Weldable titanium alloy with creep resistance, high impact toughness and corrosion resistance and preparation method

A titanium alloy, high-impact technology, applied in the field of titanium alloy materials, can solve the problems that the size and performance of the parts cannot meet the requirements of use, the creep of the pressure-resistant structure of the titanium alloy, and the safe serviceability of the deep-sea engineering equipment, etc., and achieve excellent compression resistance. Creep properties, improving the toughness of titanium alloys, and improving the effect of compression creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

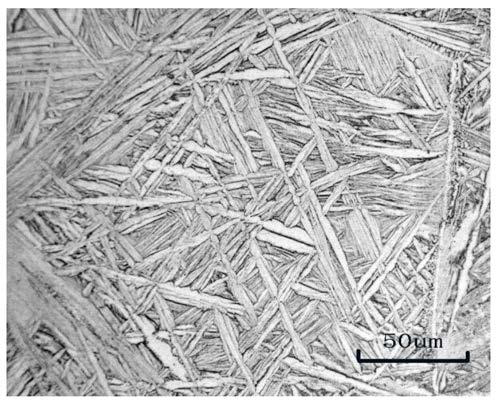

Image

Examples

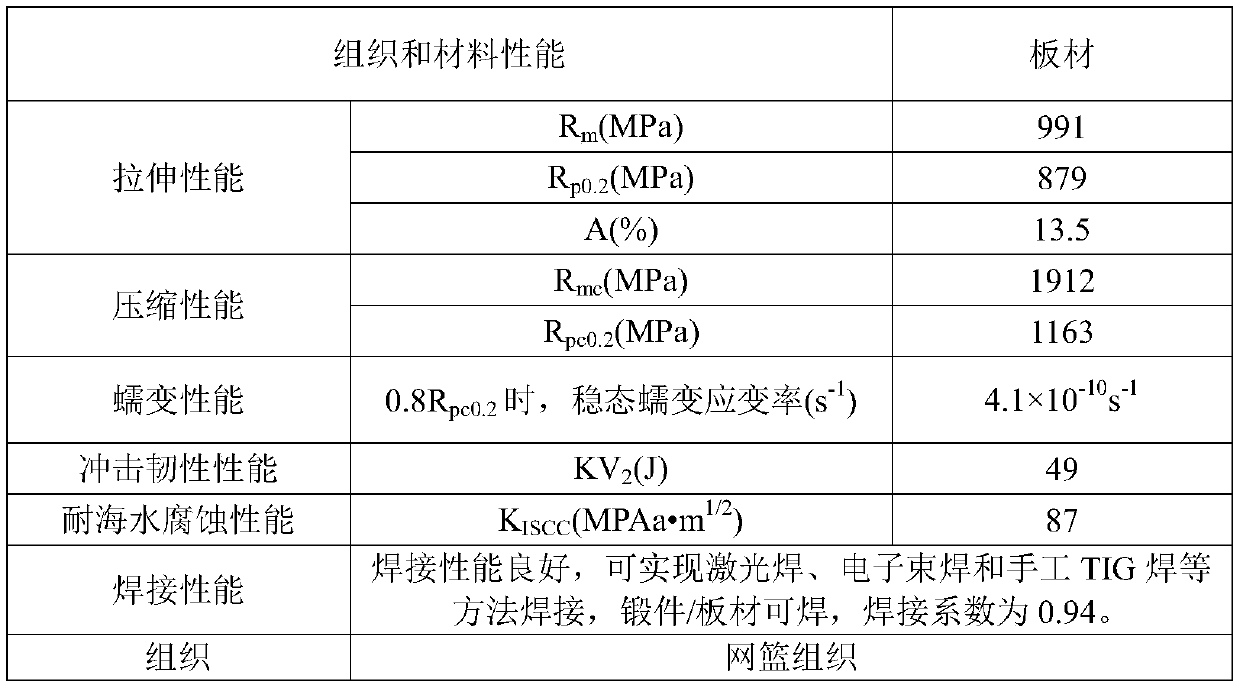

Embodiment 1

[0029] Example 1: Ti-8Al-4Mo-4Ta-4Zr-0.12O alloy

[0030]A creep-resistant, high-impact-toughness, corrosion-resistant, and weldable titanium alloy, expressed in mass percent, said creep-resistant, high-impact, toughness, and corrosion-resistant, weldable titanium alloy is composed of the following components: Al 8.0%, Mo 4.0%, Ta 4.0%, Zr 4.0%, O 0.12%, and the balance is Ti and unavoidable impurities.

[0031] The preparation method of the above-mentioned creep-resistant high-impact-toughness corrosion-resistant weldable titanium alloy comprises the following steps:

[0032] (1) Weigh and batch according to the composition of the above-mentioned creep-resistant, high-impact, tough, corrosion-resistant, weldable titanium alloy, and the configured titanium alloy raw materials are mixed, pressed into electrode rods, and smelted into an alloy casting three times in a vacuum consumable electric arc furnace. Ingot, melting vacuum is 10 - 2 Pa, and then the ingot is rolled and d...

