LED and IC high-density integrated packaging structure and process and LED lamp strip

An integrated packaging, high-density technology, applied in the direction of lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve the problems of large spacing between components, low degree of integration, poor light-gathering performance, etc., to simplify the process , reduce the amount of materials, the effect of high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-9 , to further describe in detail the LED chip and IC high-density integrated package structure, process and LED light strip of the present invention.

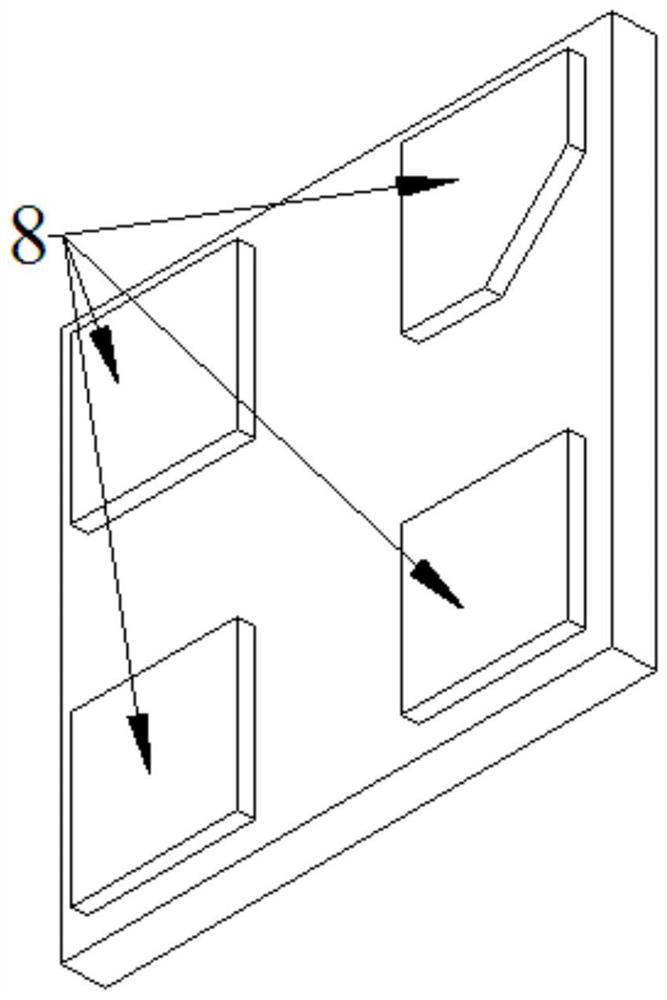

[0039] LED chips have light-emitting properties, such as Figure 8 For the traditional LED chip control shown in the figure, after pasting IC chip 1, LED chip 2 or their packages on the LED strip, connect IC chip 1 and LED chip 2 through conductive devices or wires, and then seal them with glue. For light transmission, this method of glue and wire bonding will lead to large spacing between components and low degree of integration when arranging components, resulting in large packaging volume, many materials, and high cost.

