Pipe fitting installation system for j-pipe laying, offshore pipe laying system and method of handling pipe fittings or fittings

An installation system, J-shaped pipe technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, drilling pipes, etc., can solve the problems of complex installation system of pipe fittings, significant difference in size between pipe fittings and fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

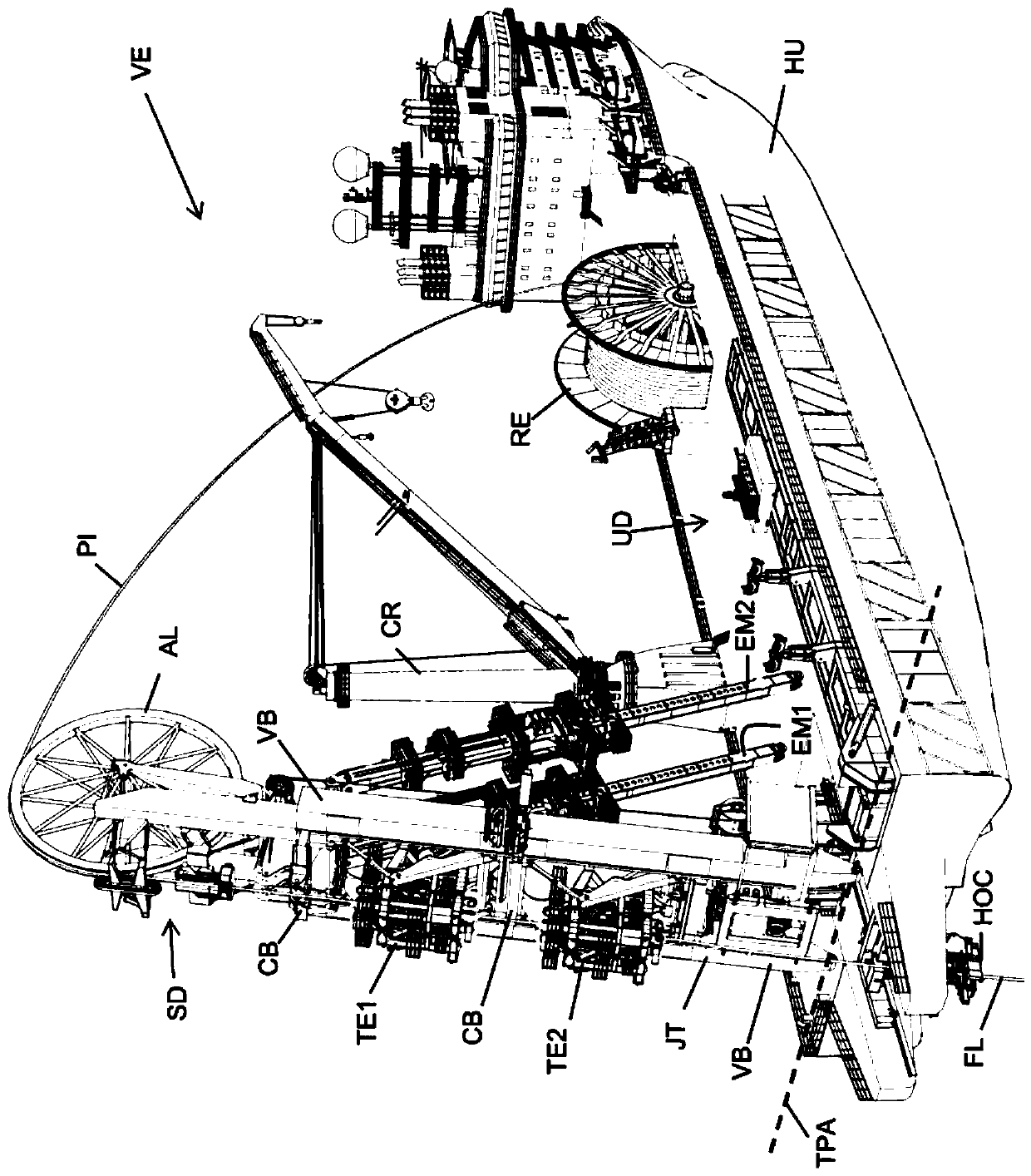

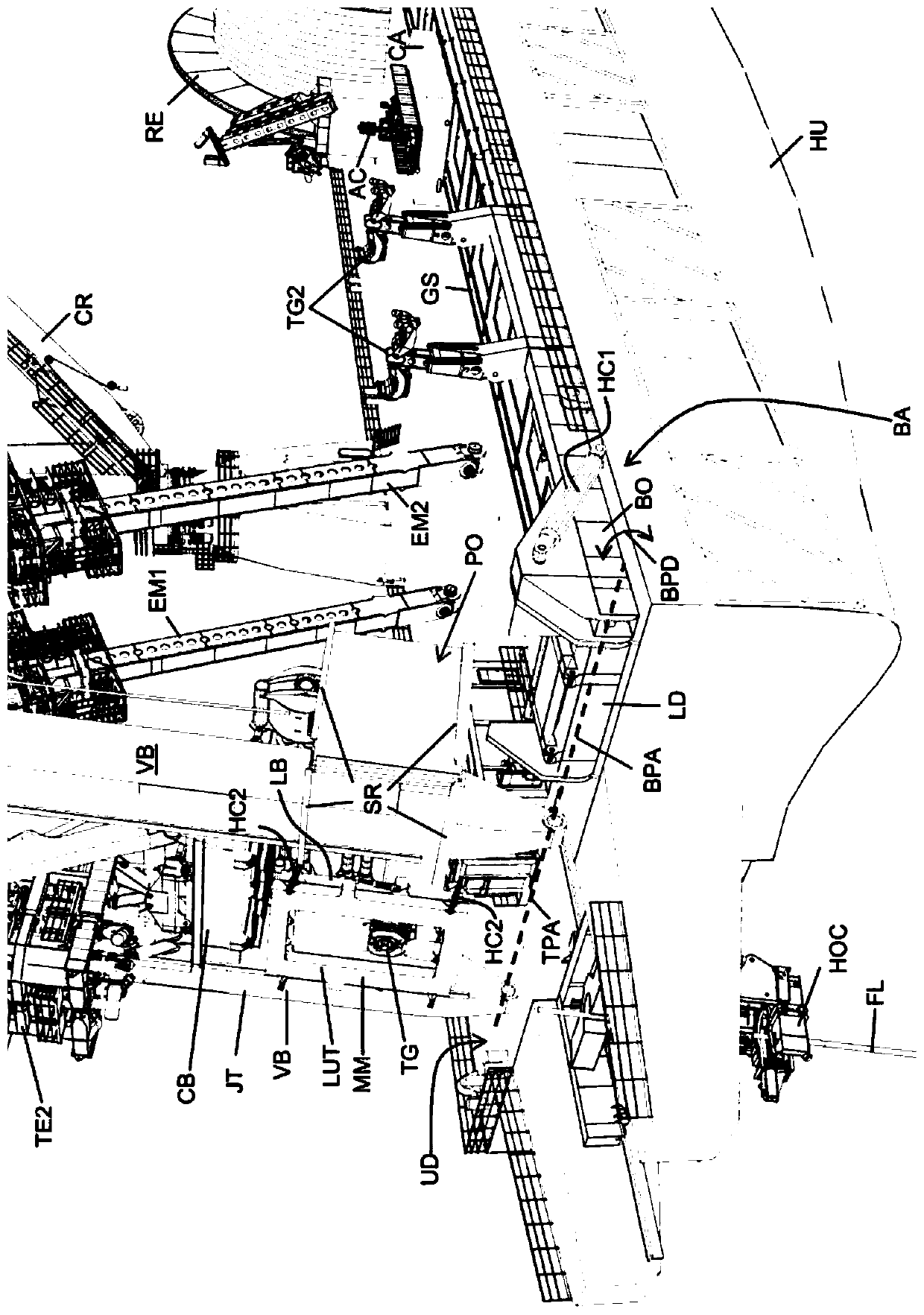

