Pressure tube for a position measuring system

a technology of pressure tube and position measuring system, which is applied in the direction of instruments, operating means/releasing devices of valves, other domestic objects, etc., can solve the problems of laborious and expensive production of pressure tube according to the state of the art, and achieve the effect of cost-effective manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

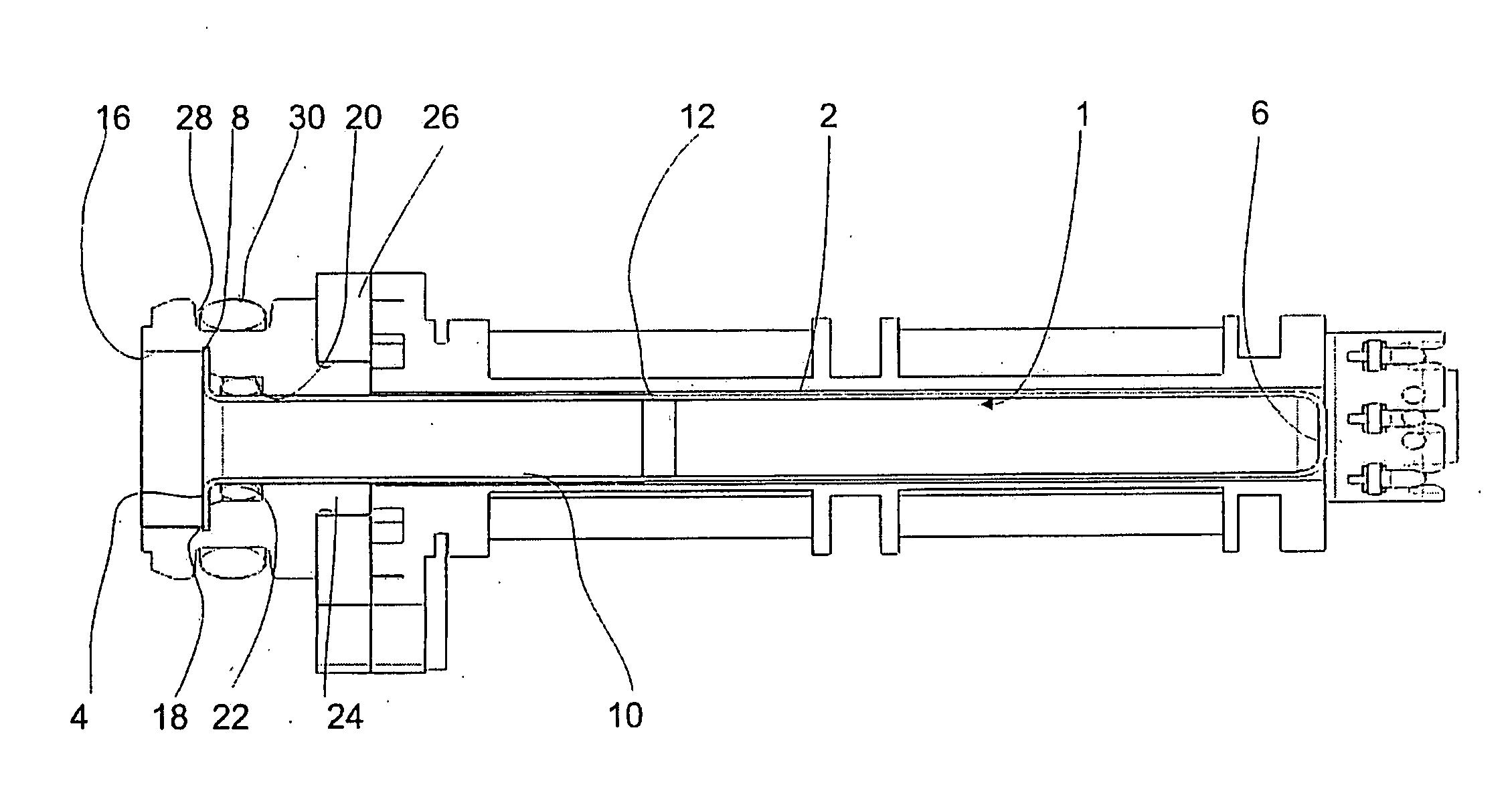

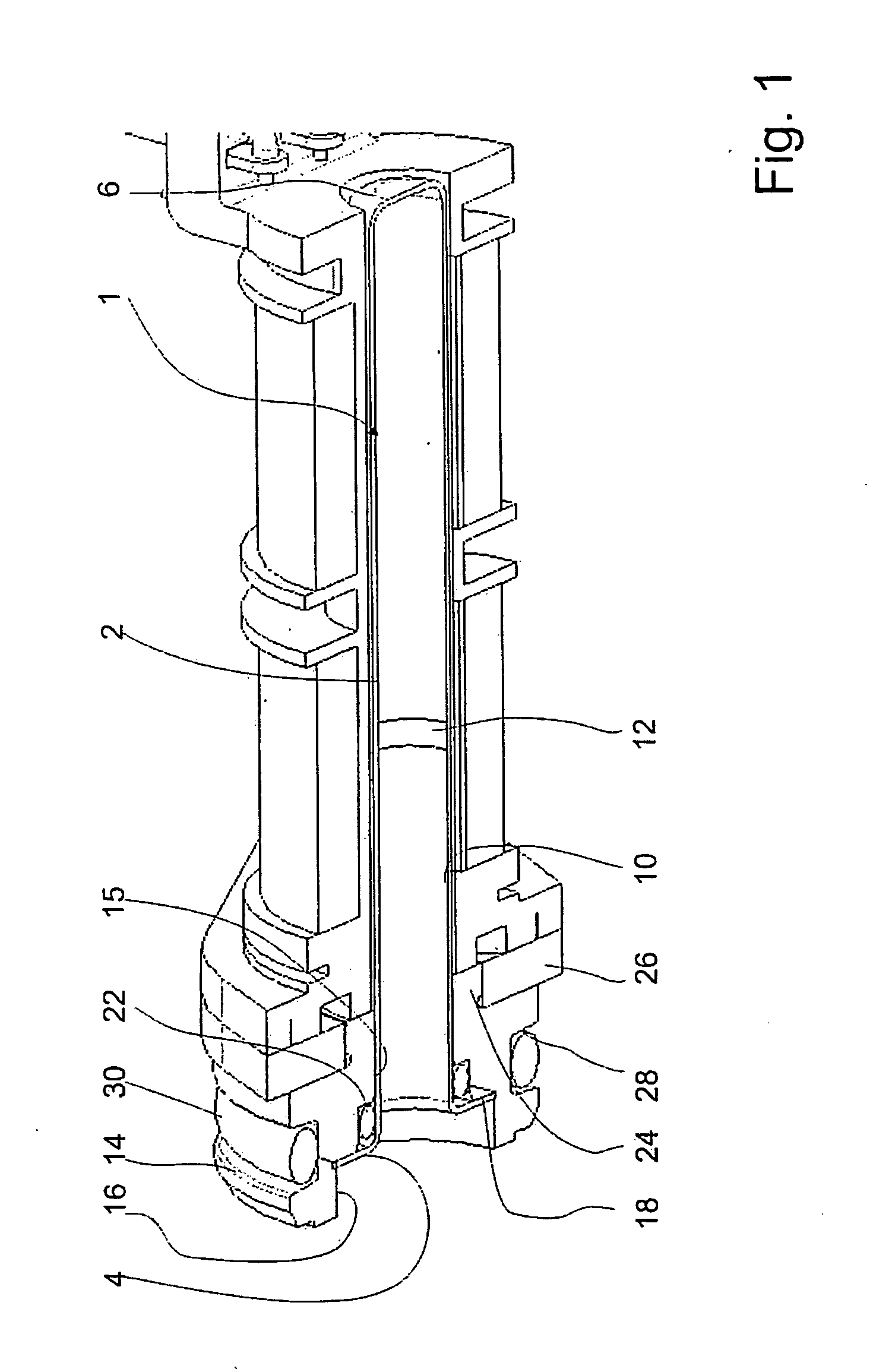

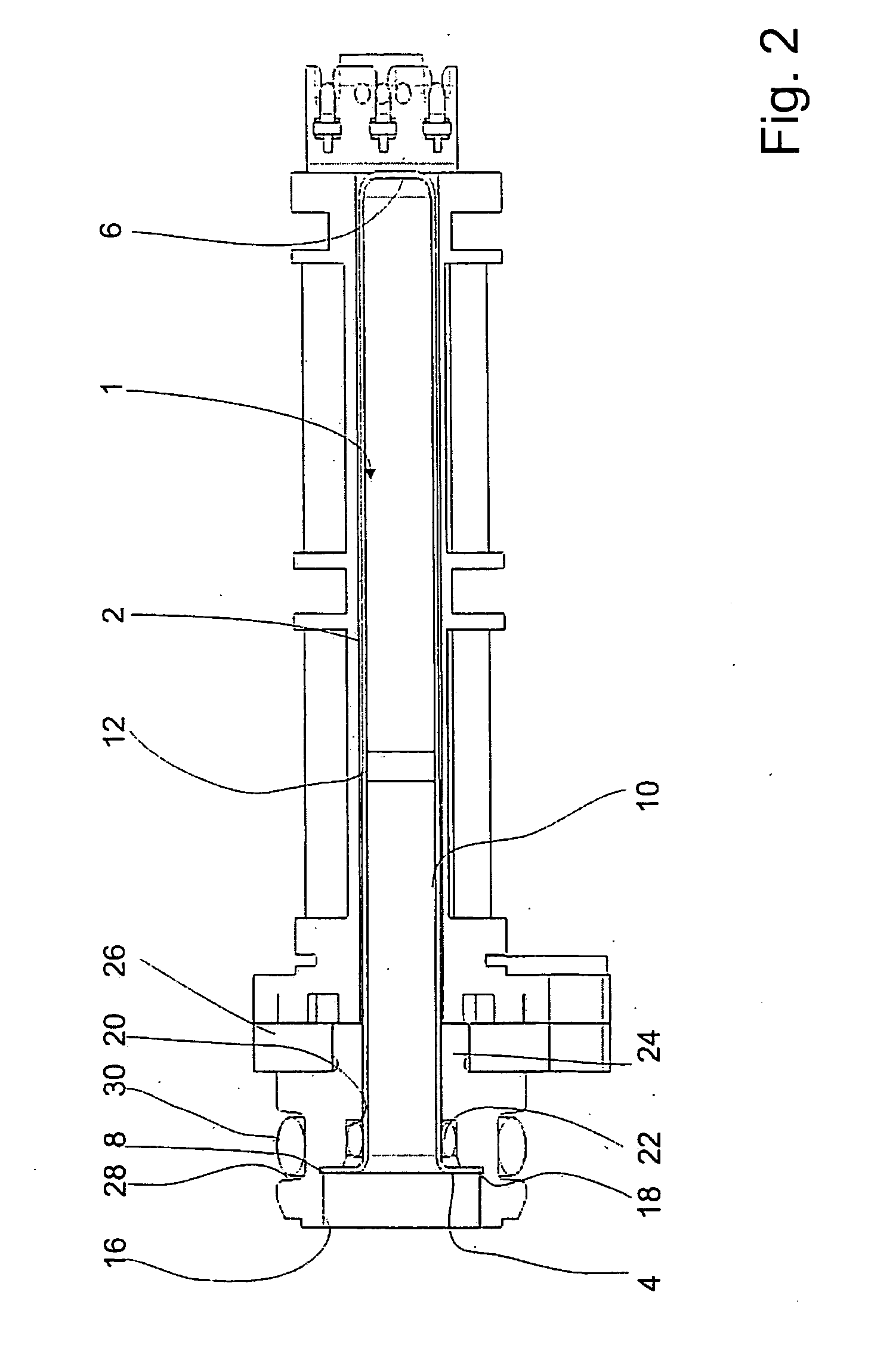

Image

Examples

first embodiment

[0035]As an alternative to the first embodiment described above, the attachment flange 26 can be dispensed with if the attachment piece 14 is provided with a thread that can be screwed into the valve housing.

[0036]With the first embodiment and its variant, a cost-effective manufacturing process can be used for the pressure tube, even for pressures in the order of magnitude of several 100 bar, a process in which inexpensive O-rings are used to create a seal.

second embodiment

[0037]FIG. 3 shows a pressure tube 101 corresponding to the second embodiment and FIG. 4 depicts the pressure tube with a holding element and a sealing ring.

[0038]The pressure tube 101 of the second embodiment, like the pressure tube 1 of the first embodiment, has a face section 106 and a tube section 102. The tube section 102 of the second embodiment has a constant diameter along its entire length in the axial direction, as a result of which it does not exhibit any conical widening. The flange section 103 is configured symmetrically with respect to an axis X that runs through the mid-axis of the tube section 102 and it has two attachment cutouts 108a, 108b.

[0039]As an alternative to this, a conical widening corresponding to that of the first embodiment can be configured in the tube section 102. This conical widening then serves only to facilitate the manufacturing process employing the deep-drawing method.

[0040]As shown in FIG. 4, an essentially annular holding element 114 can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com