Compact multi-level output hybrid gas generator

A technology of gas generators and gas generating parts, which is applied in transportation and packaging, vehicle parts, pedestrian/passenger safety arrangements, etc., and can solve problems such as complex devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

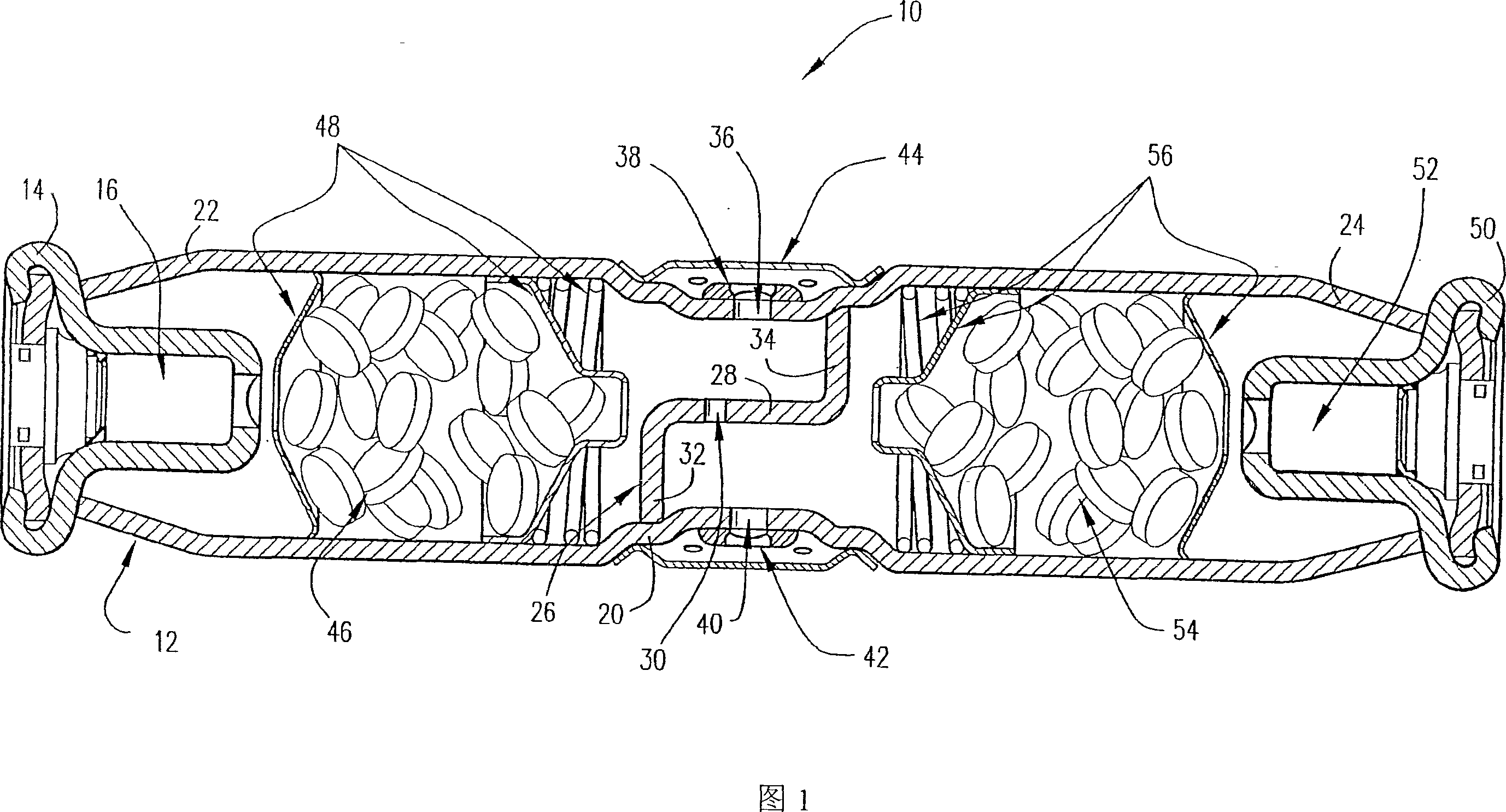

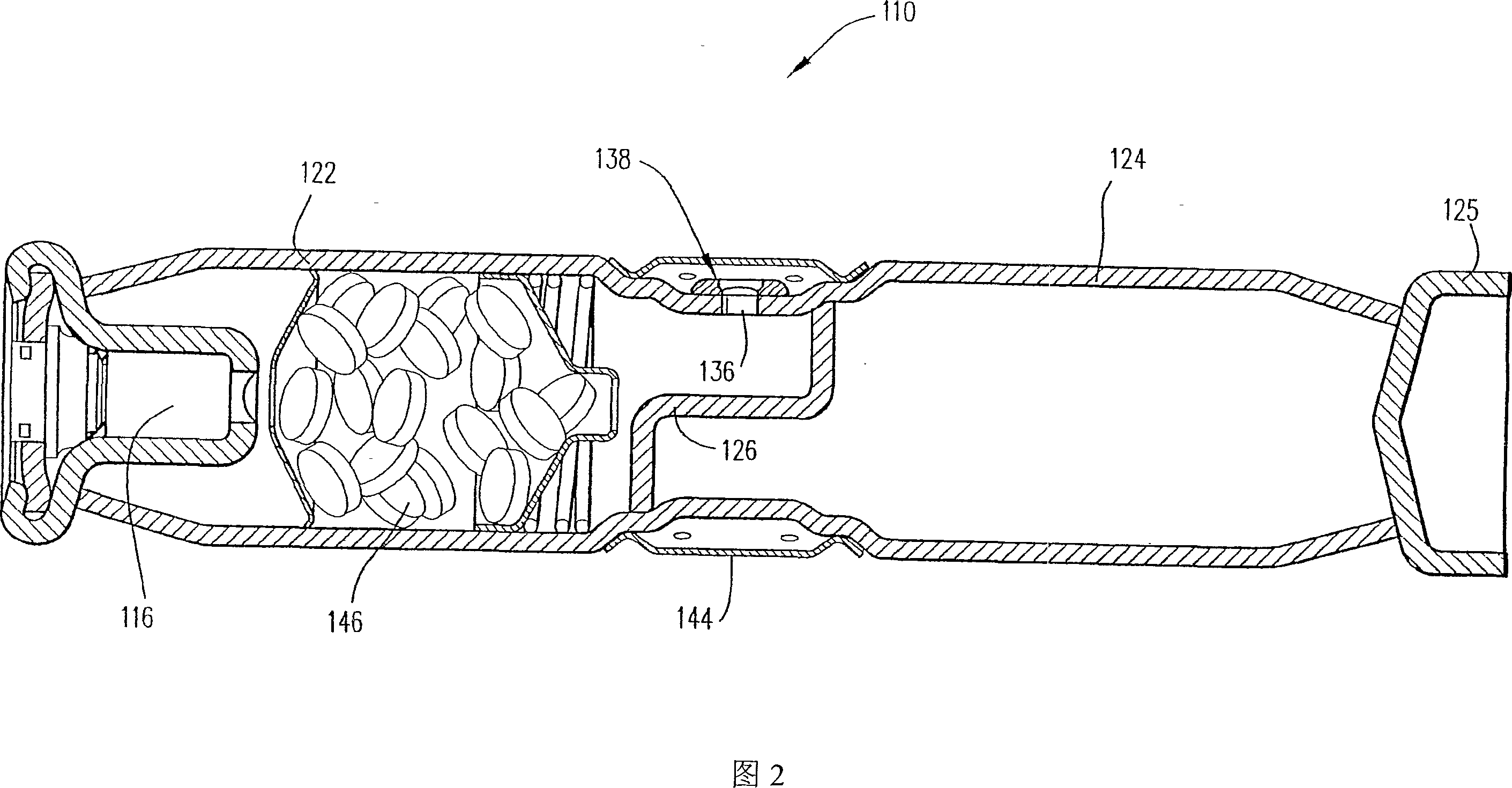

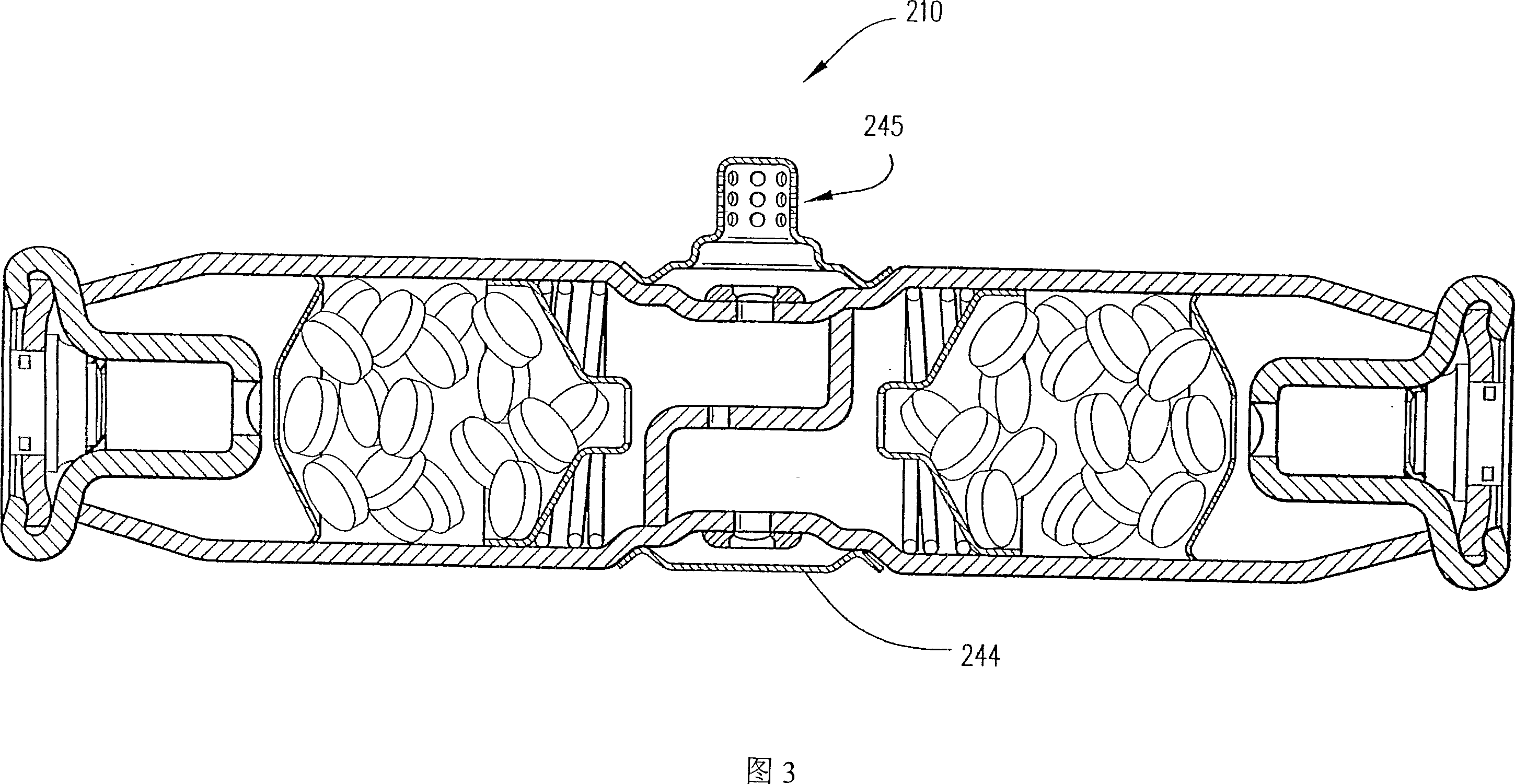

[0032] Figure 1 illustrates a multi-stage output inflator or gas generator 10 according to one embodiment of the present invention. The inflator 10 includes an elongated pressure vessel 12 made of any suitable material, such as steel, aluminum or other material. An igniter body 14 of any suitable material, such as steel, aluminum or other material, is secured to the pressure by any suitable means, such as crimping or friction welding. One end of the tube 12. The ignition body 14 supports a primary ignition device 16 of any suitable construction. The main ignition device 16 can be an initiator or a microgas generator.

[0033]The pressure tube 12 is preferably formed with an indented portion 20 of any suitable configuration near its center. The concave portion 20 is used to form a primary gas generating portion 22 between the primary ignition device 16 of the pressure tube 12 and the concave portion 20 , and the concave portion 20 is opposite to the pressure tube 12 A secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com