Micro-arc oxidation preparation method of magnetic TiO2 bioactive coating

A bioactive, micro-arc oxidation technology, applied in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve problems such as cellular immune rejection, weak binding between particles and substrates, and limitations in the clinical application of magnetic hard tissue materials , to achieve the effect of enhancing osteoinduction and improving biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

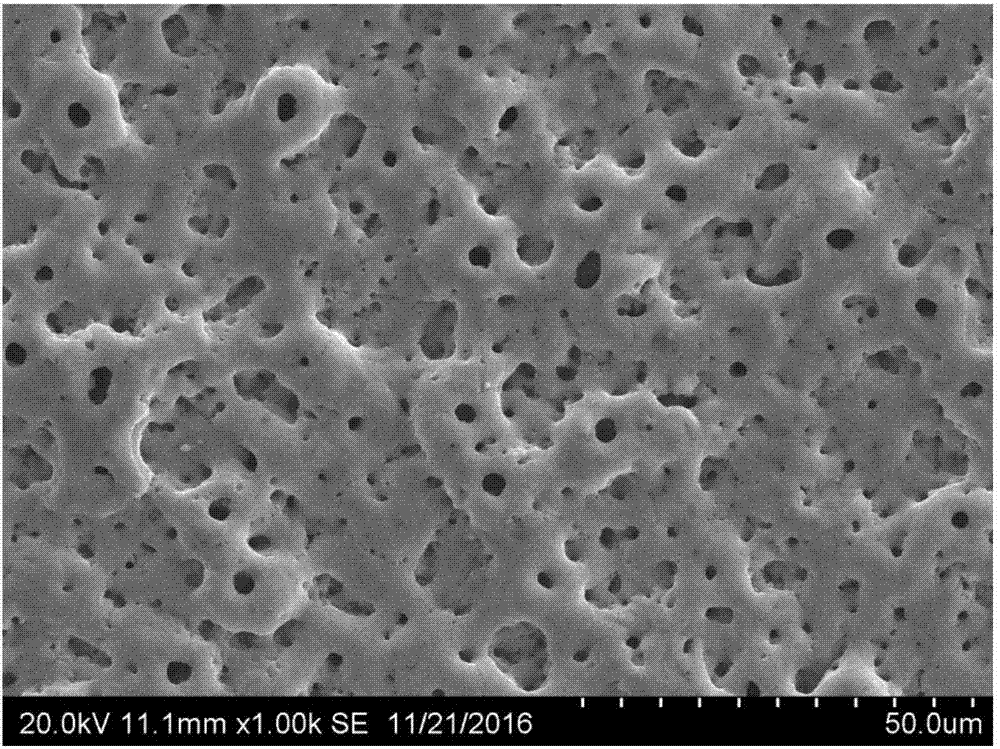

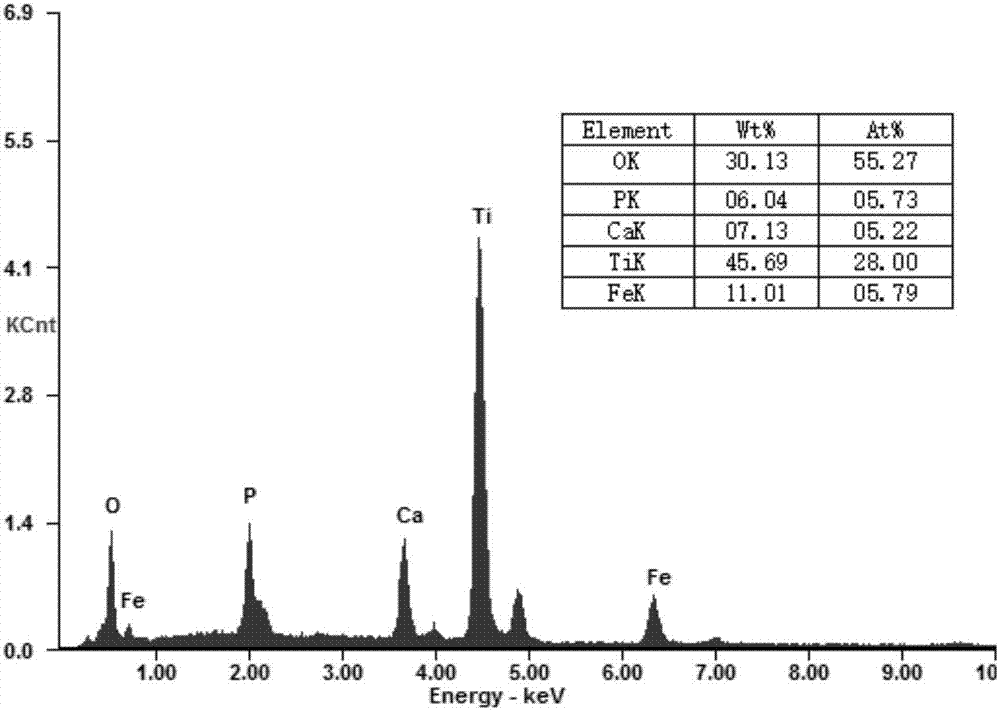

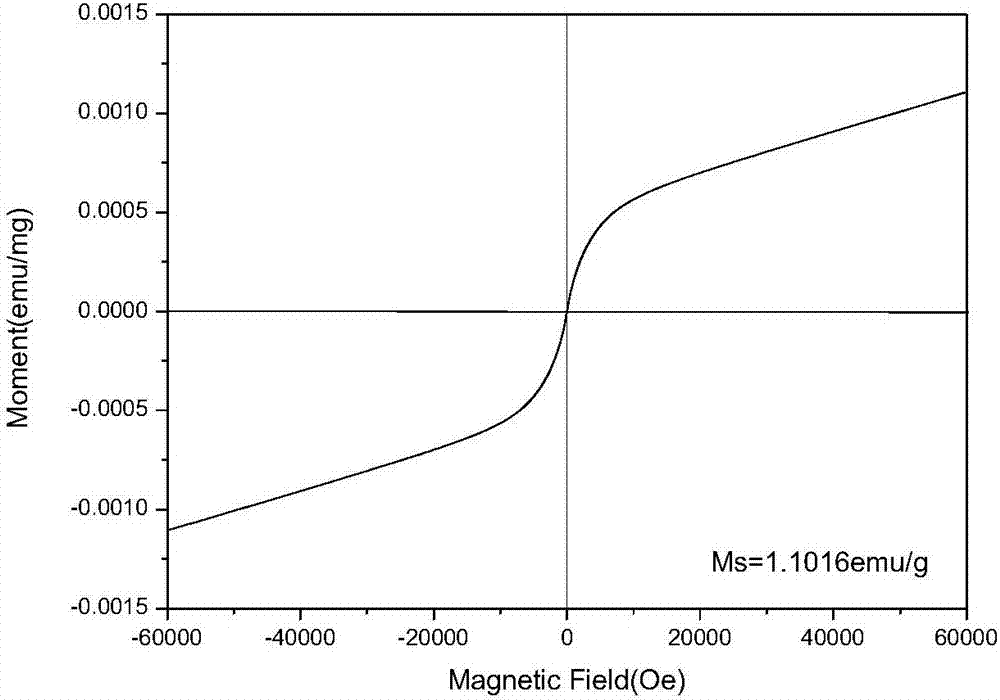

Embodiment 1

[0025] With deionized water as solvent, calcium acetate, β-glycerophosphate disodium salt and EDTA iron sodium salt as solute electrolyte, the pH of the electrolyte is adjusted to 5.3 by acetic acid solution, and calcium acetate, β-glycerophosphate disodium salt The molar ratio of sodium salt and EDTA iron sodium salt is 10:1:0.625, the concentration of calcium acetate in the electrolyte is 0.2mol / L, and then pure titanium is used as the anode and stainless steel as the cathode, and the pulse power supply is used at a voltage of 550V and a frequency of Under the conditions of 500Hz, 7.5% duty cycle, and 8cm spacing between cathode and anode plates, titanium is subjected to micro-arc oxidation treatment, the treatment time is 8 minutes, and the temperature of the electrolyte is kept at 5-25°C to form porous Ca-containing , P magnetic TiO 2 Bioactive coating, its saturation magnetization can reach 1.101emu / g.

Embodiment 2

