Universal fixture for compression creep aging and stress relaxation aging experiments of round bar-shaped sample

A stress relaxation and compression creep technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., which can solve the distortion of stress relaxation experimental data, the inability to test the correct relaxation curve, the unstable bending of materials, etc. problem, to achieve the effect of simple structure, ensuring data reliability, and uniform stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

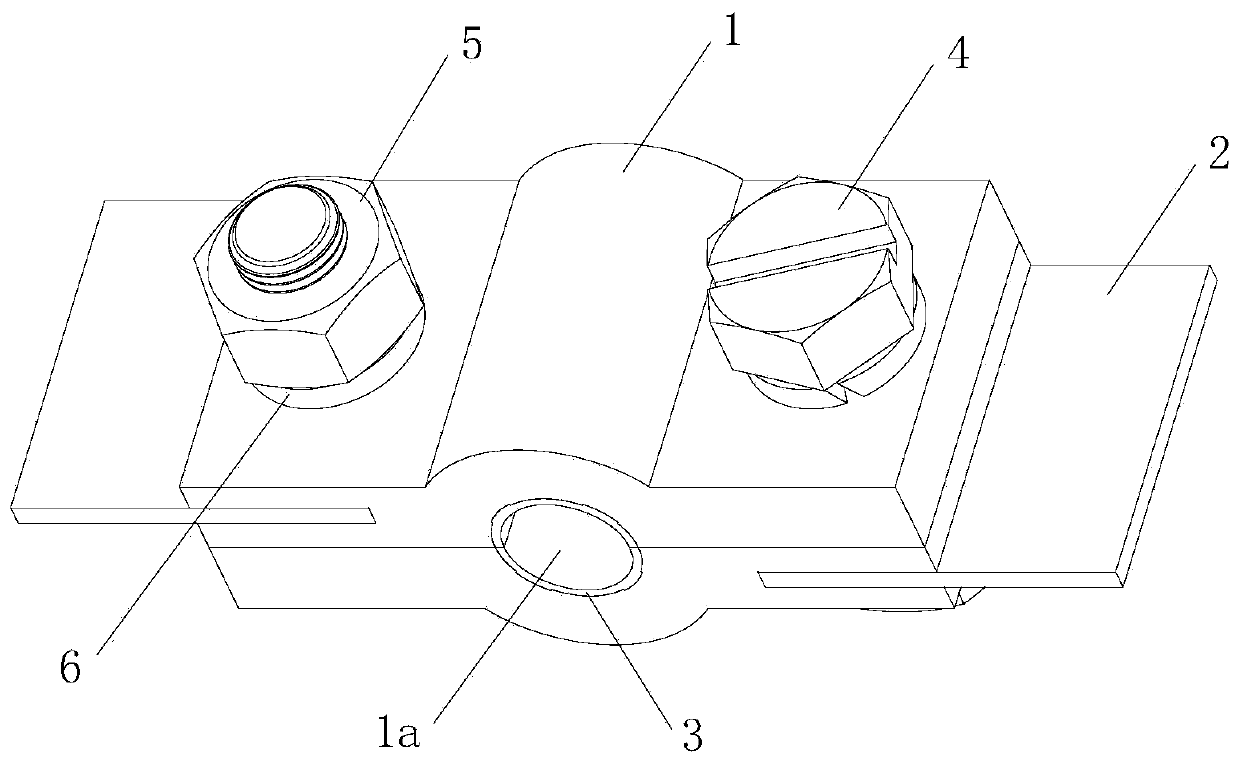

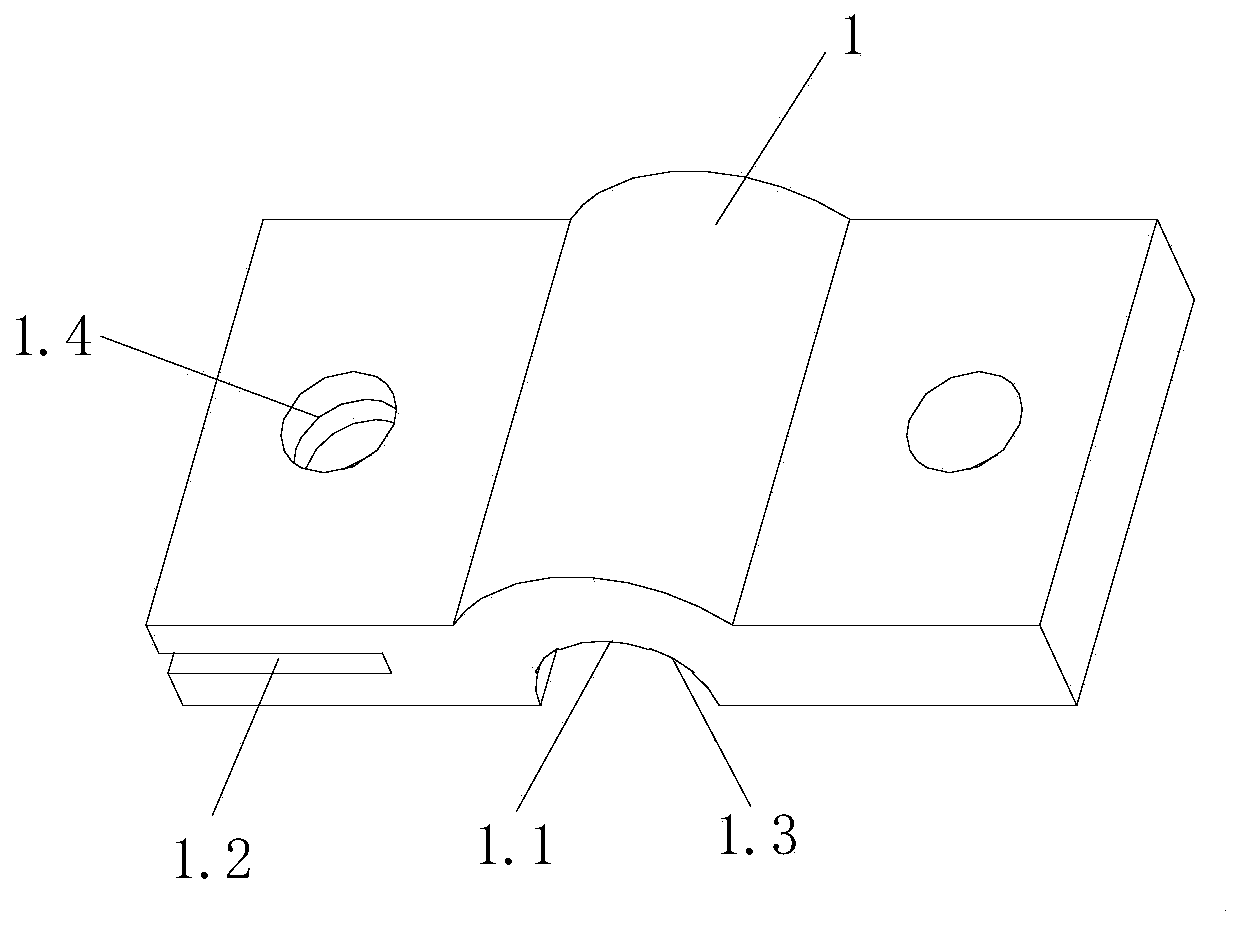

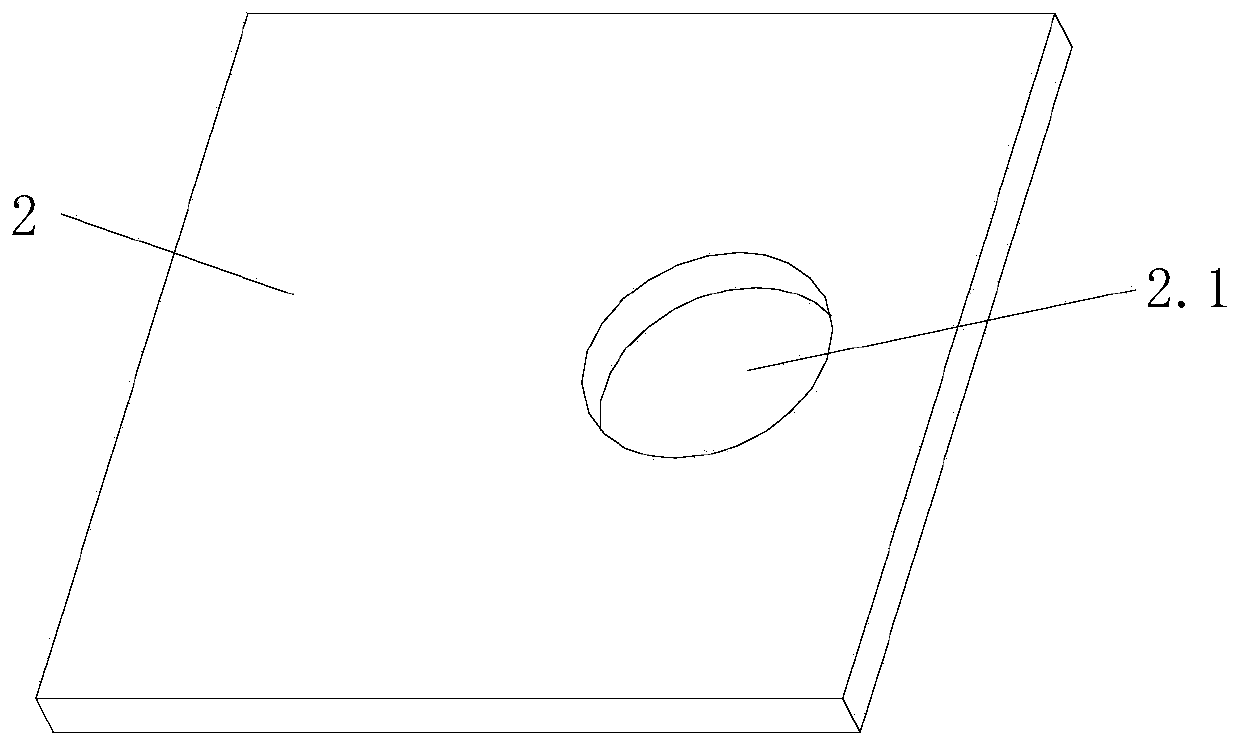

[0027] see Figure 1 to Figure 5 , a general fixture for compression creep aging and stress relaxation aging experiments of round bar-shaped samples, which includes a fixture main body, a conductive device and a plurality of locking devices, the fixture main body includes two clamping parts 1, each clamping part An inner groove 1.1 is provided, and the two clamping parts are fixedly connected by a locking device. The inner grooves 1.1 of the two clamping parts are enclosed to form a clamping through hole 1a for accommodating the round bar-shaped sample 7. Each clamping The holding parts are all provided with a mounting groove 1.2 at one end thereof, and the concave direction of the mounting groove is different from that of the inner groove 1.1; the clampin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com