Metallocene polypropylene modified material for corrosion-inhibiting coating of steel pipe and preparation method and application thereof

A metallocene polypropylene and anti-corrosion coating technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of using nano-reinforced materials and other problems that are not mentioned, and achieve outstanding UV aging resistance and thermal resistance. Oxygen aging performance, excellent impact resistance, and the effect of wide coating processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Formula: 90wt% metallocene polypropylene (mPP), 5.3wt% block copolymerized polypropylene, 0.3wt% metal soap thermal oxygen stabilizer, 0.5wt% benzophenone ultraviolet absorber and hindered methyl piperidine Light stabilizer, 0.3wt% titanate coupling agent and stearic acid amide dispersant, 0.6wt% nano CaCO 3 , 3wt% black masterbatch.

[0027] The above-mentioned components are extruded and granulated by plasticizing and blending process with a twin-screw extruder, the length-to-diameter ratio of the extruder is L / D=40:1, and the processing temperature is 160-210°C.

Embodiment 2

[0029] Formula: 80wt% metallocene polypropylene (mPP), 17.3wt% block copolymer polypropylene, 0.5wt% metal soap thermal oxygen stabilizer, 0.7wt% chlorinated benzotriazole ultraviolet absorber and hindered phosphorous acid Ester light stabilizer, 0.5wt% polypropylene dispersant, 1.0wt% nano talcum powder.

[0030] The above-mentioned components are extruded and granulated by plasticizing and blending process with a twin-screw extruder, the length-to-diameter ratio of the extruder is L / D=40:1, and the processing temperature is 160-210°C.

Embodiment 3

[0032] Formula: 75wt% metallocene polypropylene (mPP), 21.4wt% block copolymer polypropylene and random copolymer polypropylene mixture, 0.6wt% benzofuranone thermal oxygen stabilizer, 0.8wt% benzophenone ultraviolet Absorbent and hindered methyl piperidine light stabilizer, 0.7wt% silane coupling agent, 1.3wt% nano TiO 2 .

[0033] The above-mentioned components are extruded and granulated by plasticizing and blending process with a twin-screw extruder, the length-to-diameter ratio of the extruder is L / D=40:1, and the processing temperature is 160-210°C.