[0027] Use deionized water as solvent, calcium chloride, sodium phosphate and ferric chloride as solute in the electrolyte, adjust the pH of the electrolyte to 5 by carbonic acid solution, and the moles of calcium chloride, sodium phosphate and ferric chloride The ratio is 10:1:0.125, the concentration of calcium chloride in the electrolyte is 0.2mol / L, and then the titanium alloy is used as the anode and the stainless steel is used as the cathode. %, under the condition that the distance between the cathode and anode plates is 6cm, micro-arc oxidation treatment is performed on titanium, the treatment time is 3 minutes, and the temperature of the electrolyte is kept at 5-25°C, and porous magnetic TiO containing Ca and P can be formed on the surface of titanium. 2 Bioactive coating, its saturation magnetization can reach 0.2696emu / g.

Embodiment 3

[0029] Taking deionized water as a solvent, taking calcium nitrate, sodium hydrogen phosphate and ferric chloride as the electrolytic solution of solute, adjusting pH by acetic acid solution is 5.2, and the mol ratio of calcium nitrate, sodium hydrogen phosphate and ferric chloride is 10: 1:0.375, the concentration of calcium nitrate in the electrolyte is 0.2mol / L, then pure titanium is used as the anode, stainless steel is used as the cathode, and the pulse power supply is used at a voltage of 400V, a frequency of 100Hz, a duty ratio of 60%, and the distance between the cathode and anode plates Under the condition of 3cm, titanium is subjected to micro-arc oxidation treatment, the treatment time is 1 minute, and the temperature of the electrolyte is kept at 5-25°C, and porous magnetic TiO containing Ca and P can be formed on the surface of titanium. 2 Bioactive coating, its saturation magnetization can reach 0.689emu / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com