High and low temperature resistant zone sealing strip PTFE resin composite material and preparation method thereof

A technology of resin composite material and low temperature zone, which is applied in the field of composite materials, can solve problems such as deformation, and achieve the effects of improving wear resistance and heat resistance, excellent thermal stability, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0023] The preparation method of the high-temperature-resistant and low-temperature zone sealing strip for the air scroll compressor comprises the steps of:

[0024] (1) Add nano-silica and solid glass microspheres to ethanol solution respectively, after ultrasonic dispersion is uniform, add silane coupling agent, ultrasonically stir, filter to obtain precipitate, wash and dry;

[0025] (2) Add POB powder into dimethylformamide and stir evenly;

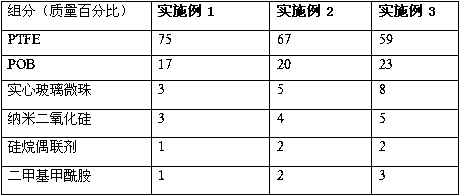

[0026] (3) Use acetone to infiltrate the product obtained in step (1) (2) with polytetrafluoroethylene powder, stir thoroughly through a high-shear dispersing emulsifier to make it evenly mixed, and dry it at 120°C for 2-6h. Moisture and solvent are removed; the content of each component is shown in Table 1;

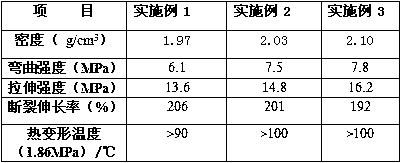

[0027] (4) Molding after cooling, holding pressure for 2 minutes, holding pressure 15-30MPa, sintering temperature 360-400°C, sintering for 3~6h, naturally cooling to room temperature with the furnace, mechanical processing aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com