Preparation method and application of sulfur-doped graphite-phase carbon nitride nanosheet loaded graphene and ferroferric oxide composite magnetic photocatalyst

A technology of graphite phase carbon nitride and ferric oxide, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the limitation of carbon nitride material application Prospects, high photogenerated electron-hole recombination rate, difficult catalyst recycling, etc., to achieve the effect of improving effective separation and reuse performance, improving photocatalytic efficiency, and improving photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

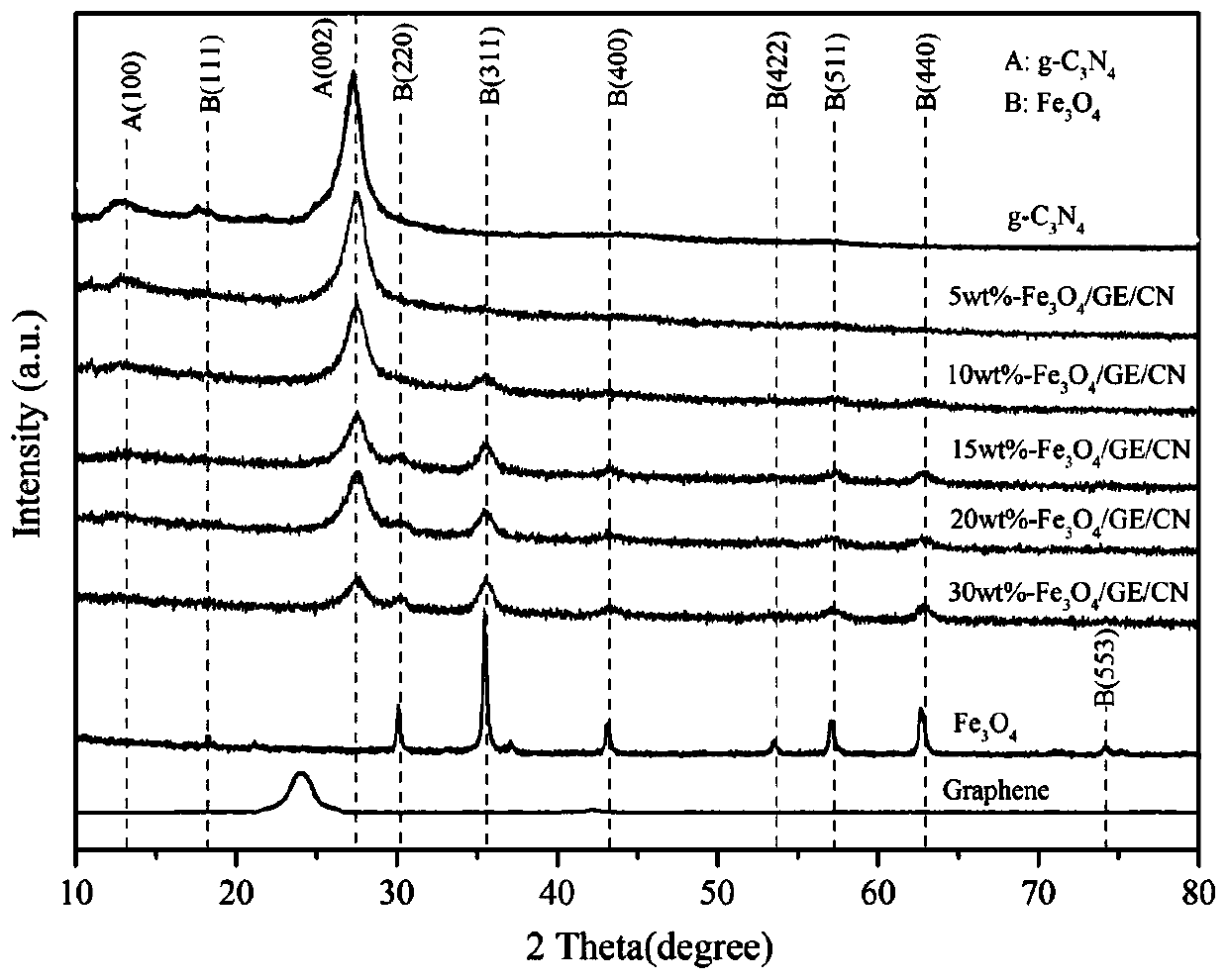

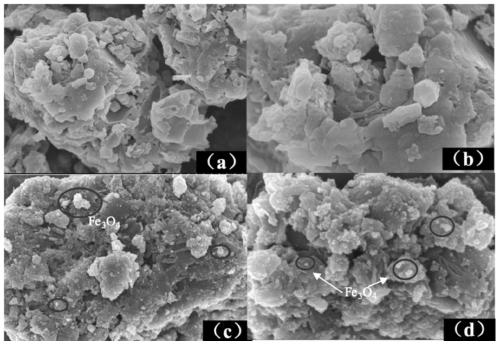

[0060] To specifically produce a sulfur-doped graphitic phase carbon nitride nanosheet-loaded graphene (mass fraction accounts for 0.2%) and ferric oxide composite magnetic photocatalyst (20%- Fe 3 o 4 / GE / CN) as an example, including sulfur-doped graphite phase carbon nitride nanosheets, graphene dispersion (purchased in the market), and ferric oxide particles. Wherein the catalyst is supported by sulfur-doped graphite-like carbon nitride nano-sheets, and the sulfur-doped graphite-like carbon nitride nano-sheets are decorated with graphene and ferroferric oxide particles.

[0061] In this embodiment, graphene and ferric oxide particles are evenly attached to the surface of sulfur-doped graphite-like carbon nitride nanosheets.

[0062]In this embodiment, the graphene dispersion is loaded and modified on sulfur-doped graphite-like carbon nitride nanosheets by impregnation to form a sulfur-doped graphite-like carbon nitride-supported graphene photocatalyst composite material, ...

Embodiment 2

[0091] A kind of sulfur-doped graphitic phase carbon nitride nanosheet loaded graphene and iron ferric oxide composite magnetic photocatalyst in the application in the treatment of ranitidine antibiotic wastewater, comprising the following steps:

[0092] (1) Take by weighing 50 milligrams of the sulfur-doped graphitic phase carbon nitride nanoplates that 50 milligrams of embodiment 1 make support graphene and ferroferric oxide composite magnetic photocatalyst (20%-Fe 3 o 4 / GE / CN), added to 50 milliliters of ranitidine wastewater with an initial concentration of 5 milligrams per liter, and then placed in a photocatalytic reaction device and stirred for 30 minutes at a rate of 500 rpm in a dark and light-proof environment.

[0093] (2) Adopt the above-mentioned 300-watt xenon lamp as the light source, use a cut-off filter below 400 nanometers to ensure that ranitidine and the composite photocatalyst carry out the photocatalytic reaction in the visible light region (wavelength λ...

Embodiment 3

[0097] The application of a kind of sulfur-doped graphitic phase carbon nitride nanosheet loaded graphene and iron ferric oxide composite magnetic photocatalyst in the treatment of ranitidine antibiotic wastewater comprises the following steps:

[0098] (1) Take by weighing 50 milligrams of the sulfur-doped graphitic phase carbon nitride nanosheets loaded graphene and ferroferric oxide composite magnetic photocatalyst (20%-Fe 3 o 4 / GE / CN), added to 50 milliliters of ranitidine wastewater with an initial concentration of 5 milligrams per liter, and then placed in a photocatalytic reaction device and stirred for 30 minutes at a rate of 500 rpm in a dark and light-proof environment.

[0099] (2) Adopt the above-mentioned 300-watt xenon lamp as the light source, use a cut-off filter below 400 nanometers to ensure that ranitidine and the composite photocatalyst carry out the photocatalytic reaction in the visible light region (wavelength λ>400 nanometers) for 60 minutes, and compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com