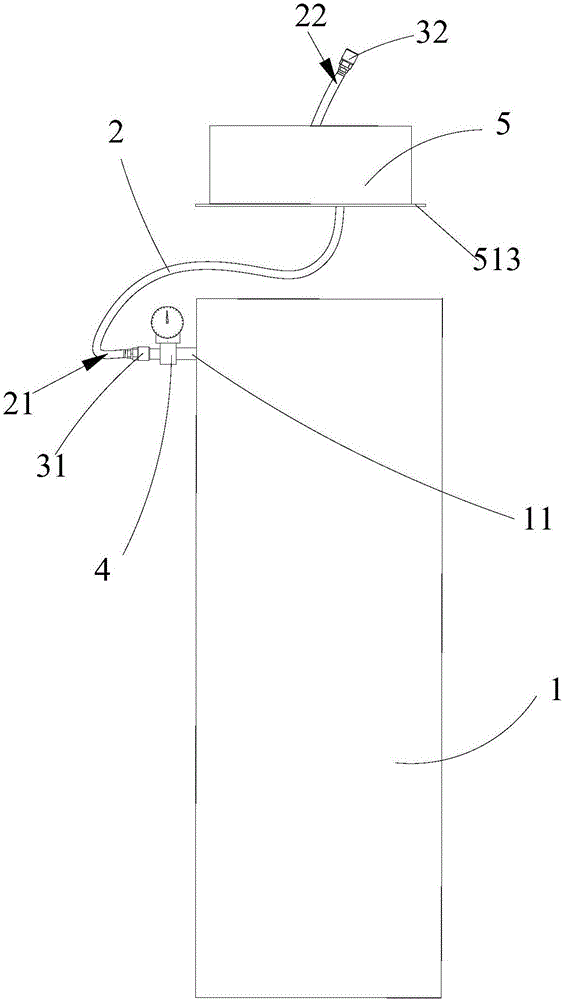

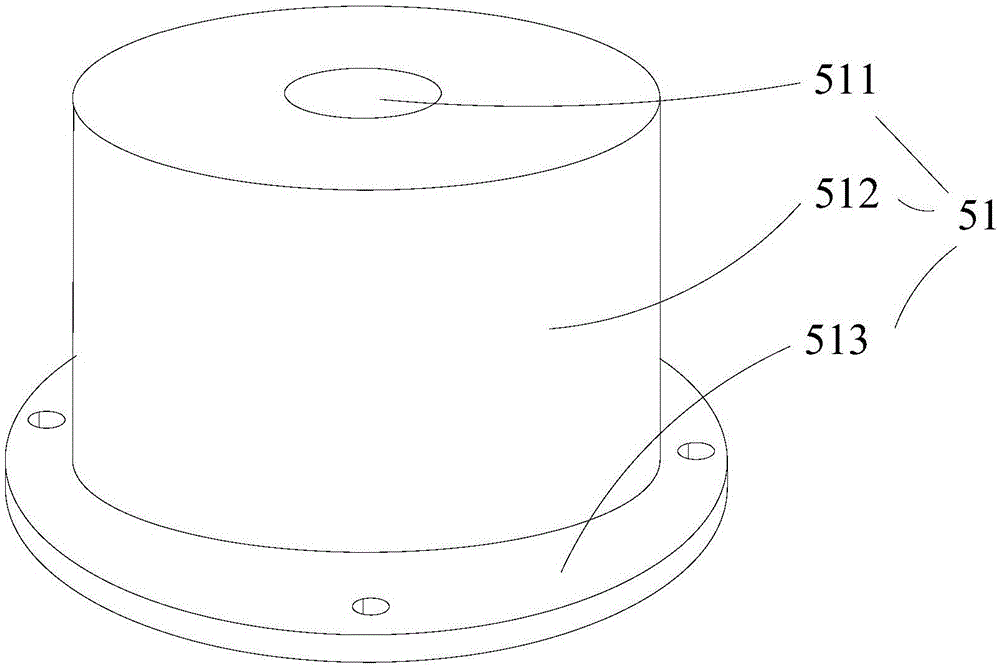

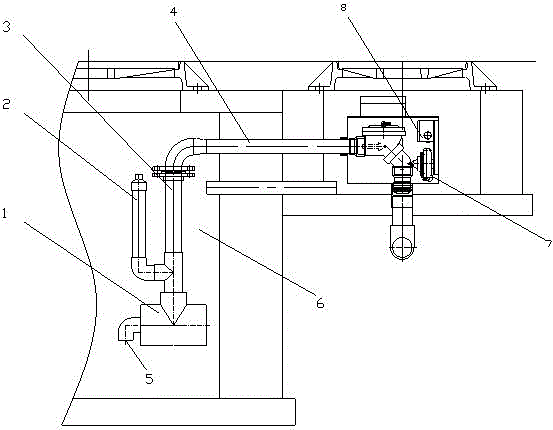

Gas inflation device of sulfur hexafluoride equipment

PendingCN106801786APrevent leakageReduce wasteVessel mounting detailsFluid handledSulfur hexafluoridePositive pressure

The invention relates to the technical field of SF6 equipment, and discloses a gas inflation device of sulfur hexafluoride equipment. The gas inflation device comprises a gas inflation bottle, a long pressure pipe and a closed valve set. The closed valve set comprises a first closed valve and a second closed valve. A gas inflation joint is arranged on the gas inflation bottle. A pressure gage is arranged at the end of the gas inflation joint. One end of the pressure gage communicates with the gas inflation joint, and the other end of the pressure gage is connected with the first closed valve through the long pressure pipe. The second closed valve is arranged at the end, away from the pressure gage, of the long pressure pipe. Therefore, the long pressure pipe is adopted for connecting the gas inflation bottle with the SF6 equipment needing gas inflation, and inconvenience brought by frequent movement of the gas inflation bottle can be effectively avoided. The closed valve set is arranged at the two ends of the long pressure pipe, the situation that SF6 gas is prone to leaking due to the too large length of the long pressure pipe can be avoided, and therefore SF6 gas waste is reduced, and it is guaranteed that positive-pressure SF6 gas exists in the long pressure pipe all the time.

Owner:HENGSHUI POWER SUPPLY BRANCH OF STATE GRID HEBEI ELECTRIC POWER +2

Glue gun stable in pressure and flow

PendingCN110465450AGuaranteed stable voltage and currentLow costLiquid surface applicatorsCoatingsEngineeringMechanical engineering

A glue gun stable in pressure and flow comprises a controller, a pushing device and a glue outlet. A gun body is connected with the pushing device through a connection frame. The glue gun stable in pressure and flow further comprises a pressure pipe and a pressure transmitter communicating with the pressure pipe. The controller is connected with the pressure transmitter and the pushing device. A connection piece, a valve rod, a seal guide piece, a valve element and a valve ball fixed to the tail end of the valve rod are arranged in the gun body. The valve element and the connection piece are fixed to the two ends of the gun body correspondingly. The seal guide piece is fixed to the middle in the gun body. The valve element, the pressure pipe and the glue discharge head are sequentially andfixedly connected in a sealed manner. One end of the connection piece is connected with the top end of the valve rod. The other end of the connection piece is fixedly connected with the pushing device. The valve rod penetrates through the seal guide piece. The valve ball at the tail end of the valve rod is matched with the valve element. On the gun body, a glue inlet pipe communicates between theseal guide piece and the valve element. The glue gun stable in pressure and flow has the beneficial effects that the cost is low, the pressure and flow of the glue gun can be guaranteed to be stable,so that the glue output amount is constant, and metering is accurate.

