Patents

Literature

30results about How to "Improve heating conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

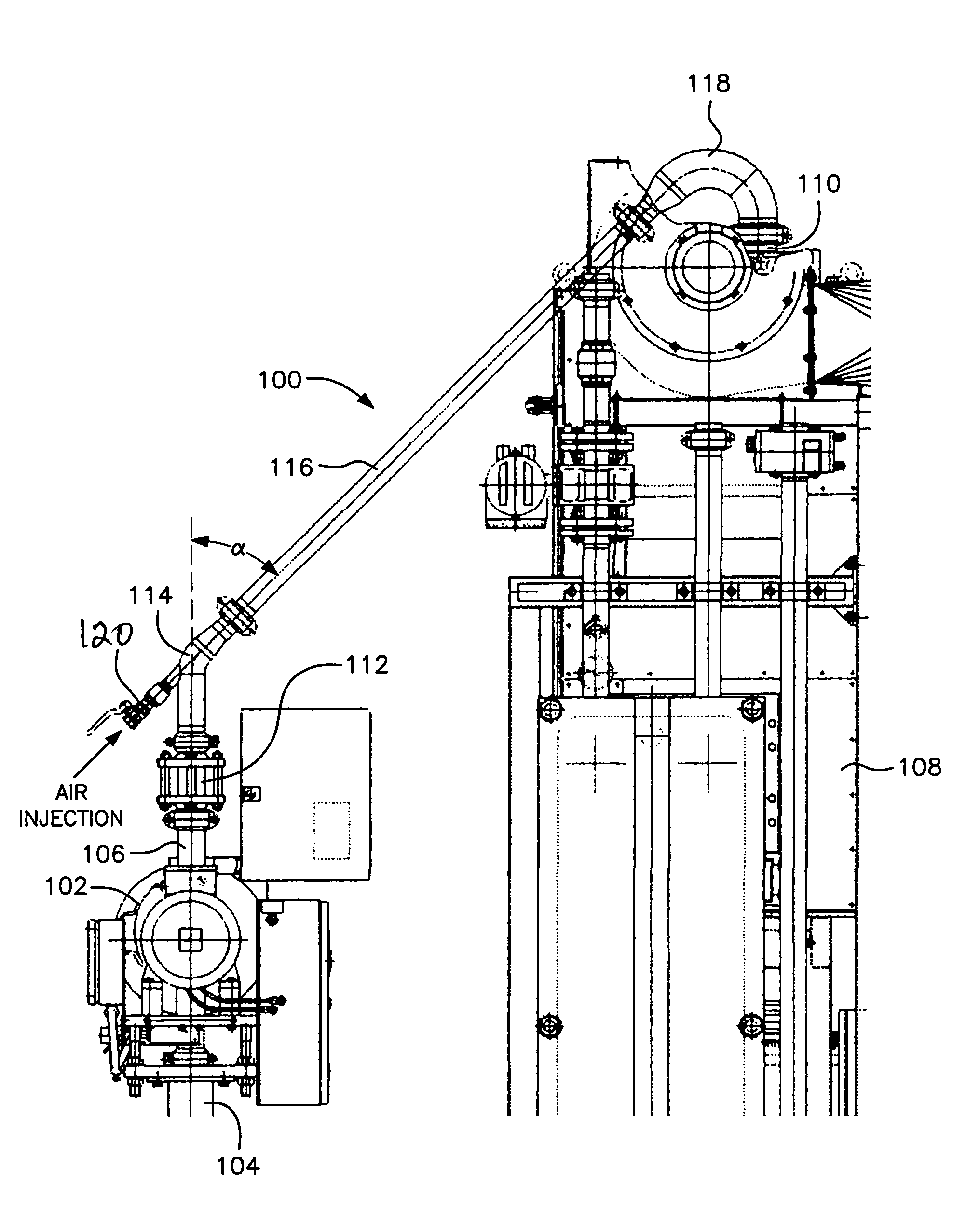

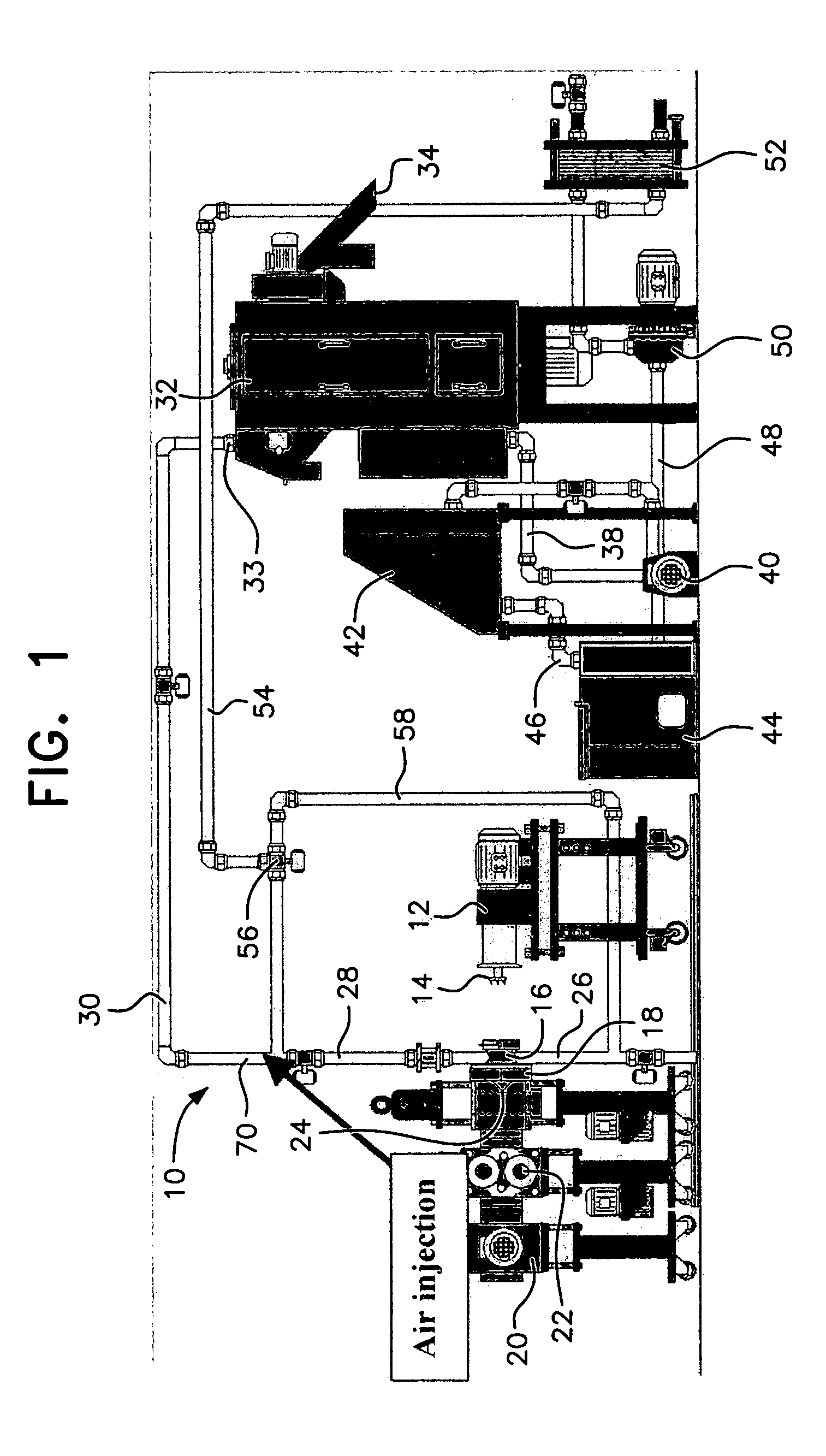

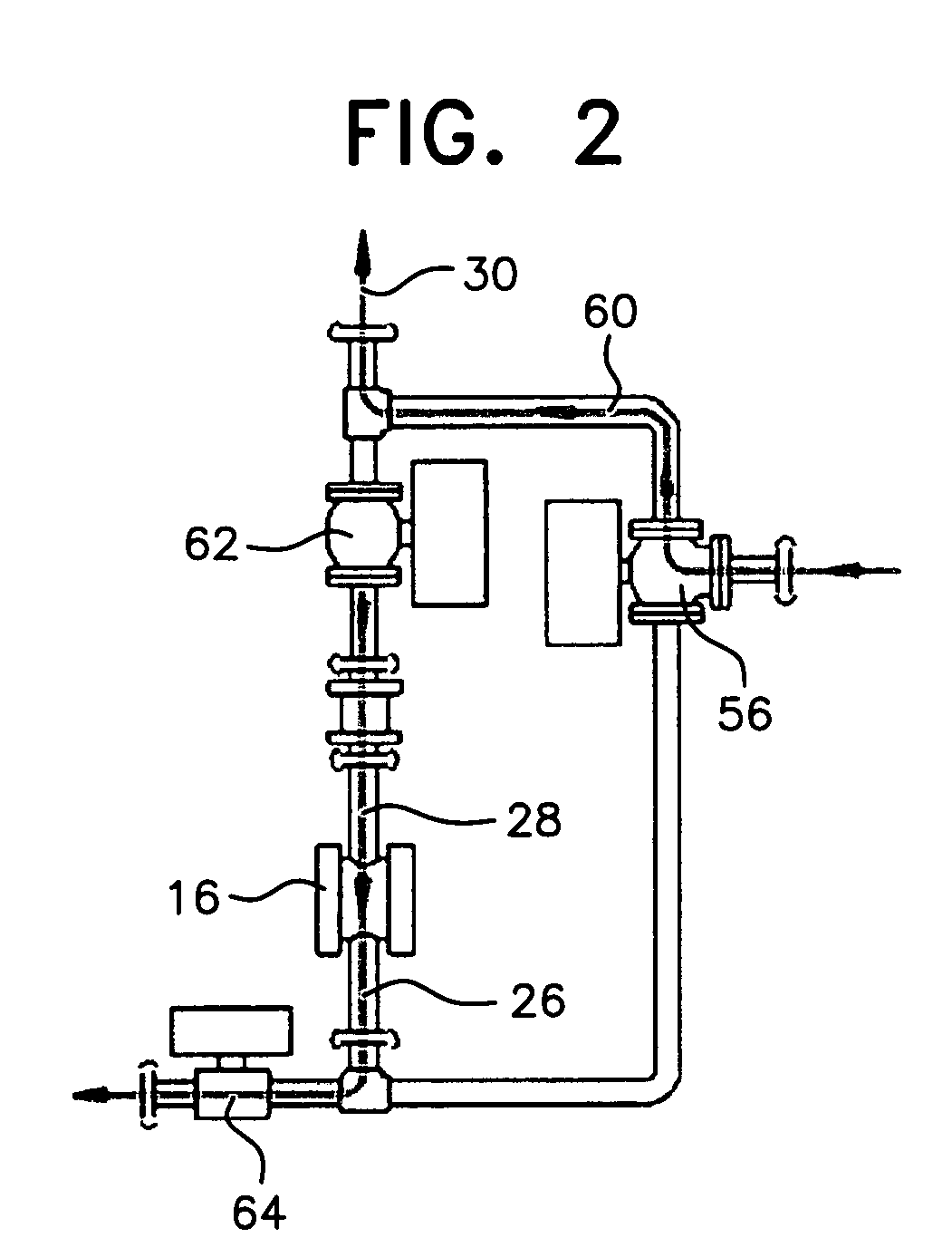

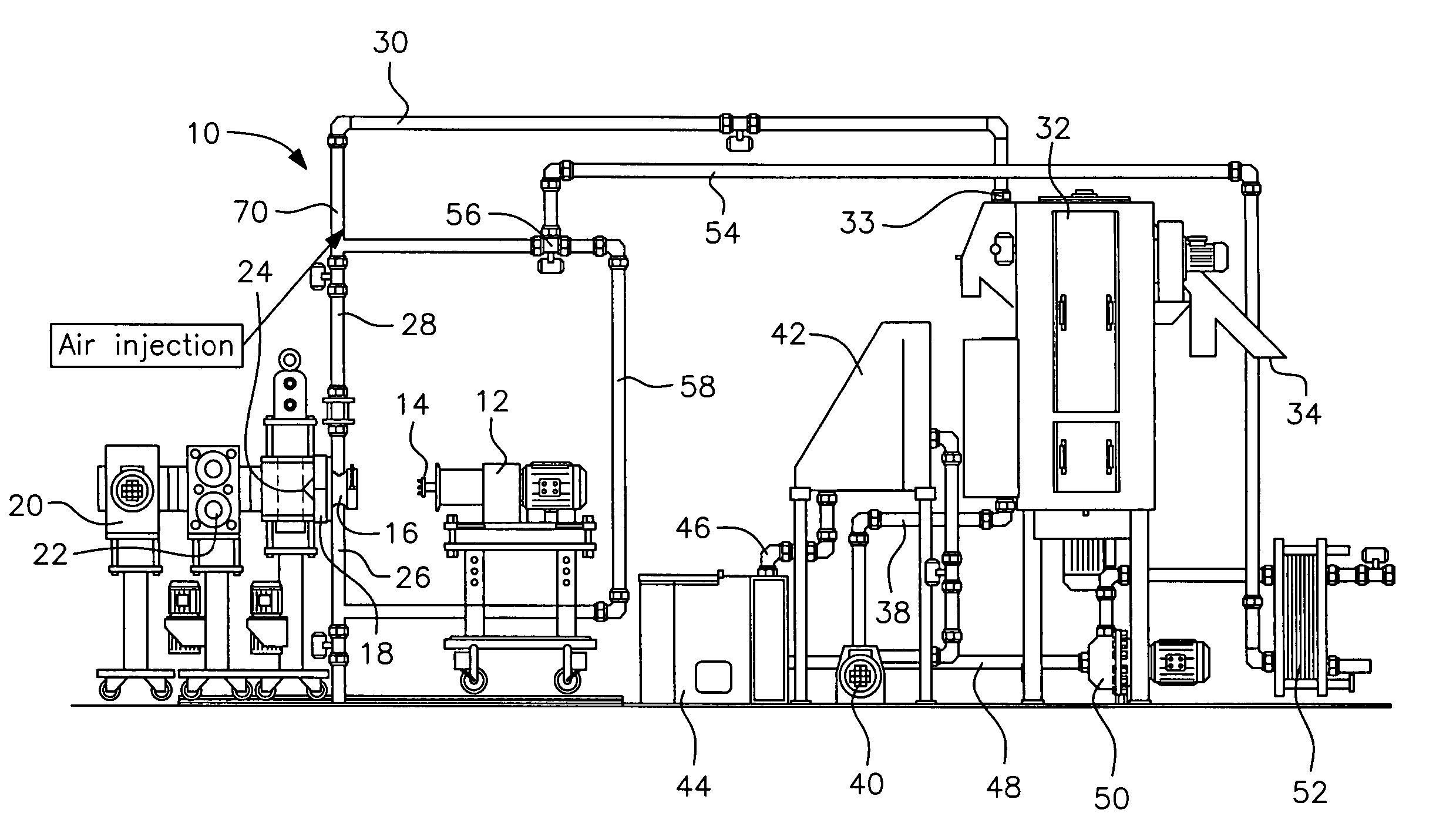

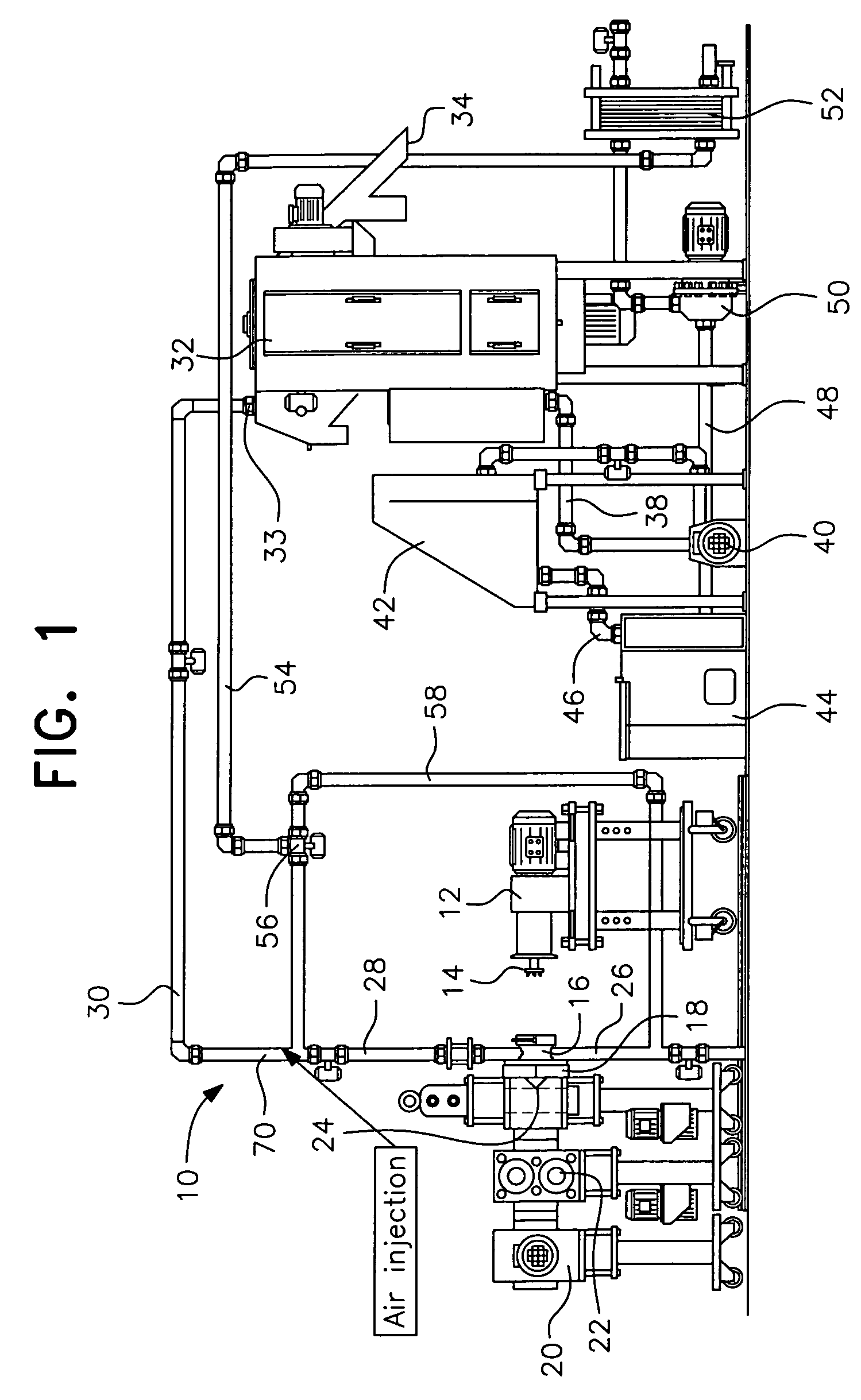

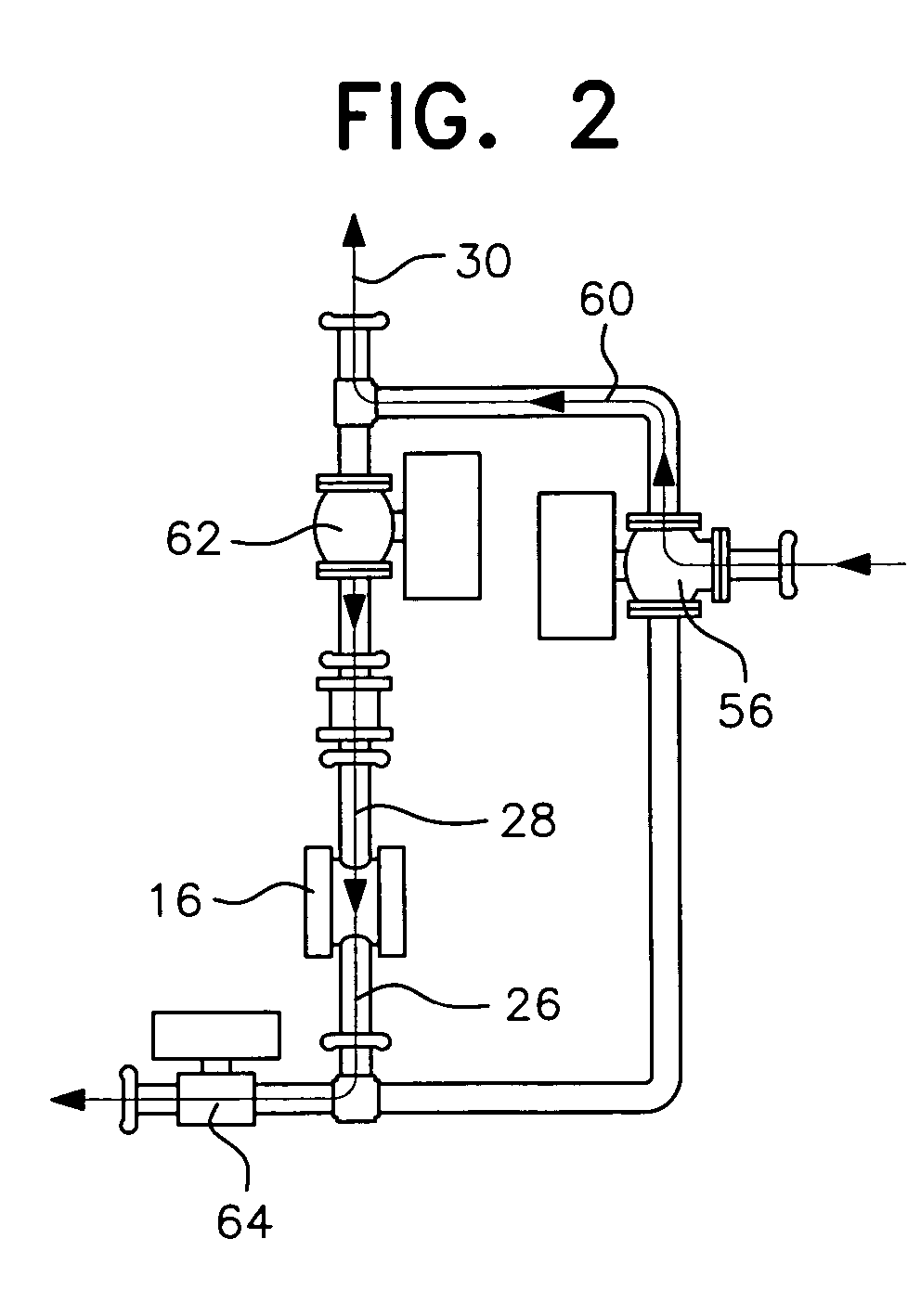

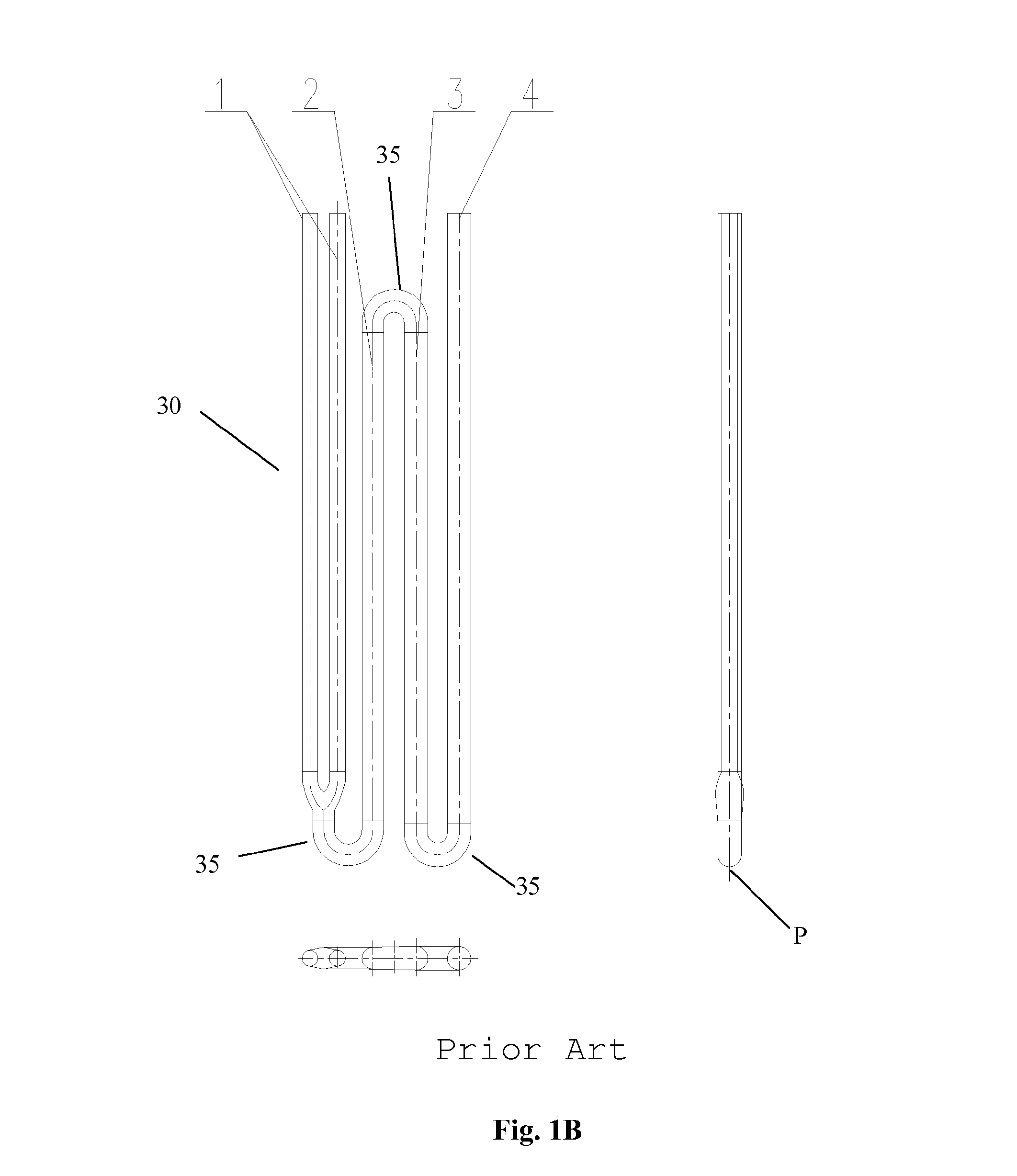

Method and apparatus for making crystalline PET pellets

InactiveUS7157032B2Reduce dwell timeImprove heating conditionsMouldsDrying solid materials without heatPolyethylene terephthalateSlurry

Owner:GALA INDUSTRIES INC

Method and apparatus for making crystalline pet pellets

InactiveUS20070132134A1Reduce dwell timeImprove heating conditionsMouldsDrying solid materials without heatPolyethylene terephthalateSlurry

Owner:GALA IND INC

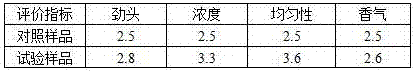

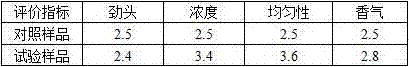

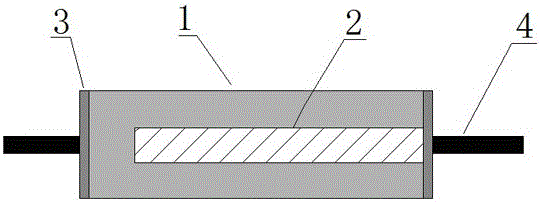

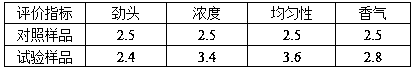

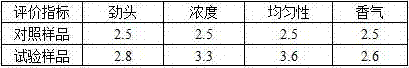

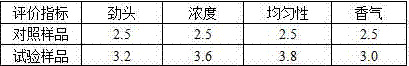

