L-shaped shallow sea pipeline laying process

A pipeline laying and pipeline technology, which is applied in the field of L-shaped shallow sea pipeline laying technology, can solve the problems of low construction efficiency of towed pipeline laying construction technology, complex and changeable construction operation environment, large influence of wind and wave conditions, etc., and achieves construction operation conditions. Stable and reliable, improving the efficiency of pipeline laying, the effect of long construction window period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

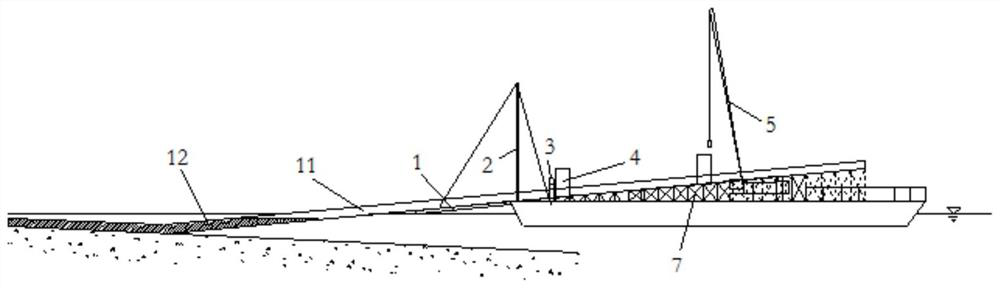

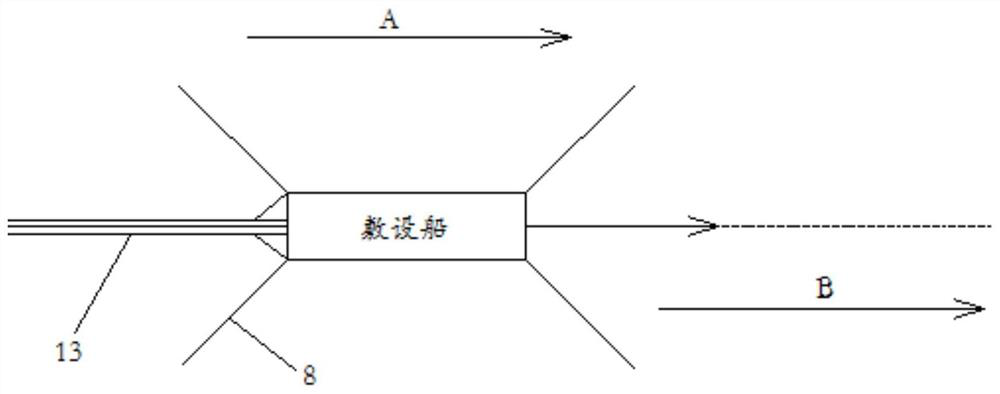

[0036] Embodiment 1, with reference to figure 1 , a kind of " L " type shallow sea pipeline laying technology provided by the present invention, by adopting the shallow sea area pipeline laying special vessel to carry out pipeline laying installation work, use windlass 9 installed on the barge to control the construction route of pipeline laying.

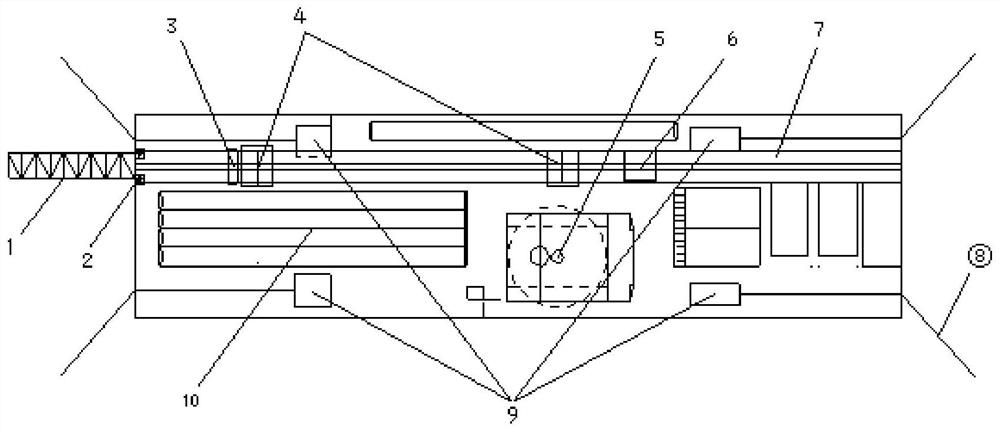

[0037] The special ship for pipeline laying in shallow sea area includes a hull, on which a guide frame 7 is fixed, on which a track is arranged along the direction of the hull keel, and in front of the guide frame 7 is provided with a stinger 1 protruding from the hull. The rear end of the frame 1 is hinged with the front end of the hull; a clamper 3 is fixedly installed between the guide frame 7 and the stinger frame 1, and the clamper 3 can realize the clamping and release of the pipeline 11, thereby controlling the flow of the pipeline 11. speed. A welding platform 4 for butt jointing of pipelines 11 is provided on the guide fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com