Owner:重庆宏广机电设备有限公司

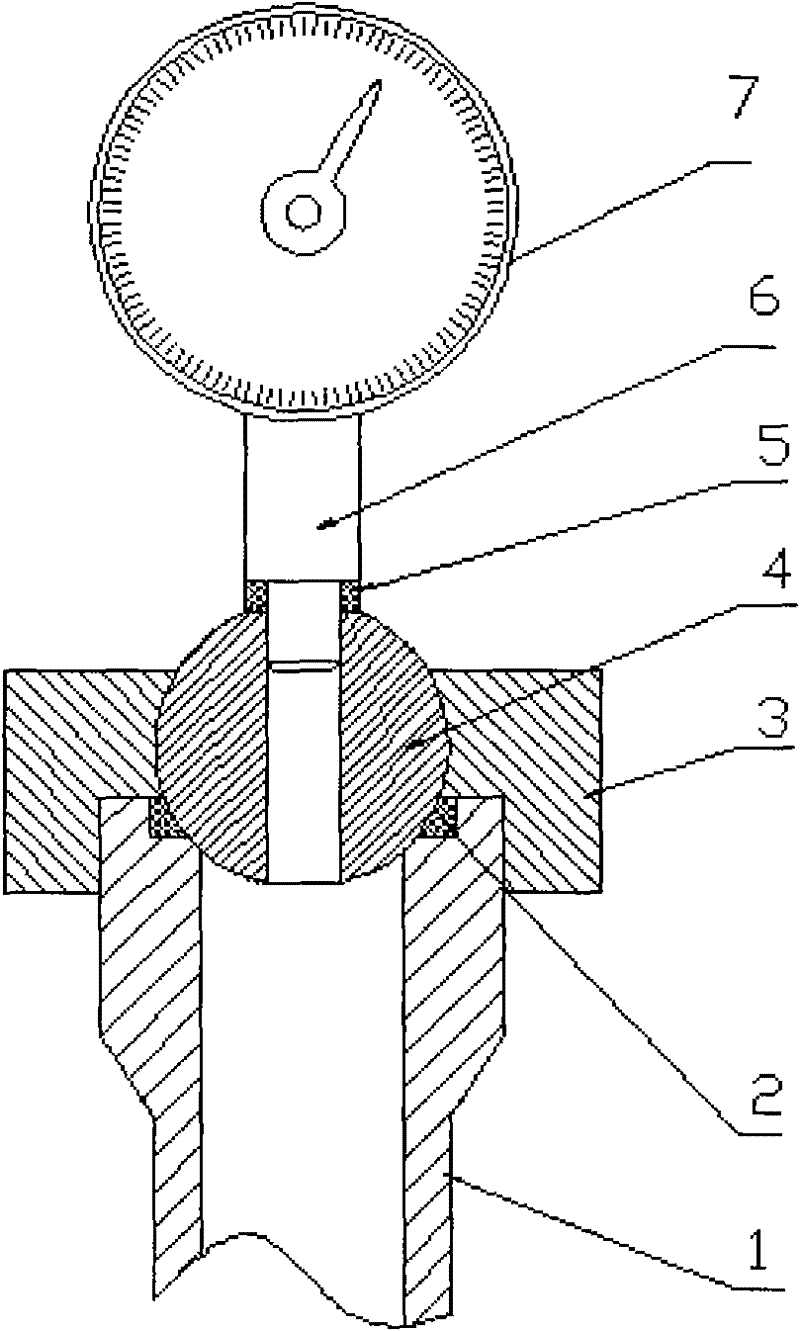

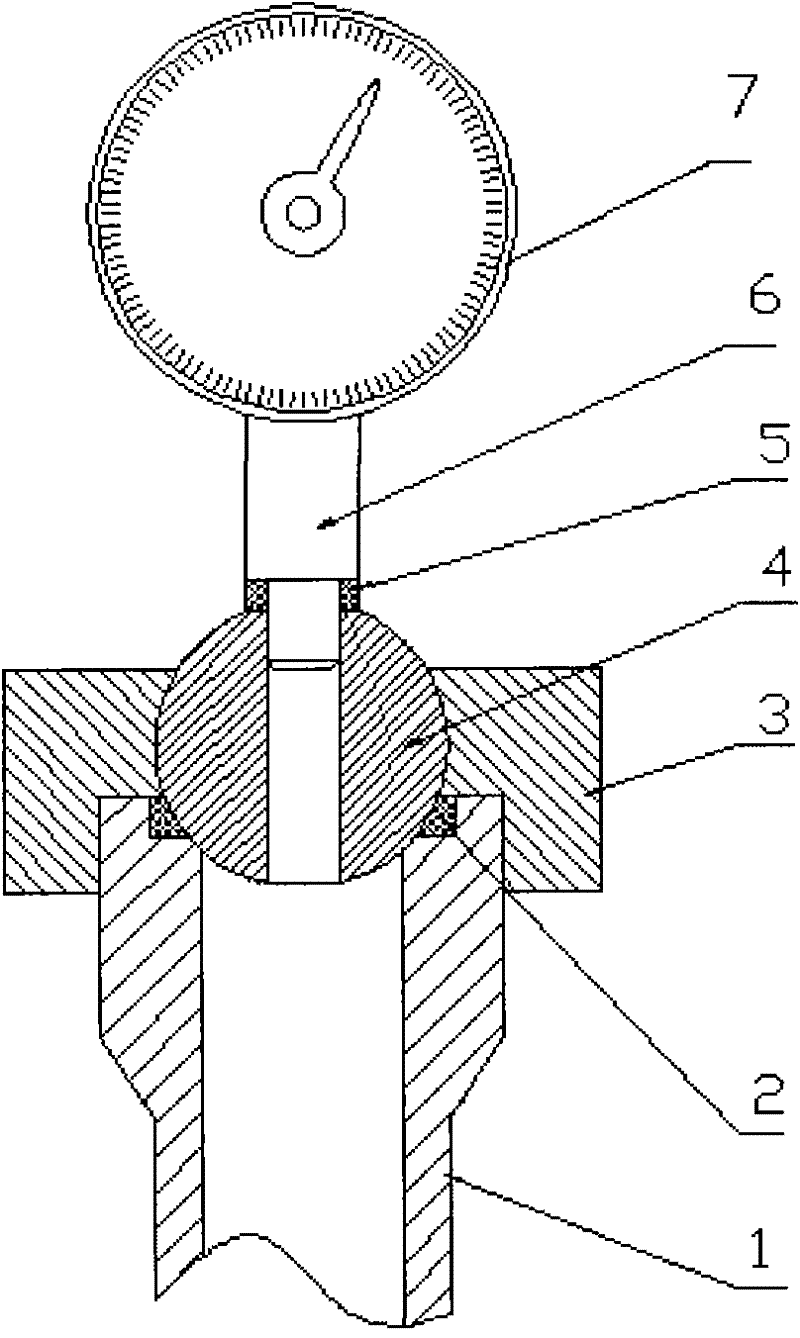

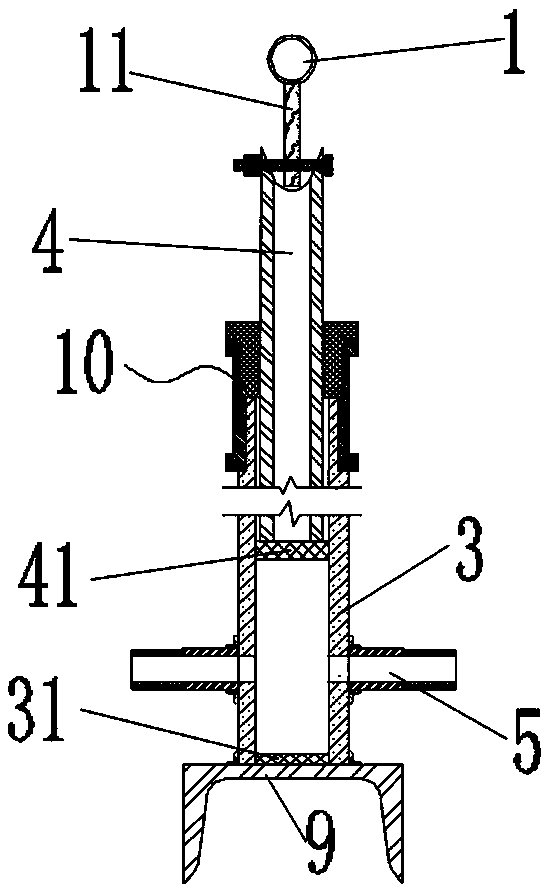

Hydraulic compression gauge sealing rotation structure

InactiveCN102221439AEasy to operateEasy to observeFluid pressure measurementSpherical jointEngineering

Provided is a hydraulic compression gauge sealing rotation structure which is that a fix pipe and the body or hydraulic station of a hydraulic machine are fixed and installed. A sealing ring is placed at the upper opening part of the fix pipe and a spherical joint is placed on the upper opening part of the fix pipe. A joint is used to fix the spherical joint on the upper opening part of the fix pipe. An annular sealing ring is provided on the joint position of a manometer tube and the manometer tube and the spherical joint are connected and fixed through a screw thread connection method.

Owner:赵瑶志

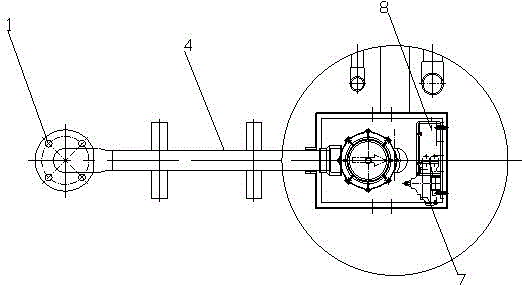

Average Pitot Tube Type Flow Meter

InactiveUS20150114136A1Easy to installIncrease freedomVolume meteringFluid speed measurementEngineeringMechanical engineering