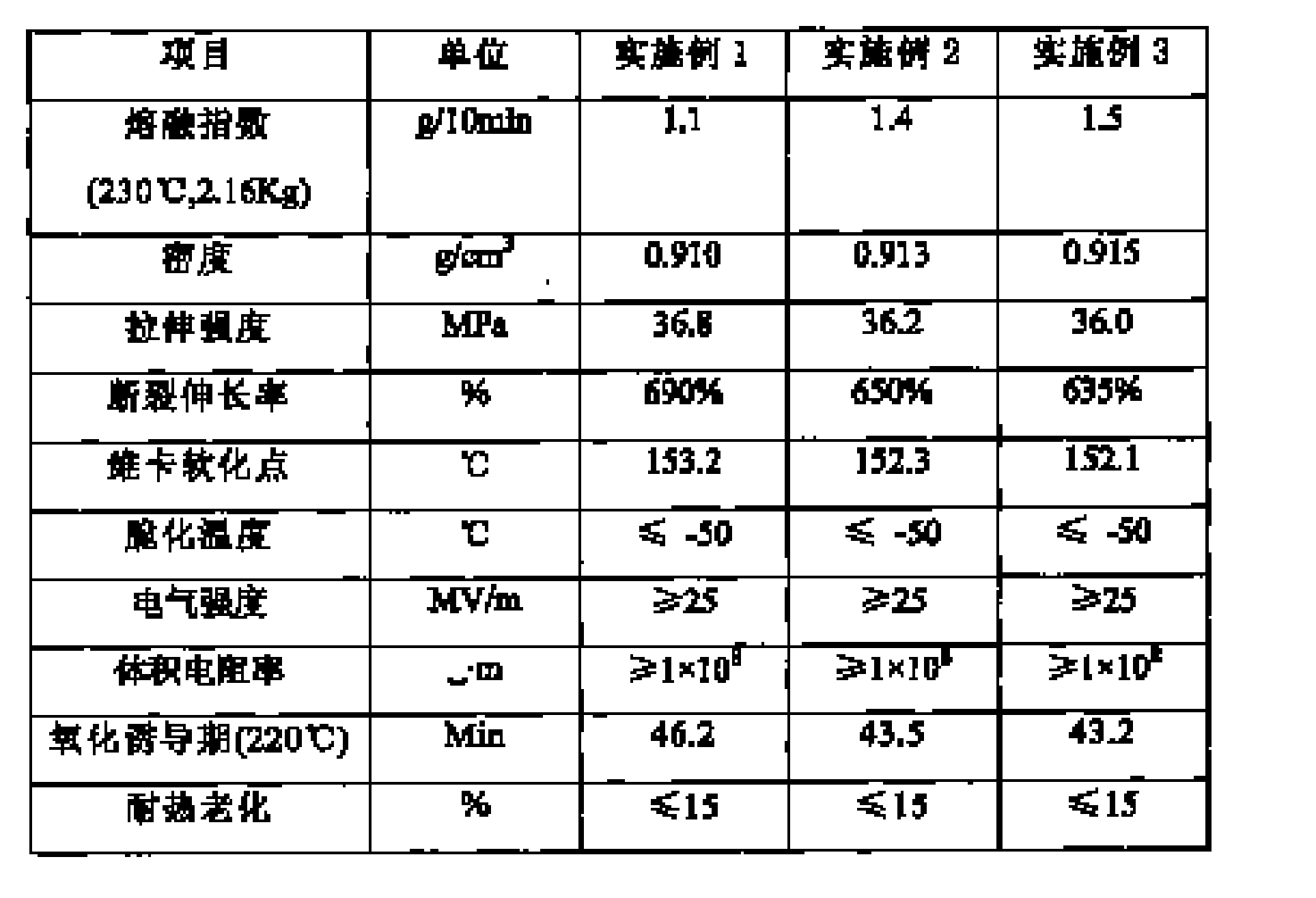

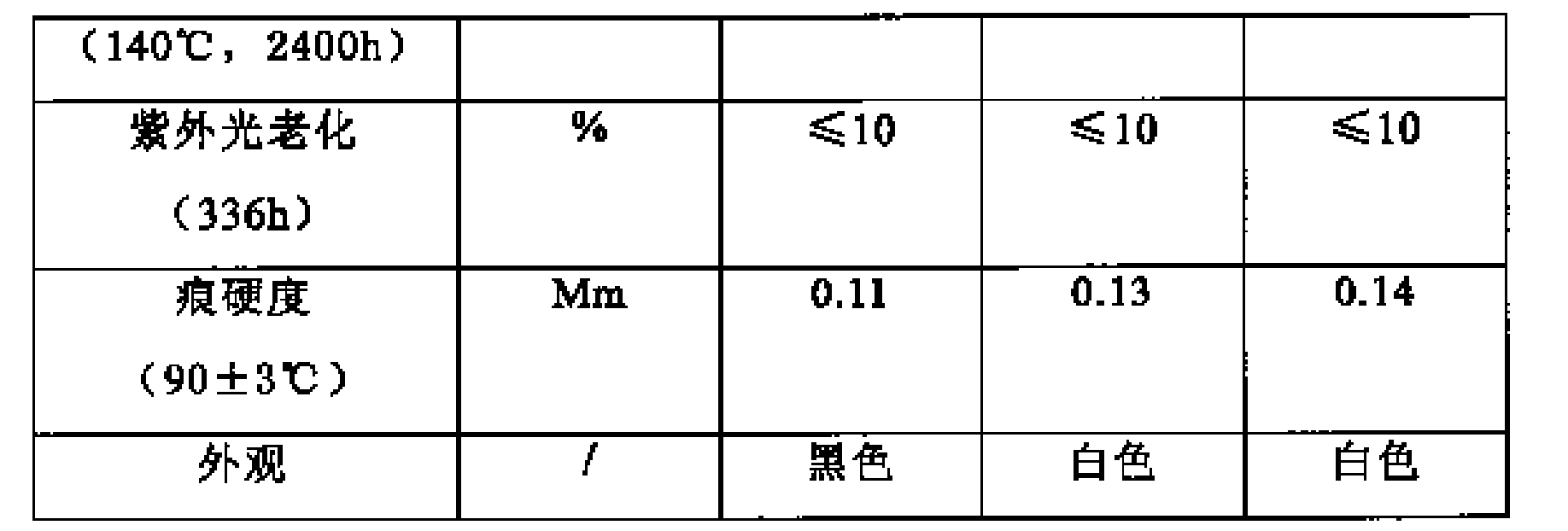

[0034] The properties of the products of Examples 1-3 are shown in Table 1.

[0035] Table 1

[0036]

[0037]

[0038]It can be seen from the table that the products of Examples 1-3 all have outstanding thermal oxygen resistance, light aging performance and excellent comprehensive performance, which can greatly prolong the service life of anti-corrosion steel pipes and broaden the service environment of anti-corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com