Method for constructing dislocation-resistant tunnel secondary lining passing through active fault

A secondary lining and active fault technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of limited anti-misalignment effect, cost a lot of financial resources, material resources and manpower, and cannot ensure structural safety well, so as to reduce If the rail surface is uneven or even crashes, the effect of anti-misalignment is good, and the effect of strengthening the connection is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

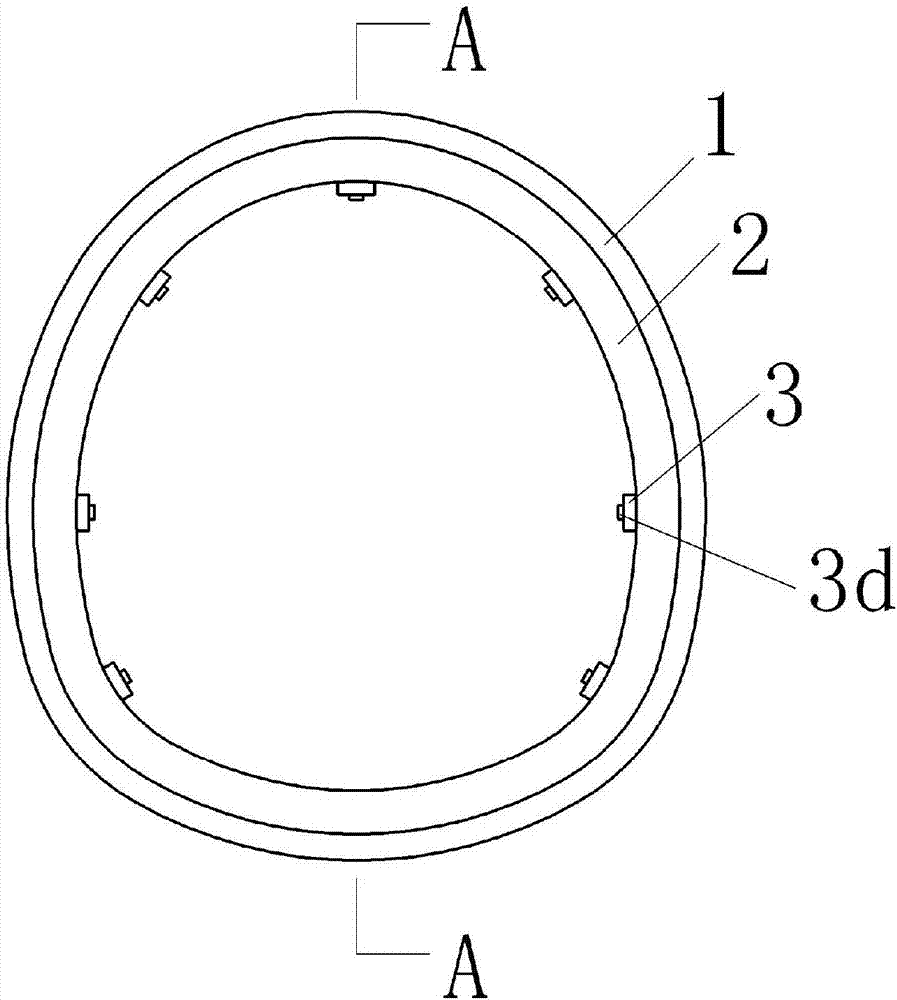

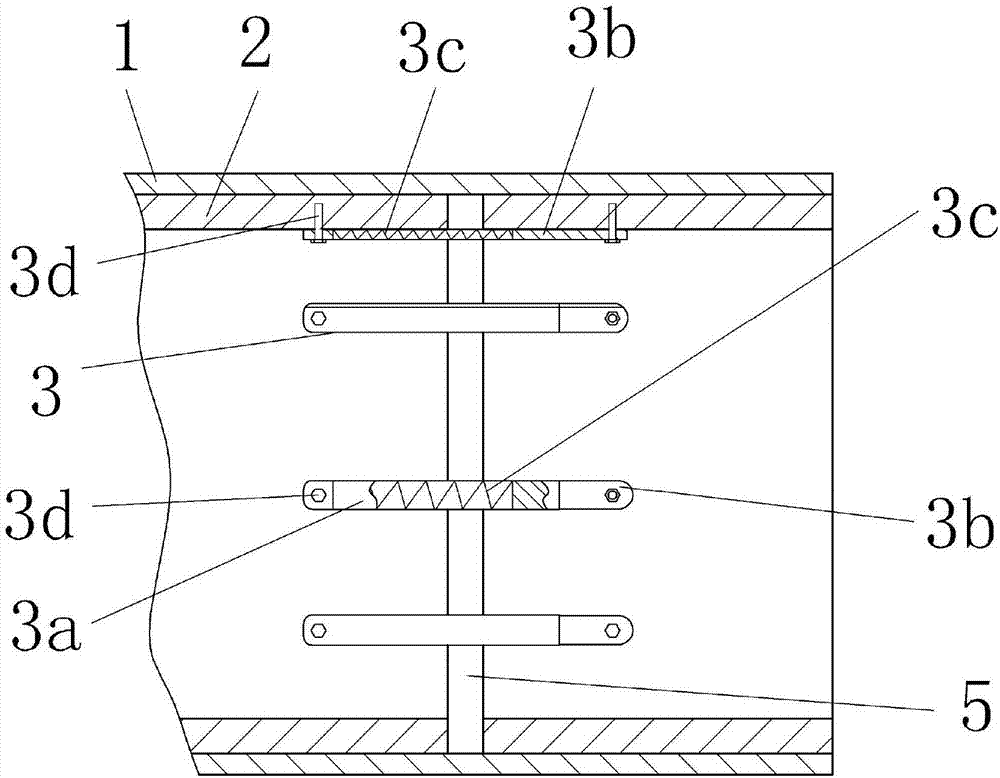

[0020] figure 1 , figure 2 It is shown that a specific embodiment of the present invention is a method for constructing a secondary lining of a dislocation-resistant tunnel crossing active faults, the steps of which are:

[0021] A. The segmental length of the secondary lining 2 built in the active fault fracture zone and the upper and lower walls adjacent to the active fault fracture zone within 20-100m is 1 / 2 of the segmental length of the secondary lining outside the active fault ~1 / 3;

[0022] B. The inner wall of the adjacent segment of the secondary lining 2 in the active fault fracture zone is connected to the high-strength tension-compression spring tube 3 across the deformation joint 5 by bolt 3d, and the high-strength tension-compression spring tube 3 connected to the inner wall of the adjacent segment is 7, located at the top of the vault, the left arch waist, the right arch waist, the left arch foot, the right arch foot, the left wall foot and the right wall foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com