Tobacco material suitable for heating non-combustion device and preparing method of tobacco material

ActiveCN105433430AImprove heating conditionsIncrease smoke concentrationTobacco treatmentWater contentEngineering

The invention belongs to the technical field of tobaccos, and particularly relates to a tobacco material suitable for heating a non-combustion device and a preparing method of the tobacco material. The tobacco material is prepared from, by mass, 30-80 parts of tobacco powder, 10-30 parts of tobacco extract, 5-30 parts of polyhydric alcohols, 1-5 parts of an expanding auxiliary, 0.1-5 parts of a heat conducting material, 1-5 parts of a dispersing auxiliary and 0.1-5 parts of a natural antibacterial agent, and the water content is 8-15%. Compared with other tobacco materials for heating the non-combustion device in the prior art, the tobacco material has the obvious advantages that the smoke concentration is obviously increased, smoke release uniformity is obviously improved, the quality is more stable, and the application range is wide.

Owner:CHINA TOBACCO HENAN IND +1

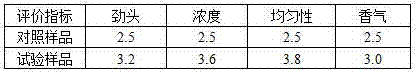

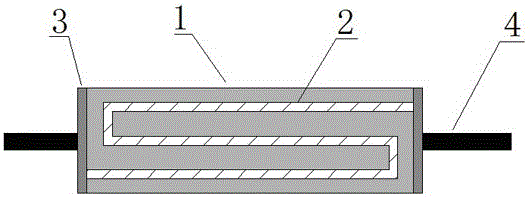

Tobacco material for smoking and preparation method thereof

ActiveCN105433434AIncrease concentrationImprove utilization efficiencyTobacco treatmentTobacco devicesAdhesivePolyethylene glycol

The invention belongs to the technical field of tobaccos, and particularly relates to a tobacco material for smoking and a preparation method thereof. The tobacco material is in a sheet or film shape and is 0.1-2 mm thick. The tobacco material is prepared from, by mass, 10-50 parts of tobacco powder, 20-50 parts of a tobacco extract, 10-30 parts of an aerosol generating agent, 0.1-5 parts of heat conductive materials, 1-5 parts of polyethylene glycol and 1-5 parts of an adhesive. The tobacco material has the advantages that the heated condition of the tobacco material is improved by adding the heat conductive materials into the tobacco material, and the smoke density is well improved; by evenly scattering the heat conductive materials in the polyethylene glycol solution, the tobacco material heated uniformity is improved, and the smoke release uniformity is obviously improved; the tobacco material application range is wide.

