Gas-coagulation lightweight surface exterior wall coating

An exterior wall paint, lightweight technology, applied in magnetic paint, antifouling/underwater paint, coating, etc., can solve the problems of performance degradation, low strength, powder drop, peeling, etc., to improve adhesion and toughness , Solve the effect of easy cracking and improve the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

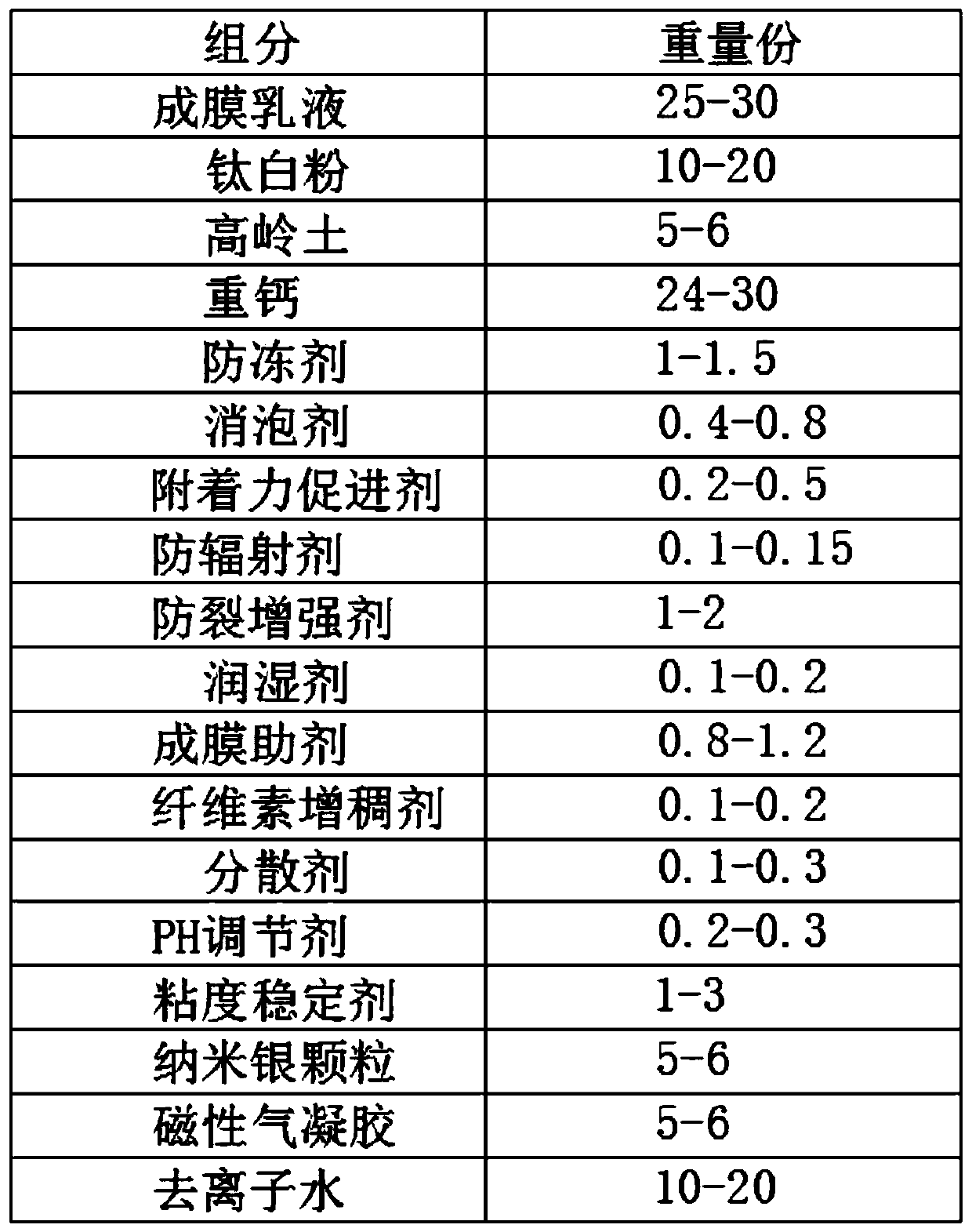

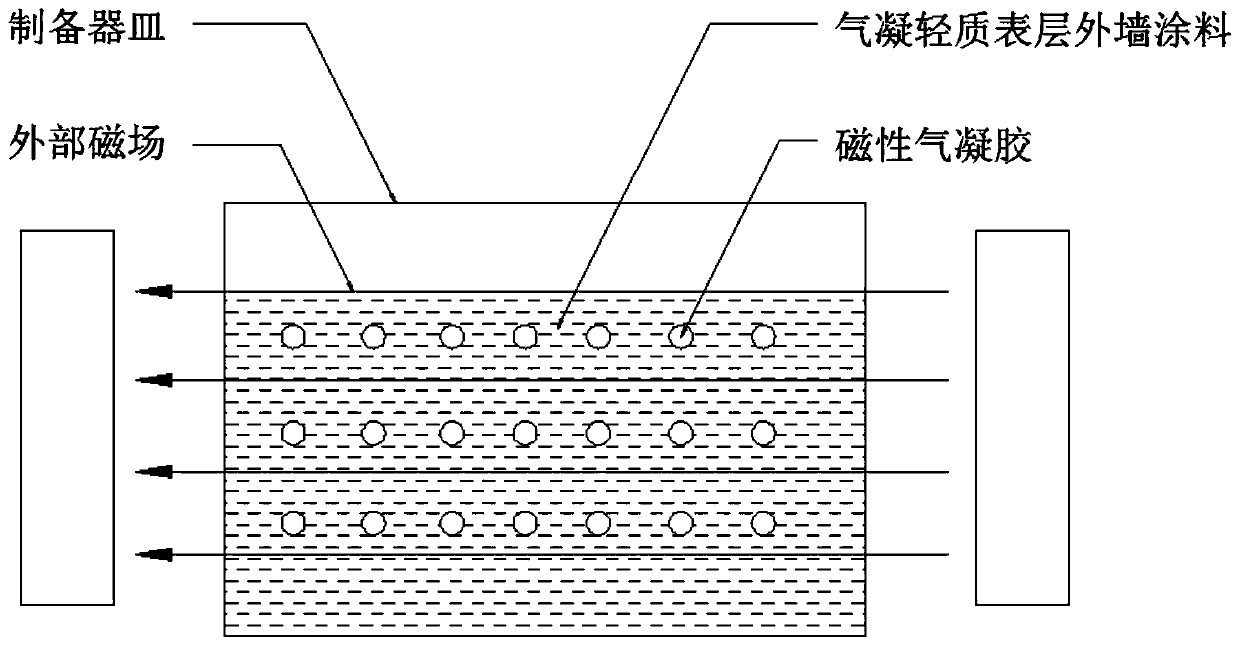

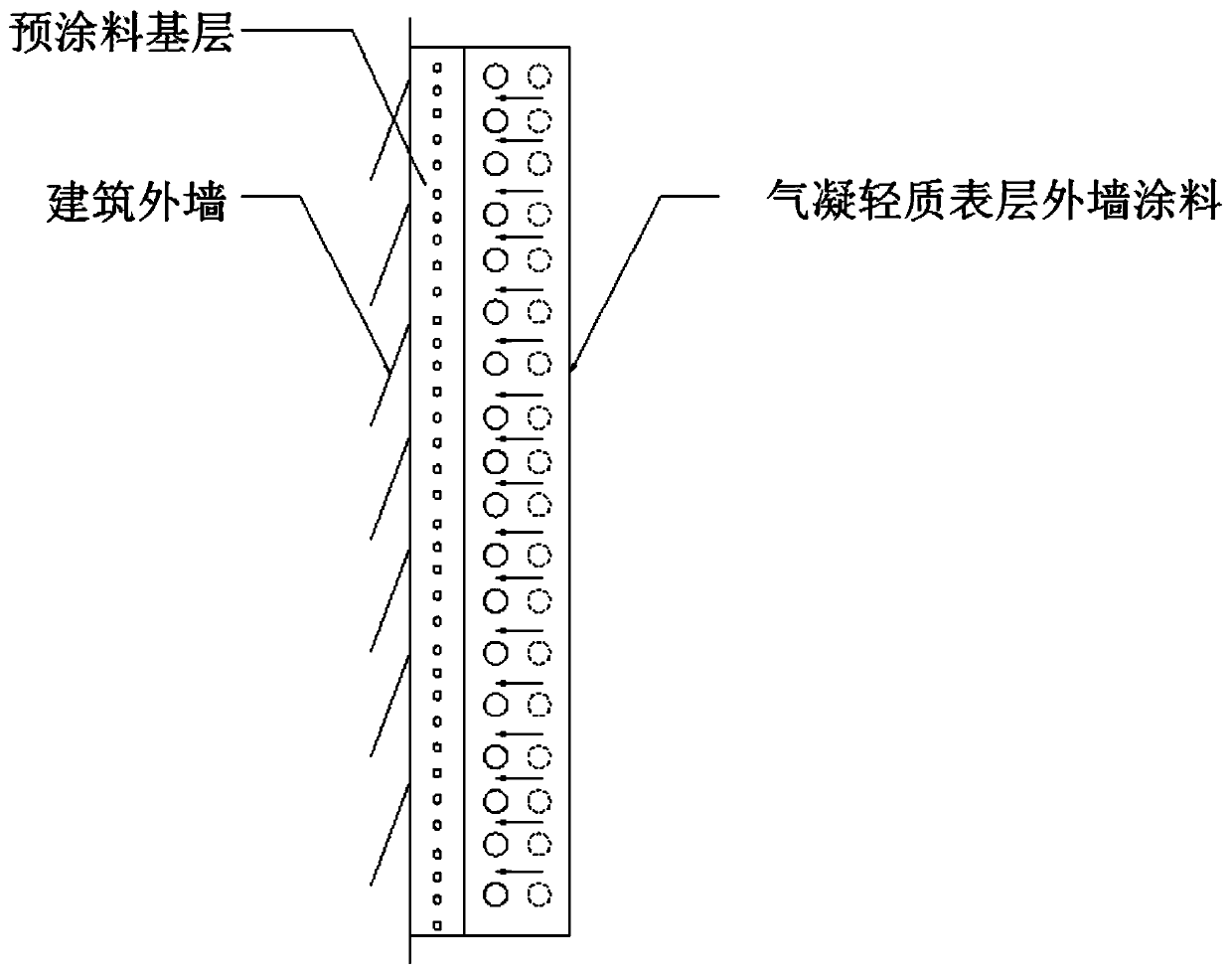

[0041] see Figure 1-3 , an air-condensing lightweight surface exterior wall coating, the air-condensing lightweight surface exterior wall coating is composed of the following components according to the weight ratio: 28 parts of film-forming emulsion, 15 parts of titanium dioxide, 5 parts of kaolin, 25 parts of heavy calcium, 