Owner:DAE HAN INSTR

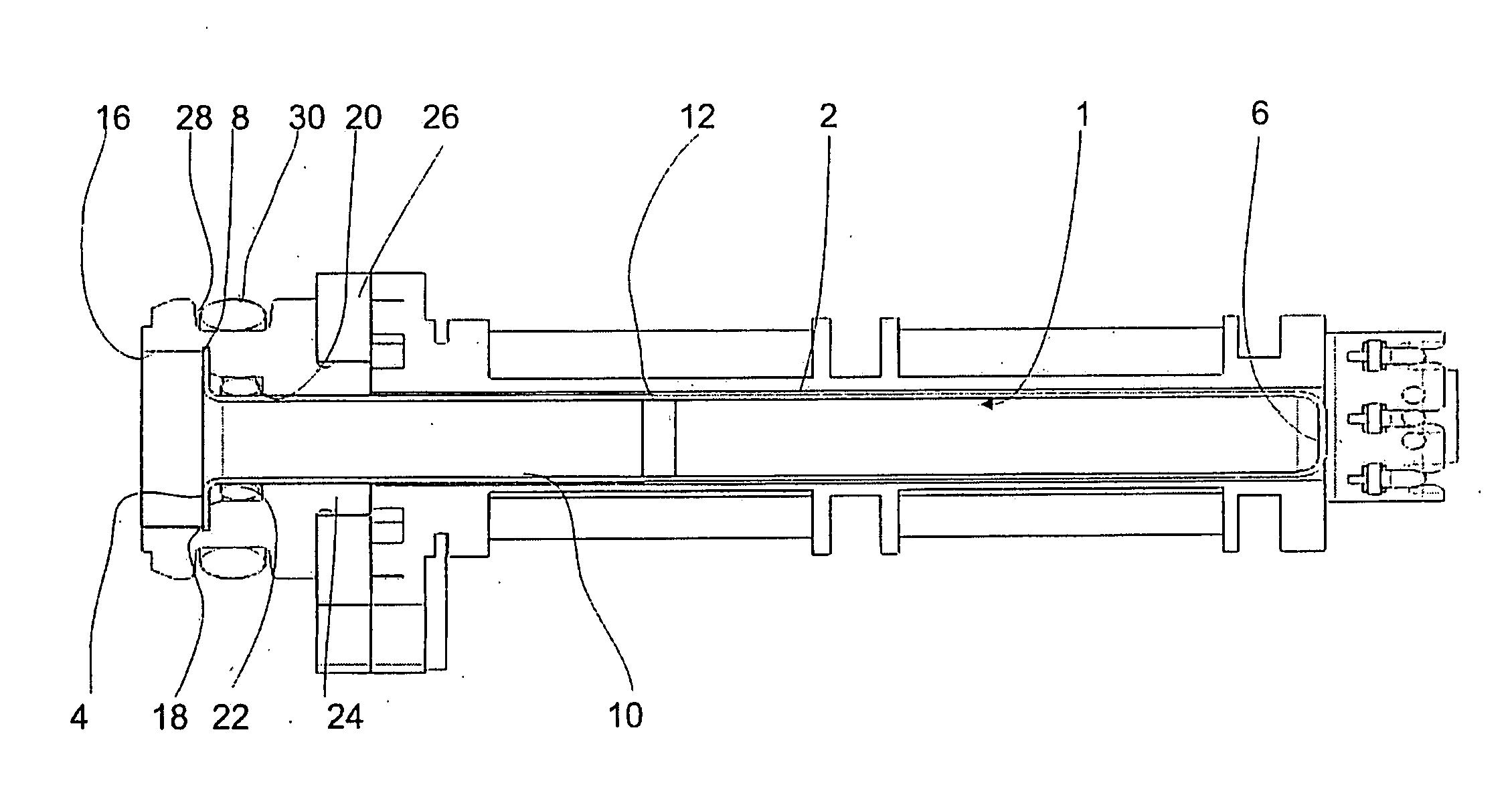

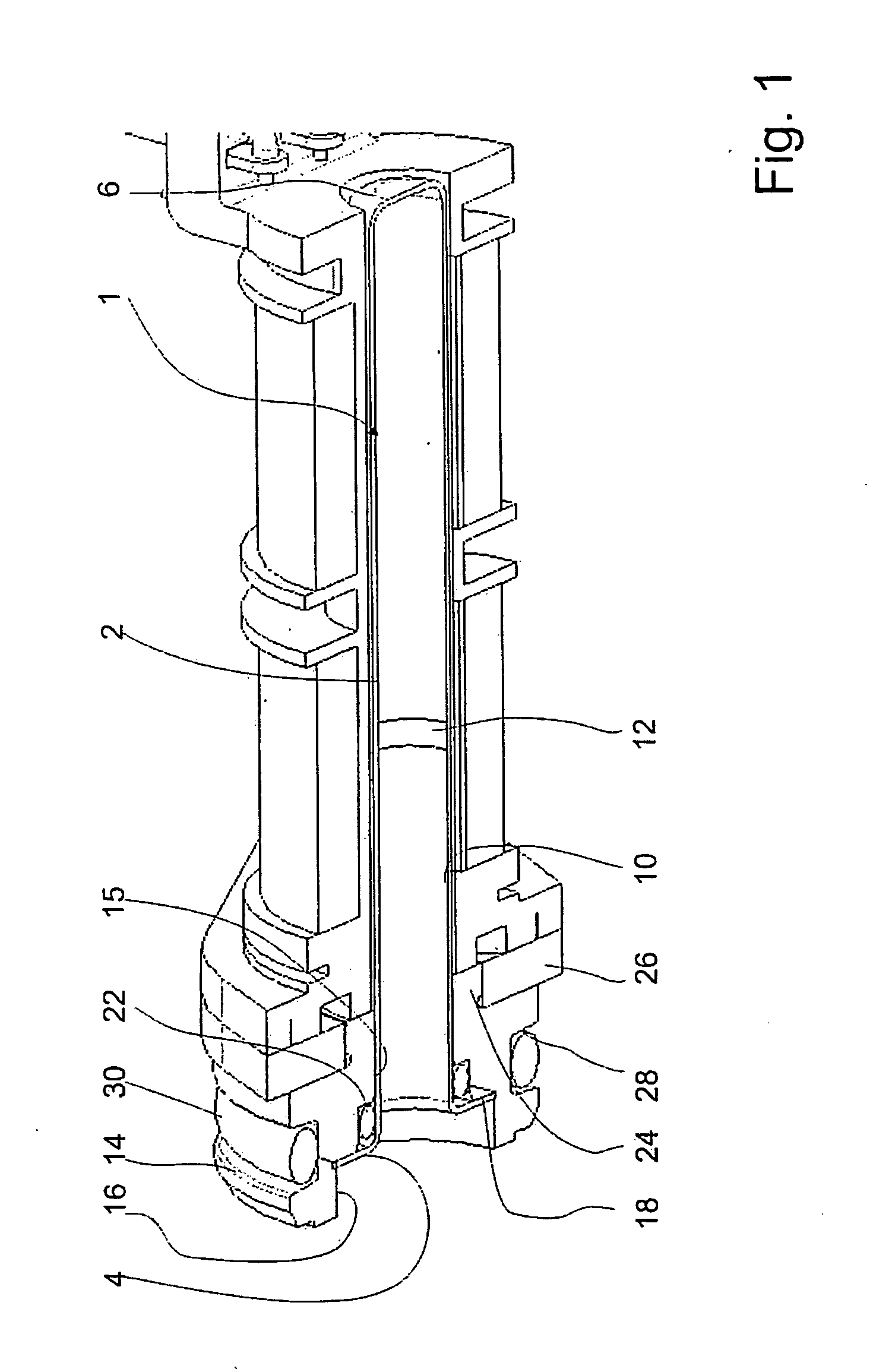

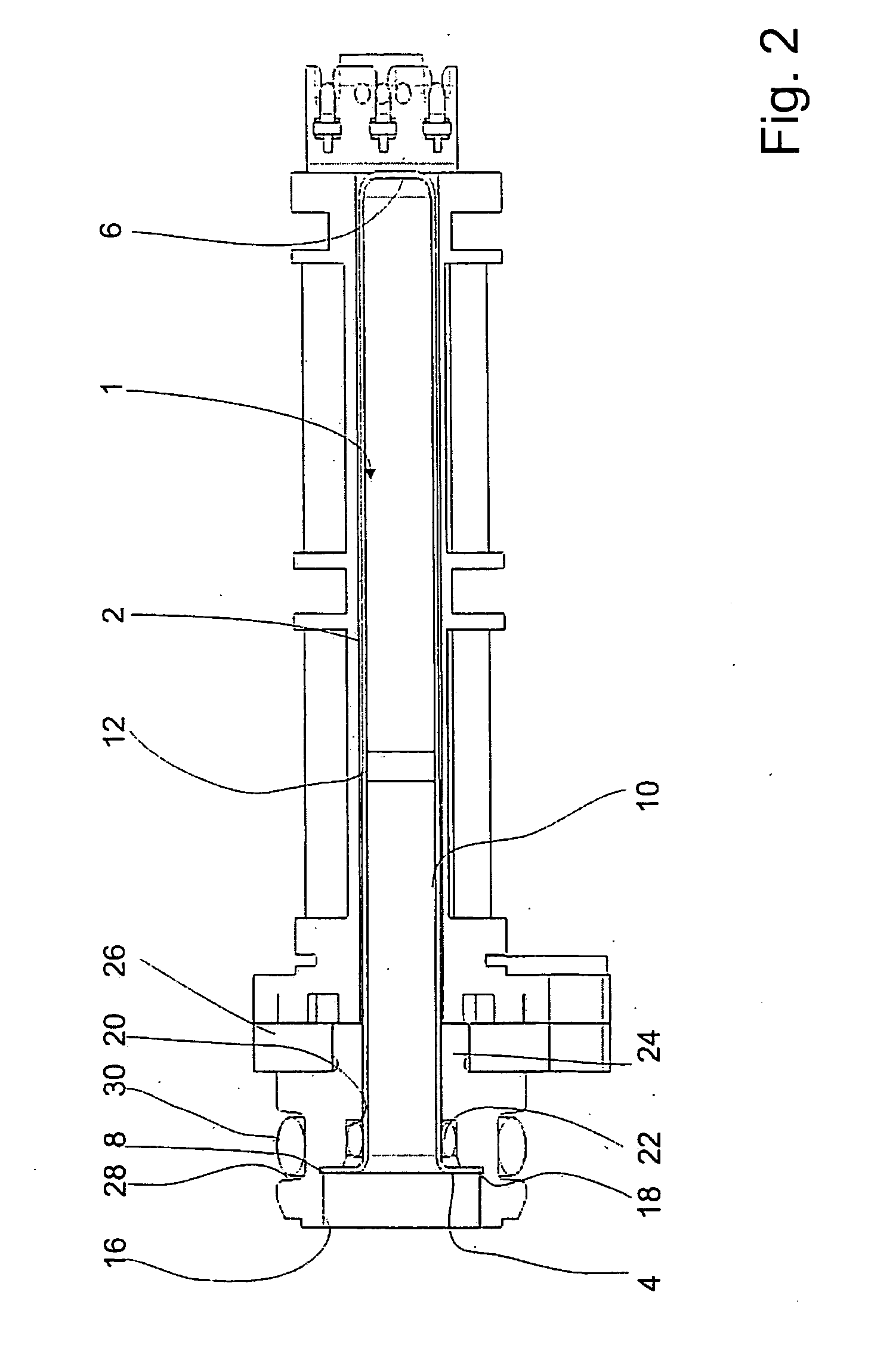

Pressure tube for a position measuring system

InactiveUS20080236272A1Reduce the impactCost-effective manufacturingOperating means/releasing devices for valvesStructural/machines measurementEngineeringDeep drawing

A position measuring system, especially for hydraulic valve, having a pressure tube to accommodate an armature is provided, whereby the pressure tube is manufactured by deep-drawing. As a result, a cost-effective manufacturing process can be employed for the pressure tube. The pressure tube can be firmly attached to a valve housing by means of a holding element and, optionally, an attachment flange.

Owner:ROBERT BOSCH GMBH

Self-locking control device used for starting electromagnetic valve

InactiveCN105041480AAvoid rich flameout failuresRealize self-lockingTurbine/propulsion fuel controlEngineeringSelf locking

A self-locking control device used for starting an electromagnetic valve comprises a fuel pipe connected with a starting nozzle. The fuel pipe is internally provided with the electromagnetic valve. The fuel pipe is connected with an air inlet pipe. A ball valve is arranged in the air inlet pipe. A control circuit, connected with a power source, of the electromagnetic valve is provided with a start button. The air inlet pipe is connected with a pressure pipe through a bypass. The pressure pipe is provided with a pressure switch controlling the on-off state of the control circuit through the pressure of the air inlet pipe. The pressure switch is additionally arranged on the air inlet pipe and used for automatically cutting off the control circuit of the electromagnetic valve through the pressure of the air inlet pipe after an engine is successfully started, and self-locking is achieved; the system cannot be connected when an aviator presses the start button again, the electromagnetic valve is kept in a closed state, the electromagnetic valve cannot spray oil when started, accordingly, the failure of engine rich extinction is avoided, and flying safety is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

