Polyethylene with polyethylene glycol with increased environmental stress crack resistance

A technology resistant to environmental stress and polyethylene glycol, which can be used in applications, household appliances, and other household appliances, and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

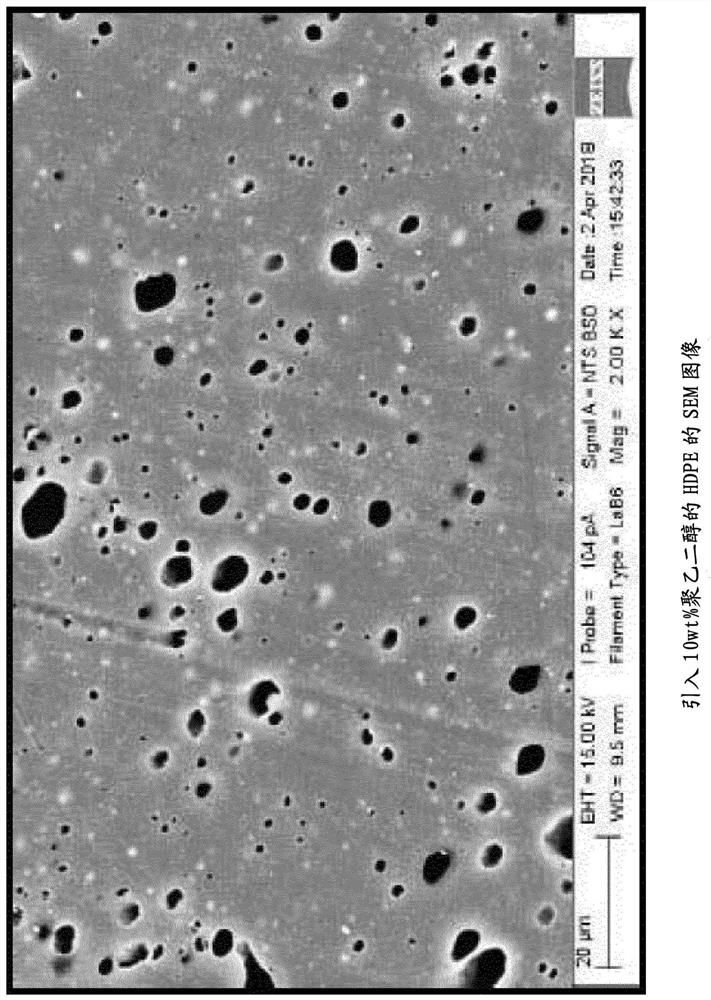

Image

Examples

Embodiment 1

[0050] PEG with a MW of 20000 (ie, PEG-20000) was dry-blended with commercially available HDPE in different amounts ranging from 2.5 wt% to 15 wt% as powder or flakes. The HDPE used is HDPE CC253 and HDPECC254. HDPE CC253 is a unimodal HDPE with an MFR of 1.8dg / min and a density of 952kg / m at 190°C and 2.16kg 3 . HDPE CC254 is a bimodal HDPE with an MFR of 2.1dg / min and a density of 953kg / m at 190°C and 2.16kg 3 . For comparison, pure HDPE without any PEG-20000 and HDPE with low molecular weight PEG (ie PEG-1500, MW=1500) were also tested. The different mixtures were fed into the hopper of a ZSK-25 mm six-barrel twin-screw extruder with an L / D ratio of 25:1. The run parameters used are listed in Table 1 below:

[0051] Table 1

[0052] Barrel-1 (connected to the hopper) Temperature = 160°C Barrel-2 Temperature = 185°C Barrel-3 Temperature = 195°C Barrel-4 Temperature = 195°C Barrel-5 Temperature = 200°C Barrel-6 (die) ...

Embodiment 2

[0055] The pellets obtained after melt extrusion of Example 1 were compression molded at a temperature of 195° C. to 210° C. into a sheet with a thickness of 1.85 mm to 1.95 mm, and the holding time was 5 min and the cooling time was 5 min. There were no clearly visible inhomogeneities in the compressed tablets. The ESCR performance of the compression molded sheets (both neat and formulated HDPE) was then evaluated according to ASTM D 1693-15B (Bell Test).

[0056] The compression molded sheet was cut into test specimens with a length of 38 mm and a width of 13 mm. A notch of 0.5 mm depth was made at the center of each test sample, after which it was stored in a conditioned environment at 23° C. and 55% RH humidity. The conditioned sample is subjected to a U-bend with the aid of a clamp. For each of the pure and formulated HDPE materials, 10 bent samples were placed on aluminum sample holders, followed by a sample filled with Igepol CO-630 (nonylphenoxypoly(ethyleneoxy)ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com