Preparation method for synthesizing carbon nanotube reinforced foam aluminum composite material based on rapid foaming method

A technology of aluminum composite materials and reinforced foam, which is applied in metal processing equipment, transportation and packaging, etc., to achieve the effect of simple process, high production efficiency and controllable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

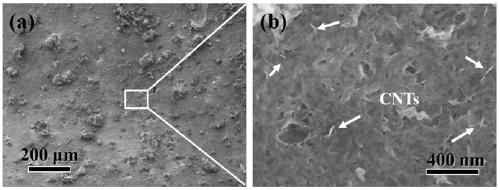

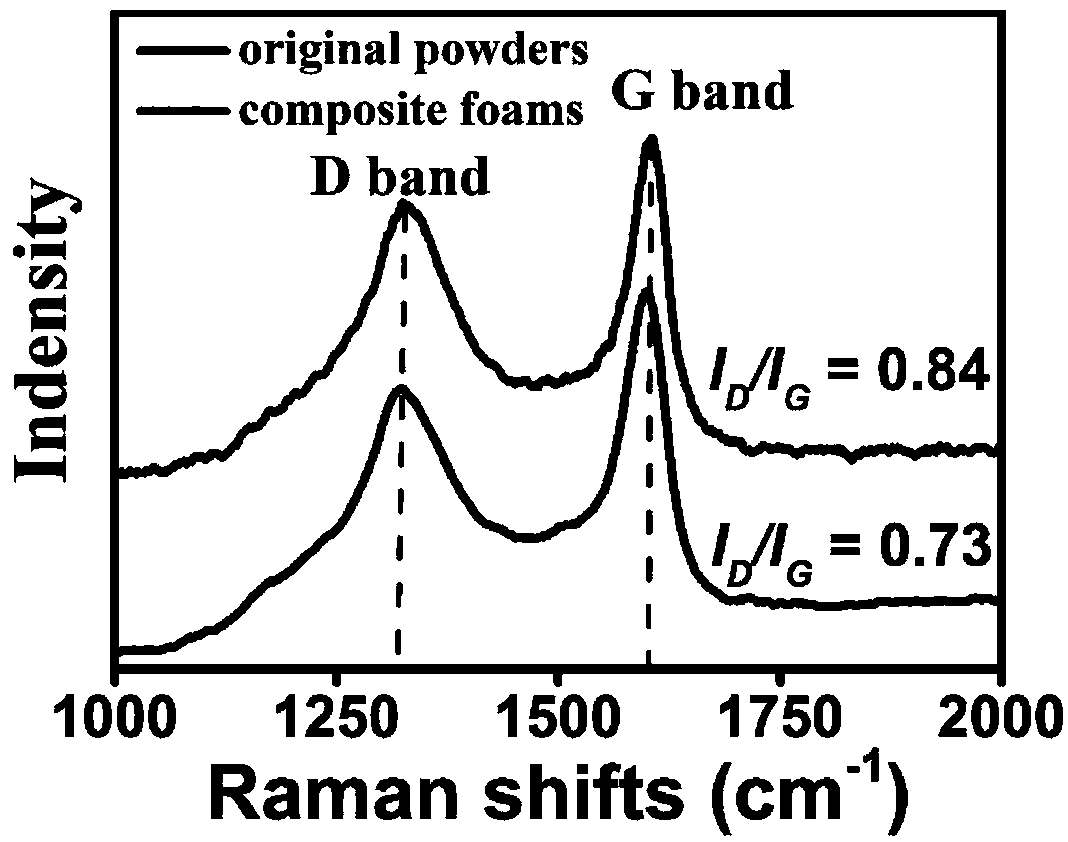

[0021] 2) Preparation of CNT / Al composite powder: put 10-30g of precursor powder into a corundum ark placed in a tube furnace, heat it to 250°C under an argon (120-400ml / min) atmosphere, and then heat it under hydrogen (150ml / min) -250ml / min) atmosphere heated to 450°C, reduced for 2-4h, then heated to 600°C under argon for 10-120min of chemical vapor deposition, the atmosphere conditions are acetylene and argon (10-30ml / min, 150 -250ml / min), obtain CNT / Al composite powder;

[0022] 3) Preparation of foaming precursor: mix the CNT / Al composite powder obtained above with 7wt.% Si powder and 0.3wt.% TiH 2 Mix the powder in a three-dimensional mixer for 0.5-3 hours to obtain a uniform mixed powder, then weigh 24g of powder and use a cold press to hold the pressure at 450MPa for 5 minutes to obtain Φ38×8mm 3 The foamed precursor of the cylinder;

[0023] 4) Preparation of foamed aluminum: Preheat the Φ38 cylindrical mold in a foaming furnace for 20-60 minutes to 740°C, then plac...

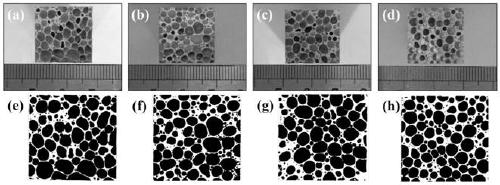

example 1

[0026] Pure aluminum powder with 7wt.% Si powder and 0.3wt.% TiH 2 Mix the powder in a three-dimensional mixer for 2 hours to obtain a uniform mixed powder, then weigh 24g of powder and use a cold press to hold the pressure at 450MPa for 5 minutes to obtain Φ38×8mm 3 The foaming precursor of the cylinder; preheat the Φ38 cylinder mold in the foaming furnace for 40min to 740°C, then place the foaming precursor in the mold for 90s and take it out, and quickly water-cool the mold to obtain a nearly cylinder Shaped samples, then wire cut to get 20×20×20mm 3 samples, such as image 3 a and 3e, the average pore diameter is 2.29mm, and the porosity is 78.1%.

example 2

[0028] 19.9g of pure aluminum powder and 0.4949g of Co(NO 3 ) 2 ·6H 2 O was ultrasonicated in 150ml of absolute ethanol solution for 30min, then stirred and heated in a water bath at 60°C, after 4h, the alcohol was evaporated to dryness, and then dried in an oven for 8h to obtain the precursor powder; put 20g of the precursor powder into the In the corundum ark of the tube furnace, heated to 250°C under argon (300ml / min) atmosphere, then heated to 450°C under hydrogen (250ml / min) atmosphere, reduced for 2.5h, and then heated to Carry out chemical vapor deposition at 600 ℃ for 10min, the atmosphere condition is acetylene and argon (20ml / min, 240ml / min), obtain 0.5wt.%CNT / Al composite powder; Si powder and 0.3wt.% TiH 2 Mix the powder in a three-dimensional mixer for 1 hour to obtain a uniform mixed powder, then weigh 24g of the powder and use a cold press to hold the pressure at 450MPa for 5 minutes to obtain Φ38×8mm 3 The foaming precursor of the cylinder; preheat the Φ38 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com