Owner:CHINA TOBACCO HENAN IND +1

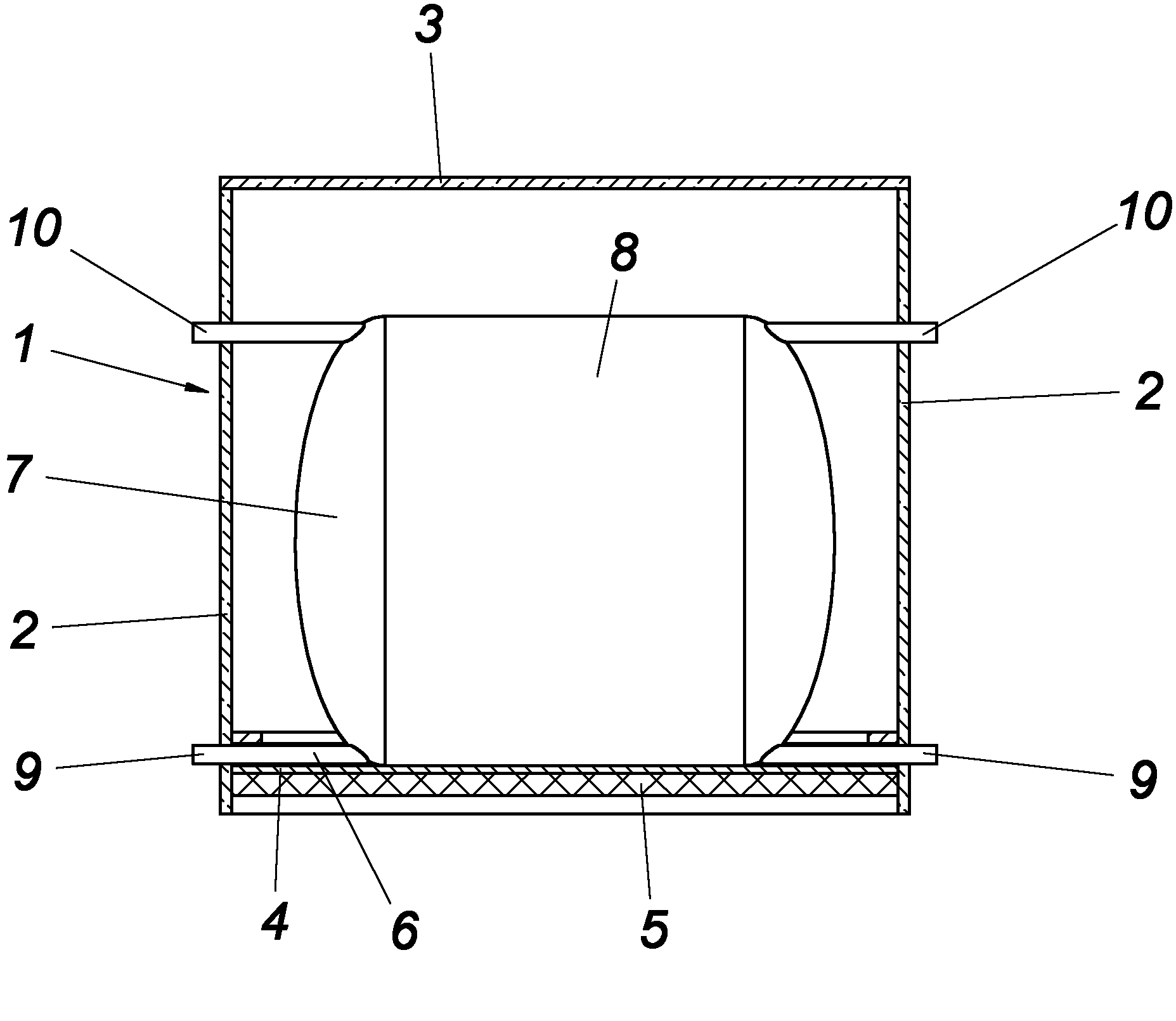

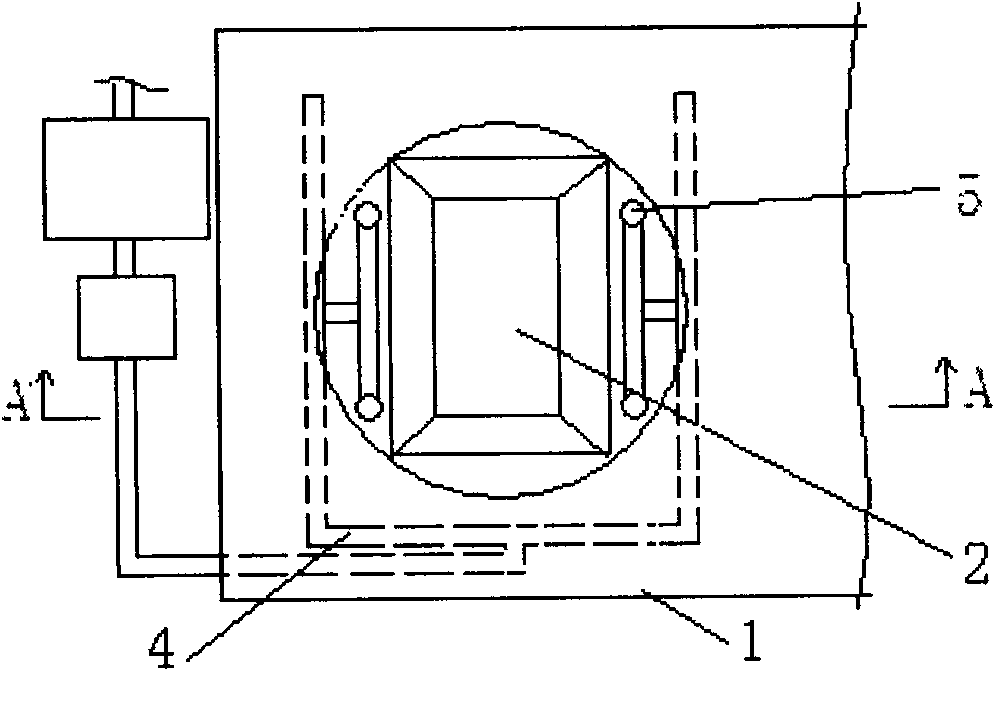

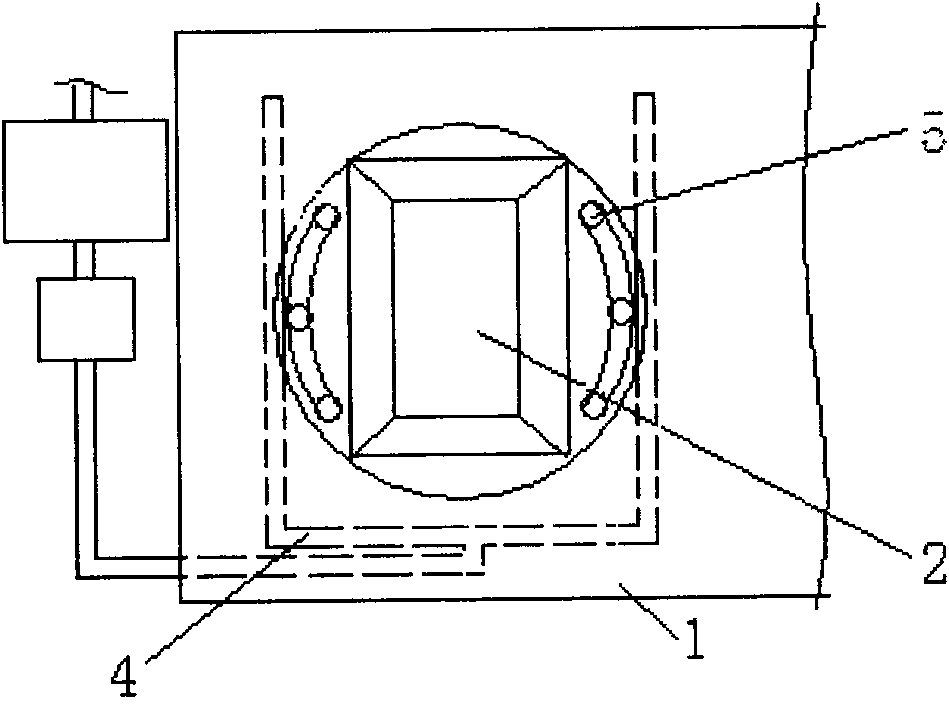

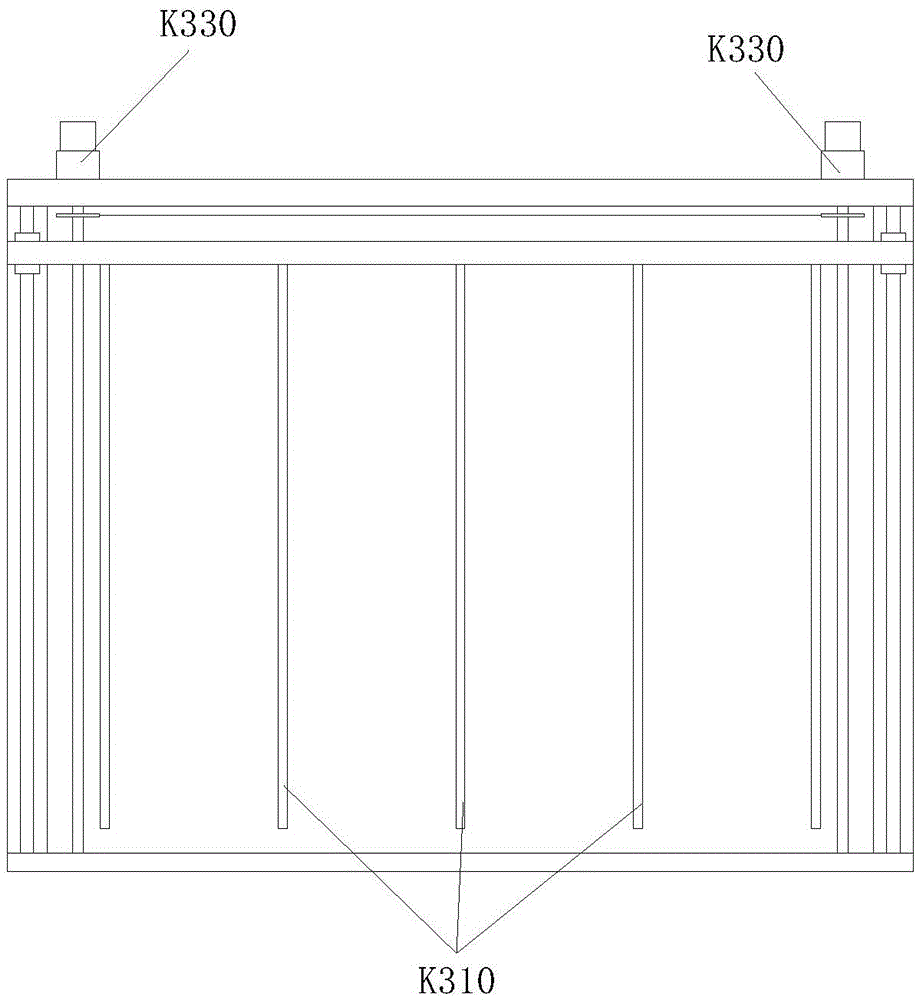

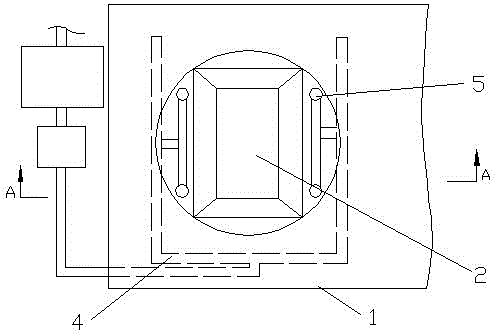

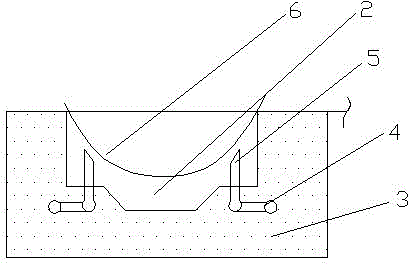

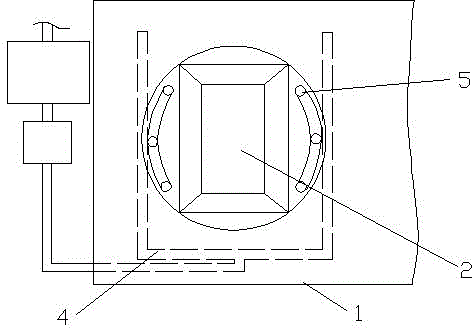

Rapid vulcanization die for building lamination shock insulation rubber bearing

InactiveCN103786282AAvoid heat transfer barriersAchieving direct heat conductionVulcanizationEngineering

The invention discloses a rapid vulcanization die for a building lamination shock insulation rubber bearing. The rapid vulcanization die comprises an inner heating die with a heat conduction strip, an outer heating die with a heat conduction strip, an excessive glue groove, heat conduction strips, an upper heating template, a lower heating template, a positioning shaft, a positioning hole and a positioning shaft mounting groove, wherein the lower heating template is mounted on a support, the outer heating die with the heat conduction strip is arranged on the upper surface of the lower heating template, the inner heating die with the heat conduction strip is arranged in the center of the outer heating die with the heat conduction strip, the height of the outer heating die with the heat conduction strip is equal to that of the inner heating die with the heat conduction strip, and the upper heating template is arranged at the tops of the outer heating die with the heat conduction strip and the inner heating die with the heat conduction strip. The rapid vulcanization die fully utilizes the structural principle of vulcanization equipment and a vulcanization target to realize rapid and uniform vulcanization and efficient mounting, is applicable to vulcanization processing of various rubber bearings, such as a standard rubber bearing, a pencil lead rubber bearing, a high damping rubber bearing and a stacked rubber bearing, and is high in vulcanization efficiency and rapid and convenient to mount and maintain.

