On-board engine using compressed air as power

A compressed air and engine technology, applied to engine components, variable displacement engines, machines/engines, etc., can solve problems such as short cruising range, damage to human living environment, complicated engine structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

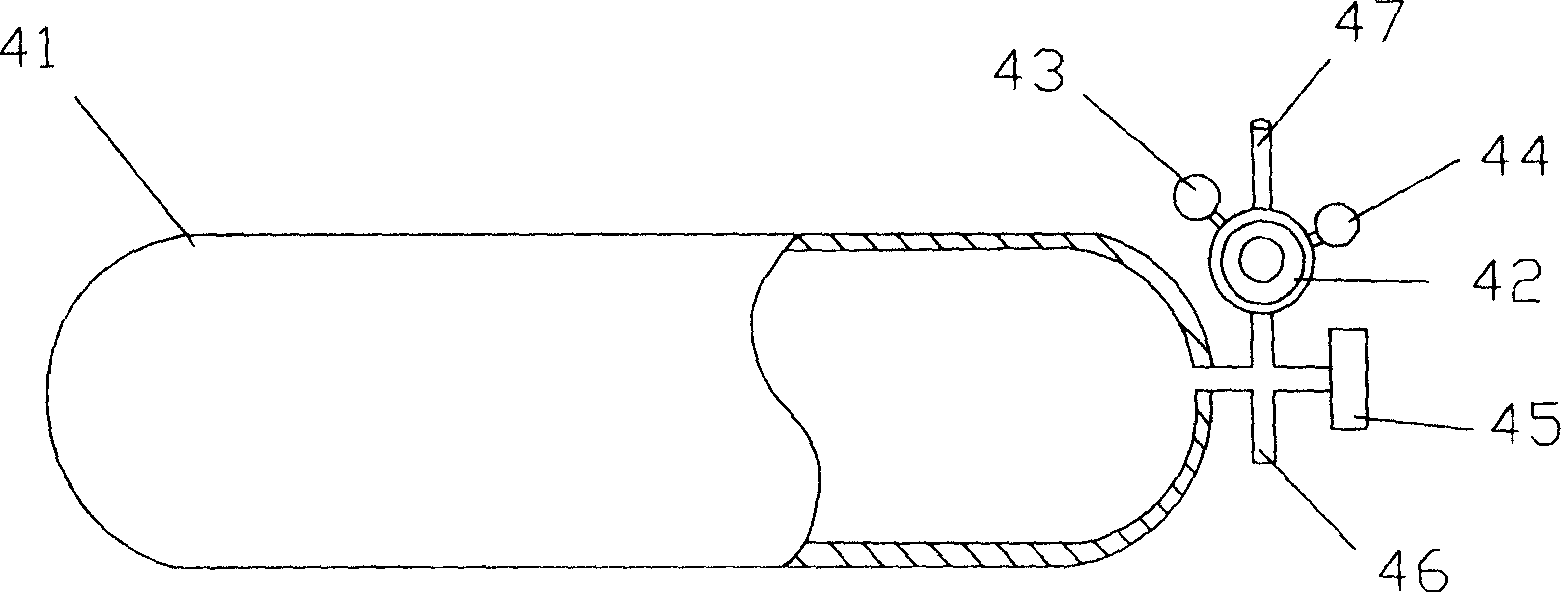

[0022] Such as figure 1 Shown is a structural schematic diagram of the energy cylinder and the pressure regulating system of the present invention. Wherein there is an energy cylinder 41, which is a cylindrical or cuboid high-pressure container made of carbon fiber. Adjust the decompressed system pressure according to the conditions (engine speed and load). 43 among the figure is the high pressure side pressure gauge. According to its reading, the residual pressure in the energy cylinder can be known. 44 among the figure is the pressure gauge after decompression. The pressure in the system after decompression can be known according to the reading. 45 in the figure is a manual open valve, which is used to artificially open the working valve that the energy cylinder communicates with the outside. 46 among the figure is the output gas pipe joint, is used for connecting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com