0.5 parts Defoamer, 0.1 part of wetting agent, 0.1 part of cellulose thickener, 0.2 part of dispersant, 1 part of film-forming aid, 1.2 part of antifreeze, 0.4 part of adhesion promoter, 0.12 part of anti-radiation agent, 1 part Anti-crack enhancer, 0.2 parts of PH regulator, 2 parts of viscosity stabilizer, 5 parts of nano silver particles, 5 parts of magnetic airgel and 18 parts of deionized water.

[0042] The film-forming emulsion is made by mixing elastic acrylic emulsion and styrene-acrylic emulsion, and the mixing ratio of elastic acrylic emulsion and styrene-acrylic emulsion is 1:1.2, and the film-forming aid is lauryl alcohol.

[0043] Antifree...

Embodiment 2

[0056] see figure 1, an air-condensing lightweight surface exterior wall coating, the air-condensing lightweight surface exterior wall coating is composed of the following components according to the weight ratio: 30 parts of film-forming emulsion, 15 parts of titanium dioxide, 6 parts of kaolin, 28 parts of heavy calcium, 1- 1.5 parts of antifreeze, 1.5 parts of antifreeze, 0.7 parts of defoamer, 0.2 parts of wetting agent, 0.2 parts of cellulose thickener, 0.3 parts of dispersant, 0.4 parts of adhesion promoter, 0.15 parts of anti-radiation agent, 2 parts Anti-crack enhancer, 0.3 parts of PH regulator, 2 parts of viscosity stabilizer, 6 parts of nano silver particles, 6 parts of magnetic airgel and 20 parts of deionized water.

[0057] The film-forming emulsion is made by mixing elastic acrylic emulsion and styrene-acrylic emulsion, and the mixing ratio of elastic acrylic emulsion and styrene-acrylic emulsion is 1:1.4, and the film-forming aid is lauryl alcohol.

[0058] An...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com