Connection structure and connection method for non-pressure tubes between modularized upper floor and lower floor

A technology for connecting structures and pressure pipes, applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve the problems of increased engineering volume and maintenance costs, non-compliance with specifications, high civil construction costs, and achieve positioning effect. Good, good fire resistance effect, simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

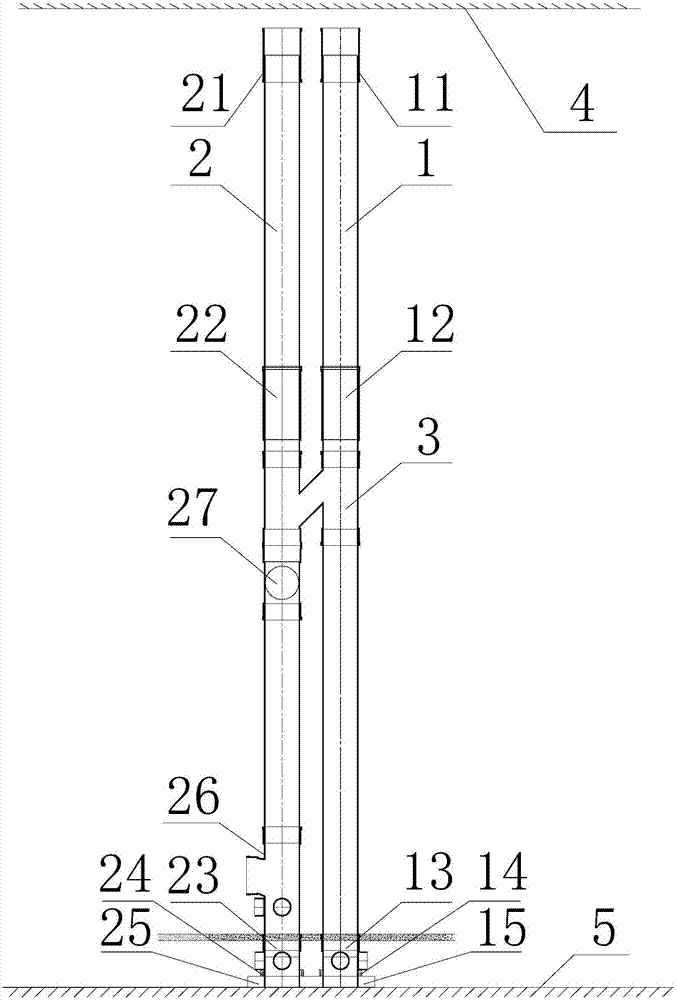

[0049] The connection structure and method between the pressure-free pipes on the upper and lower floors of the modules of the present invention will be further described in detail below in conjunction with specific drawings.

[0050] Such as figure 2As shown, it is a connection structure between the pressure-free pipes on the upper and lower floors of the modules of the present invention, including the ventilation riser 1 and the drainage riser 2 arranged between the upper module 4 and the lower module 5, the ventilation riser 1 An H pipe 3 is connected between the drainage riser 2, the drainage riser 2 is provided with a vertical inspection port 27, the top of the ventilation riser 1 is provided with a first direct pipe fitting 11, and the middle and upper part is provided with a first telescopic Section 12, the lower part is provided with the first four-way embedded part 13, the first four-way embedded part 13 is covered with a first fire arresting ring 14, and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com