Curved-surface micro-slit aluminum veneer edge closing structure

An aluminum veneer and micro-slit technology, which is applied to building components, building structures, walls, etc., can solve the problems of easy connection deviation, the inability of the aluminum veneer and the curtain wall to reach the connection position accurately, and the inability to abut the connection. , to achieve the effect of easy connection and fixation, natural appearance, smooth and beautiful connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

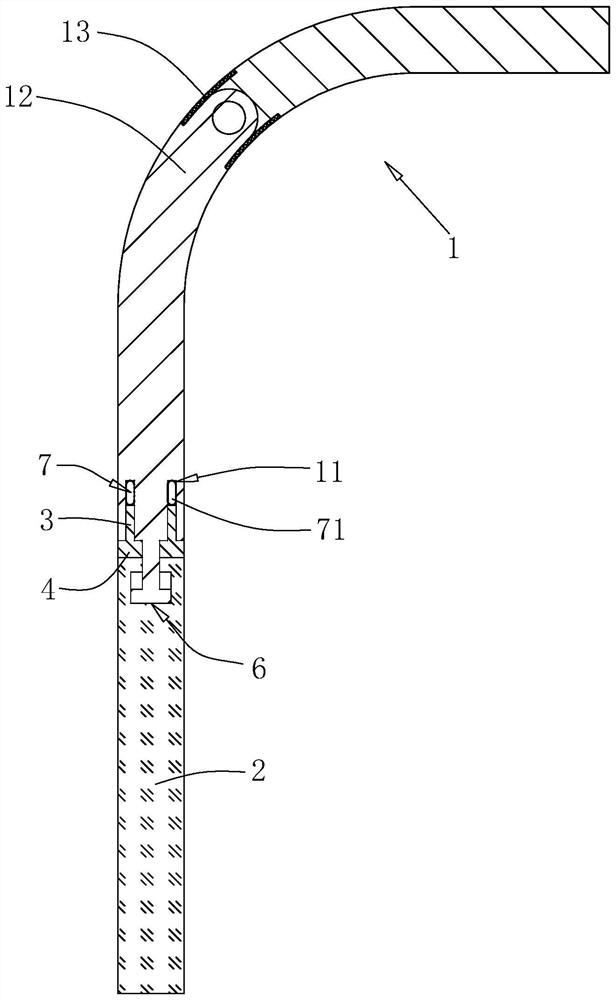

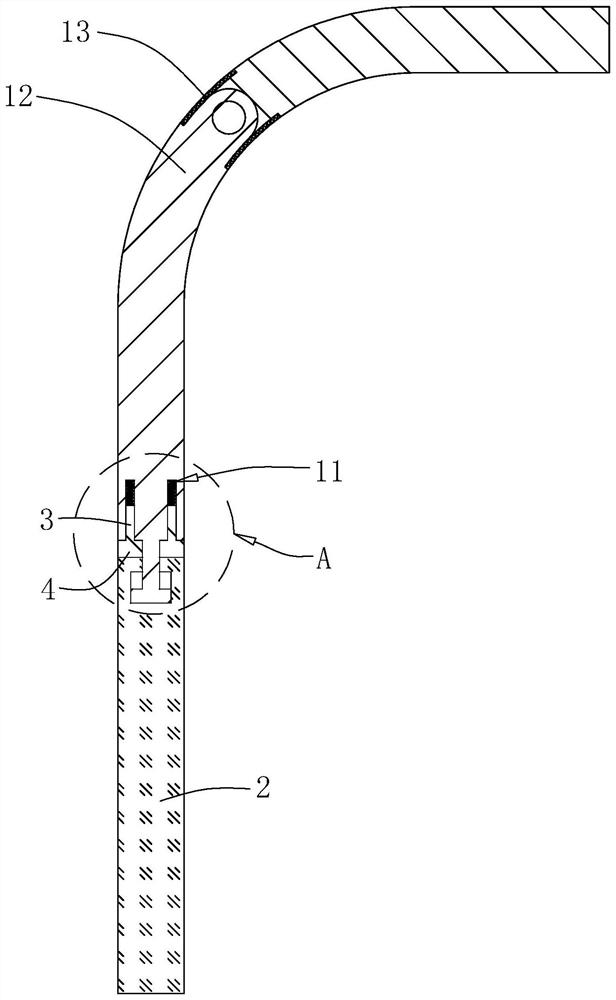

[0035] The embodiment of the present application discloses a curved micro-slit aluminum veneer edge structure. refer to figure 1 and figure 2 The curved surface micro-slit aluminum veneer edge structure includes arc plate 1, curtain wall plate 2 and connecting components. The vertical curtain wall connected by the arc plate 1, the curtain wall plate 2 of the embodiment of the present application is a glass plate, and the connecting component is arranged between the arc plate 1 and the curtain wall plate 2 for connection.

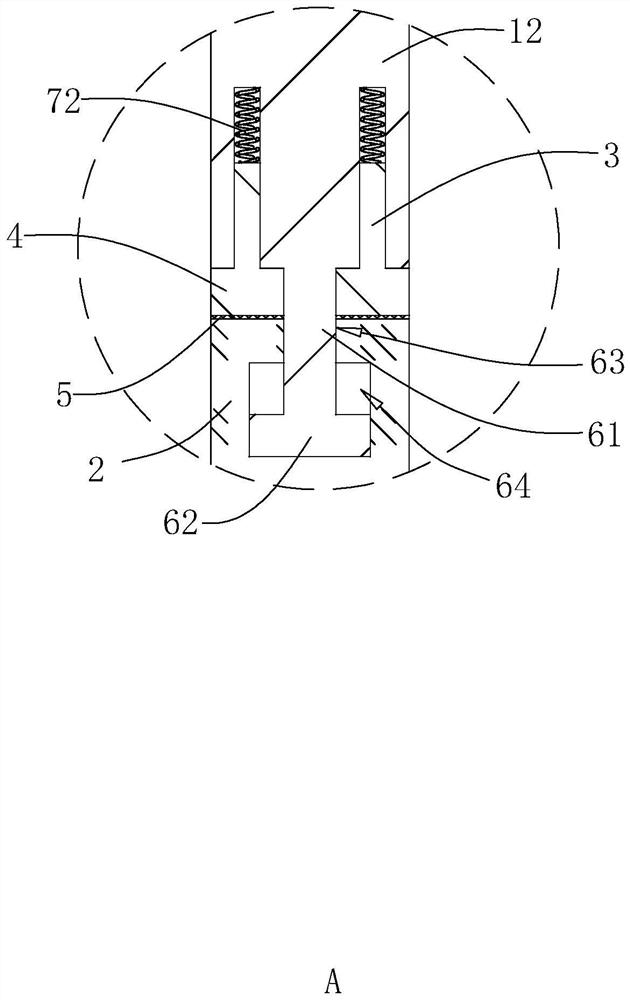

[0036] refer to image 3 The connection assembly includes a slide plate 3, a connection plate 4, an expansion rubber 5, a locking member 6 and an elastic member 7. The slide plate 3 and the connection plate 4 are integrally cast and formed in a “T” shape, and the connection end of the arc plate 1 is provided with a The chute 11 in which the slide plate 3 slides is slidably connected in the chute 11, and the length direction of the chute 11 is perpendicul...

Embodiment 2

[0042] refer to Figure 4 and Figure 5 , Embodiment 2 of the present application differs from Embodiment 1 in that: the protruding strip plate 61 and the clamping strip plate 62 are arranged in an “L” shape. The convex strip plate 61 is arranged near the inner wall of the arc plate 1, and the card jumper is arranged on the convex strip plate 61 and is arranged near the outside of the building.

[0043] When connecting the curtain wall panel 2, make the connecting end of the curtain wall panel 2 push the connecting plate 4 and the slide plate 3 to slide, directly hang the curtain wall panel 2 in the clamping groove 64 through the clip plate 62, and connect the connecting end of the curtain wall panel 2 and The connecting plate 4 is adhered and fixed to realize the pre-fixation of the curtain wall panel 2 and the curved panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com