Heated offshore pipeline and method of manufacturing

A pipeline and pipe technology, which is applied to heated submarine pipelines and their manufacturing fields, can solve problems such as the consumption of steel windings or ground electrodes, and achieve the effect of reducing the amount of steel used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

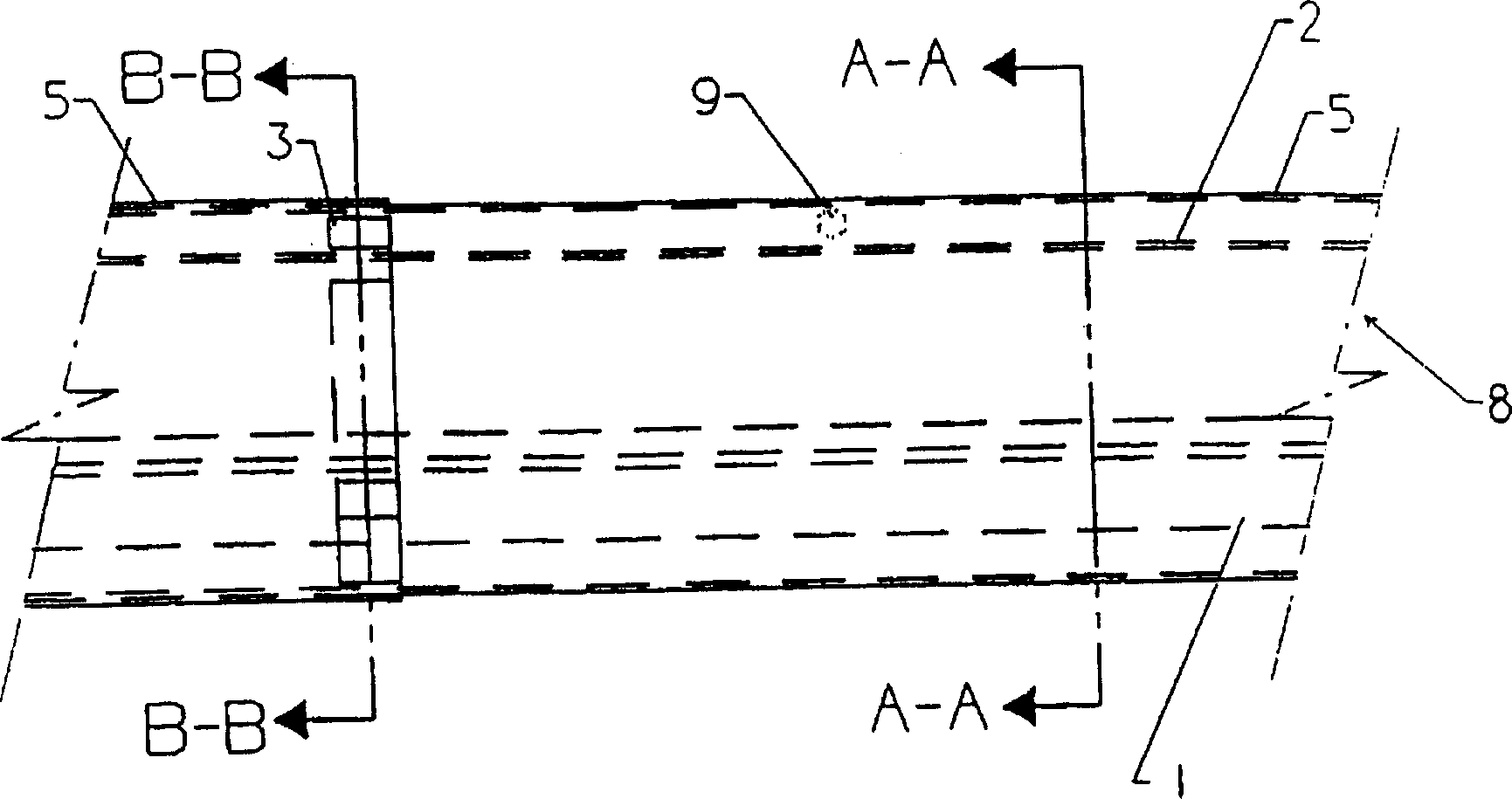

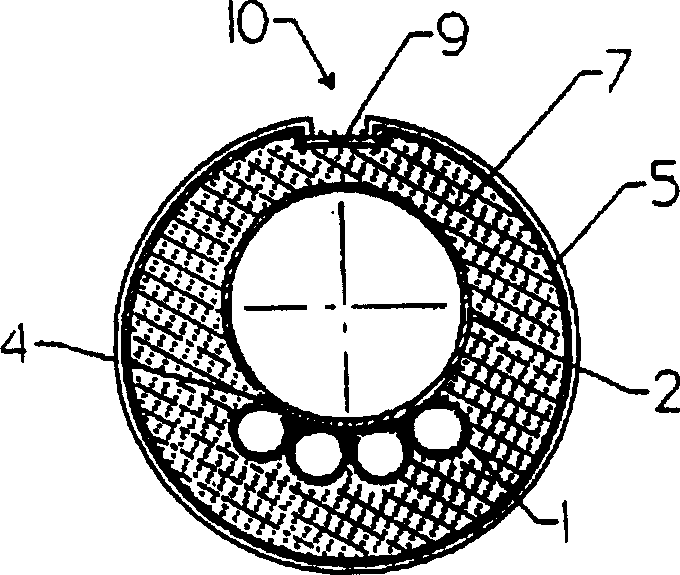

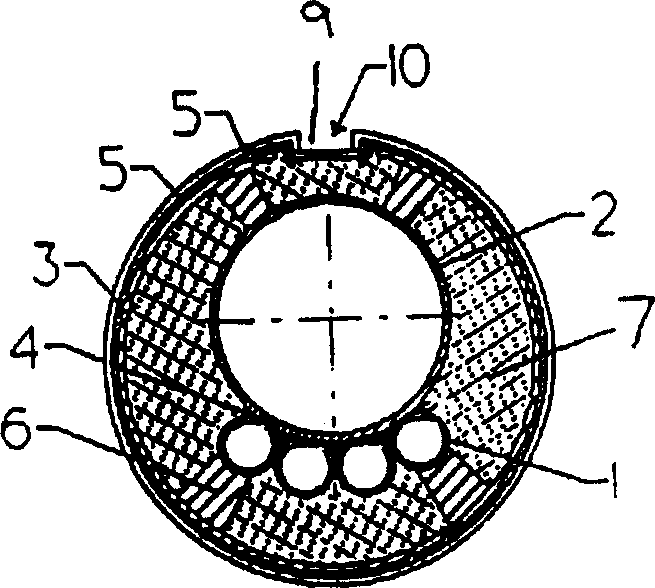

[0041] Figure 1-3 The tubing bundle is shown in a circular die. If such an arrangement is made on a flat surface, such as for towed tube bundles, such as Figure 15 As shown, some or all of the spacers can be formed to extend across the cross-section of the mold so that the mold is divided into short segments which can be top filled with insulating material. Such spacers such as Figure 15 and 16 shown. As shown in Figures 7, 10, 11, it is possible, for example, to cast the insulating material when the pipeline is inclined, but this is not required.

[0042] Such as figure 1 As shown, continuous or discontinuous pipes are used to reduce the underwater weight of pipelines or pipe bundles with wood and other lightweight materials including particles dispersed therein which are lighter than insulating compounds. If the lightweight material contains porosity, it should be strong enough to resist the static pressure of any seawater passing to it through the insulation. It d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com