Owner:彭勃

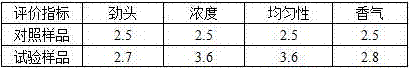

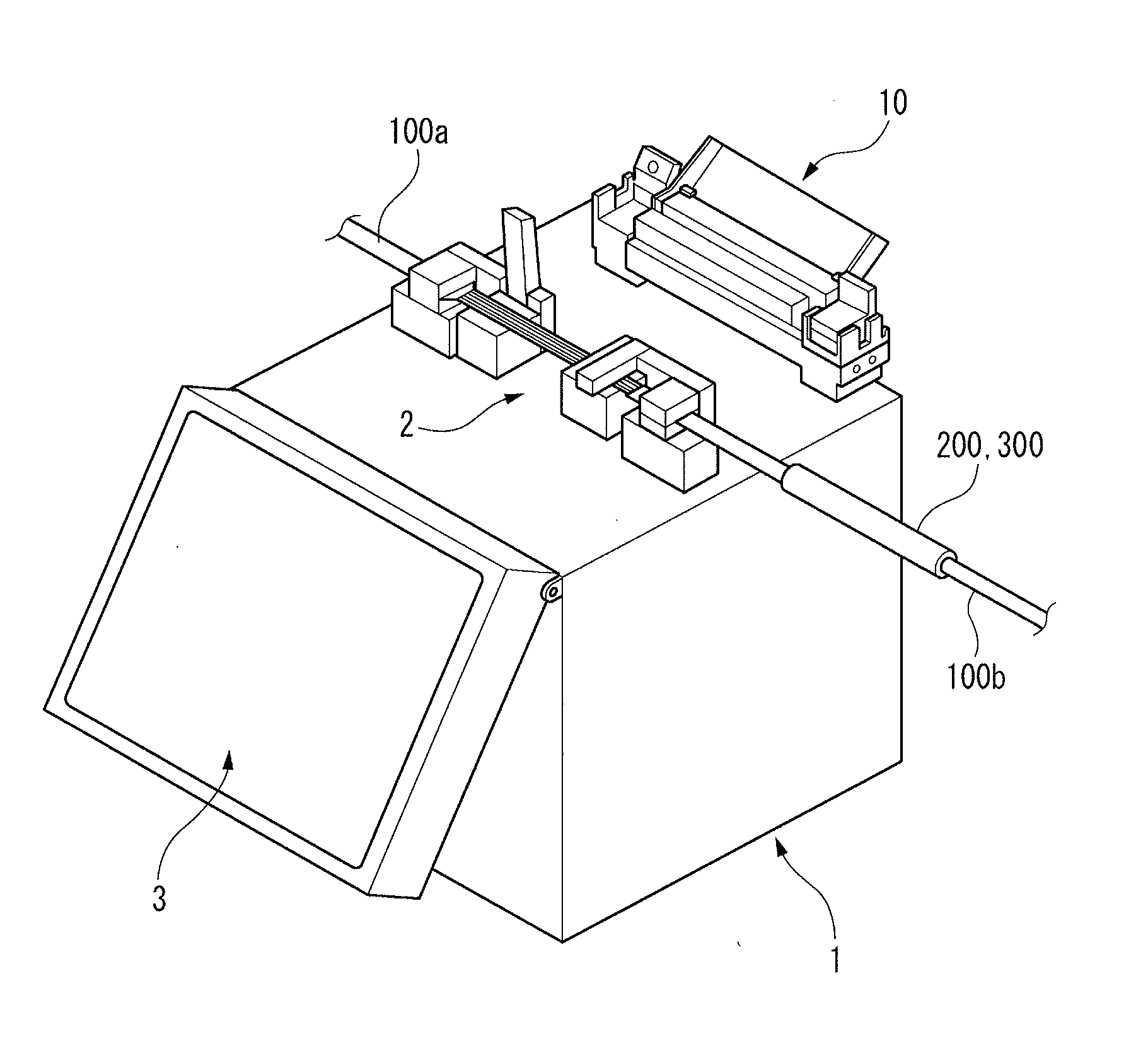

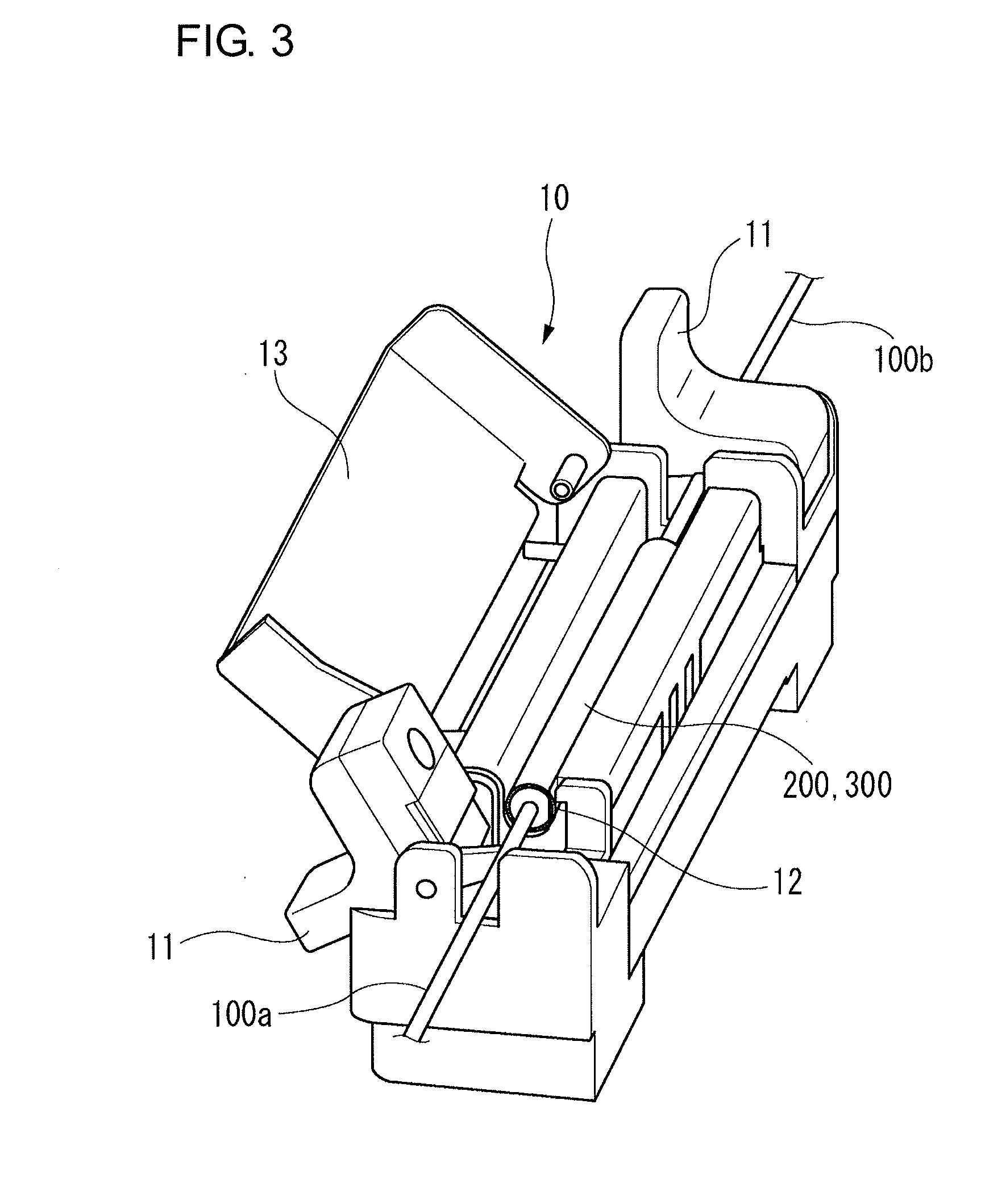

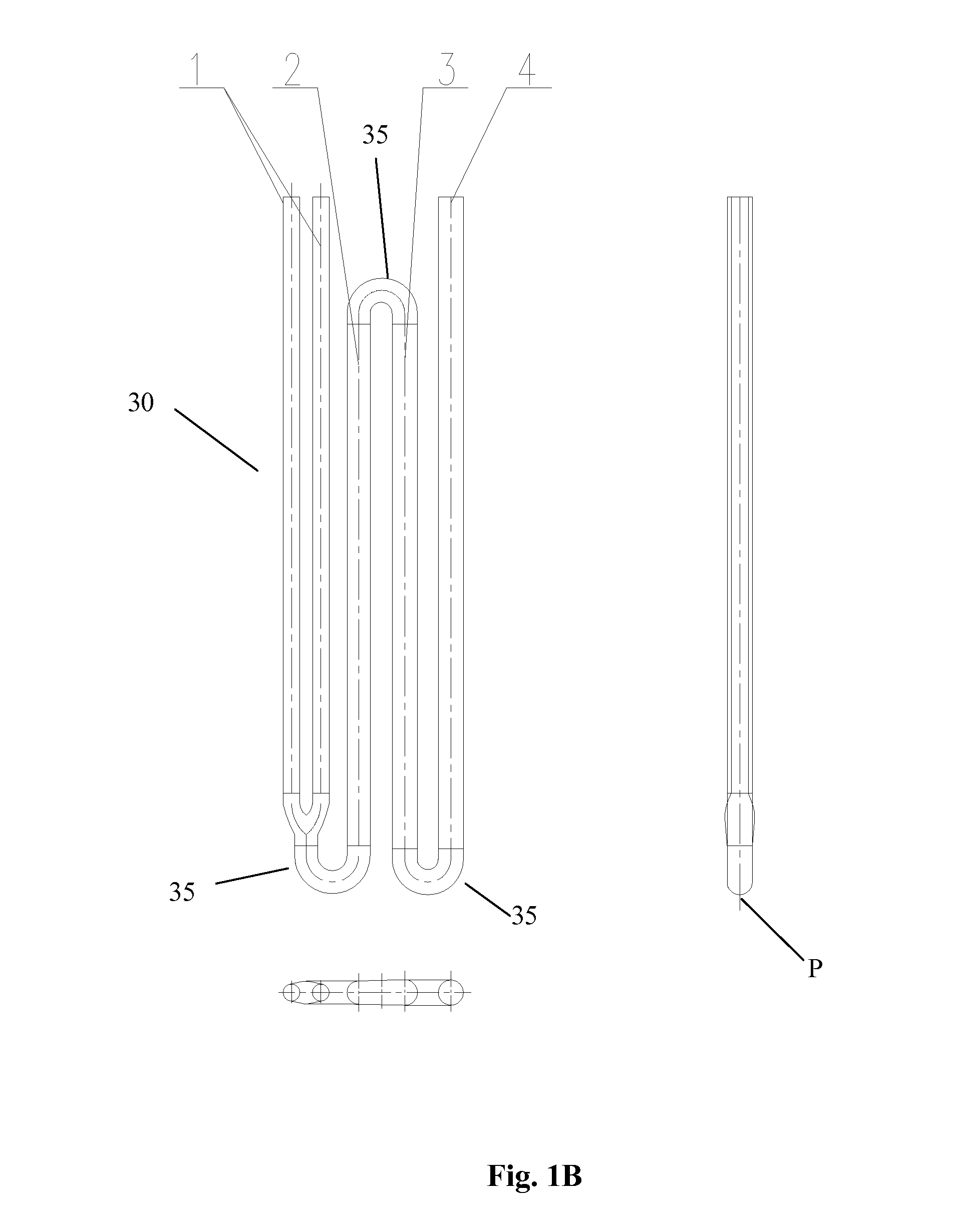

Heat treatment device for optical fiber reinforcing member, optical fiber fusion splicer provided with same heat treatment device, and method for heat treating optical fiber reinforcing member

