Long-chain branched high-density polyethylene material resisting environmental stress cracking and preparation method thereof

A high-density polyethylene, environmental stress-resistant technology, applied in the field of polymer materials, can solve the problems of limiting the application range of high-density polyethylene, crystal grains are prone to slip, environmental stress cracking, etc., and achieve excellent environmental stress cracking resistance. , The effect of improving environmental stress crack resistance and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

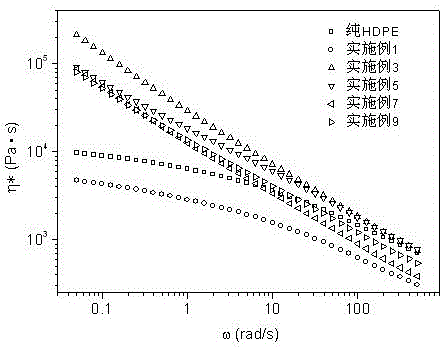

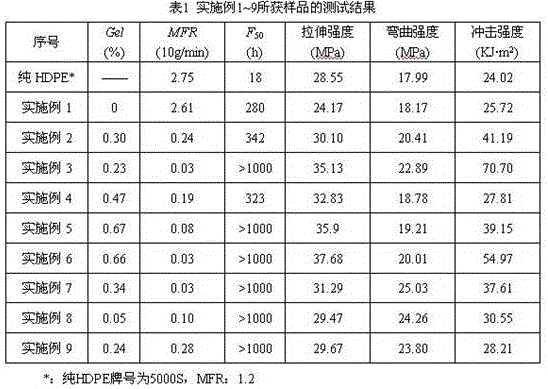

[0017] Embodiment 1 of the present invention: long-chain branched high-density polyethylene material resistant to environmental stress cracking, calculated in parts by mass, including 100 parts of high-density polyethylene (brand name: HD5218EA, MFR: 20), 0.05 parts of dimethyl Zinc dithiocarbamate, 1 part of neopentyl glycol diacrylate, 0.03 part of dicumyl peroxide and 0.05 part of antioxidant B215.

[0018] The preparation method of the long-chain branched high-density polyethylene material resistant to environmental stress cracking comprises high-density polyethylene, neopentyl glycol diacrylate, zinc dimethyl dithiocarbamate, over After dicumyl oxide and antioxidant B215 are fully mixed and uniform, they are added to a Φ65 twin-screw extruder for melt blending. The main engine speed is 400r / min, the reaction time is 2min, the temperature is 170°C, and the product is granulated. Some samples were taken for performance testing, and the results are shown in Table 1.

Embodiment 2

[0019] Example 2 of the present invention: long-chain branched high-density polyethylene material resistant to environmental stress cracking, calculated in parts by mass, including 100 parts of high-density polyethylene (brand name HD5218EA, MFR: 20), 0.15 parts of diisobutylene Dithiocarbamate zinc salt, 1 part of neopentyl glycol diacrylate, 0.05 part of dicumyl peroxide and 0.1 part of antioxidant B215.

[0020] The preparation method of the long-chain branched high-density polyethylene material resistant to environmental stress cracking comprises high-density polyethylene, neopentyl glycol diacrylate, zinc diisobutyldithiocarbamate, After dicumyl peroxide and antioxidant B215 are fully mixed, they are added to a Φ60 single-screw extruder for melt blending. The main engine speed is 60r / min, the reaction time is 4min, the temperature is 180°C, and the product is granulated. Some samples were taken for performance testing, and the results are shown in Table 1.

Embodiment 3

[0021] Example 3 of the present invention: long-chain branched high-density polyethylene material resistant to environmental stress cracking, calculated in parts by mass, including 100 parts of high-density polyethylene (grade 5000S, MFR: 1.2), 0.1 part of dimethyl Zinc dithiocarbamate, 1 part of neopentyl glycol diacrylate, 0.1 part of dicumyl peroxide and 0.2 part of antioxidant 1010.

[0022] The preparation method of the long-chain branched high-density polyethylene material resistant to environmental stress cracking comprises high-density polyethylene, neopentyl glycol diacrylate, zinc dimethyl dithiocarbamate, over After dicumyl oxide and antioxidant 1010 are fully mixed and uniform, they are added to a Φ65 single-screw extruder for melt blending. The main engine speed is 80r / min, the reaction time is 3min, the temperature is 170°C, and the product is granulated. . Some samples were taken for performance testing, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com