Marine pipe laying system method and hoisting device

A pipeline laying and submarine pipeline technology, which is applied in pipeline laying and maintenance, cranes, mechanical equipment, etc., can solve the problems of slow upward movement of moving blocks and limit the length of pipeline laying, and achieve the effect of saving time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

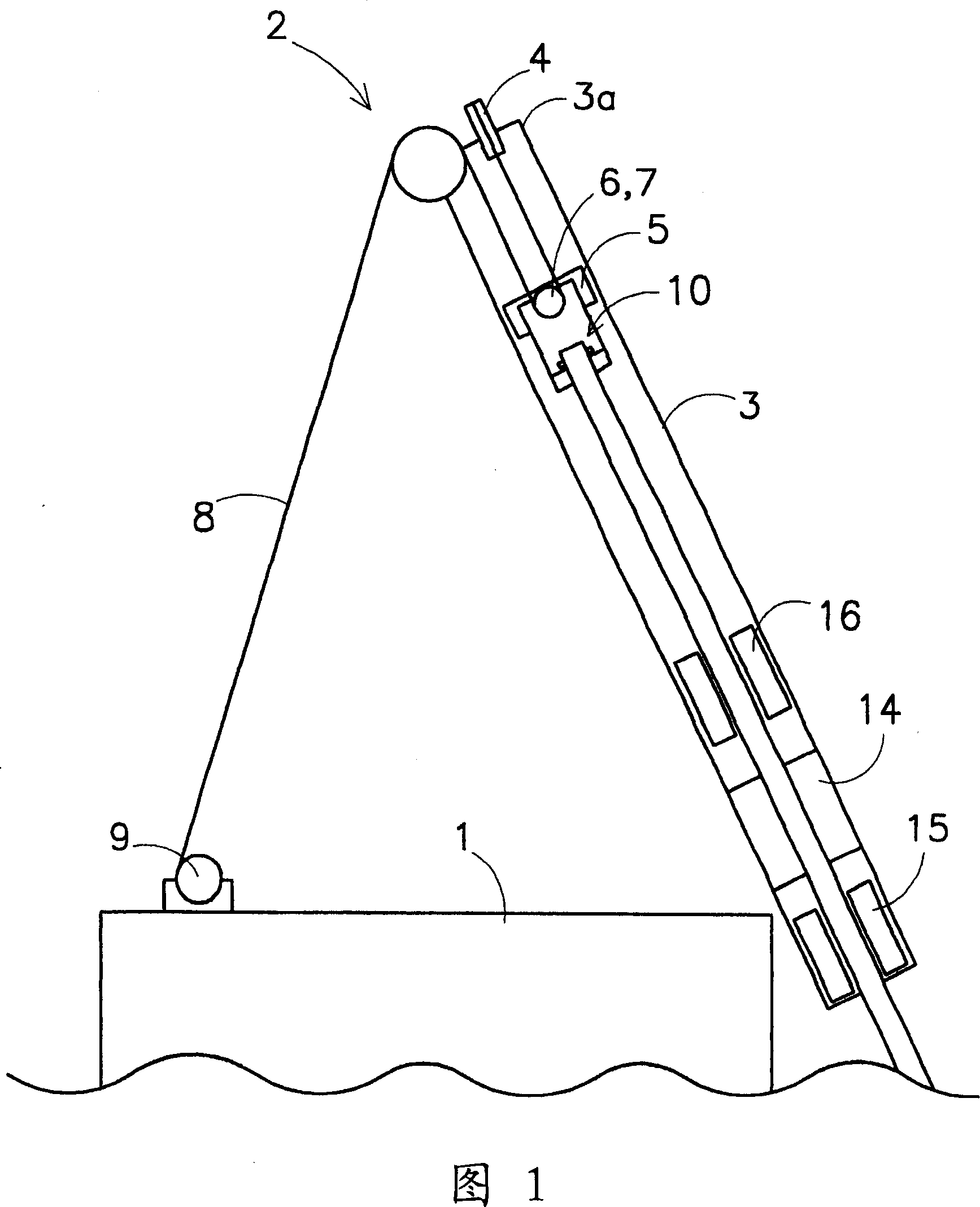

[0062]The system involves a vertical or near-vertical pipelaying technique, such as the J-lay technique, for introducing a pipe from a ship into the water in a substantially vertical orientation. The system provides an improved pipeline laying system for vertical or near vertical marine pipeline laying, especially deep water pipeline laying.

