Novel sea area pipeline laying floating assisting method

A pipeline laying and pipeline technology, applied in the direction of pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as pipe damage, increased steel pipe stress, pipe buckling, etc., to avoid buckling and folds, operation steps Simple, high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

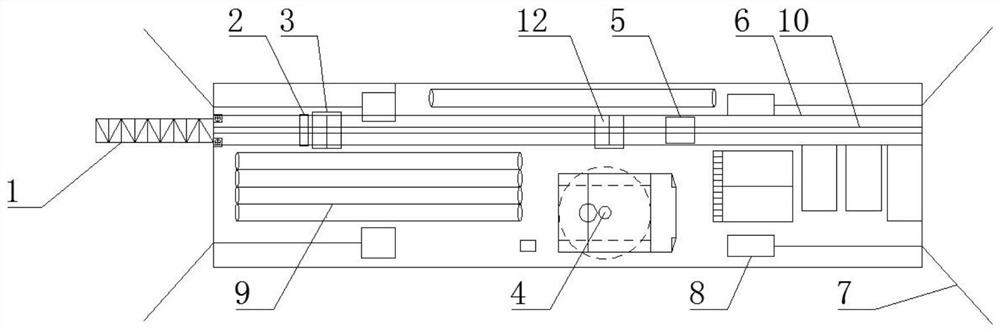

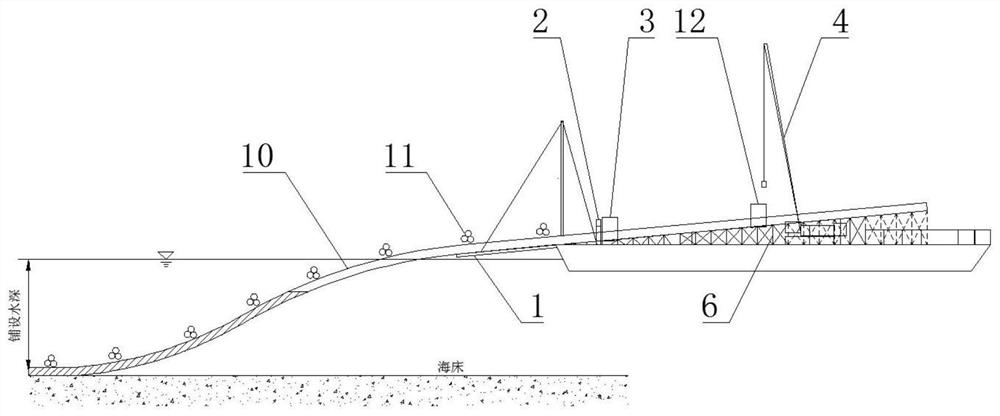

[0023] Embodiment 1, with reference to Figure 1-Figure 3 , the application is a new type of buoyancy aid method for laying pipelines in sea areas, which is used for laying submarine pipelines. The process is as follows:

[0024] (1) Shipping location:

[0025] Considering the impact of the ebb and flow of the construction site on the berthing of the pipeline-laying vessel, the direction of the bow of the vessel is consistent with the direction of the tide, and the towing vessel is used to tow and transport the pipeline-laying vessel carrying steel pipes to the designated sea area. The GPS positioning device at the terminal will accurately park the pipeline laying vessel on the pipeline laying axis planned in advance in the designated sea area, and fix the pipeline laying vessel through the anchor cable 7 on the pipeline laying vessel.

[0026] (2) Pipeline welding treatment:

[0027] Each time, two steel pipes are welded at the back end of the pipe section that has not ente...

Embodiment 2

[0033] Embodiment 2, in the novel sea area pipeline laying buoyancy aid method described in Embodiment 1, there are four anchor cables 7 on the pipeline laying ship, which are symmetrically arranged at both ends of the hull, and the four anchor cables 7 are arranged symmetrically in pairs. Make the pipeline laying ship berth on the pipeline laying axis stably, so as to ensure the progress of the construction.

