Pad molding mold and pad

A technology for forming molds and pads, which is applied in the direction of instruments, electrical recording process equipment using charge patterns, optics, etc., can solve the problem of unbalanced pushing force, reduced paper peelability and image quality, and reduced dimensional accuracy of pressurized pads and other problems, to achieve the effect of suppressing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

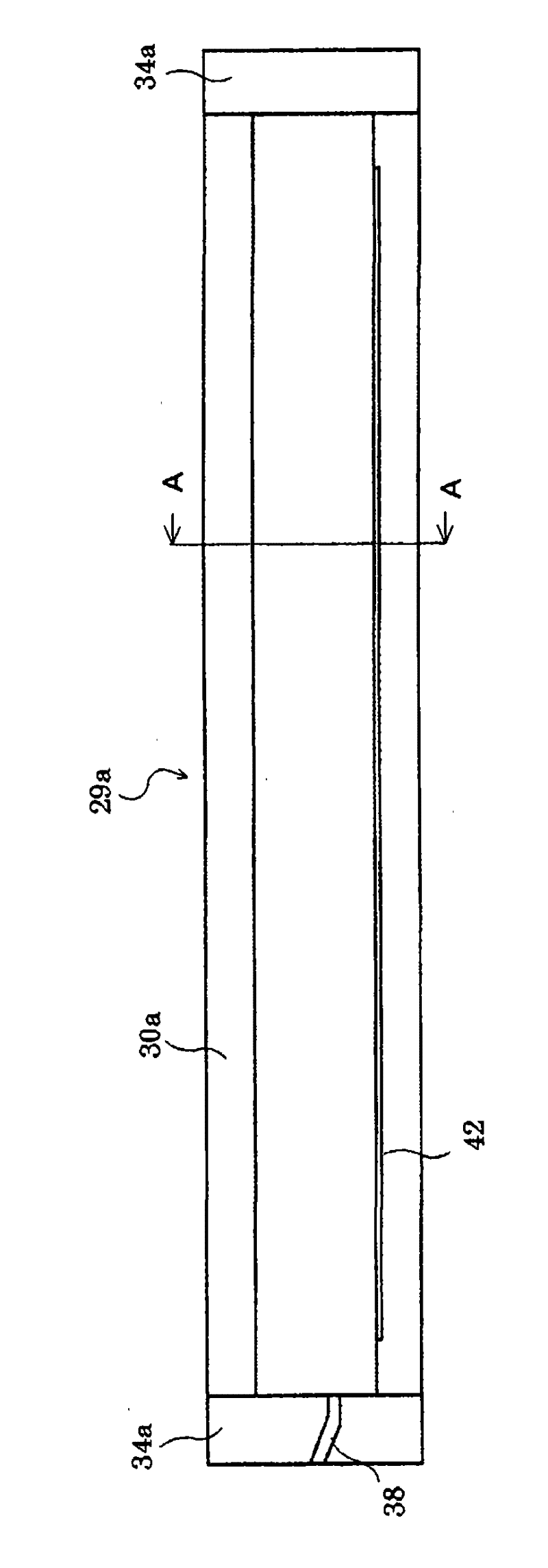

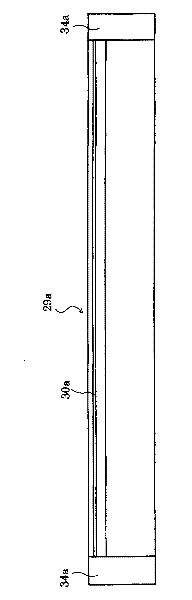

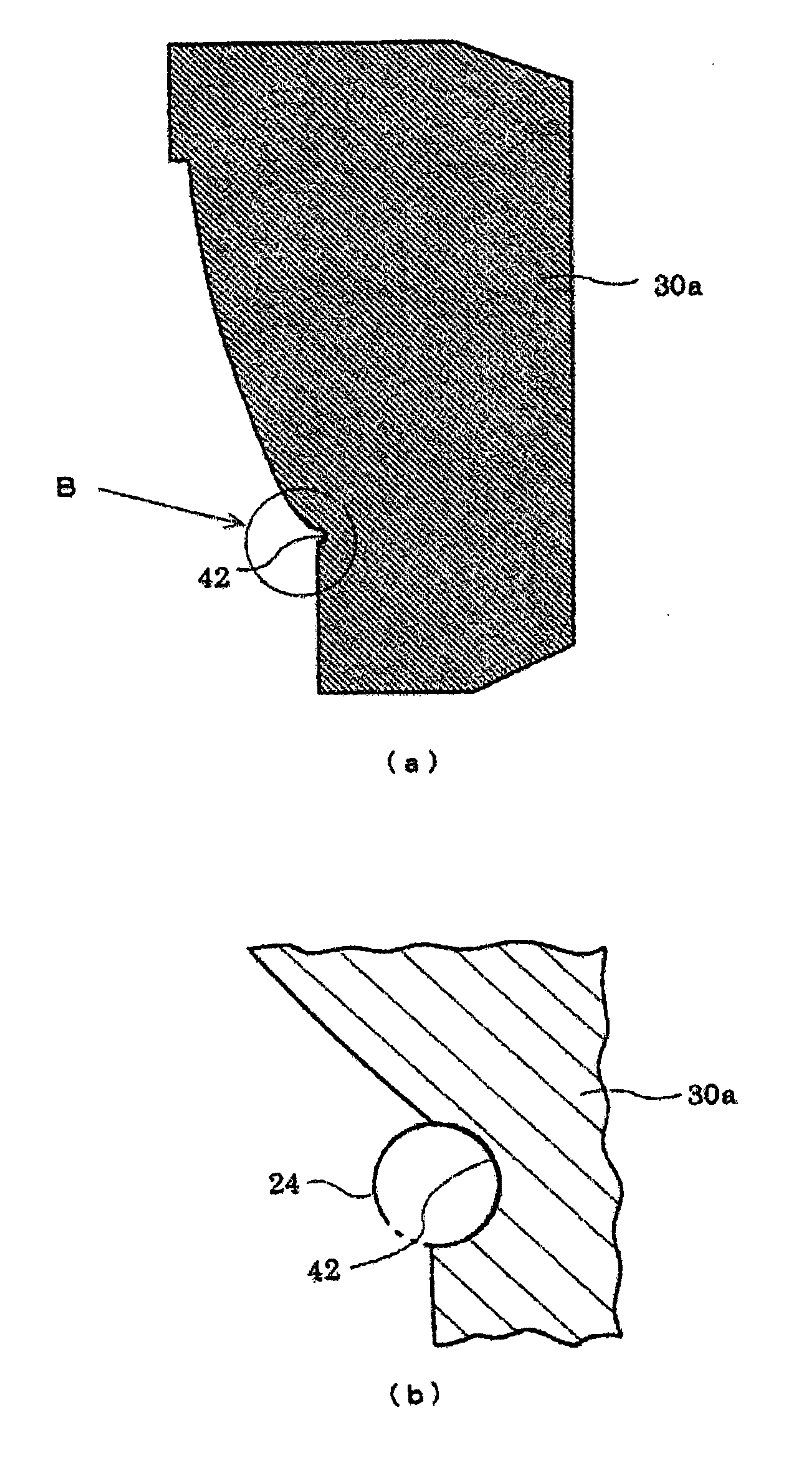

[0031] Figure 1 ~ Figure 3 It is a figure which shows the lower die of the liner molding die of one embodiment of the present invention, figure 1 is a top view, figure 2 is the main view, image 3 (a) is along figure 1 An enlarged sectional view of line A-A, image 3 (b) is an enlarged cross-sectional view of part B of (a). Figure 4 ~ Figure 6 It is a figure showing the upper die of this liner molding die, Figure 4 is a top view, Figure 5 is the main view, Figure 6 (a) is along Figure 4 An enlarged cross-sectional view of line C-C, (b) is an enlarged cross-sectional view of part D of (a). Figure 7 It is a figure which shows the state which combined the lower mold and the upper mold of this liner molding die 28, (a) is a transverse cross-sectional view, (b) is an enlarged cross-sectional view of the E part of this (a).

[0032] Such as Figure 7 As shown in (a), the liner molding die 28 of the present invention is a two-part mold, consisting of one parting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com