Compression fixture on mechanical tensile creep tester

A tensile creep and testing machine technology, applied in the field of material mechanics research, can solve problems such as the limitation of the action direction of the creep loading range, and achieve the effects of high machining accuracy, guaranteed accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

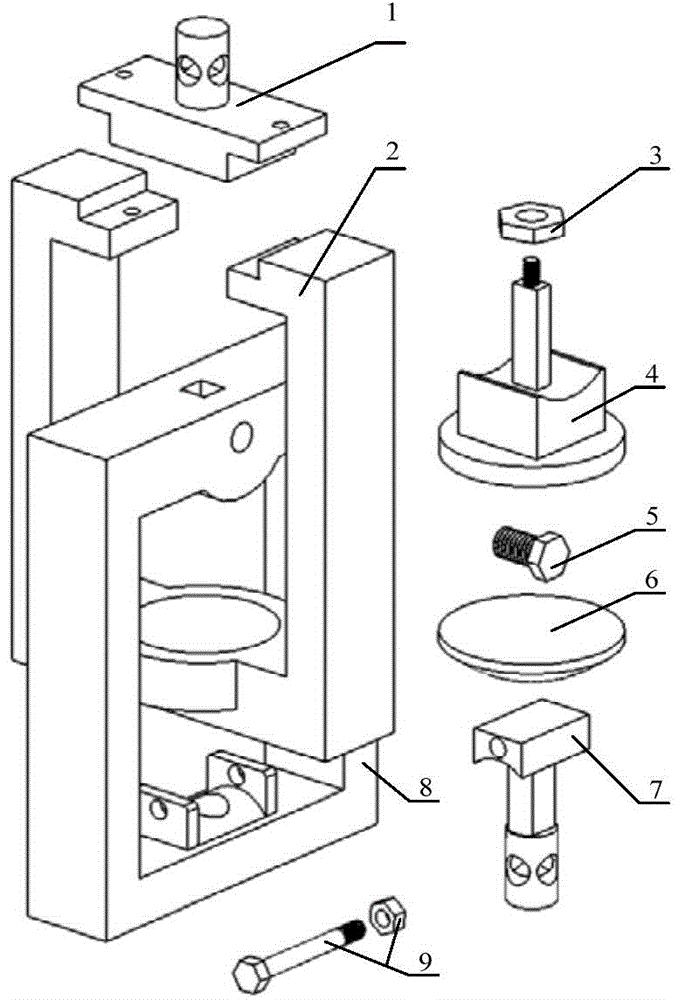

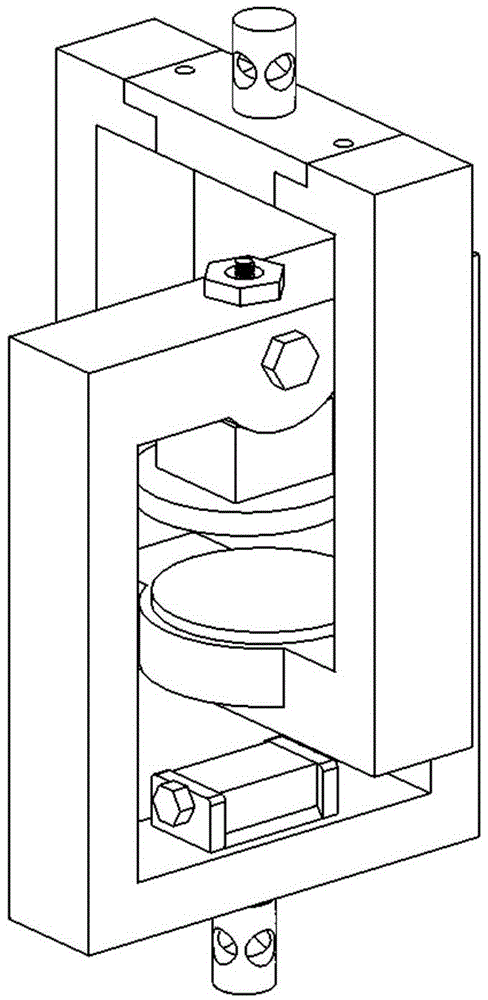

[0022] A compression fixture on a mechanical tensile creep testing machine, including an upper connector 1, an upper rectangular ring 2, an upper indenter 4, an adjustment ball 6, a lower connector 7, and a lower rectangular ring 8; one end of the upper rectangular ring 2 There is an opening, and there are stepped surfaces at both ends of the opening. The upper rectangular ring 2 and the lower rectangular ring 8 are vertically nested. The end of the upper rectangular ring 2 opposite to the opening is provided with an inwardly concave spherical structure. Adjust the ball head 6 and the upper rectangular ring 2. The inwardly recessed spherical surface is matched with the spherical structure on one side of the upper rectangular ring 2, and the other side is a plane. The lower rectangular ring 8 and the upper indenter 4 are cylindrically matched, and can be aligned along the relative surface of the cylindrical surface. Rotate, there is a square hole at one end of the lower rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com