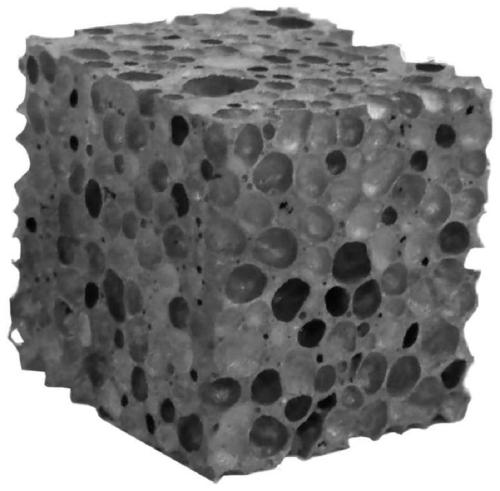

A kind of preparation method of closed-cell cnts/al-si composite foam material

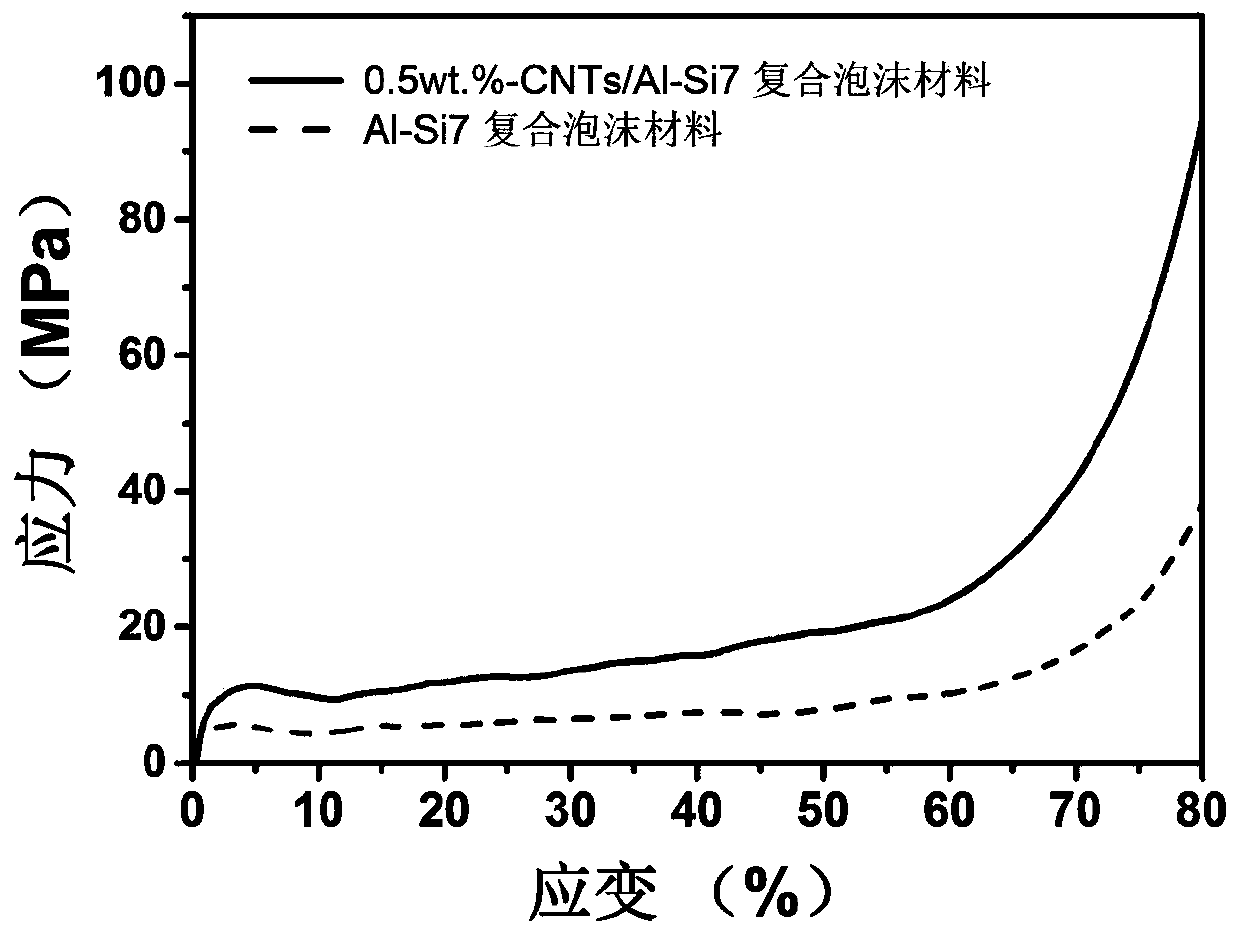

A composite foam and closed-cell technology, applied in the field of foam materials, can solve problems such as low efficiency and long process time, and achieve the effects of simple and stable preparation process, low strain rate sensitivity effect, and consistent size and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A closed-cell CNTs / Al-Si composite foam material prepared from the following raw materials: 7wt% silicon powder, 1.5wt% TiH 2 powder, and the rest is CNTs / Al powder obtained by in-situ chemical vapor deposition. Among them, the particle size of silicon powder is 40-200 mesh, TiH 2 The particle size of the powder is 325-400 mesh, and the particle size of the CNTs / Al powder obtained by in-situ chemical vapor deposition is 100-250 mesh.

[0032] The preparation method of the closed-cell CNTs / Al-Si composite foam material in this embodiment includes the following steps: (1) The CNTs / Al powder obtained by in-situ chemical vapor deposition is subjected to mechanical ball milling, the ball milling speed is 400rpm, and the time is 90min. Material ratio is 10:1; (2) TiH 2 The foaming agent was pre-oxidized at 450°C for 90 minutes, and then the CNTs / Al powder obtained after ball milling in step (1) was mixed with silicon powder, magnesium powder, and foaming agent in a mixer fo...

Embodiment 2

[0036] A closed-cell CNTs / Al-Si composite foam material prepared from the following raw materials: 5wt% silicon powder, 0.5wt% magnesium powder, 0.15wt% TiH 2 powder, and the rest is CNTs / Al powder obtained by in-situ chemical vapor deposition. Among them, the particle size of silicon powder is 40-200 mesh, the particle size of magnesium powder is 40-200 mesh, TiH 2 The particle size of the powder is 325-400 mesh, and the particle size of the CNTs / Al powder obtained by in-situ chemical vapor deposition is 100-250 mesh.

