Efficient foaming machine

A foaming machine, high-efficiency technology, applied in food forming, food science, application, etc., can solve the problems of slow foaming, low foaming rate, long foaming time, etc., to achieve sufficient foaming and high foaming efficiency , The effect of short foaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme and structure of the present invention are described below in conjunction with the accompanying drawings, so that those skilled in the art can understand.

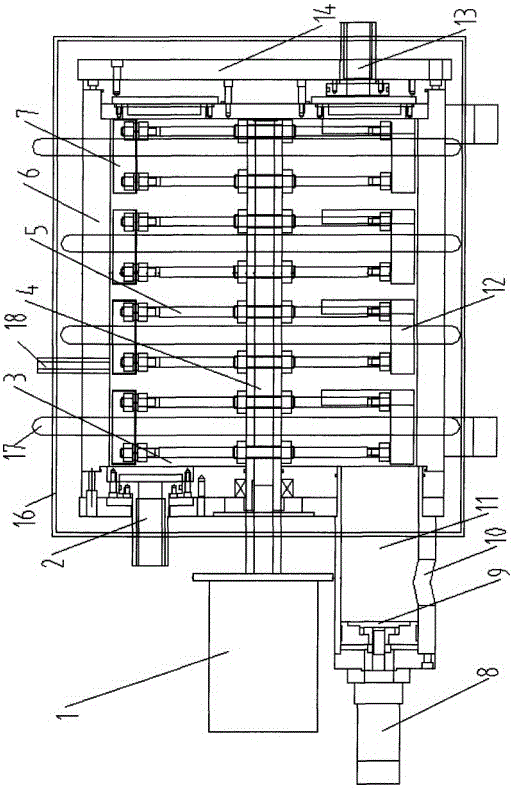

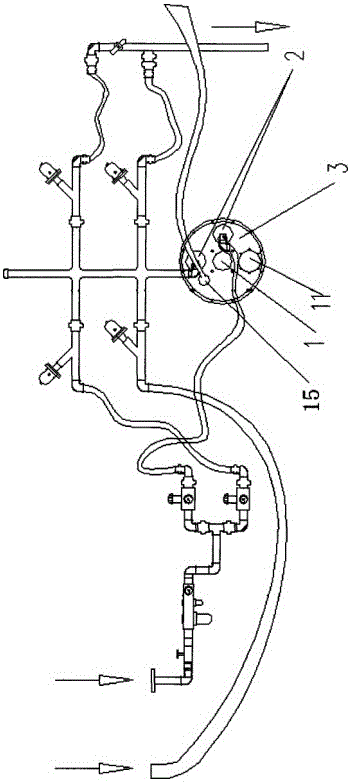

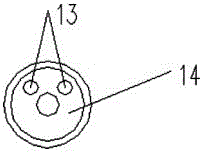

[0020] As shown in Figure 1, Figure 2 and Figure 3, a high-efficiency foaming machine includes a columnar body 6, and the axis of the body 6 is parallel to the ground, and the two ends of the body 6 are respectively provided with a front end cover 14 and a rear end cover 3 so that A sealed space is formed inside the body 6. A main shaft 4 is arranged on the inner axis of the body 6, and a rotating rod 5 is arranged on the main shaft 4. The number of rotating rods 5 is not less than two, and one end of two adjacent rotating rods 5 is in the same direction. Rotary blade one 7 is connected, the other end is connected with rotary blade two 12, stirring motor 1 is fixed on rear end cover 3, the output shaft of stirring motor 1 is connected with main shaft 4, the lower position of stirring motor 1 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com