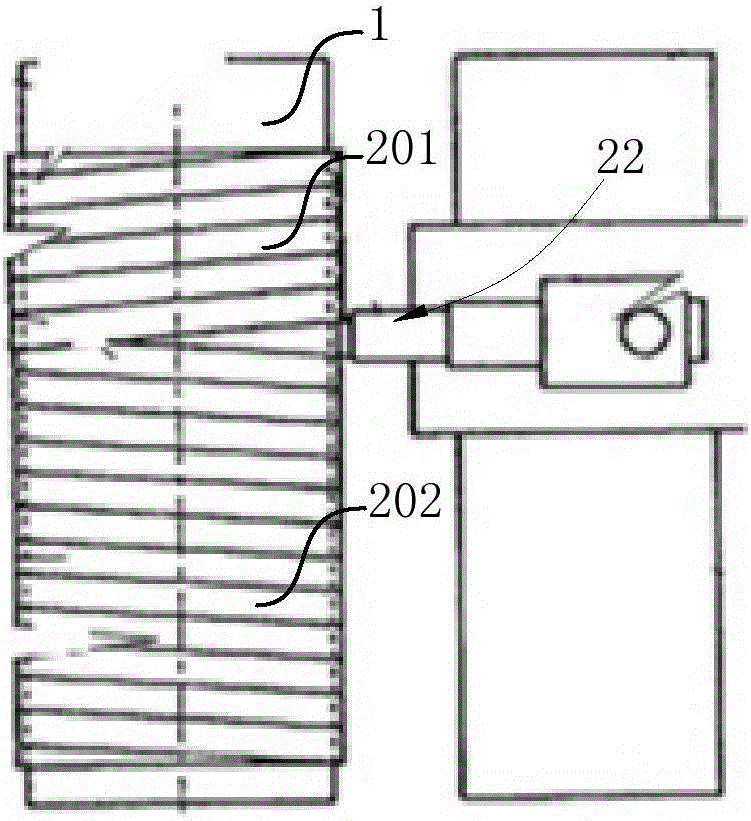

Organ-shaped pinch roller structure and working method thereof

PendingCN108262936AAchieving a press-fit bondEffective bondingTubular articlesProduction lineFilament winding

The invention relates to an organ-shaped pinch roller structure which is used for a continuous fiber winding plastic composite pressure pipe production line and can press and stick plastic layers wound in different fiber face states in the manufacturing and winding process of composite pressure pipes and a working method thereof. The organ-shaped pinch roller structure is composed of pressing sheets, multiple swinging arms, shafts C, springs and shafts B, wherein the pressing sheets are located in grooves of the heads of the swinging arms, the swinging arms provided with the pressing sheets penetrate through the shafts C through shaft holes in sequence and constitute an organ-shaped pinch roller organ face, the shafts C and the shafts B are fixed to a support A, the shafts B are located below the shafts C, one ends of the springs are fixed to the shafts B, and the other ends of the springs and the grooves of the lower portions of the swinging arms are in clamping and elastic pressing cooperation. The organ-shaped pinch roller structure has the advantages that in the manufacturing process of continuous fiber winding plastic composite pressure pipes, organ keys of the organ-shaped pinch roller structure can press and stick the plastic layers whether a fused plastic belt is even or not, and thus the plastic belt and a fiber belt pre-impregnated with resin are fused and effectivelyadhere to each other.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

Average pitot tube type flow meter

InactiveUS9075075B2Easy to installIncrease freedomVolume meteringFluid speed measurementEngineeringMechanical engineering

