Hydraulic compression gauge sealing rotation structure

A technology of rotating structure and hydraulic pressure, applied in the field of hydraulic machinery, can solve the problems of easy operation errors, easy damage, and inability for operators to operate, so as to achieve the effect of not easy operation errors and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

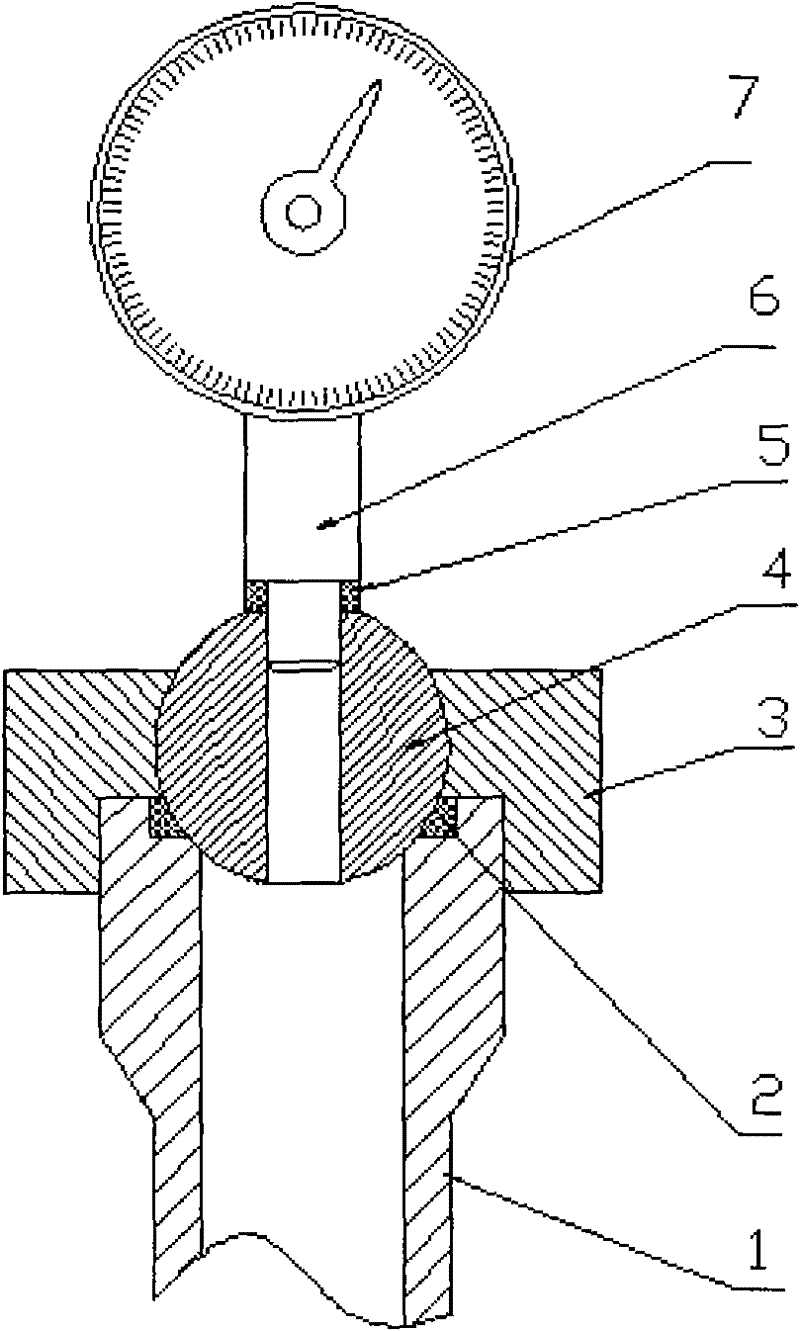

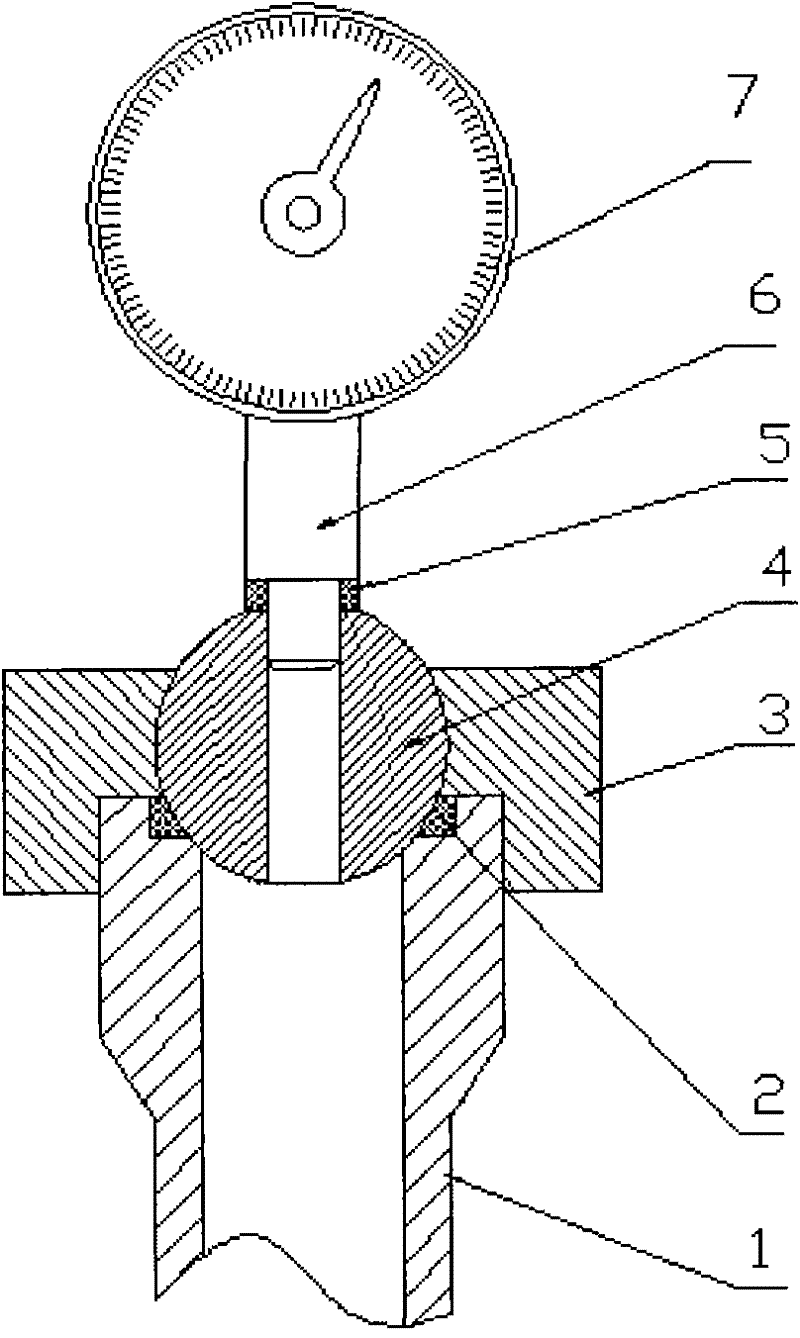

[0009] Install and fix the fixed pipe (1) with the fuselage of the hydraulic machine or the hydraulic station, and place the sealing ring (2) on the upper mouth of the fixed pipe (1) and place the ball joint (4) on the fixed On the upper part of the pipe (1), fix the ball joint (4) on the upper part of the fixed pipe (1) with the connection head (3), and install the ring sealing ring (5) on the joint part of the pressure pipe (6) , and the pressure pipe (6) is connected and fixed with the ball joint (4) by threaded connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com