Embodiment 2

[0038] Example 2: Ti-4Al-0.3Mo-0.5Ta-0.5Zr-0.03O alloy

[0039] A creep-resistant, high-impact-toughness, corrosion-resistant, weldable titanium alloy expressed in mass percent, said creep-resistant, high-impact-toughness, corrosion-resistant, weldable titanium alloy is composed of the following components: Al 4.0%, Mo 0.3%, Ta 0.5%, Zr0.5%, O0.03%, and the balance is Ti and unavoidable impurities.

[0040] The preparation method of the above-mentioned creep-resistant high-impact-toughness corrosion-resistant weldable titanium alloy comprises the following steps:

[0041] (1) Weigh and batch according to the composition of the above-mentioned creep-resistant, high-impact, tough, corrosion-resistant, weldable titanium alloy, and the configured titanium alloy raw materials are mixed, pressed into electrode rods, and smelted into an alloy casting three times in a vacuum consumable electric arc furnace. Ingot, melting vacuum is 10 - 2 Pa, and then the ingot is rolled and de-shr...

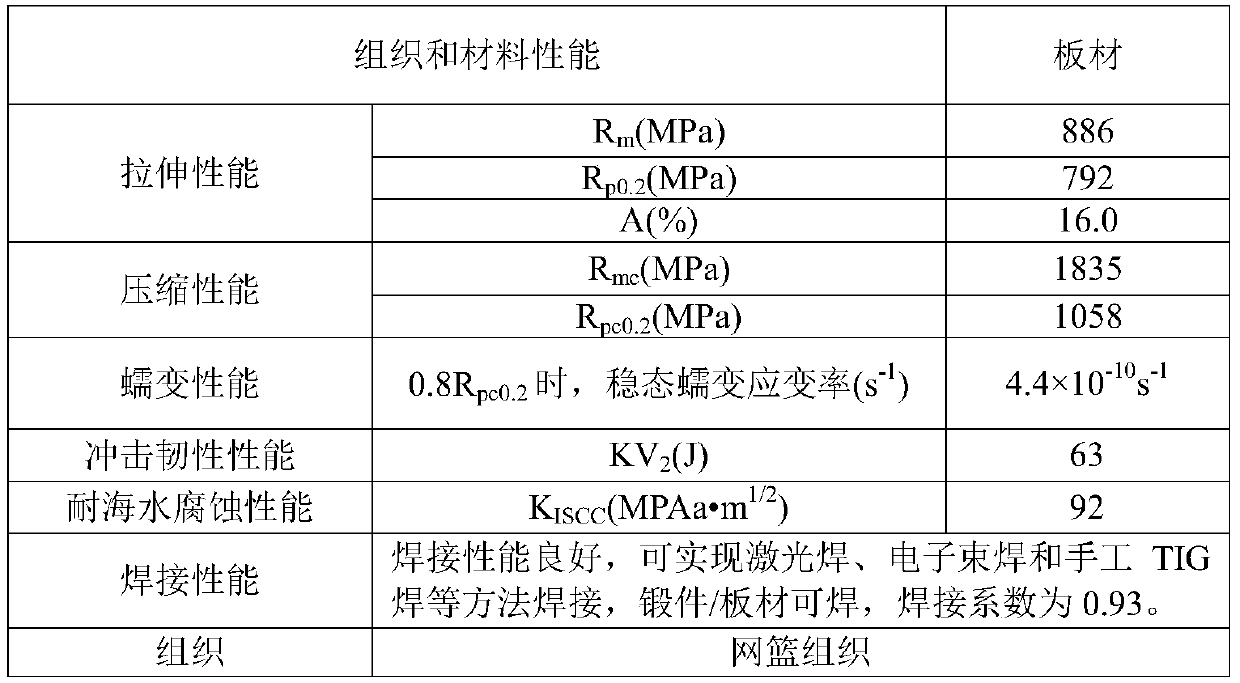

Embodiment 3

[0048] Example 3: Ti-6Al-0.3Mo-3Ta-2Zr-0.08O alloy

[0049] A creep-resistant, high-impact-toughness, corrosion-resistant, weldable titanium alloy, expressed in mass percent, said creep-resistant, high-impact-toughness, corrosion-resistant, weldable titanium alloy is composed of the following components: Al 6.0%, Mo 0.3%, Ta 3.0%, Zr2.0%, O0.08%, and the balance is Ti and unavoidable impurities.

[0050] The preparation method of the above-mentioned creep-resistant high-impact-toughness corrosion-resistant weldable titanium alloy comprises the following steps:

[0051] (1) Weigh and batch according to the composition of the above-mentioned creep-resistant, high-impact, tough, corrosion-resistant, weldable titanium alloy, and the configured titanium alloy raw materials are mixed, pressed into electrode rods, and smelted into an alloy casting three times in a vacuum consumable electric arc furnace. Ingot, melting vacuum is 10 - 2 Pa, and then the ingot is rolled and de-shrink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com