[0037] The preparation method of the closed-cell CNTs / Al-Si composite foam material in this example includes the following steps: (1) The CNTs / Al powder obtained by in-situ chemical vapor deposition is subjected to mechanical ball milling, the ball milling speed is 300rpm, and the time is 30min. Material ratio is 5:1; (2) TiH 2 The foaming agent was pre-oxidized at 400°C for 60 minutes, and then the CNTs / Al powder obtained after ball milling in step (1) was ...

Embodiment 3

[0040] A closed-cell CNTs / Al-Si composite foam material prepared from the following raw materials: 25wt% silicon powder, 5wt% magnesium powder, 0.75wt% TiH 2 powder, and the rest is CNTs / Al powder obtained by in-situ chemical vapor deposition. Among them, the particle size of silicon powder is 40-200 mesh, the particle size of magnesium powder is 40-200 mesh, TiH 2 The particle size of the powder is 325-400 mesh, and the particle size of the CNTs / Al powder obtained by in-situ chemical vapor deposition is 100-250 mesh.

[0041] The preparation method of the closed-cell CNTs / Al-Si composite foam material in this embodiment includes the following steps: (1) The CNTs / Al powder obtained by in-situ chemical vapor deposition is subjected to mechanical ball milling, the ball milling speed is 500rpm, and the time is 120min. The material ratio is 15:1; (2) TiH 2 The foaming agent was pre-oxidized at 500°C for 120 minutes, and then the CNTs / Al powder obtained after ball milling in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com