Hydraulic screwup control device and method of skin-pass mill

A technology of control device and hydraulic control valve, which is applied in the direction of fluid pressure actuation device, contour control, mechanical equipment, etc., can solve the problems of energy waste in pumping station, complicated design of hydraulic pressure control device, and high system design cost, so as to reduce the Spare parts consumption and the effect of reducing work energy consumption and simplifying design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

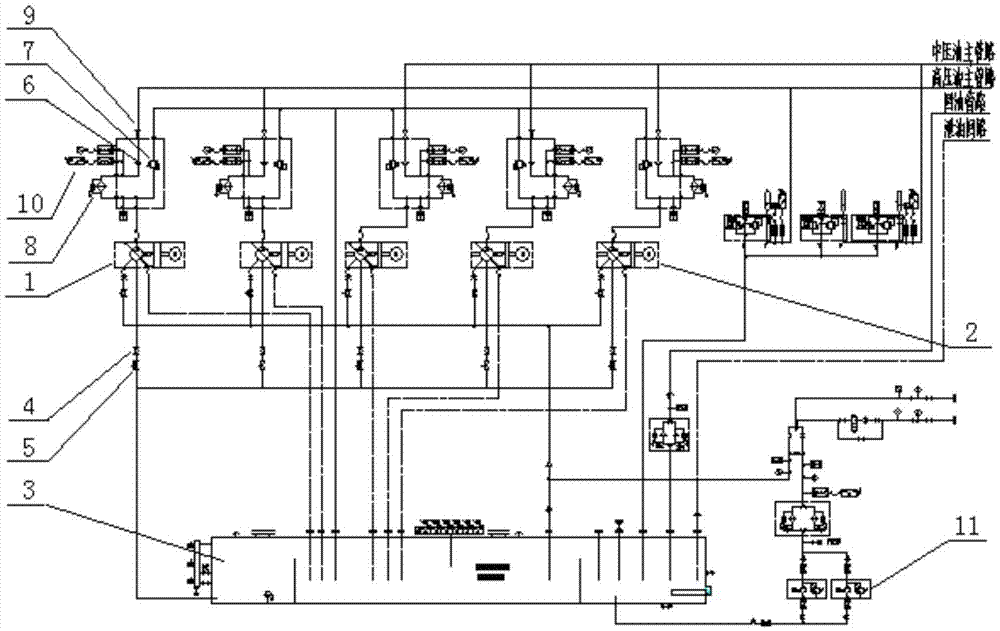

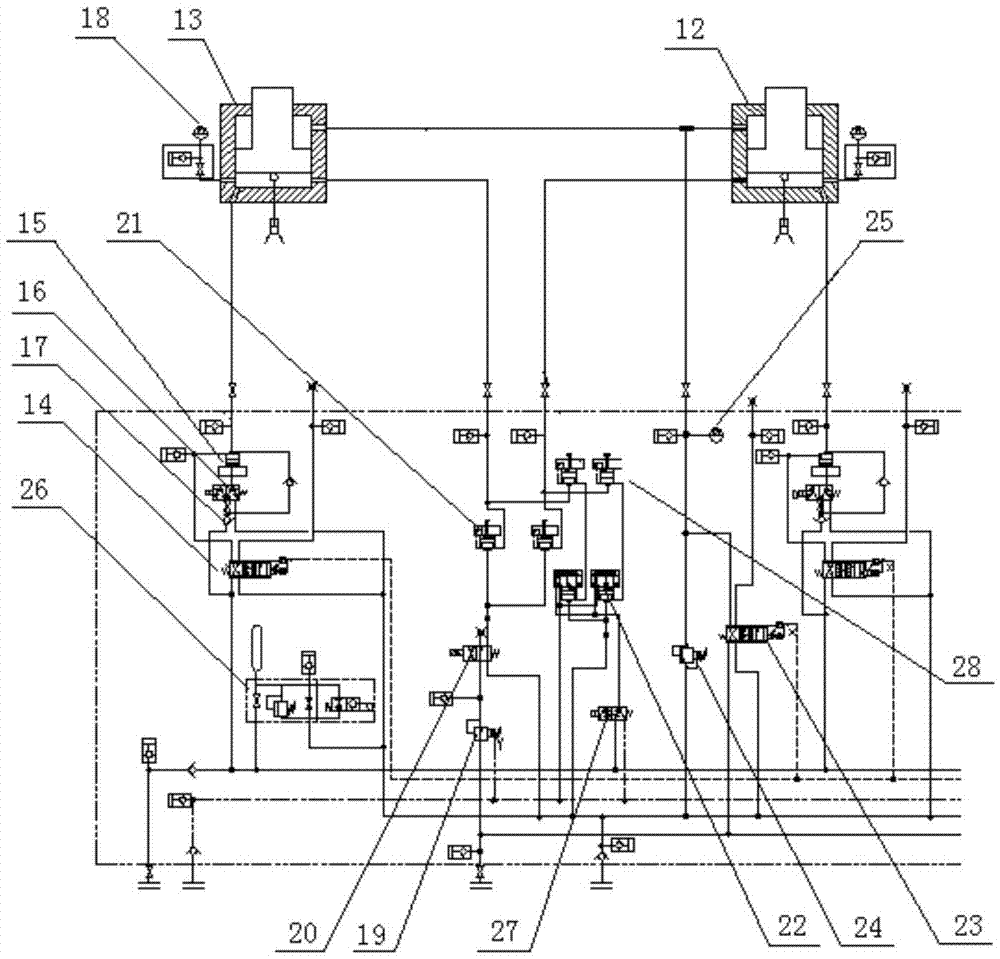

[0020] The hydraulic press-up control device of the skin pass machine of the present invention is composed of a hydraulic pump station and a hydraulic control valve table.

[0021] The hydraulic pump station is equipped with 2 high-pressure pumps 1, 3 medium-pressure pumps 2 and an oil tank 3. The 2 high-pressure pumps 1 are connected in parallel. Master Road. The three medium-pressure pumps 2 are connected in parallel, the medium-pressure pump 2 is connected with the small valve block of the outlet by rubber hose, and the small valve block is connected to the main medium-pressure oil pipeline through a stainless steel high-pressure steel pipe. The inlet side of the high-pressure pump 1 and the medium-pressure pump 2 are equipped with stop valve Ⅰ4 and damping throat 5, and the shut-off valve Ⅰ4 and damping throat 5 are connected in series on the suction pipeline; the outlet sides of high-pressure pump 1 and medium-pressure pump 2 are equipped with single Directional valve I6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com