Embodiment 3

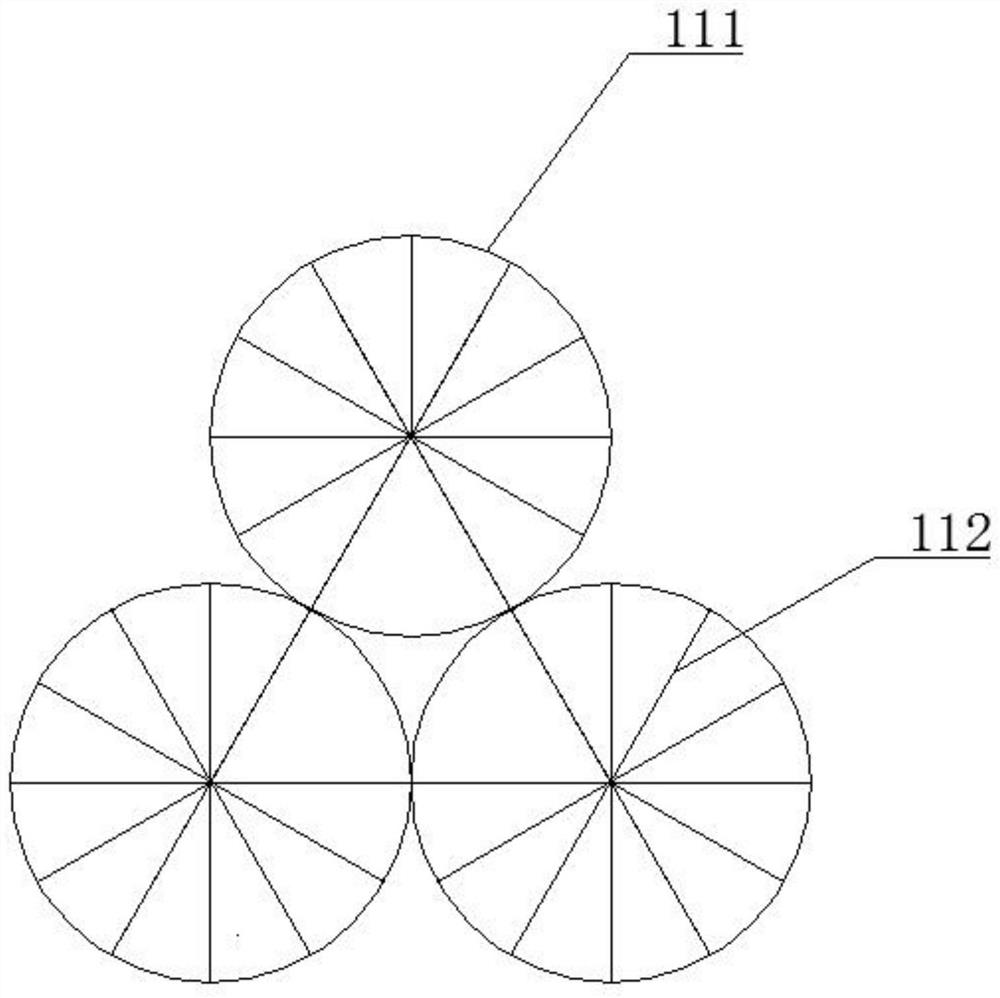

[0034] Embodiment 3, in the method for laying buoyancy aid of novel speech pipes described in embodiment 1, each steel pipe is 24m long, and two steel pipes are welded together at a time, and the total length is 48m. When laying, on the pipeline 10 A buoyancy aid is installed every 4m, and a single buoyancy aid can provide a buoyancy of 2000N for the pipeline. By filling the pipeline 10 with water, the weight of the pipeline 10 is increased, so that the pipeline 10 slides from the stinger 1 to the seabed by itself, and the buoyancy aid 11 is used. The provided buoyancy keeps the pipeline 10 sinking at a low speed; the clamp 2 provides a frictional force of 2000N for the pipeline 10, which can avoid buckling and wrinkling of the pipeline 10 when it slides down too fast; at the same time, the pipeline laying The ship moves along the direction of the pipeline laying axis, under the joint action of the ship moving windlass 8 and the anchor cable 7 on the field, until the laying of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com