Cable sheath material for wind power generation

A cable sheath material, non-crystalline technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor physical and mechanical properties of the sheath, achieve good flexibility, improve dispersion uniformity, and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

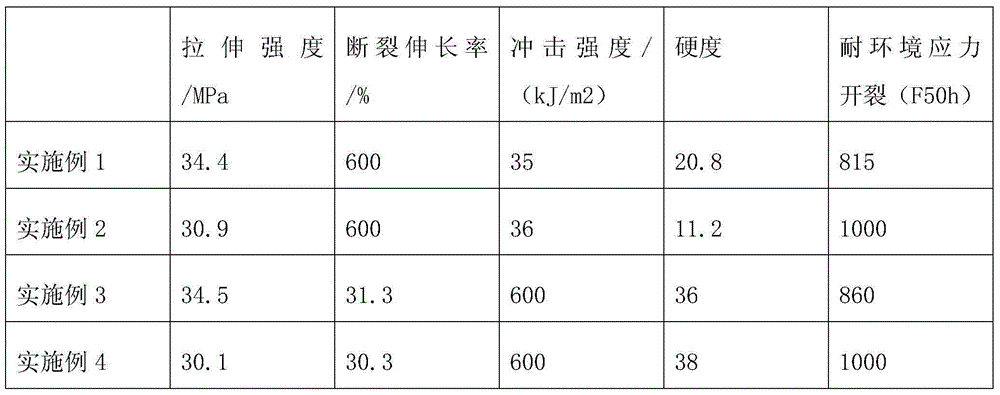

Examples

Embodiment 1

[0015] A cable sheathing material for wind power generation, consisting of the following materials in parts by weight: 70 parts of HDPE, 30 parts of LLDPE, 20 parts of a mixture of amorphous polyolefin thermoplastic elastomer and chlorinated polyethylene elastomer, 20 parts of acetylene carbon black, 15 parts of cold-resistant plasticizer, 30 parts of reinforcing filler, 10 parts of nano-sized zinc oxide and magnesium oxide, 2 parts of cross-linking agent, 2 parts of auxiliary cross-linking agent, 1 part of polytrimethyldihydroquinoline, inorganic resistance Fuel agent 10 parts.

Embodiment 2

[0017] A cable sheath material for wind power generation, consisting of the following materials in parts by weight: 75 parts of HDPE, 25 parts of LLDPE, 25 parts of a mixture of amorphous polyolefin thermoplastic elastomer and chlorinated polyethylene elastomer, 25 parts of acetylene carbon black, 20 parts of cold-resistant plasticizer, 30 parts of reinforcing filler, 5 parts of nano-sized zinc oxide and magnesium oxide, 3 parts of cross-linking agent, 3 parts of auxiliary cross-linking agent, 2 parts of polytrimethyldihydroquinoline, inorganic barrier Fuel 15 parts.

Embodiment 3

[0019] A cable sheathing material for wind power generation, consisting of the following materials in parts by weight: 85 parts of HDPE, 15 parts of EVA, 20 parts of a mixture of amorphous polyolefin thermoplastic elastomer and chlorinated polyethylene elastomer, 20 parts of acetylene carbon black, 15 parts of cold-resistant plasticizer, 30 parts of reinforcing filler, 10 parts of nano-sized zinc oxide and magnesium oxide, 2 parts of cross-linking agent, 2 parts of auxiliary cross-linking agent, 3 parts of polytrimethyldihydroquinoline, inorganic barrier 20 parts of fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com