Owner:DAE HAN INSTR

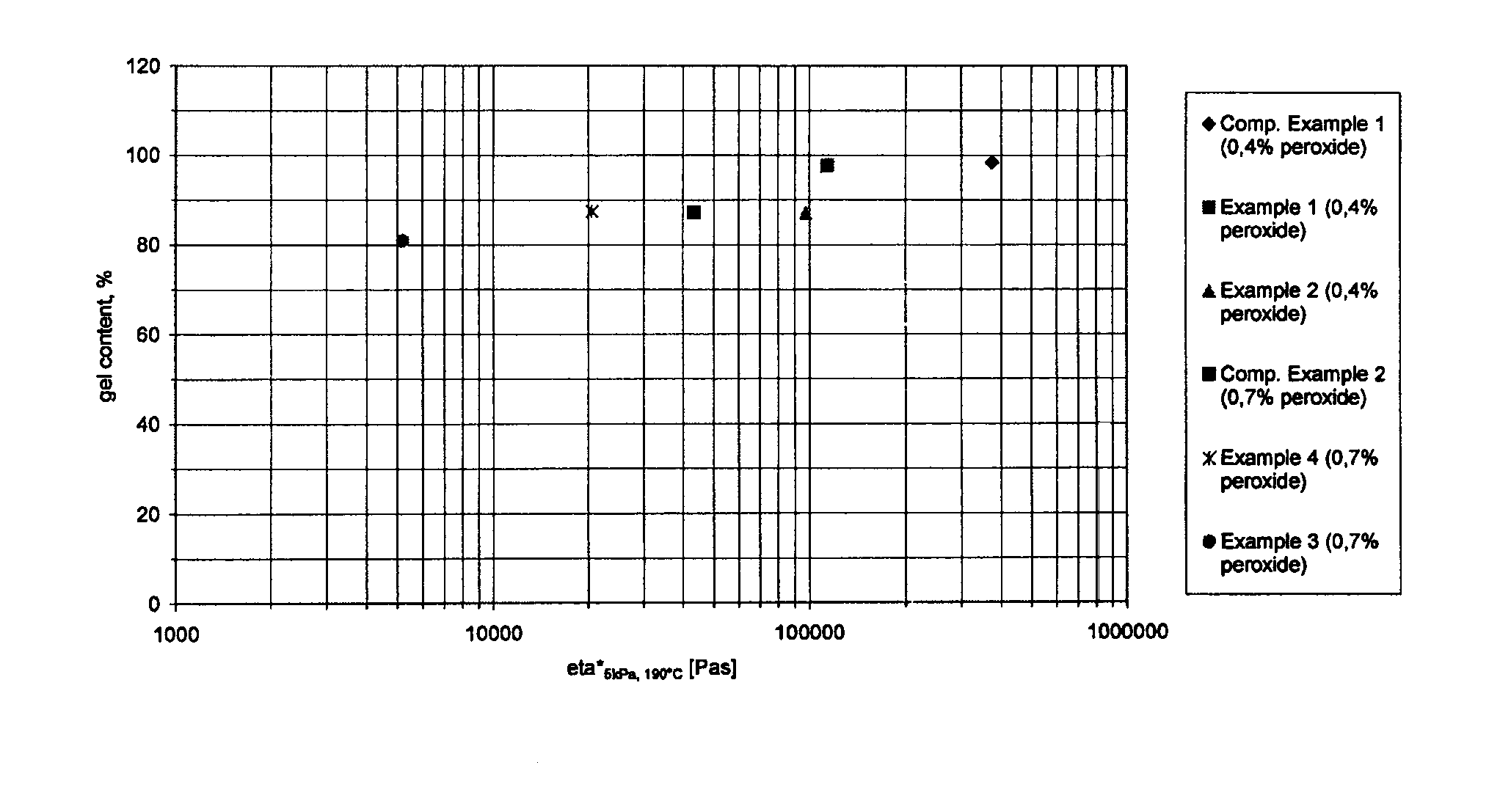

Peroxide crosslinked ethylene polymer pressure pipe and a method for the preparation thereof

ActiveUS8968851B2Low densityLess energyLayered productsCeramic shaping apparatusPolymer scienceEthylene Polymers

A peroxide crosslinked ethylene polymer pressure pipe and a method for the preparation thereof are described. The pipe is characterized in that it comprises an ethylene polymer with a density of less than 950 kg / m3 obtained by polymerization with a single-site catalyst and having a shear thinning index, SHI5 / 300 of less than 20 and a MWD of <10. The method is characterized in that it comprises polymerizing ethylene, optionally together with at least one comonomer, with a single-site catalyst to provide the above defined ethylene polymer, forming the ethylene polymer into a pipe by extrusion and crosslinking it.

