Modified halogen-free flame-retardant thermoplastic elastomer cable material and production method thereof

A thermoplastic elastomer, cable material technology, used in plastic/resin/wax insulators, rubber insulators, organic insulators, etc., can solve the problems of poor thermal stability of materials, burning droplets, precipitation, etc., and achieve excellent processing performance. , high flame retardant efficiency, good tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An improved halogen-free flame retardant thermoplastic elastomer cable material is characterized in that it consists of the following raw materials in parts by weight:

[0034] Butadiene-styrene copolymer: 30-50 parts;

[0035] Polyphenylene ether resin: 20 to 40 parts;

[0036] Polyethylene or polypropylene: 15 to 35 parts;

[0037] Polyolefin elastomer: 15-40 parts;

[0038] Plasticizer: 15 to 30 parts;

[0039] Mica: 15 to 25 servings;

[0040] Aluminum hydroxide: 10 to 20 parts;

[0041] Talc powder: 3 to 8 parts;

[0042] Ethylene-vinyl acetate copolymer: 3 to 8 parts;

[0043] PTFE: 3 to 6 parts;

[0044] Lubricant: 2 to 4 parts;

[0045] Antioxidant: 0.1 to 0.8 parts;

[0046] Silica gel with a fineness of less than 300 mesh: 6 to 8 parts;

[0047] Carbon black: 4 to 8 parts.

[0048]The above-mentioned halogen-free flame retardant thermoplastic elastomer cable material is characterized in that it is prepared by the following method: it is characterize...

Embodiment 2

[0052] An improved halogen-free flame retardant thermoplastic elastomer cable material is characterized in that it consists of the following raw materials in parts by weight:

[0053] Butadiene-styrene copolymer: 30 parts;

[0054] Polyphenylene ether resin: 20 parts;

[0055] Polyethylene or polypropylene: 15 parts;

[0056] Polyolefin elastomer: 15 parts;

[0057] Plasticizer: 15 parts;

[0058] Mica: 15 servings;

[0059] Aluminum hydroxide: 10 parts;

[0060] Talc: 3 parts;

[0061] Ethylene-vinyl acetate copolymer: 3 parts;

[0062] PTFE: 3 parts;

[0063] Lubricant: 2 parts;

[0064] Antioxidant: 0.1 part;

[0065] Silica gel with a fineness of less than 300 mesh: 6 parts;

[0066] Carbon Black: 4 parts.

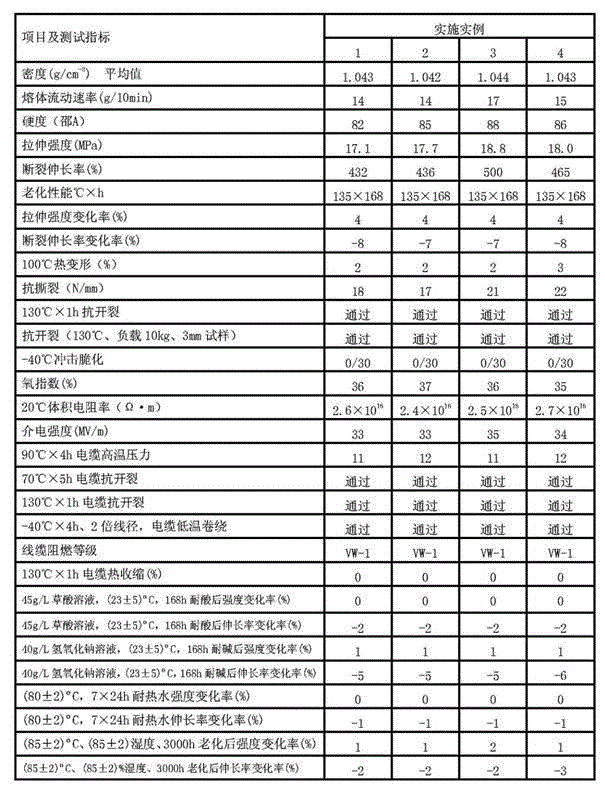

[0067] The performance test results in this example are shown in Table 1.

Embodiment 3

[0069] An improved halogen-free flame retardant thermoplastic elastomer cable material is characterized in that it consists of the following raw materials in parts by weight:

[0070] Butadiene-styrene copolymer: 50 parts;

[0071] Polyphenylene ether resin: 40 parts;

[0072] Polyethylene or polypropylene: 35 parts;

[0073] Polyolefin elastomer: 40 parts;

[0074] Plasticizer: 30 parts;

[0075] Mica: 25 servings;

[0076] Aluminum hydroxide: 20 parts;

[0077] Talc: 8 parts;

[0078] Ethylene-vinyl acetate copolymer: 8 parts;

[0079] PTFE: 6 parts;

[0080] Lubricant: 4 parts;

[0081] Antioxidant: 0.8 part;

[0082] Silica gel with fineness less than 300 mesh: 8 parts;

[0083] Carbon Black: 8 parts.

[0084] The performance test results in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com