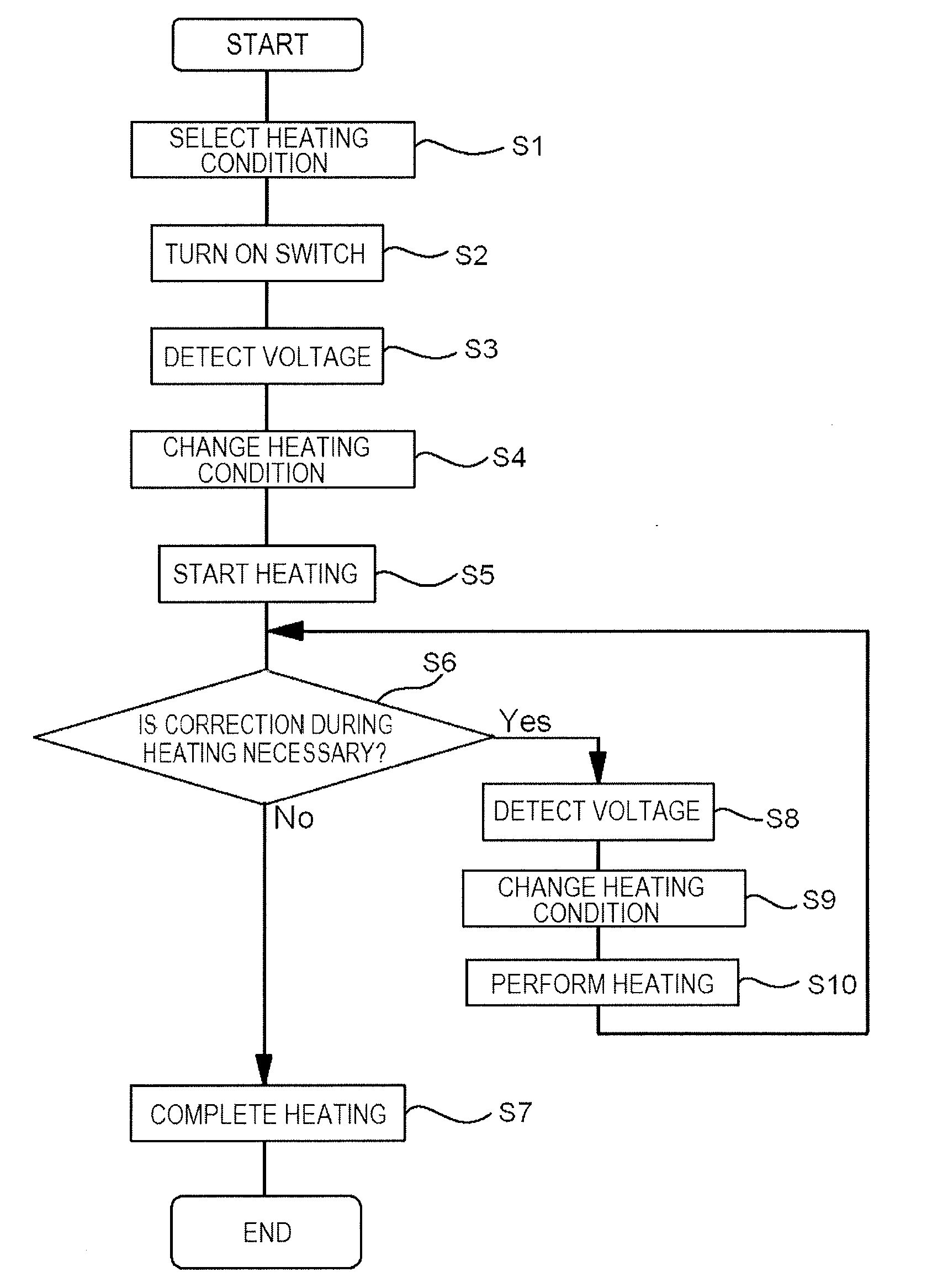

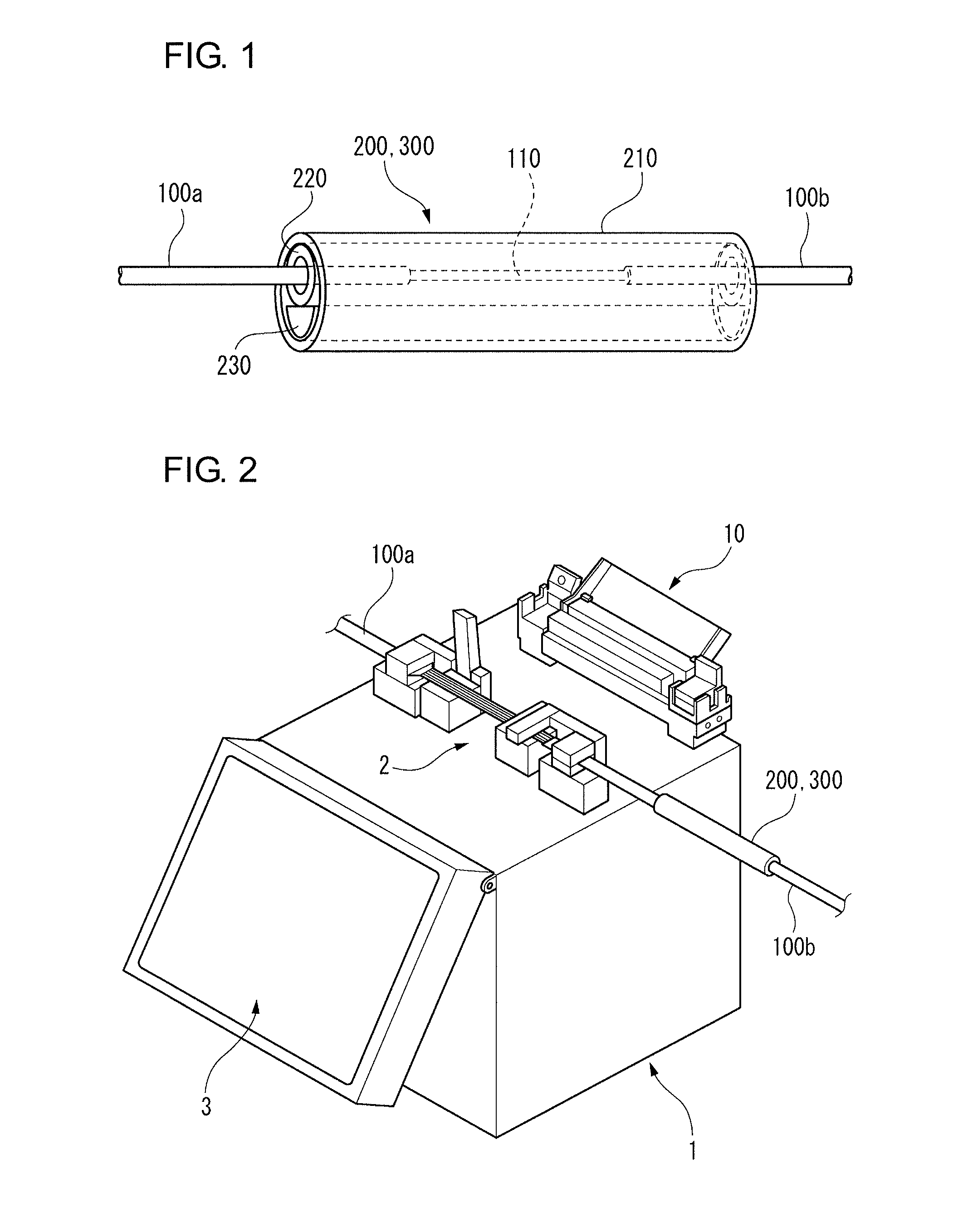

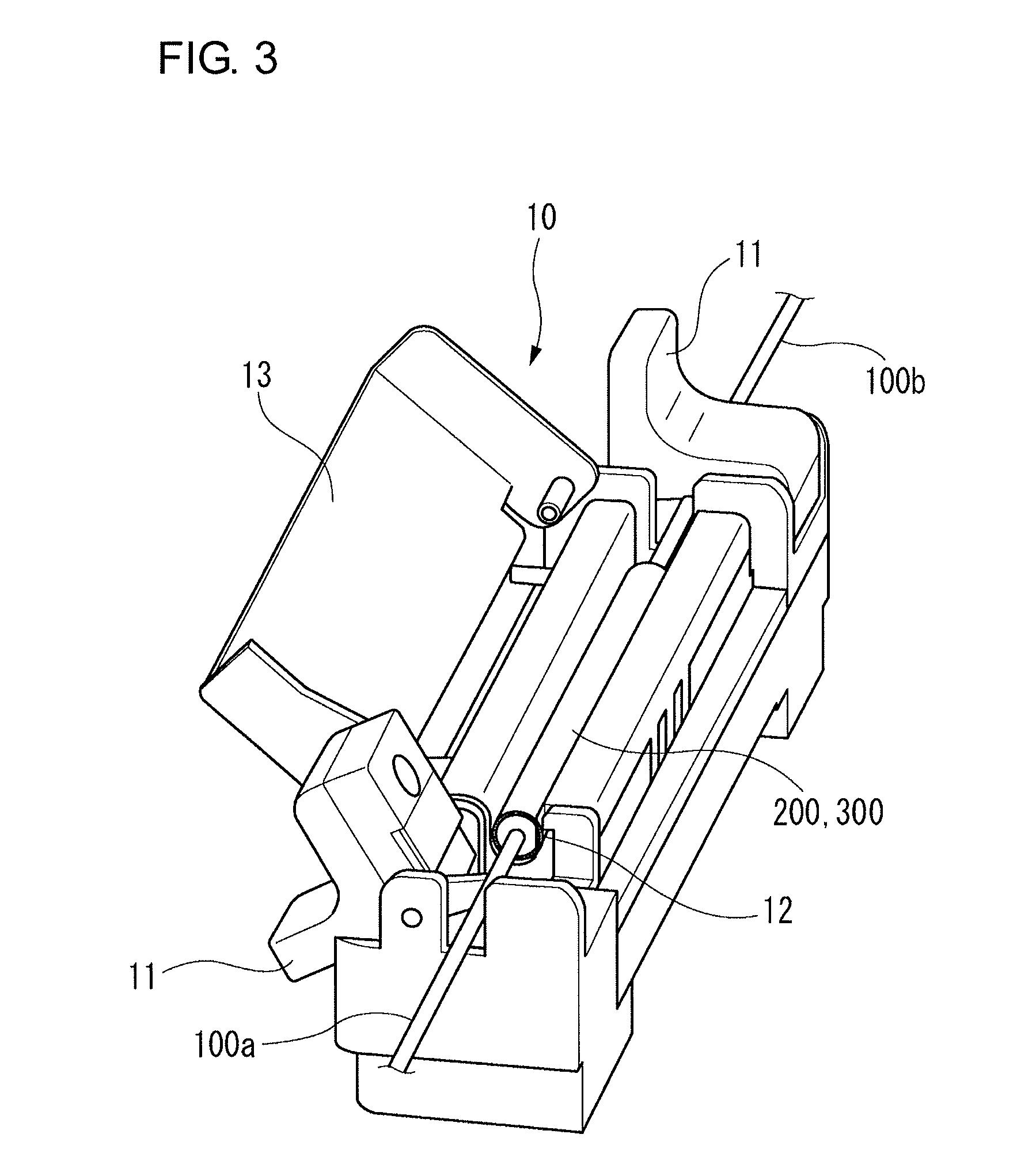

ActiveUS20150168649A1Improve heating conditionsElectric heatingCoupling light guidesFiberInstruction unit

A heating device for heating an optical fiber reinforcing member includes fiber holders to hold optical fibers covered with the reinforcing member at a fusion-spliced portion, a heater to heat the reinforcing member, a power supply unit to apply a voltage to the heater, and a controller to control the application of a voltage from the power supply unit to the heater. The controller includes a detecting unit that detects a parameter for determining the amount of heat generation of the heater, a storage unit that stores a plurality of heating conditions that vary depending on the parameter value, and a condition instruction unit that selects any of the plurality of heating conditions in accordance with the parameter value detected by the detecting unit and instructs the power supply unit to apply a voltage to the heater on the basis of the selected heating condition.

Owner:SEI OPTIFRONTIER CO LTD

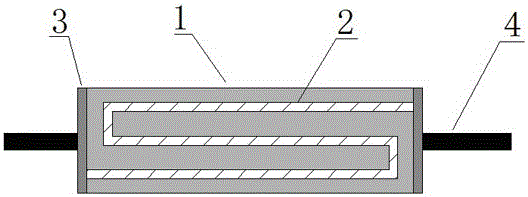

Heater structure for heating and activating micro-miniature self-heating air suction agents and method for manufacturing heater structure

ActiveCN105858587AGood consistencyIncrease surface areaSolid-state devicesFluid speed measurementChemical platingGetter

The invention relates to the field of vacuum packaging technologies for MEMS (micro-mechanical systems) sensors, in particular to a heater structure for heating and activating micro-miniature self-heating air suction agents and a method for manufacturing the heater structure. The heater structure comprises a ceramic body, metal slurry, metal coatings and metal leading wires. The inside of the ceramic body is divided into a plurality of layers, the metal slurry wraps each layer, metal slurry layers are communicated with one another in the up-down directions, the metal slurry on two end surfaces of the ceramic body is reserved to be exposed, the metal coatings are formed on two end surfaces of the ceramic body by means of chemical plating or electroplating, and the metal leading wires of heating electrodes are welded on the two end surfaces of the ceramic body after the metal coatings are formed. The heater structure and the method have the advantages that resistance of the metal slurry layers is controlled, so that the consistency of resistance values of different devices can be guaranteed; whether heating and activating temperatures reach ideal activating temperatures of air suction materials or not can be monitored by special circuits in an online manner and can be controlled, accordingly, the activated air suction agents can be assuredly in the optimal activated states, and the activated states of the air suction agents are consistent and stable on a large scale.

