Anti-termite adhesive tape substrate of polyethylene pipeline and preparation method of substrate

A polyethylene and anti-termite technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of poor thermal stability, no anti-termite, short service life, etc., to achieve heat aging resistance and anti-aging The effect of improving abrasiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

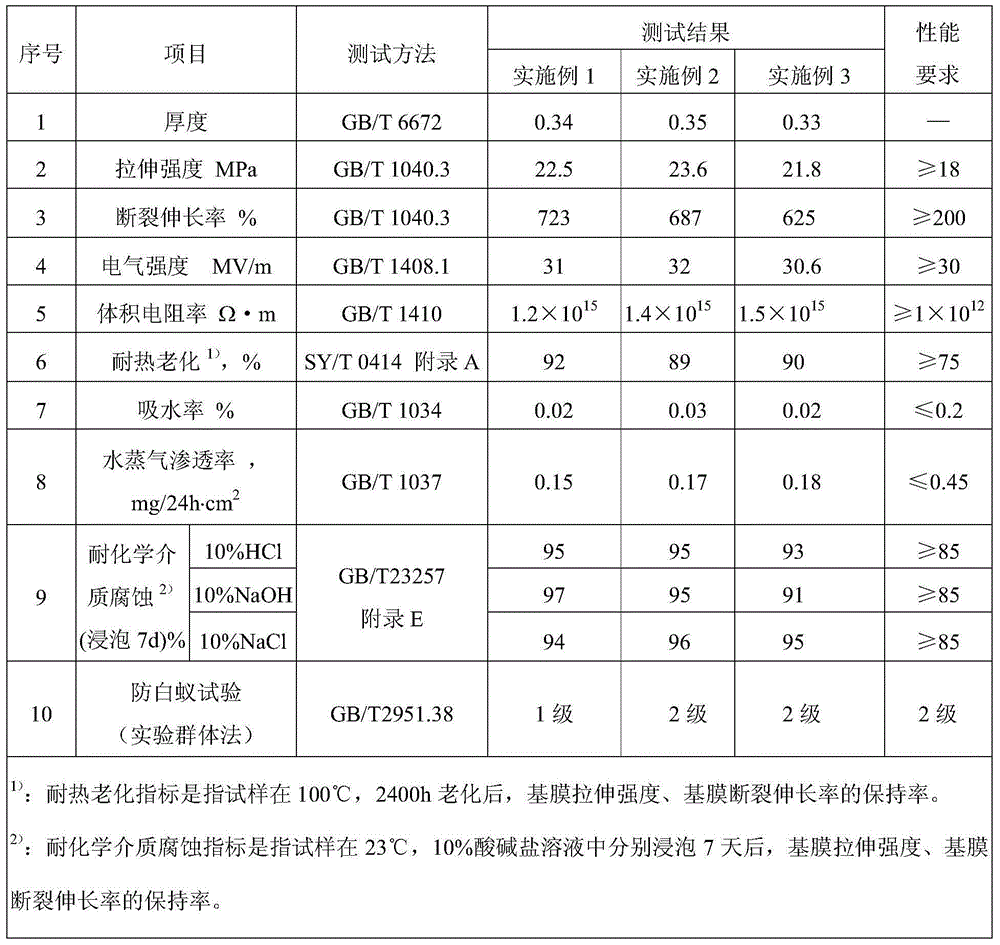

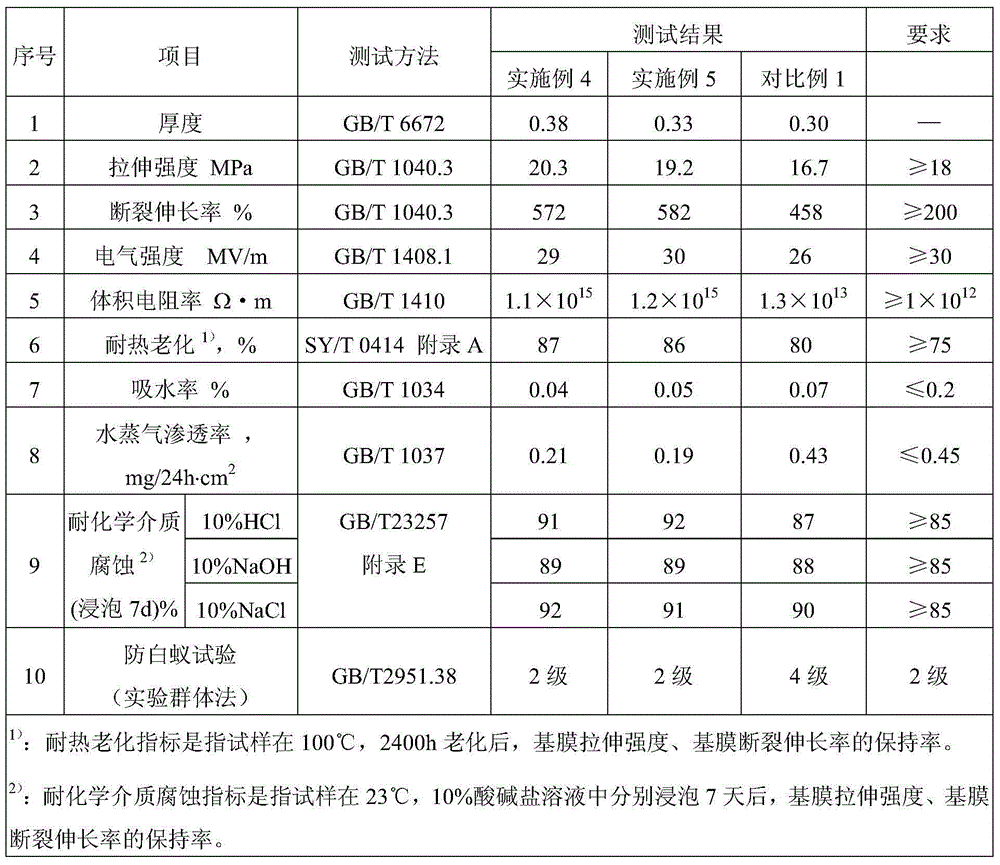

Embodiment 1

[0035] According to mass percentage, the formula is: ultra-low density polyethylene (DFDA-1095NT) 70%; maleic anhydride modified linear low density polyethylene (208) 10%; medium density polyethylene (3321C) 8.0%; high density polyethylene Ethylene (5300B) 7.0%; primary antioxidant 10101.0%; secondary antioxidant DSTDP 1.0%; black masterbatch 1.0%; bifenthrin 1.0%, permethrin 1.0%.

[0036] Follow the steps below to prepare:

[0037] Step 1: Weigh each component according to the formula, mix uniformly and pass through a twin-screw extruder to extrude granulated material;

[0038] Step 2: Add the pellets obtained in Step 1 into a single-screw extruder, extrude and granulate to obtain substrate pellets, and the barrel of the single-screw extruder is sequentially set with seven stages of heating from the feed port to the die head zones, the temperatures in each zone are: 100±10°C, 120±10°C, 140±10°C, 160±10°C, 160±10°C, 180±10°C and 180±10°C; the single-screw extruder Die head ...

Embodiment 2

[0041] According to mass percentage, the formula is: ultra low density polyethylene (VL200) 60%; maleic anhydride modified linear low density polyethylene (208) 15%; medium density polyethylene (3802) 15%; high density polyethylene ( 5621D) 5%; primary antioxidant (1010) 1.0%; secondary antioxidant (DSTDP) 1.0%: black mother 2%; deltamethrin 1.0%.