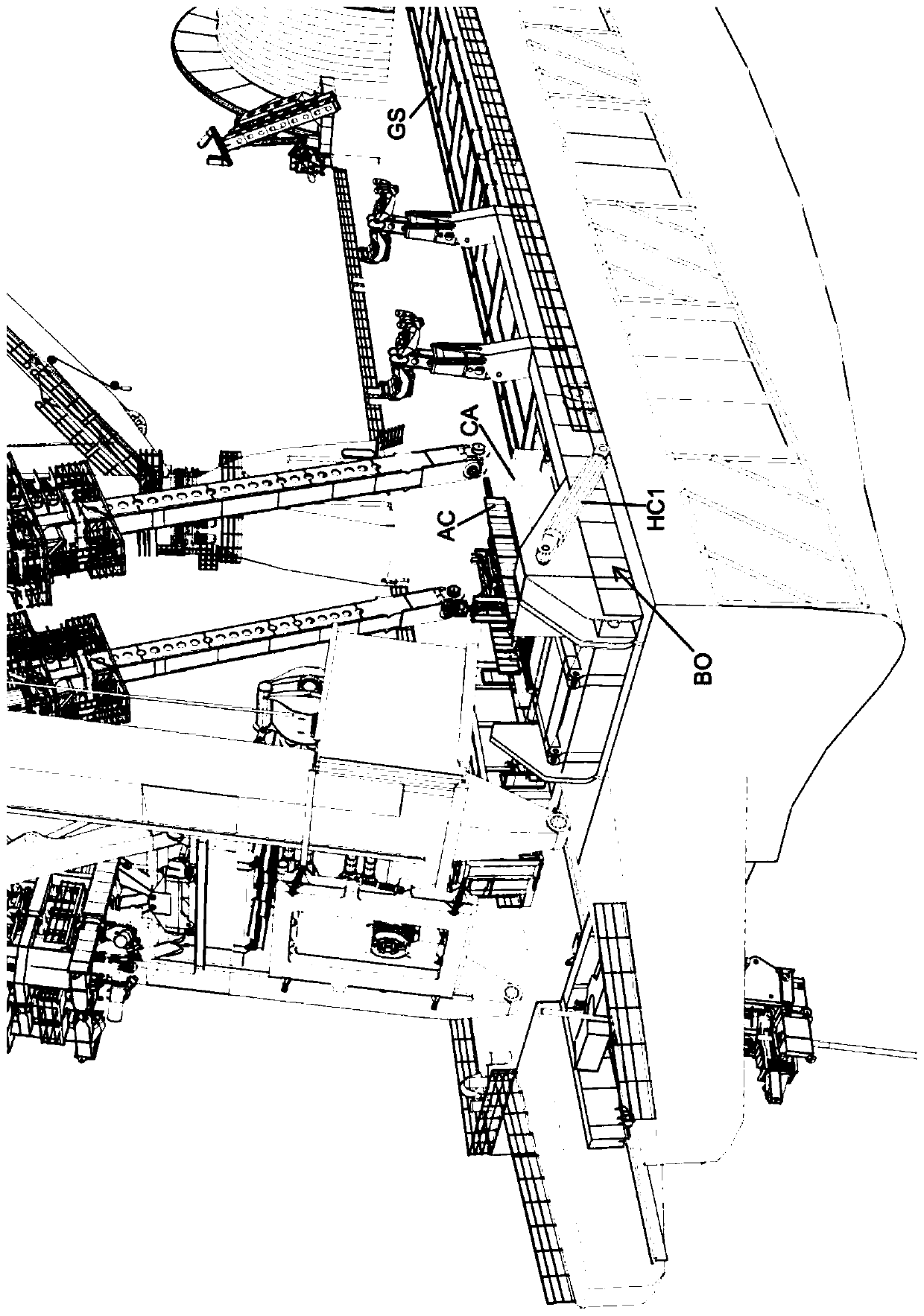

[0057] figure 1 An offshore pipelaying system according to an embodiment of the invention is shown, comprising a vessel VE having a hull HU, an upper deck UD and a pipe installation system for J-shaped pipelay.

[0058] The vessel may be of monohull design, but may also be of other designs (eg, as a semi-submersible, as a converted drilling rig, etc.).

[0059] The pipe installation system includes a J-lay tower structure JT for lowering and raising pipes and fittings in a work line FL extending along the J-lay tower structure JT. The work line FL is substantially vertical and parallel to the J-lay tower structure JT. Preferably, the work line is located adjacent to the J-lay tower structure. The J-laid tower structure may also be referred to as a tower structure or tower in this specification.

[0060] The tower structure JT is supported by the upper deck UD, whereby the upper deck UD acts as a bracing means for supporting the tower JT. Where the upper deck UD supports th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com