Organ-shaped pinch roller structure and working method thereof

A technology of organ type and pressing wheel, which is applied in the field of organ type pressing wheel structure for continuous fiber winding plastic composite pressure pipe production line, which can solve the problems of plastic pipe collapse, production failure, and plastic inability to melt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

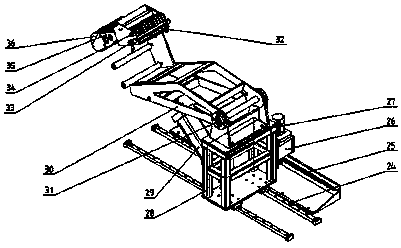

[0013] Embodiment 1: with reference to attached Figure 1-5 . An organ-type pressure wheel structure, consisting of a pressing piece 36, a swing arm 35, a shaft 34, a spring 32, and a shaft B33; the pressing piece 36 is located in the groove of the head of the swing arm 35, and multiple sets of pressing pieces are installed The shaft hole of the swing arm 35 of 36 is passed through the shaft 34 in turn to form an organ-type pressure wheel piano surface, the shaft 34 and the shaft 33 are fixed on the bracket A and the shaft B33 is located below the shaft 34, and one end of the spring 32 is fixed on the shaft B33 , the other end of the spring 32 is snap-fitted with the groove at the bottom of the swing arm 35 .

[0014] 2. The organ-type pressure wheel structure according to claim 1, characterized in that: the front part of the swing arm 35 is a notched annular groove, and a pressing piece 36 is installed in the annular groove, and the middle of the bottom of the swing arm 35 i...

Embodiment 2

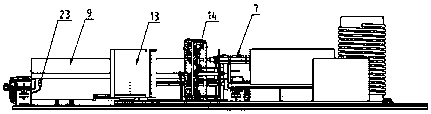

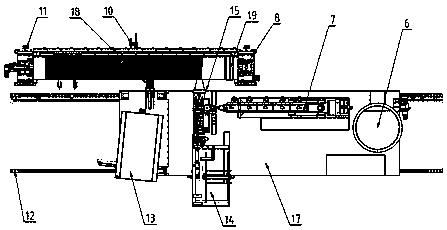

[0015] Embodiment 2: On the basis of embodiment 1, a kind of working method of organ-type pressing wheel structure, extruder 7 squeezes out the plastic melted when producing composite pipe and reaches plate mold 15 through runner, and discharges through plate mold 15 The melted plastic tape 22 is spirally wound on the surface of the heated mold 9, and the pressure roller 21 lifts up the plastic tape 22 and rolls the plastic wound on the mold 9. The inner wall and outer wall of the formed pipe are required to be smooth. The servo motor 27 drives the speed reducer 26 to drive the rack and pinion 25 to move the bottom frame 28 on the linear guide rail 24 to move back and forth, wrap the plastic belt 22 on the steel drum mold 9 and at the same time press the wheel 21 to move to the bottom surface of the steel drum mold 9, Cylinder 29 begins to rise, and movable frame 30 is rotated around axle A31, and pressing piece 36 is close to the plastic band 22 of steel drum mold 9 surface pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com