Owner:BOREALIS TECH OY

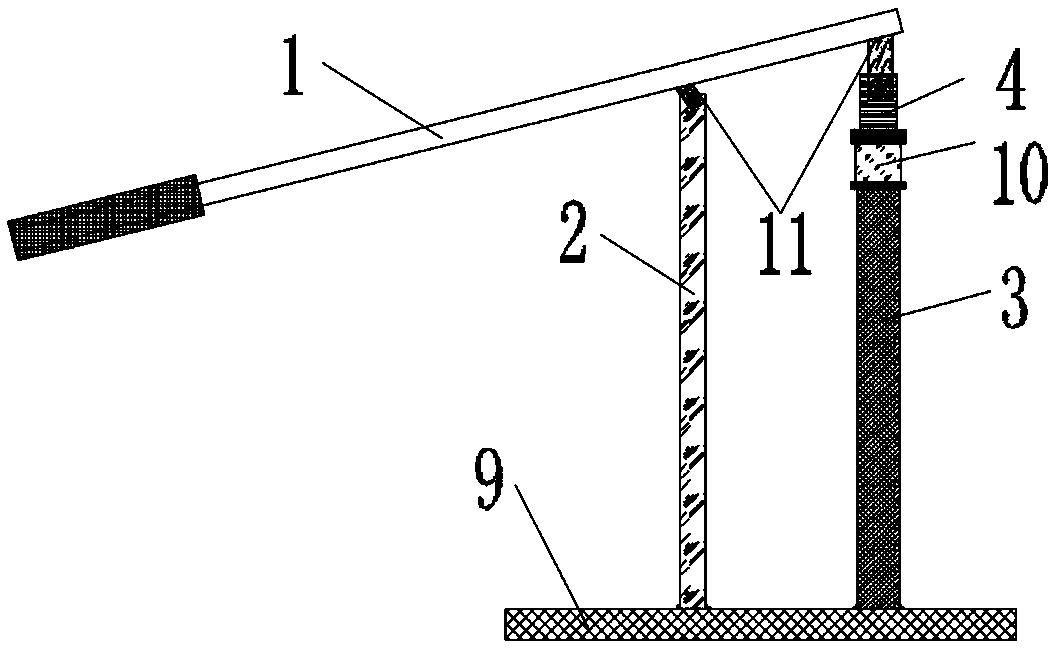

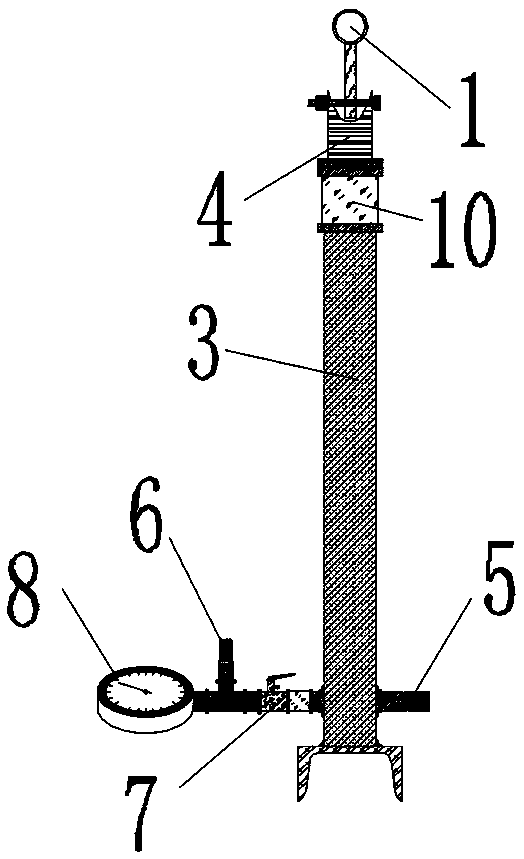

Water injection pressurization device of water pipe of mechanical and electrical installation and production method of water injection pressurization device

PendingCN109387438AReasonable structure sizeEasy to useMaterial strength using tensile/compressive forcesWater pipePiston

The invention discloses a water injection pressurization device of a water pipe of mechanical and electrical installation and a production method of the water injection pressurization device. The water injection pressurization device comprises a base, wherein the base is arranged horizontally; a pressure rod is arranged above the base; a support rod, a pressure pipe and a piston pipe are arrangedbetween the pressure rod and the base; a sealing joint is arranged at the upper end of the pressure pipe; a sealing block sheet is arranged at the bottom end of an inner cavity of the pressure pipe; the piston pipe penetrates through the sealing joint and is arranged in the inner cavity of the pressure pipe; a sealing gasket is arranged at the lower end of the piston pipe; the sealing gasket, thesealing block sheet and the inner cavity of the pressure pipe form an enclosed hydraulic chamber; and a water inlet connector and a water out connector are arranged on a side wall of the lower end ofthe pressure pipe and communicated with the enclosed hydraulic chamber. According to the device, the sealing joint, the sealing gasket and the sealing block sheet form double-layer sealing to increasedwell pressure; and the device is reasonable in structure size, convenient to use and high in pressurization speed and has low possibility of damage.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

