Low-shrinkage low-creep crack-resistant high-performance mass concrete

A large-volume concrete, high-performance technology, applied in the field of concrete, can solve the problems of lack of concrete, etc., to achieve the effect of ensuring durability, low temperature rise of heat insulation, and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a low-shrinkage, low-creep, crack-resistant high-performance mass concrete, and the mass percentages of the various raw material components of the concrete are as follows:

[0035] Cement: (14~19)%; fly ash: (2~6)%; water: (5~8)%; admixture: (0.15~0.4)%; sand: (25~31)%; gravel A: (20-25)%; gravel B: (20-25)%.

[0036] As a preferred solution, the mass percentages of each raw material component of the low-shrinkage, low-creep, crack-resistant, high-performance mass concrete provided in this example are as follows:

[0037] Cement: 16.63%; fly ash: 3.32%; water: 6.65%; admixture: 0.25%; sand: 28.51%; crushed stone: 22.32%;

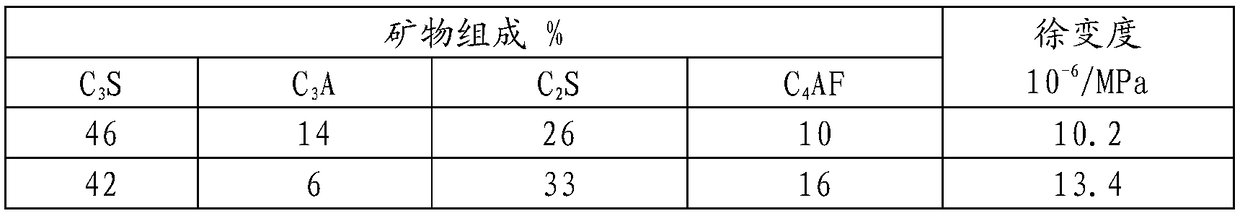

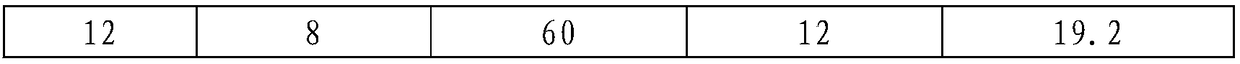

[0038] Wherein, the cement is P.O42.5 ordinary portland cement, heat of hydration 3d≤251kJ / kg, heat of hydration 7d≤293kJ / kg, C 3 A≤7%, C 3 S≤57%, C 2 S≤30%, dry shrinkage <1000μm / m.

[0039] The fly ash mentioned is Class F Class I, which meets the requirements of GB / T1596-2017.

[0040] The water described is drinking ...

Embodiment 2

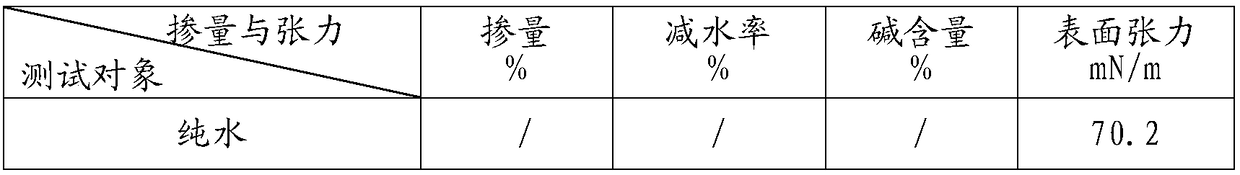

[0064] This embodiment is except the admixture that uses, and other is identical with embodiment one, difference is described as follows:

[0065] When the performance of the composite high-concentration FDN admixture is adjusted to the same dosage as in Example 1 and the water reducing rate is ≥ 30%, the admixture in Example 1 is replaced with the same mass of the composite high-concentration FDN admixture. The other components and the mixing method were consistent with those in Example 1. The obtained concrete was randomly checked and sampled, and the measurement results under standard curing conditions were tested. The results are shown in Table 9.

[0066] Table 9 concrete sampling test results 2

[0067]

[0068] From the above examples and corresponding data, it can be seen that the concrete mixture of the present invention has moderate viscosity, good cohesion, low pump pressure during construction and is easy to pump and pour, and the concrete has good crack resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat of hydration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com