Modified resin for composite material base plate and preparation method thereof

A modified resin and composite material technology, which is applied in the field of polyethylene materials, can solve the problems of poor dimensional and shape stability, easy cracking of materials, large deformation, etc., and achieve improved comprehensive mechanical properties, improved performance, and good dimensional and shape stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

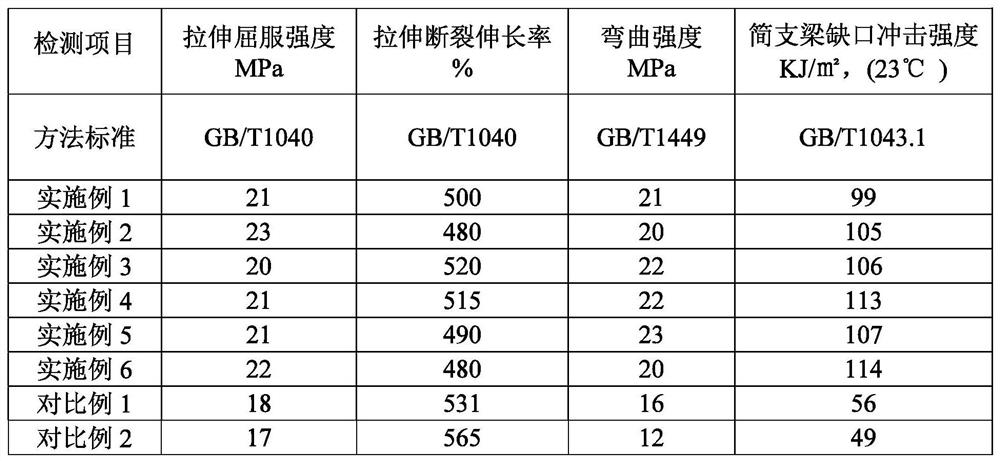

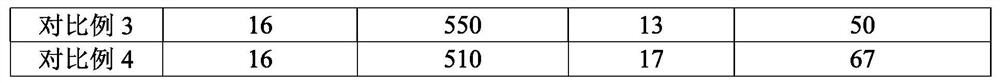

Examples

preparation example Construction

[0048] The second aspect of the present invention provides a method for preparing the modified resin for composite backing plate as described above, which includes the following steps: firstly, after the filler is treated with a coupling agent, it is added to a high-speed dispersion mixer together with other raw materials, heated and stirred After uniform mixing, drying treatment is carried out, and the dried raw materials are melted, plasticized, extruded and granulated by a twin-screw extruder to obtain the finished modified resin.

[0049] Among them, the stirring time is 5-10 minutes, the heating temperature is 50-70° C.; the drying temperature is 60-80° C., and the drying time is 0.5-1 hour; the granulation temperature is 90-265° C.

[0050] Specifically, the filler is treated as follows: after diluting the coupling agent with a solvent, adding the filler, stirring for 5-15 minutes, drying, and pulverizing into a powder with a particle size of 2000-10000 mesh.

[0051] Wh...

Embodiment 1

[0055] A modified resin formula for a composite pad, comprising the following raw materials in parts by weight: 50 parts of high-density polyethylene, 5 parts of ultra-high molecular weight polyethylene, 10 parts of linear low-density polyethylene, 0.1 part of antioxidant BASF Irganox 1010 , light stabilizer BASF CHIMASSORB 944 0.1 part, flow aid polyethylene wax 0.5 part, release agent oleic acid amide 0.2 part, lubricant calcium stearate 0.1 part, silicon dioxide 3 parts, carbon fiber 1 part, silanes Joint agent 0.018 part.

[0056] The preparation method of the modified resin for the above-mentioned composite backing plate is:

[0057] (1) Take the coupling agent and dilute it with absolute ethanol at a rate of 10:1 (volume ratio), pour the weighed filler into the diluted coupling agent solution, stir for 5 minutes, and then put it into the drying equipment, Dry at 90°C for 5 hours, take it out, grind it into a powder with a particle size of 2000 mesh, and place it in a cl...

Embodiment 2

[0060] A modified resin formula for a composite pad, comprising the following raw materials in parts by weight: 80 parts of high-density polyethylene, 20 parts of ultra-high molecular weight polyethylene, 2 parts of linear low-density polyethylene, antioxidant BASF AT-10 1 1 part, light stabilizer BASF CHIMASSORB 944 1 part, flow aid polyethylene wax 1 part, release agent oleic acid amide 1 part, lubricant calcium stearate 1 part, aluminum oxide 3 parts, titanium dioxide 2.5 parts, carbon fiber 0.5 parts, 0.1 parts of coupling agent.

[0061] The preparation method of the modified resin for the above-mentioned composite backing plate is:

[0062] (1) Take the coupling agent and dilute it with absolute ethanol at a ratio of 12:1 (volume ratio), pour the weighed filler into the diluted coupling agent solution, stir for 10 minutes, and then put it into the drying equipment, Dry at 80°C for 6 hours, take it out, grind it into a powder with a particle size of 5000 mesh, and place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com