Owner:XINFOO SENSOR TECH CO LTD

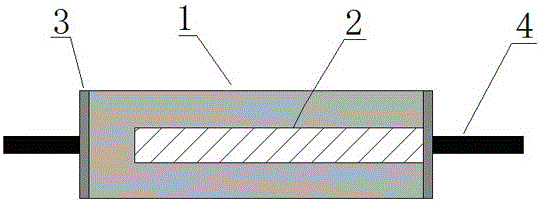

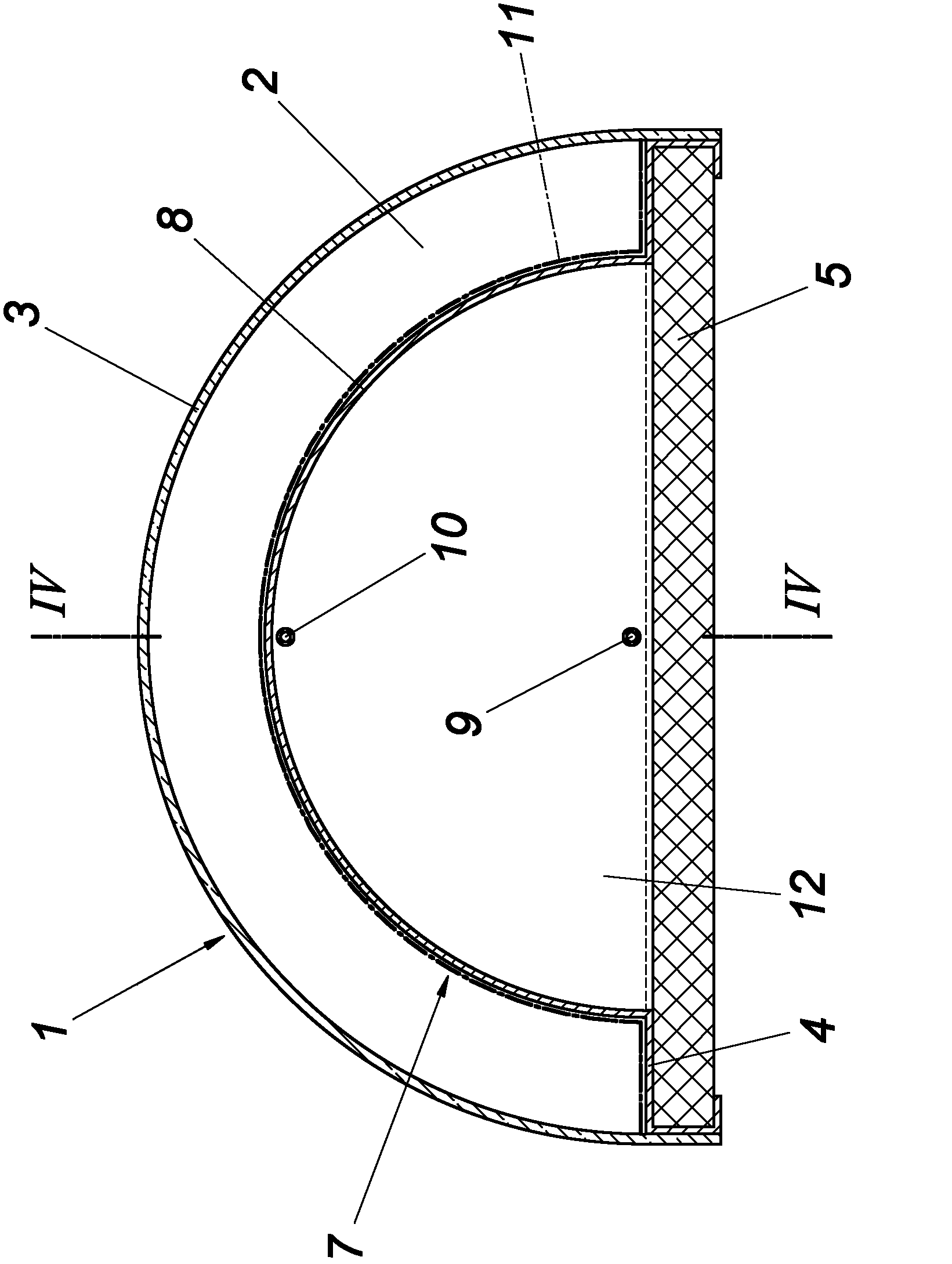

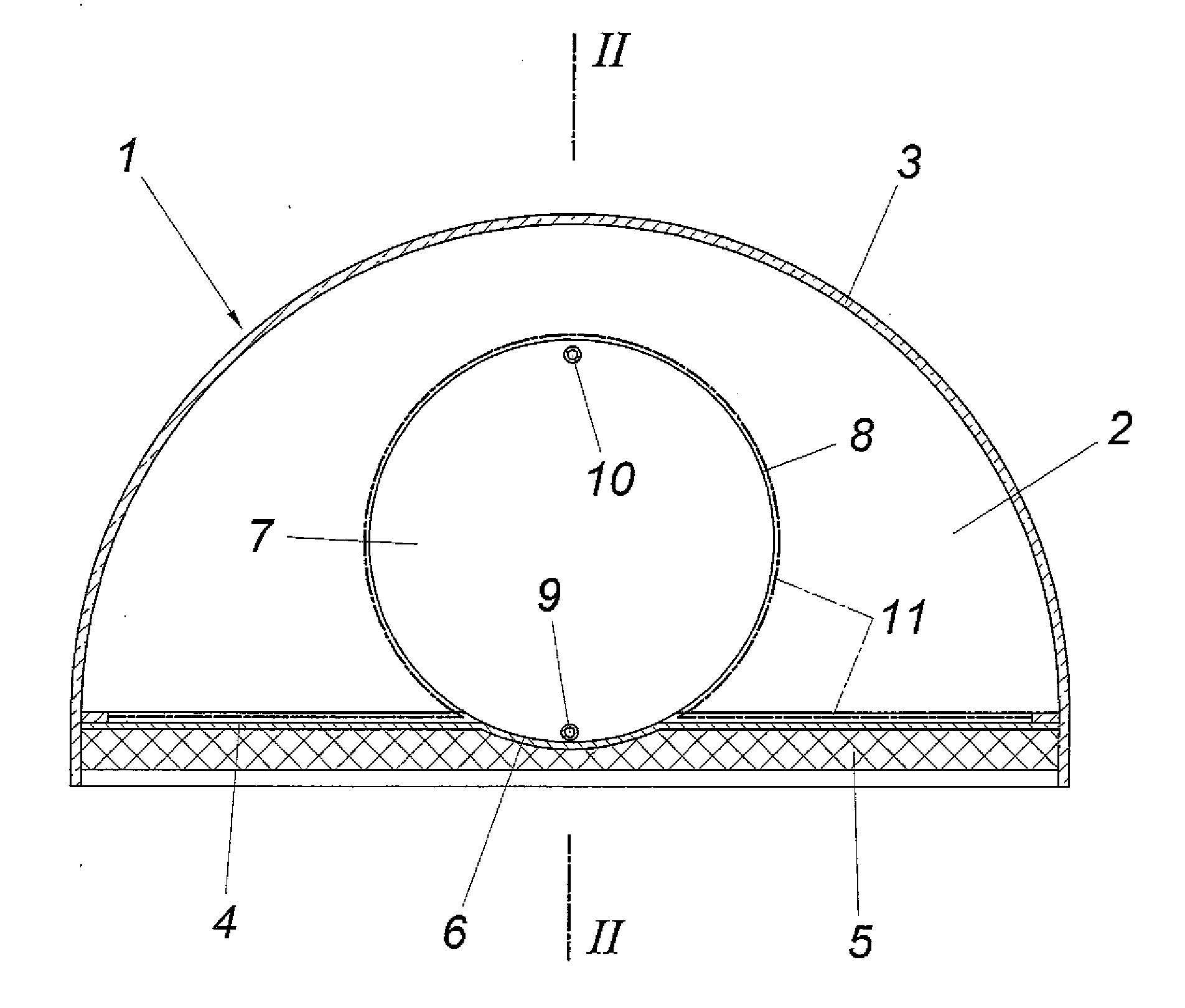

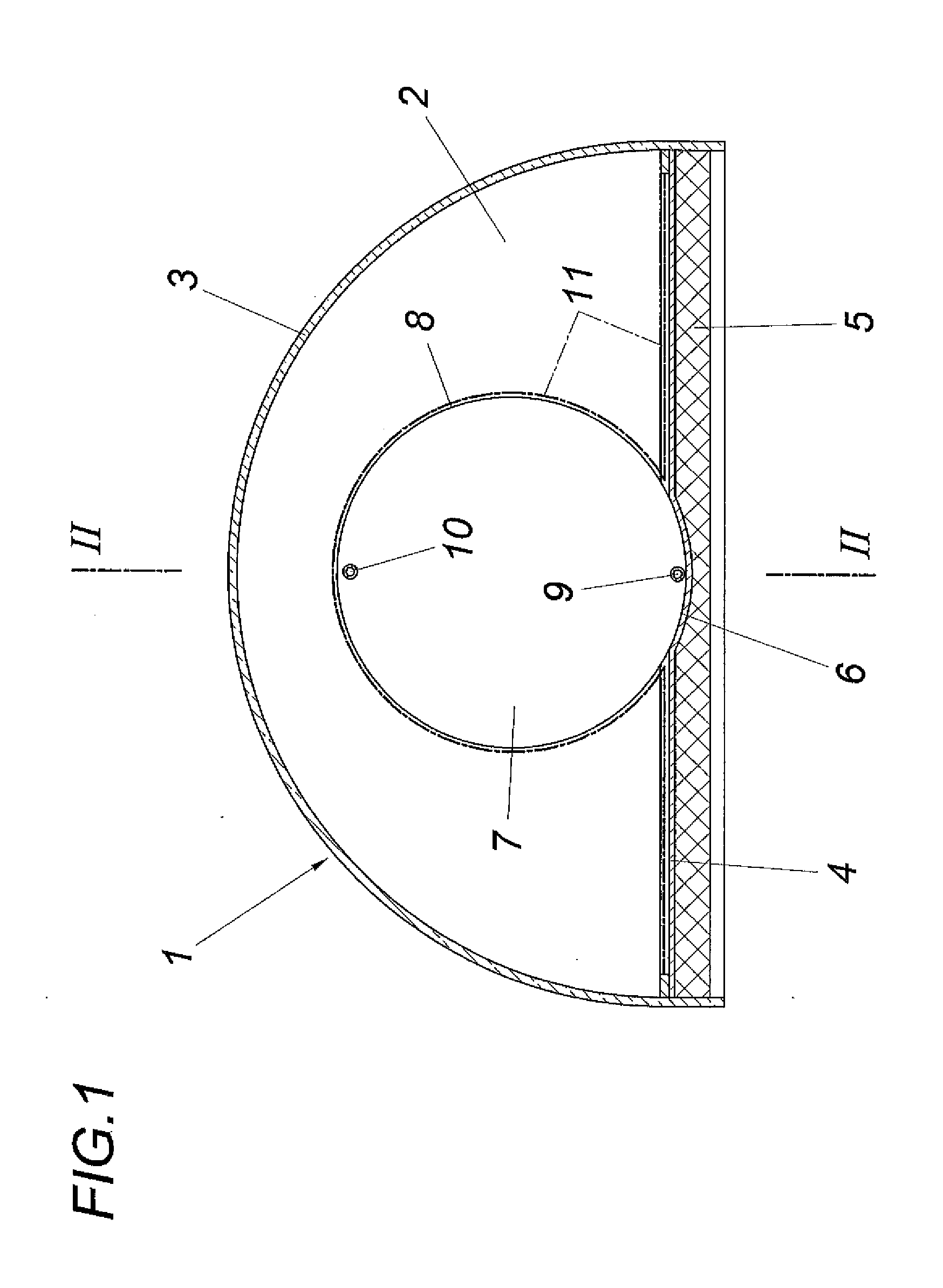

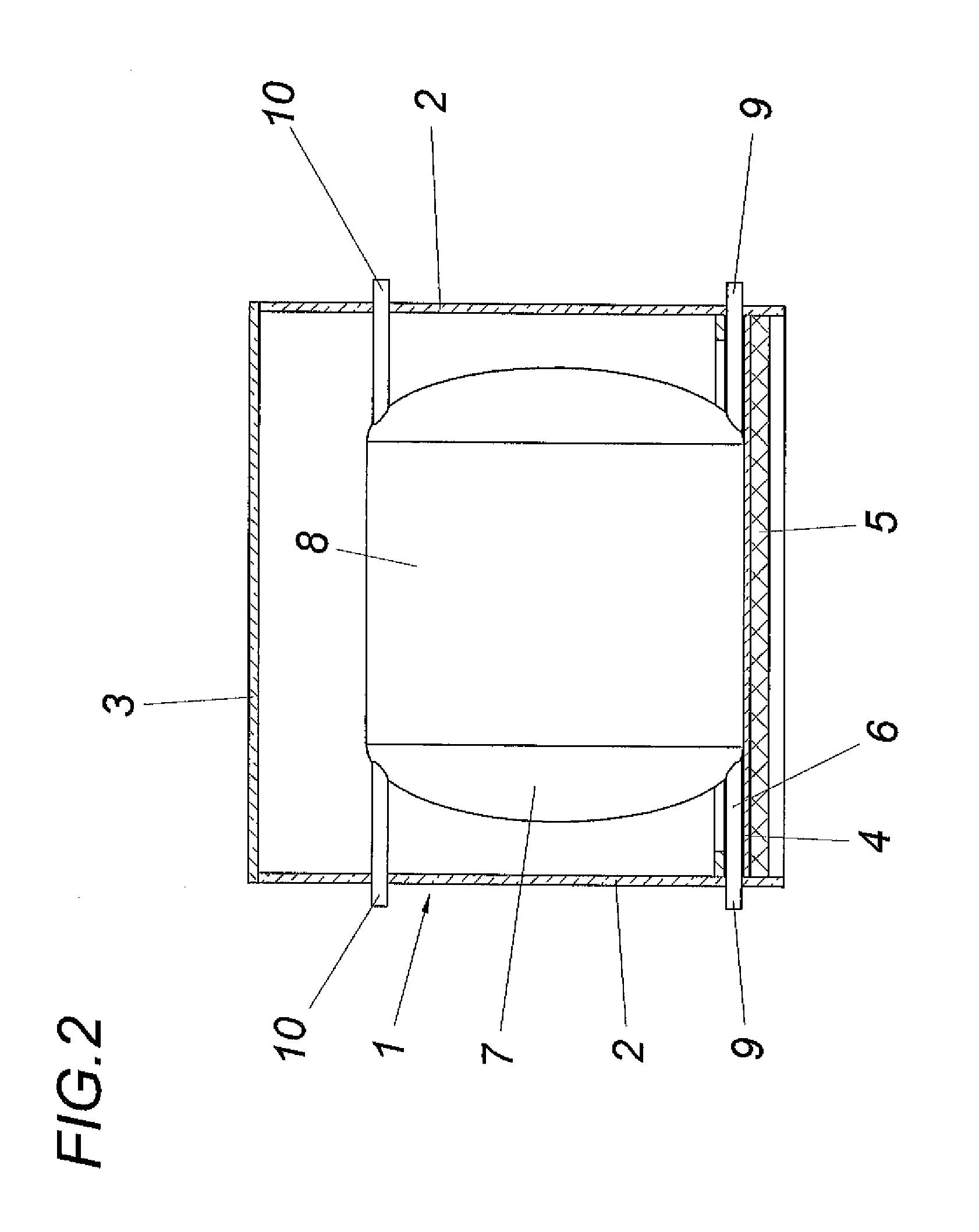

Device for heating process water

InactiveCN102422097AEfficient use ofImprove heating conditionsSolar heating energySolar heat devicesEnvironmental engineeringSolar energy harvesting

The invention relates to a device for heating process water by means of a solar collector, which comprises a process water container (7) having a partially cylindrical jacket (8) as an absorber and an enclosure (1) that covers the process water container (7). The enclosure forms a transparent cylindrical jacket (3), the axis of which extends parallel with the axis of the jacket (8) of the process water container (7). In order to create advantageous heating conditions, the process water container (7) is connected in a thermally conducting manner to an absorber plate (4) that forms a bottom of the enclosure (1), and the absorber plate (4) and the jacket (8) of the process water container (7) are covered by a coarsely meshed, heat-insulating woven fabric (11).

