Manufacturing method of carbon fiber reinforced HDPE double-wall winding pipe

A production method and carbon fiber technology, applied in the field of pipes, can solve the problems of limited glass fiber and inorganic powder fillers, poor flexibility of pipe rings, low tensile strength, etc., and achieve improved environmental stress cracking resistance and high temperature resistance, high Excellent environmental stress crack resistance and interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

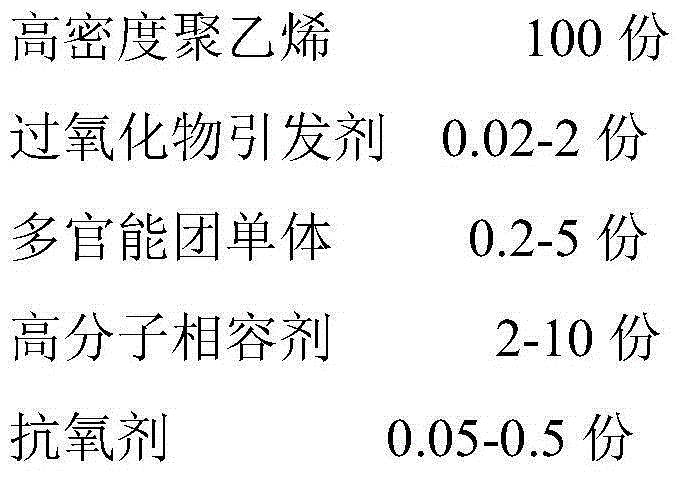

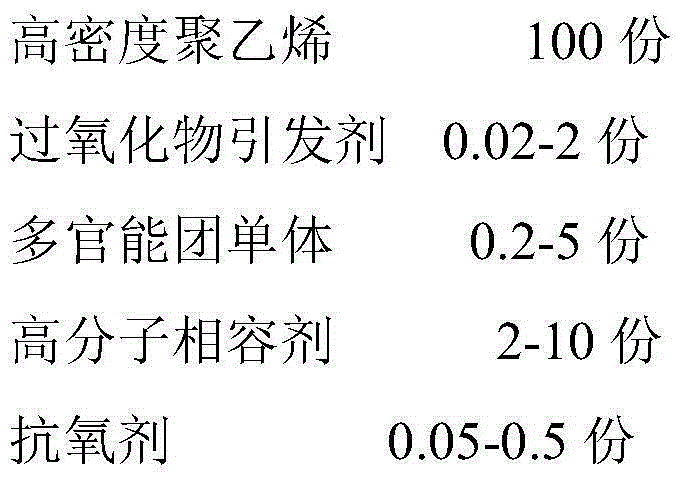

[0025] The high-density polyethylene compound is prepared from the following materials in parts by weight: 100 parts of high-density polyethylene, 1 part of 2,5-dimethyl-2,5 di-tert-butyl peroxide, 3 parts of thiourea, acrylic acid 5 parts of grafted polyethylene, 0.3 parts of dilauryl thiodipropionate; in addition, modified carbon fibers were prepared from the following substances in parts by weight: 100 parts of carbon fibers, and 3 parts of vinyltriethoxysilane.

[0026] During production, the high-density polyethylene compound and modified carbon fiber are reacted and co-extruded through a twin-screw extruder at a weight ratio of 90:10, extruded through a die and vacuum-shaped to obtain a carbon fiber-reinforced HDPE hollow square pipe; Then the carbon fiber reinforced HDPE hollow square pipe is manufactured into a carbon fiber reinforced HDPE double-walled winding pipe through spiral winding and plastic hot melt adhesive welding. The length-to-diameter ratio of the twin-s...

Embodiment 2

[0028] The high-density polyethylene compound is prepared from the following materials in parts by weight: 100 parts of high-density polyethylene, 2 parts of dicumyl peroxide, 0.5 part of diallyl maleate, glycidyl methacrylate graft poly 10 parts of ethylene, 0.05 part of tris(2,4-di-tert-butylphenyl) phosphite; in addition, modified carbon fiber was prepared from the following substances in parts by weight: 100 parts of carbon fiber, 0.5 part of vinyltrimethoxysilane.

[0029] During production, the high-density polyethylene compound and the modified carbon fiber are reacted and co-extruded through a twin-screw extruder at a weight ratio of 80:20, extruded through a die and vacuum-shaped to obtain a carbon fiber-reinforced HDPE hollow square pipe; Then the carbon fiber reinforced HDPE hollow square pipe is manufactured into a carbon fiber reinforced HDPE double-walled winding pipe through spiral winding and plastic hot melt adhesive welding.

Embodiment 3

[0031] The high-density polyethylene compound is prepared from the following materials in parts by weight: 100 parts of high-density polyethylene, 0.02 part of di-tert-butyl perphthalate, 5 parts of divinylbenzene, and 2 parts of maleic anhydride grafted polypropylene , 0.5 parts of tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythyl alcohol ester; In addition, modified carbon fiber is prepared from the following materials in parts by weight: 100 parts of carbon fiber, vinyl 5 parts of tris(2-methoxyethoxy)silane.

[0032] During production, the high-density polyethylene compound and the modified carbon fiber are first reacted and co-extruded through a twin-screw extruder at a weight ratio of 99.9:0.1, extruded through a die and vacuum-shaped to obtain a carbon fiber-reinforced HDPE hollow square pipe; Then the carbon fiber reinforced HDPE hollow square pipe is manufactured into a carbon fiber reinforced HDPE double-walled winding pipe through spiral windin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com