Ship special for pipeline laying in shoal area

A technology for laying pipelines and special ships, which is used in pipeline laying and maintenance, pipeline laying ships, machinery and equipment, etc., to achieve the effect of improving construction efficiency and having a simple and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

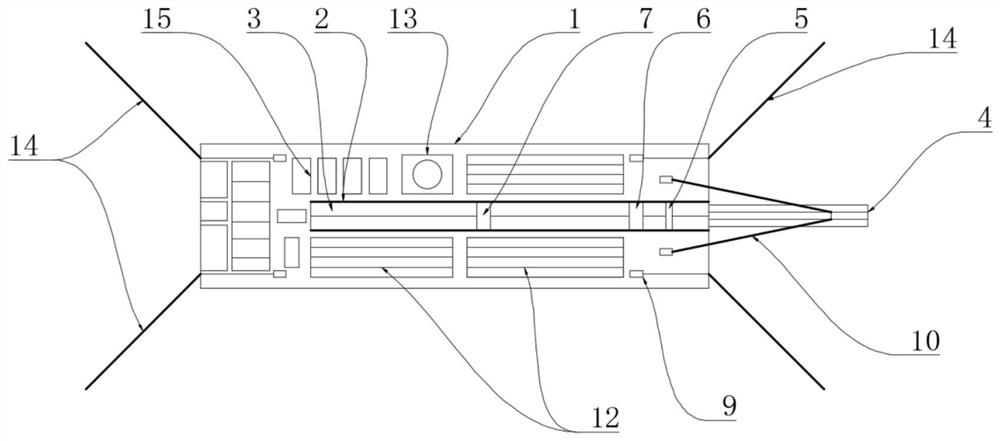

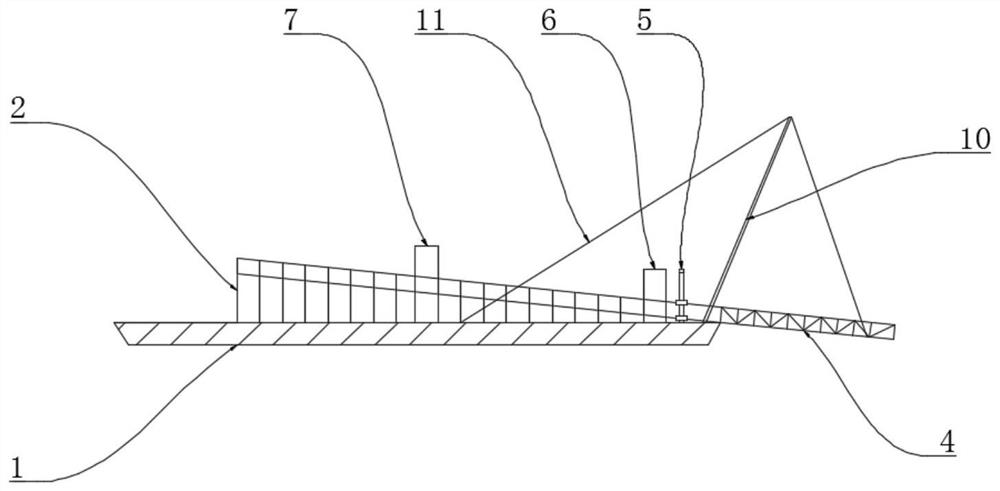

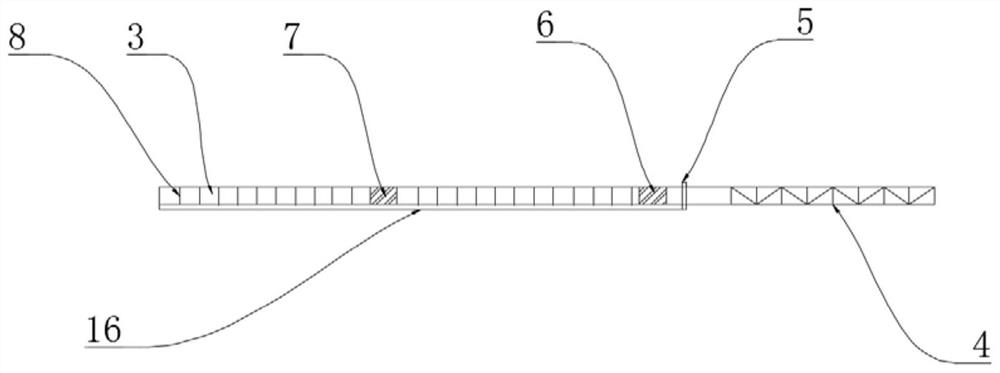

[0034] Embodiment 1, with reference to figure 1 , combined with figure 2 , image 3 , a special vessel for laying pipelines in the shoal area, including a hull 1 on which pipeline laying tools are fixed;

[0035] The pipeline laying tooling includes a guide bracket 2, on which a guide chute 3 arranged along the direction of the keel of the hull 1 is provided, and the guide chute 3 is arranged downwardly from the rear end to the front end and extends downward to the bottom of the hull 1. The end; in front of the guide bracket 2, a custodian bracket 4 protruding from the hull 1 is provided, and one end of the custodial bracket 4 is hinged with the hull 1;

[0036] The hull 1 is provided with a lowering mechanism for lowering the hosting bracket 4 so that it corresponds to the inclination angle of the guide chute 3;

[0037] A pipe clamping device 5 is fixedly installed between the guide bracket 2 and the hosting bracket 4, and the clamping center line of the pipeline clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com