[0042] Follow the steps below to prepare:

[0043] Step 1: Weigh each component according to the formula, mix uniformly and pass through a twin-screw extruder to extrude granulated material;

[0044] Step 2: Add the pellets obtained in Step 1 into a single-screw extruder, extrude and granulate to obtain substrate pellets, and the barrel of the single-screw extruder is sequentially set with seven stages of heating from the feed port to the die head zones, the temperatures in each zone are: 100±10°C, 120±10°C, 140±10°C, 160±10°C, 160±10°C, 180±10°C and 180±10°C; the single-screw extruder Die head temperature: 180±20°C.

[0045] St...

Embodiment 3

[0047] According to mass percentage, the formula is: ultra-low density polyethylene (DFDA-1098NT) 55%; maleic anhydride modified linear low density polyethylene (208) 17%; medium density polyethylene (3721C) 15%; high density polyethylene Ethylene (TR-144) 9.0%; primary antioxidant (1010) 0.5%; secondary antioxidant (DSTDP) 0.5%: black mother 1.5%; fenvalerate 1.5%.

[0048] Follow the steps below to prepare:

[0049] Step 1: Weigh each component according to the formula, mix uniformly and pass through a twin-screw extruder to extrude granulated material;

[0050] Step 2: Add the pellets obtained in Step 1 into a single-screw extruder, extrude and granulate to obtain substrate pellets, and the barrel of the single-screw extruder is sequentially set with seven stages of heating from the feed port to the die head zones, the temperatures in each zone are: 110±10°C, 130±10°C, 150±10°C, 170±10°C, 170±10°C, 190±10°C and 190±10°C; the single-screw extruder Die head temperature: 190...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com