Preparation method of NiAu projection and NiAu projection assembly

A manufacturing method and a technology of bumps, which are applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of accelerating seed layer etching, reducing the bonding area of bumps and metal layers, and reducing the bonding force, so as to avoid bonding Reduction of area and binding force, effect of avoiding galvanic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be described in detail with reference to the embodiments shown in the drawings. The following is a preferred embodiment of the present invention.

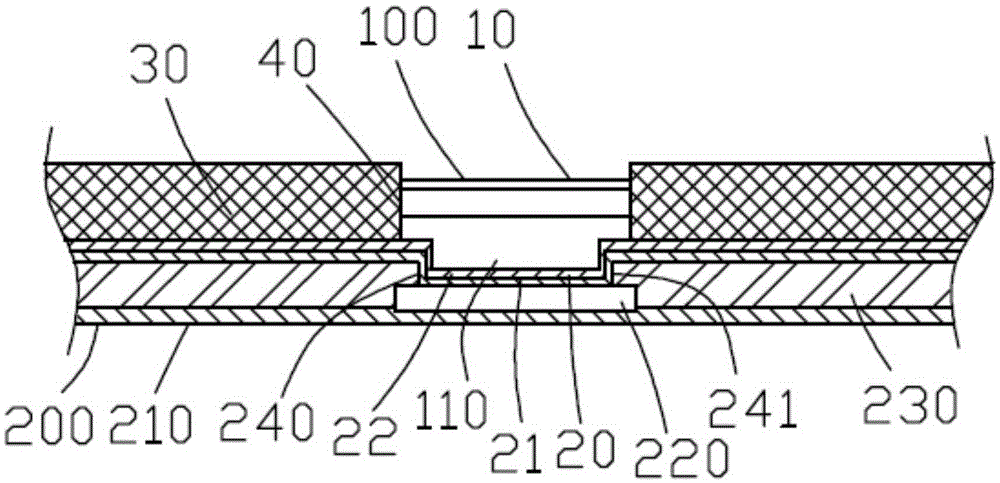

[0030] See figure 1 , image 3 , The present invention relates to a bump assembly 100 made of nickel and gold, which is protrudingly formed on the semiconductor wafer assembly 200. The bump assembly 100 includes a nickel-gold bump 10 with a protruding portion 110 at the lower end, which is bonded between the bump 10 and the wafer assembly 200, that is, the upper and lower surfaces of the bump 10 are respectively connected to the bump 10. The bottom end of the metal layer 20 is attached to the top end of the wafer assembly 200.

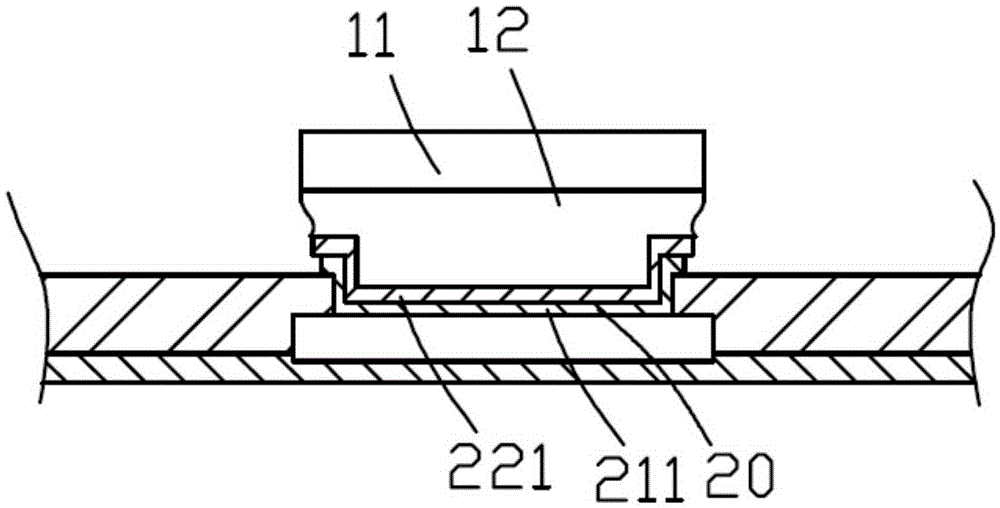

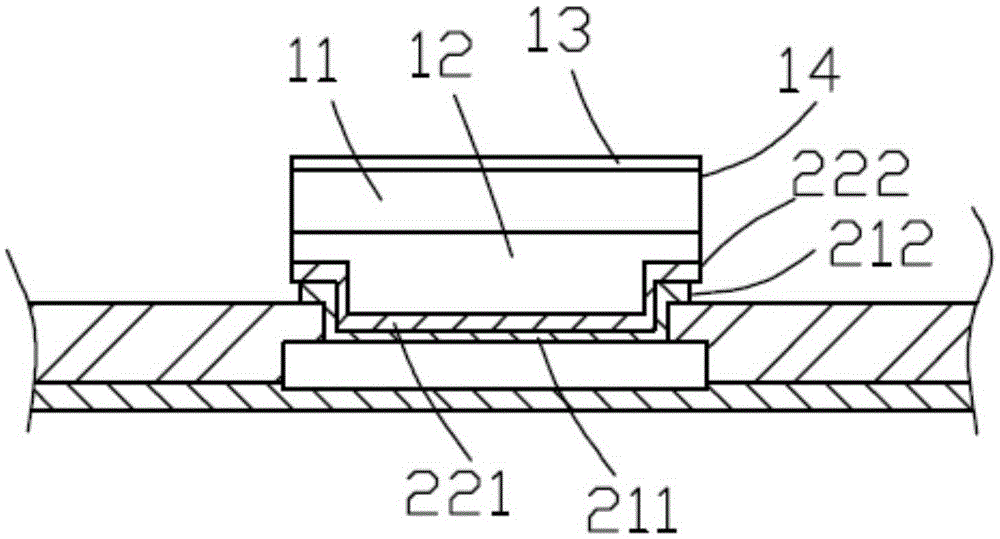

[0031] The bump 10 includes a gold metal layer 11, a nickel metal layer 12 disposed under the gold metal layer 11, and a reserve layer 13 disposed on the gold metal layer 11. The metal layer 20 includes a seed metal layer 221 sputtered on the bottom end of the bum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com