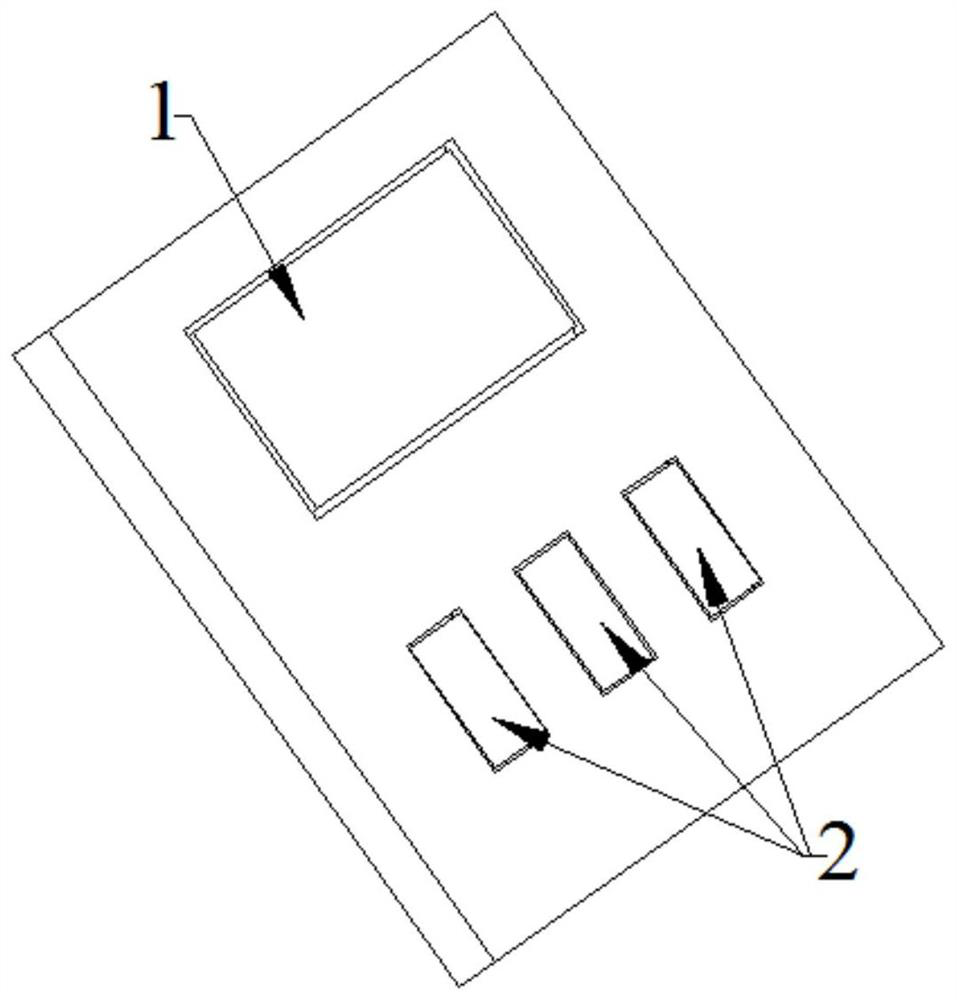

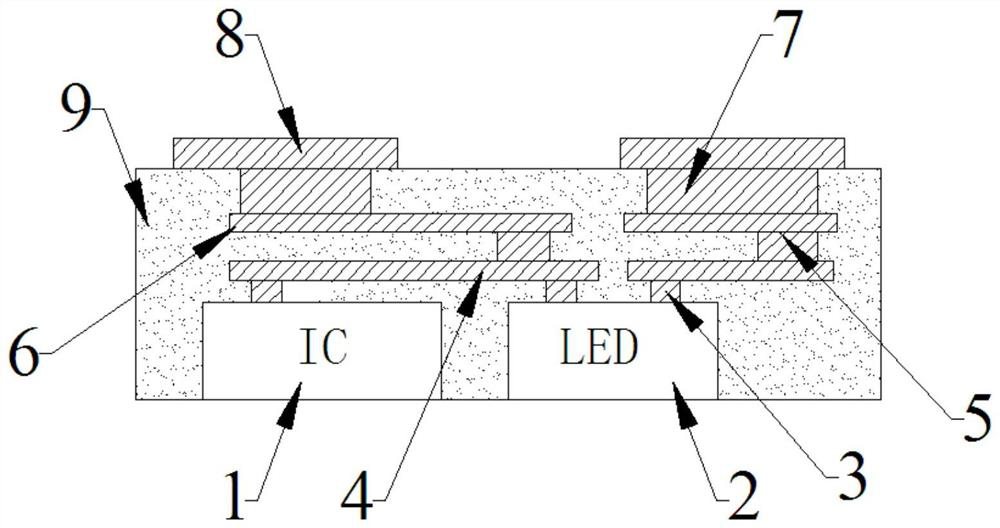

[0040] Such as image 3 , design LED and IC high-density integrated packaging structure, including IC chip 1, LED chip 2 and packaging layer 9; wherein, the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com