Control system and control method for synchronous positioning of subsea pipeline transverse moving trolley

A technology of traversing the trolley and synchronous positioning, which is applied in the control/adjustment system, two-dimensional position/channel control, vehicle position/route/altitude control, etc., which can solve the problem of frequent use, accuracy affecting cumulative errors, and increasing equipment operation difficulty. Problems such as the cost of offshore pipe laying operations to achieve the effect of improving reliability and work efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A control system for synchronous positioning of a sea pipe traversing trolley, the control system for synchronous positioning of a sea pipe traversing trolley includes an electrical control module, a hydraulic control module, and a drive unit;

[0033] The drive unit includes at least two hydraulic motors installed on the traverse trolley;

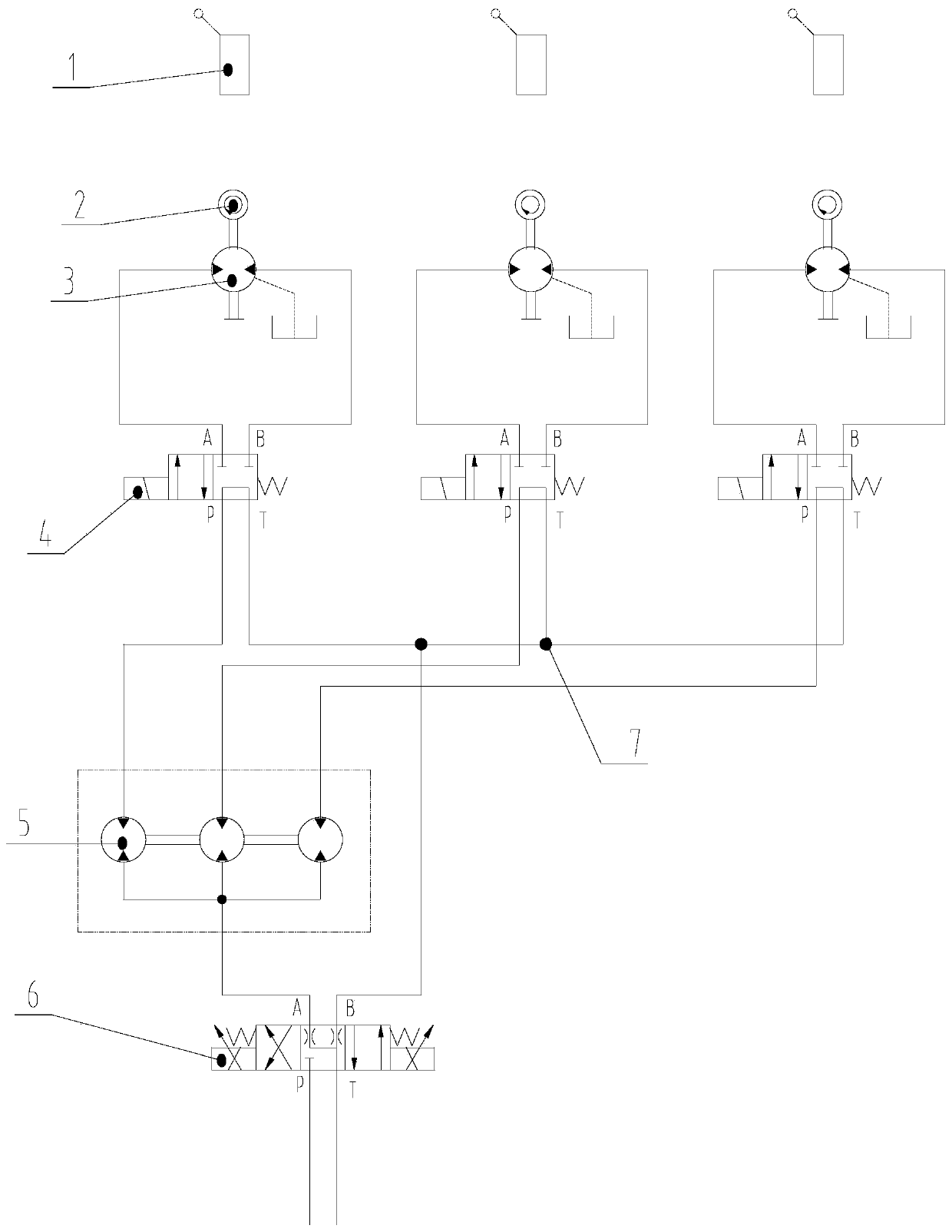

[0034] The hydraulic control module includes an electric proportional directional valve, a solenoid valve, a hydraulic flow divider, and supporting hydraulic pipelines and hydraulic accessories. The electric proportional directional valve is connected to the solenoid valve through a hydraulic flow divider, and the solenoid valve controls the the hydraulic motor;

[0035] The electrical control module includes a control unit, a master switch and a sensor group;

[0036] The control unit includes a PLC and a touch screen, wherein the input terminal of the PLC collects the data of the sensor group and the master switch, and then accor...

