Construction joint self-closing grouting pipe structure and using method thereof

A technology of self-closing and grouting pipes, which is applied in the direction of building construction, construction, and building materials processing, etc., and can solve problems such as failure of the sealing strip of the grouting pipe to return to its original position, uneven penetration of the grouting liquid, and insufficient firmness of the clips, etc. , to achieve the effects of not being easy to flush out, improving grouting efficiency and high sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

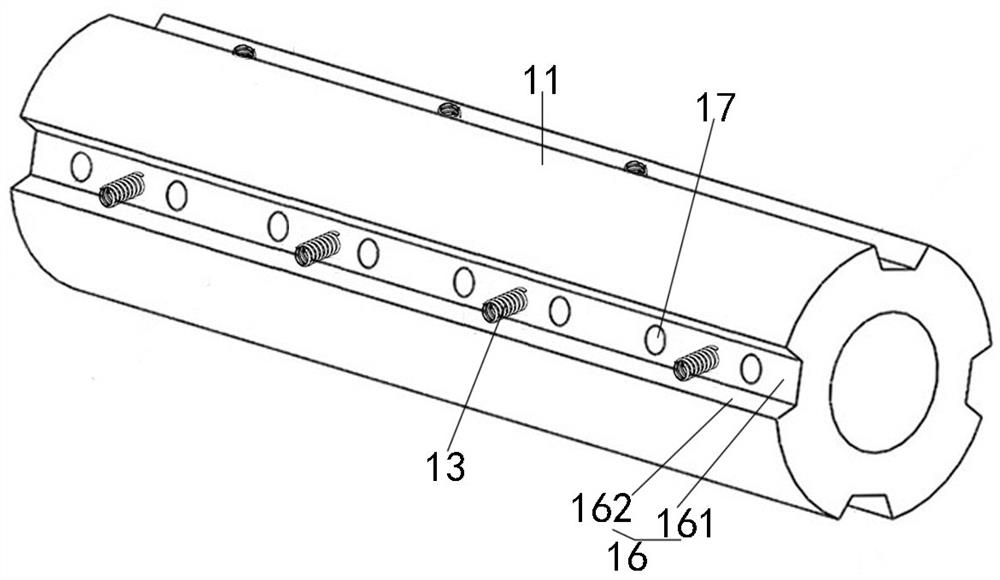

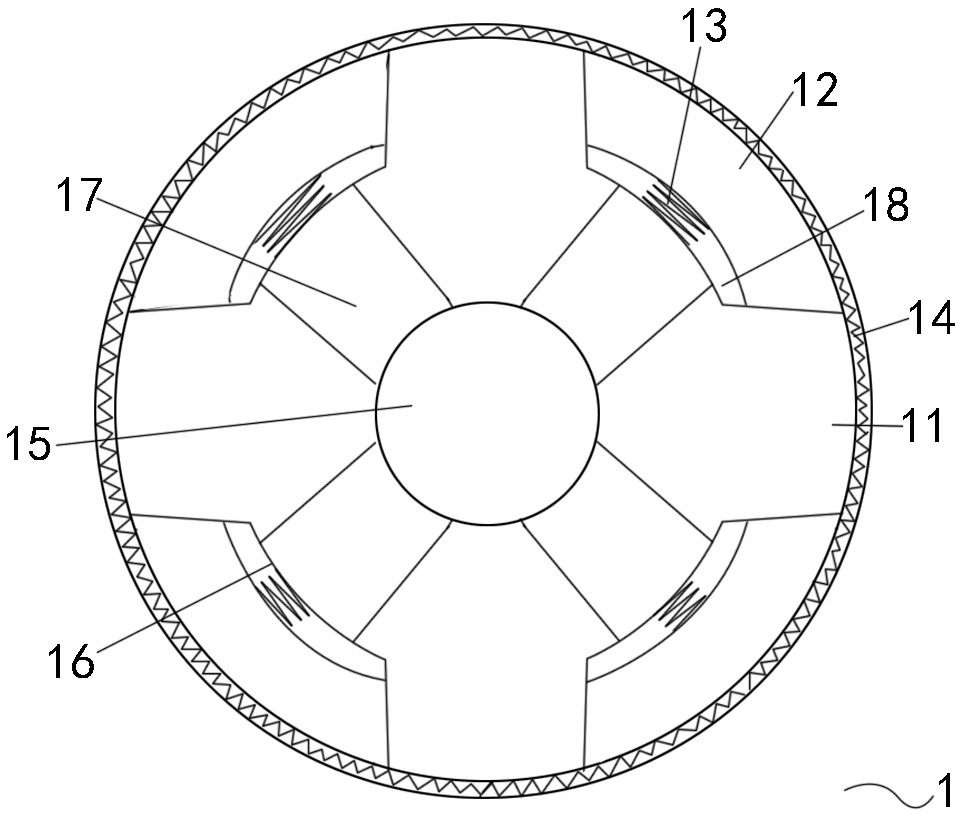

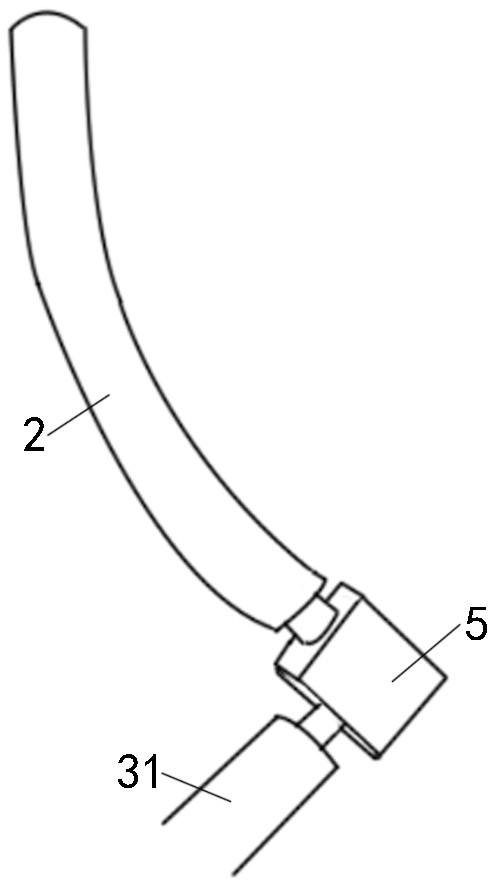

[0034] see Figure 1-4 As shown, a construction joint self-closing grouting pipe structure, including a grouting pipe 1 and a pressure pump introduction pipe 2, also includes a connecting device 3, one end of the connecting device 3 is fixedly connected to the grouting pipe 1 The main port, the other end of the connecting device 3 is fixedly connected to the main outlet of the slurry outlet of the pressure pump guide pipe 2. The connection device 3 includes a connecting pipe 31 and a double-ended transition pipe 32, the connecting pipe 31 is made of the same material as the pressurization pump guide pipe 2, and the double-ended transition pipe 32 is a variable-section pipe, including a thin pipe section 321 and a thick pipe section 322, the inner diameter of the thin pipe section 321 is compatible with the outer diameter of the connecting pipe 31, the head of the connecting pipe 31 is inserted into the thin pipe section 321, the inner diameter of the thick pipe section 322 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com