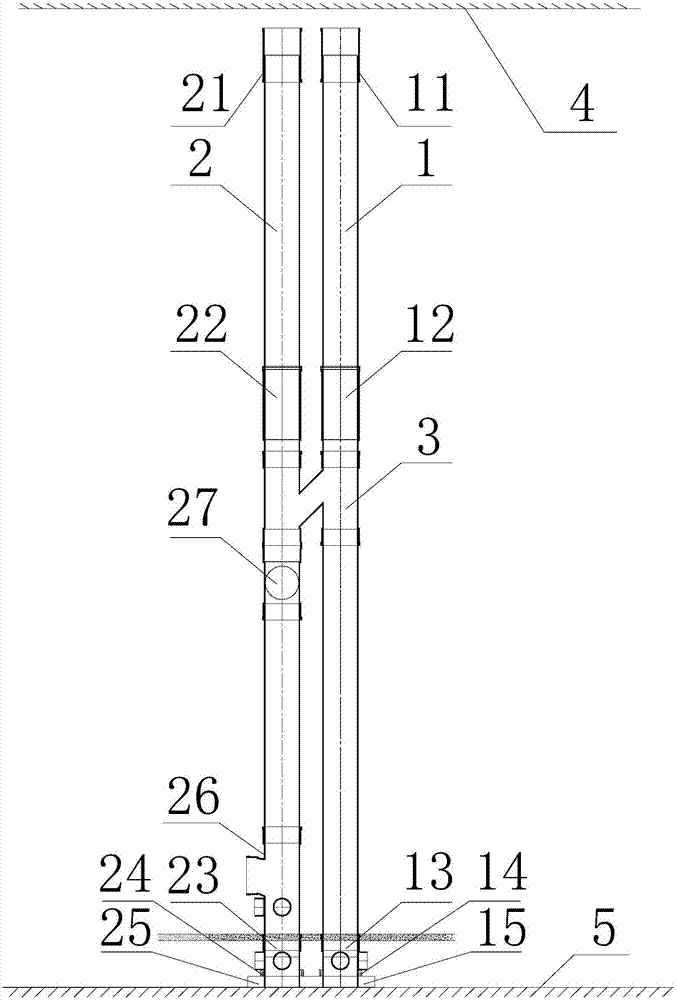

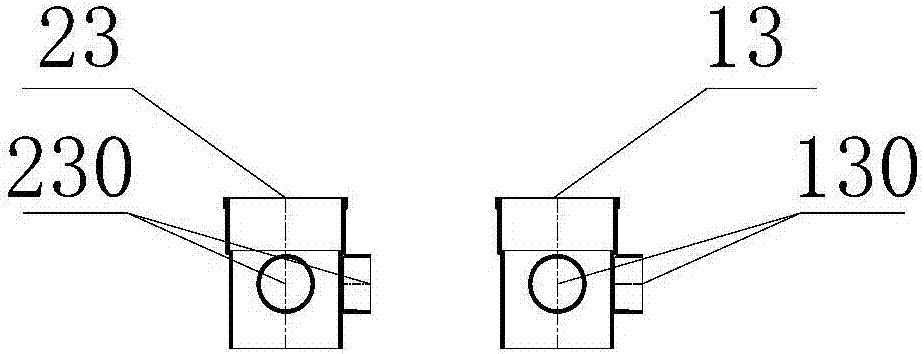

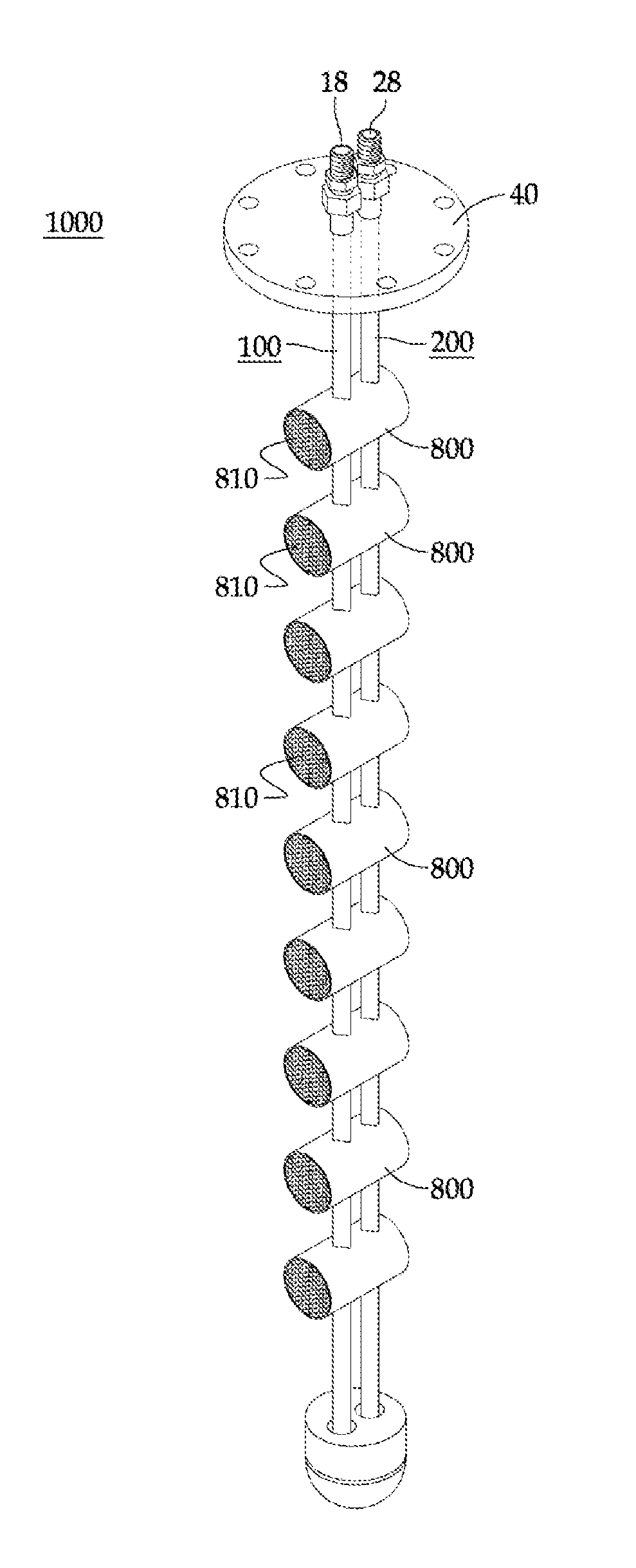

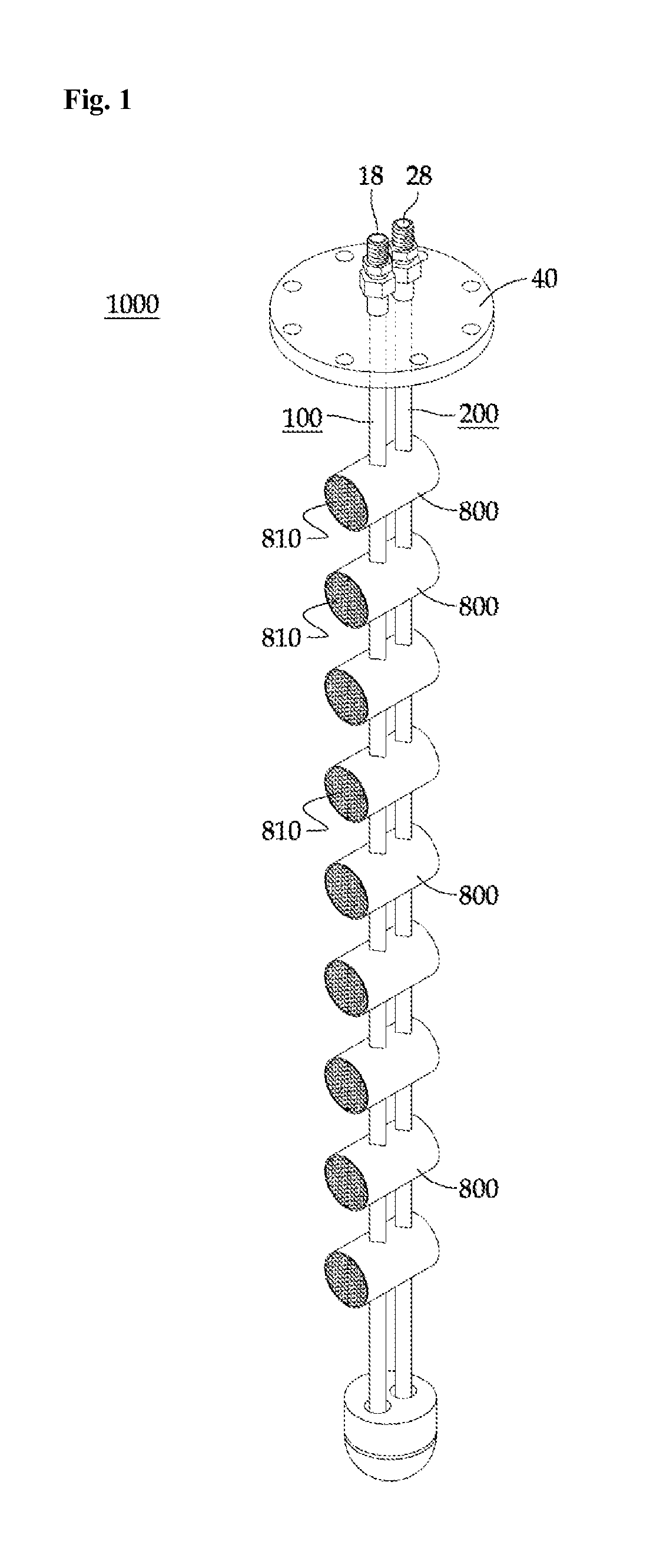

Drainage control system of water well

ActiveCN103016817BAvoid cloggingSimple structureCesspoolsOperating means/releasing devices for valvesVertical tubeControl system

The invention relates to a drainage control system of a water well, which comprises a collector and a drain pipe which is connected with the collector, also comprises an induction tube and an induction valve which is used for converting a pressure signal into an electric water level signal. The induction tube is a vertical tube, the lower end of the induction tube is communicated with the collector, and the upper end is provided with a pressure signal sampling pipe mouth which is used for acquiring the pressure signal; and the pressure signal sampling pipe mouth is connected with a signal input mouth of the induction valve through a pressure pipe. The drainage control system of the water well is applied to the field of drainage control; the current drainage control device has the defects of low safety, low reliability and poorer water level control due to long time use, caused by the self-design problem, on account of the defects of the current drainage control device, the invention develops the drainage control system which has the advantages of a simple structure, sensitivity in high level control, convenience in installation, low requirement on the environment, reliability in operation, and less maintenance workload, basically can meet the requirement of no maintenance, and adapts to all kinds of water wells (collector wells) and similar situations.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com