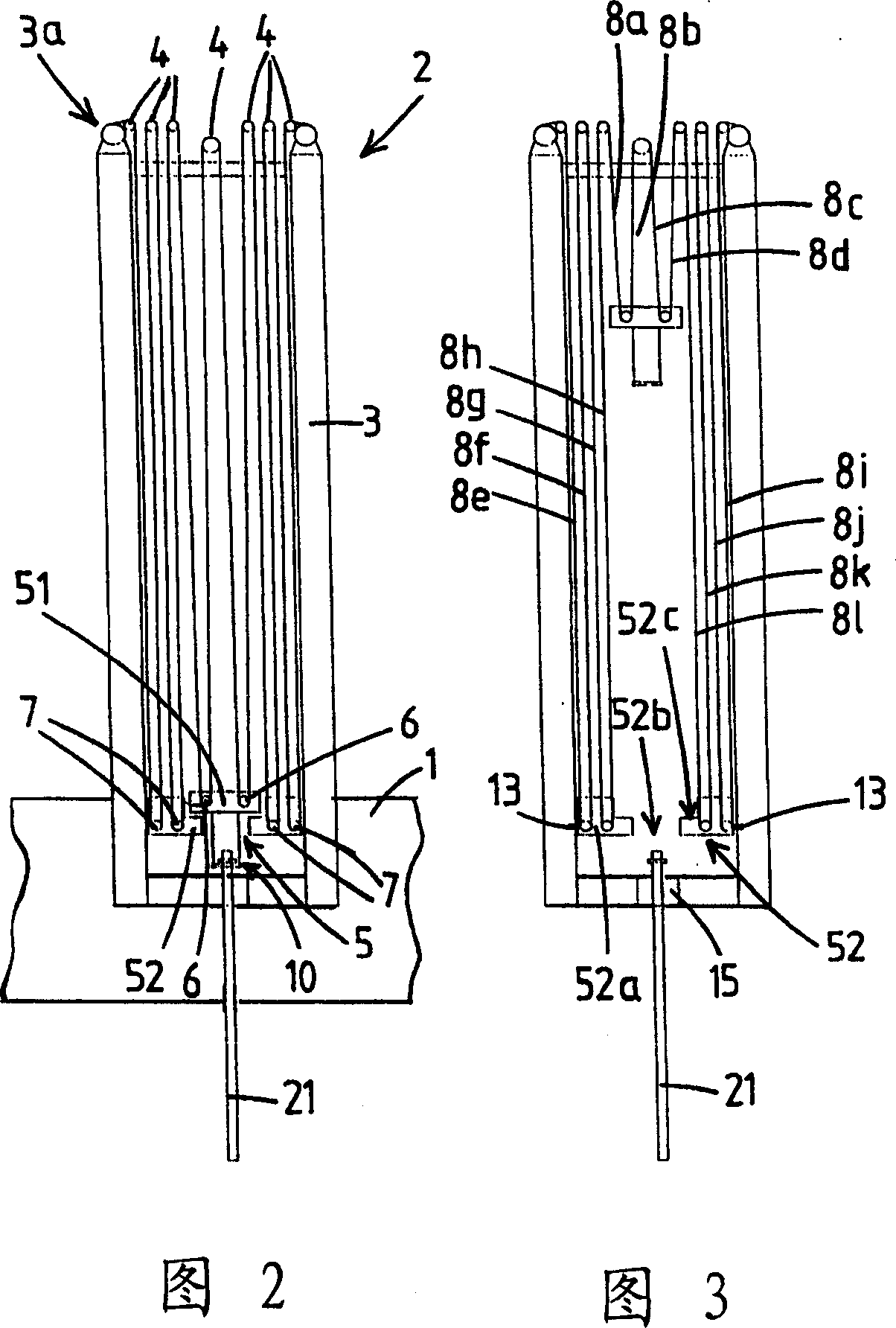

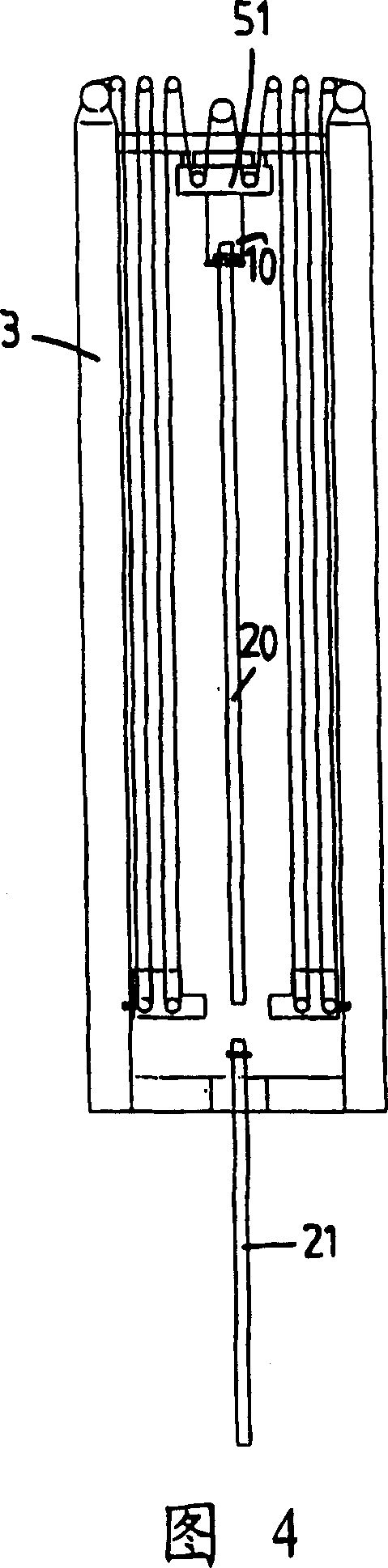

[0063] The method described with reference to Figures 1-7 relates to an efficient method for laying subsea pipelines vertically or near vertically.

[0064] The pipelaying system provides the vessel as the main support structure. A part of the ship is shown with reference number 1 in FIGS. 1 and 2 . In Figures 3-7, the boat 1 is omitted for clarity of the drawings.

[0065] Lifting equipment 2 is provided on the ship 1 . The lifting device 2 comprises a tower 3 with a tower top surface 3a. A cable pulley 4 is provided on the top surface 3a of the tower.

[0066] The lifting device 2 also includes a moving mass 5 movably connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com