Device for concrete compressive creep test in high-temperature environment

A test device, high temperature environment technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

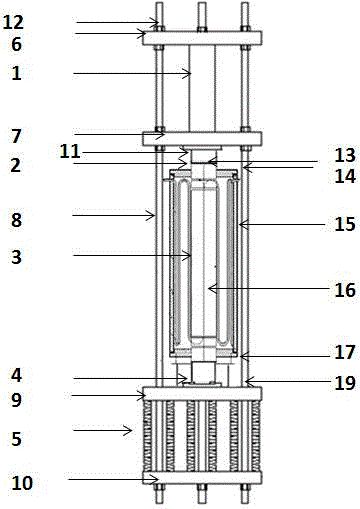

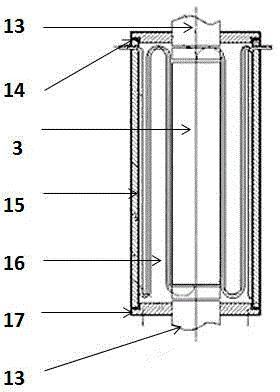

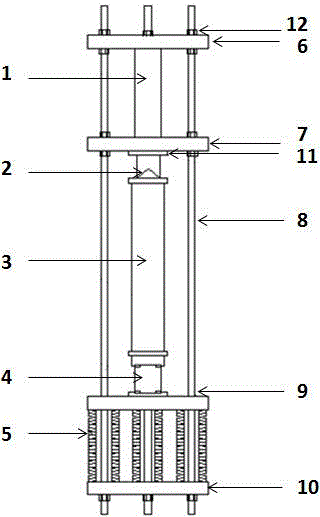

[0022] The structure of the device is as figure 2 - Figure 4 As shown, it consists of a traditional creep test device, a marble block 13 , an upper cover 14 , an oven shell 15 , an oven heating device 16 , a lower cover 17 , a cover opening hole 18 and a foot 19 . The structure of the traditional creep test device is as follows figure 1 As shown, by actuator 1, ball wrestling 2, concrete specimen 3, force sensor 4, disc spring 5, reaction force plate 6, upper pressing plate 7, screw rod 8, lower pressing plate 9, bottom plate 10, backing plate 11 and nut 12, the oven heating equipment is a cylindrical structure, consisting of an oven shell 15, an upper cover 14 and a lower cover 17, the top of the oven shell 15 is sealed by the upper cover 14, the bottom is sealed by the lower cover 17, the upper cover 14 and the lower cover The cover 17 has a through hole matching the structure of the marble pad 13, and the two marble pads 13 are respectively installed in the through hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com