specific Embodiment approach

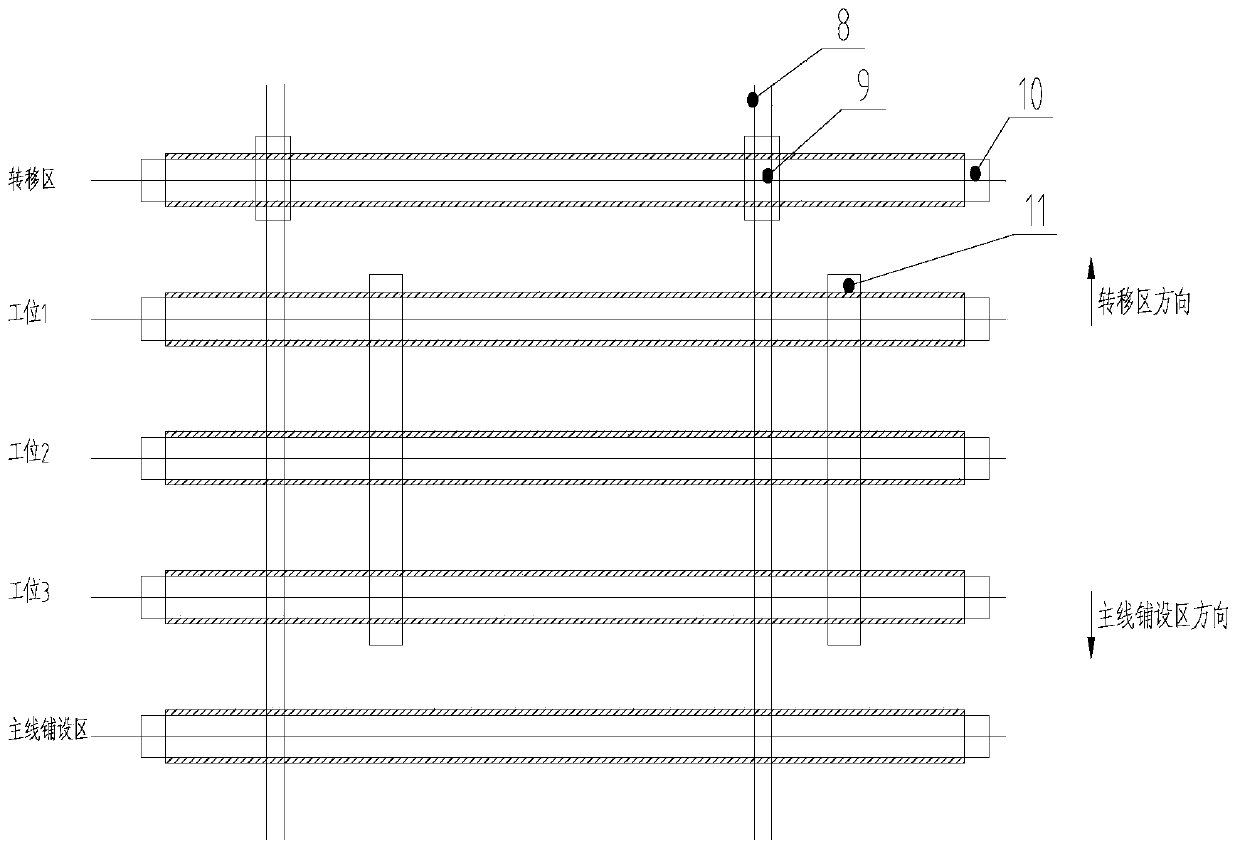

[0039] Specific embodiments: a synchronous positioning control system for a sea pipe traversing trolley, which is composed of an electrical control module, a hydraulic control module and a drive unit; the drive unit includes three hydraulic motors 3; the hydraulic control module includes an electric proportional reversing valve 6, Solenoid valve 4, hydraulic diverter 5, and supporting hydraulic pipeline 7 and hydraulic accessories; the electrical control module includes a control unit, a master switch and a sensor group; The group includes an encoder 2 and a limit switch 1, wherein the encoder 2 is used to detect the speed signal of each hydraulic motor 3, and obtain the accurate actual position signal of each traverse trolley 9 through continuous real-time pulse numbers, The limit switch 1 is used for the initial zero position verification signal of each traversing trolley 9; the control system adopts the control method combining electromechanical and hydraulic, and the contro...

Embodiment 2

[0044] A control method for synchronous positioning of a sea pipe traversing trolley. The control method for synchronous positioning of a sea pipe traversing trolley uses the control system for synchronous positioning of the sea pipe traversing trolley described above. The control method of the synchronous positioning of moving dolly comprises the following steps:

[0045] Step 1: When using for the first time, use the limit switch to detect the initial zero parameter value of the traversing trolley;

[0046]Step 2: The touch screen sets the control parameter value, and the operator operates the master switch to send out the control demand parameter value;

[0047] Step 3: the PLC collects and acquires the parameter values of the encoder and the master switch, and compares them with the control parameter values set by the touch screen to generate a control instruction;

[0048] Step 4: adjusting the control signals for controlling the electric proportional reversing valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com