Owner:沃尔特·弗莱勒

Apparatus for heating service water

InactiveUS20120067335A1Improve efficiencyImprove overall utilizationSolar heating energySolar heat devicesWater tanksSolar energy harvesting

An apparatus is described for heating service water with a solar collector, comprising a service water tank (7) with a partly cylindrical jacket (8) as an absorber and an enclosure (1) which covers the service water tank (7) and forms a translucent cylindrical jacket (3), the axis of which extends parallel to the axis of the jacket (8) of the service water tank (7). In order to provide advantageous heating conditions, it is proposed that the service water tank (7) is connected in a thermally conductive manner with an absorber plate (4) forming a bottom part of the enclosure (1) and that the absorber plate (4) and the jacket (8) of the service water tank (7) are covered with a wide-meshed, thermally insulating fabric (11).

Owner:FRELLER WALTER

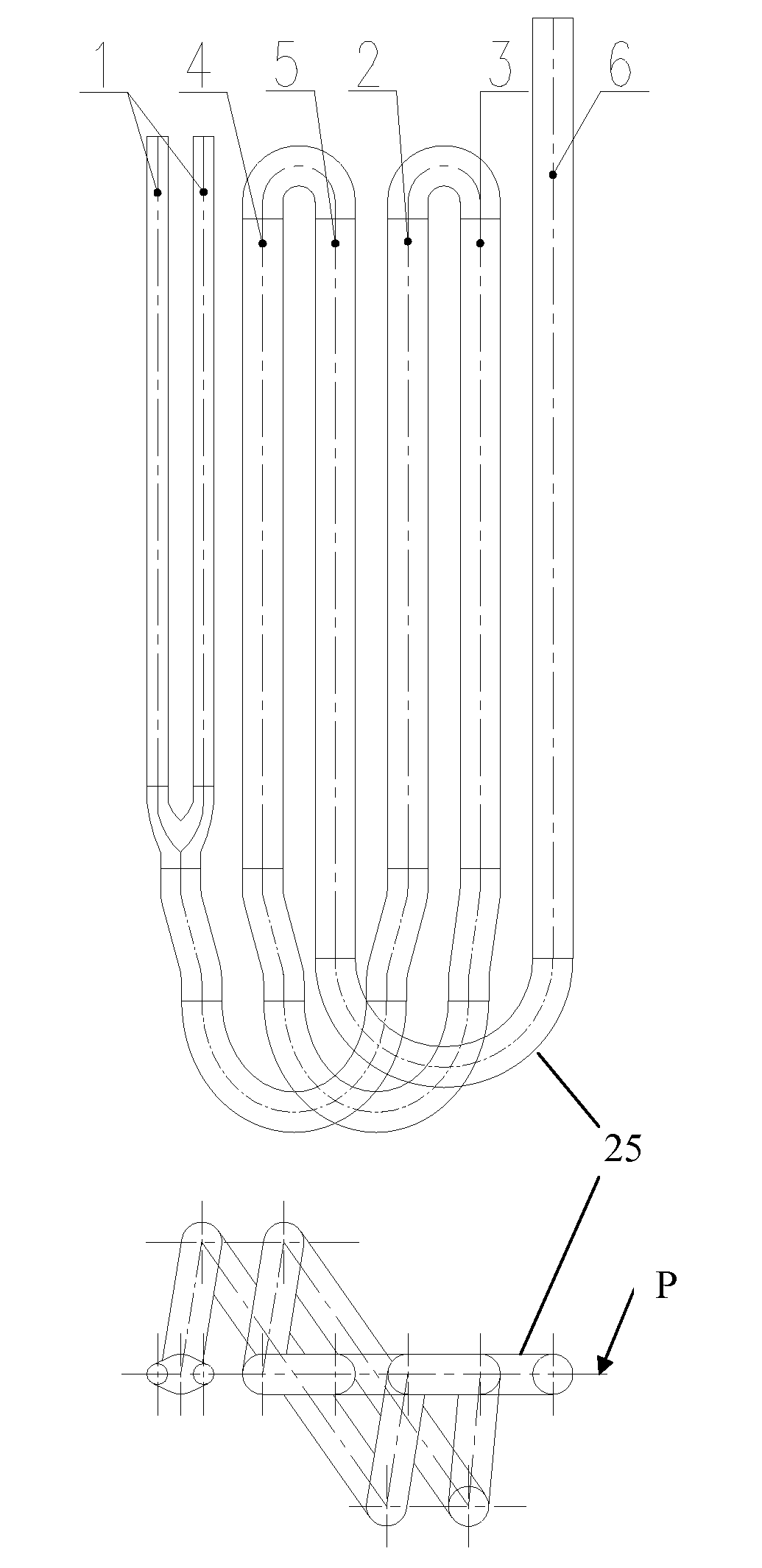

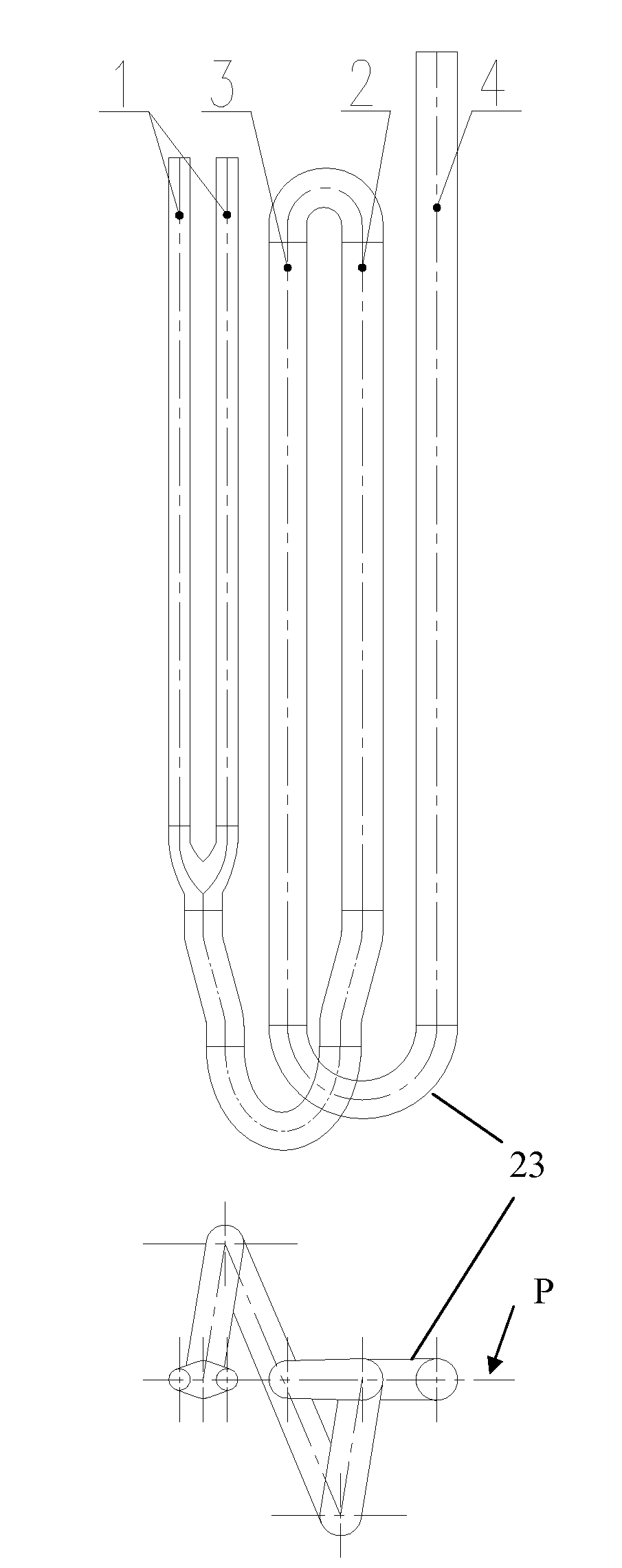

Ethylene Cracking Furnace With Multi-Pass Radiant Coil

ActiveUS20120219466A1Compact structureReduce influenceChemical/physical/physico-chemical processesHydrocarbon by hydrocarbon crackingPhysicsThermal radiation

The invention relates to an ethylene cracking furnace having a multi-pass radiant coil, comprising at least one radiant section. In the radiant section there are provided with bottom burners and / or sidewall burners, and at least one set of multi-pass radiant coil longitudinally arranged in the radiant section. The multi-pass radiant coil is a four- to ten-pass type radiant coil. At least one tube of the multi-pass radiant coil is arranged to be spatially adjacent to a tube which is not consecutive to said at least one tube. With this arrangement, the thermal radiation influence between tubes with high temperature can be reduced, so that the tubes with low temperature can absorb the radiation heat from the tubes with high temperature. Therefore, the surface temperature of the tubes with high temperature can be reduced, thus extending the lifetime of the radiant coil and the operational cycle of the cracking furnace.

Owner:CHINA PETROCHEMICAL CORP +2

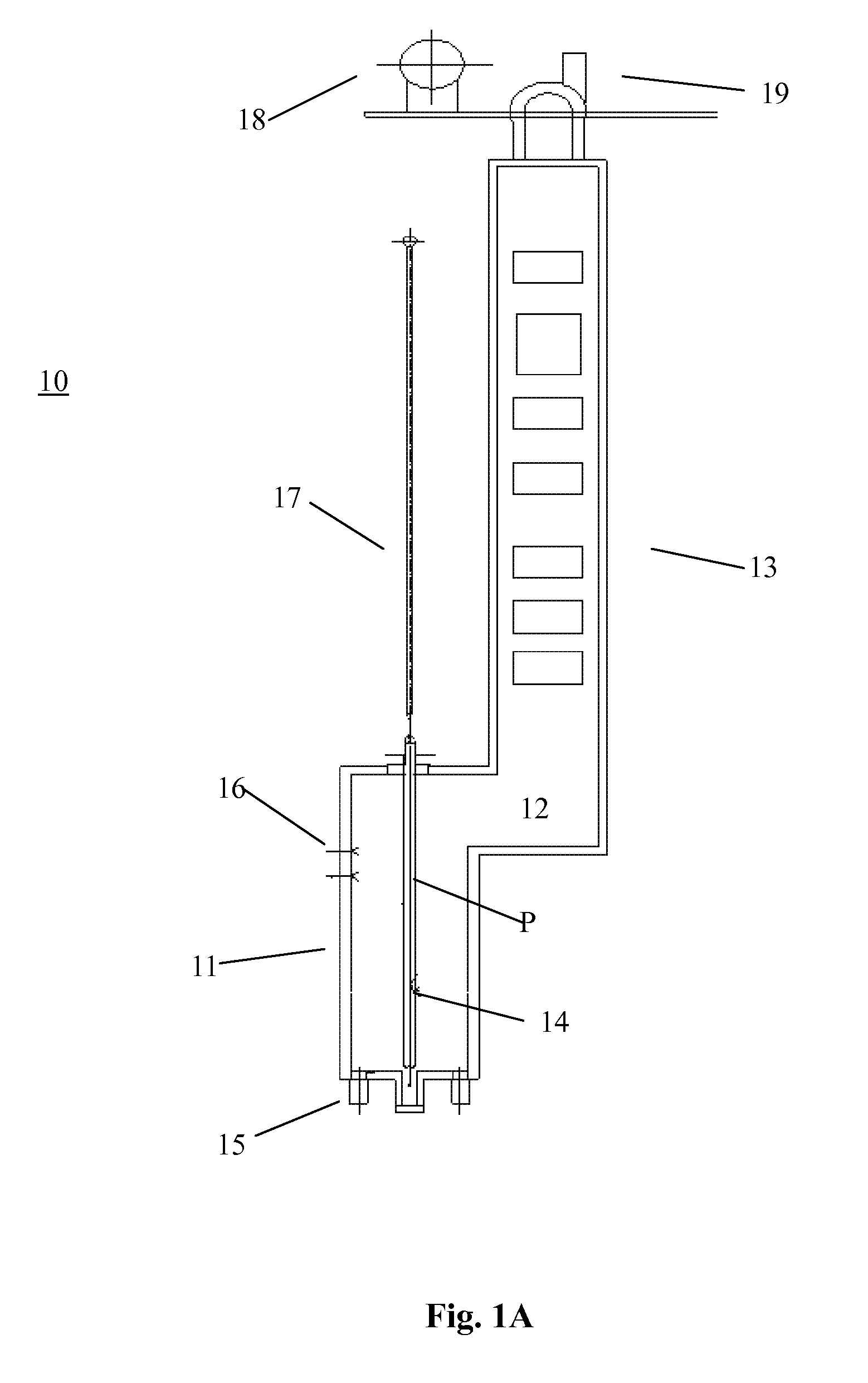

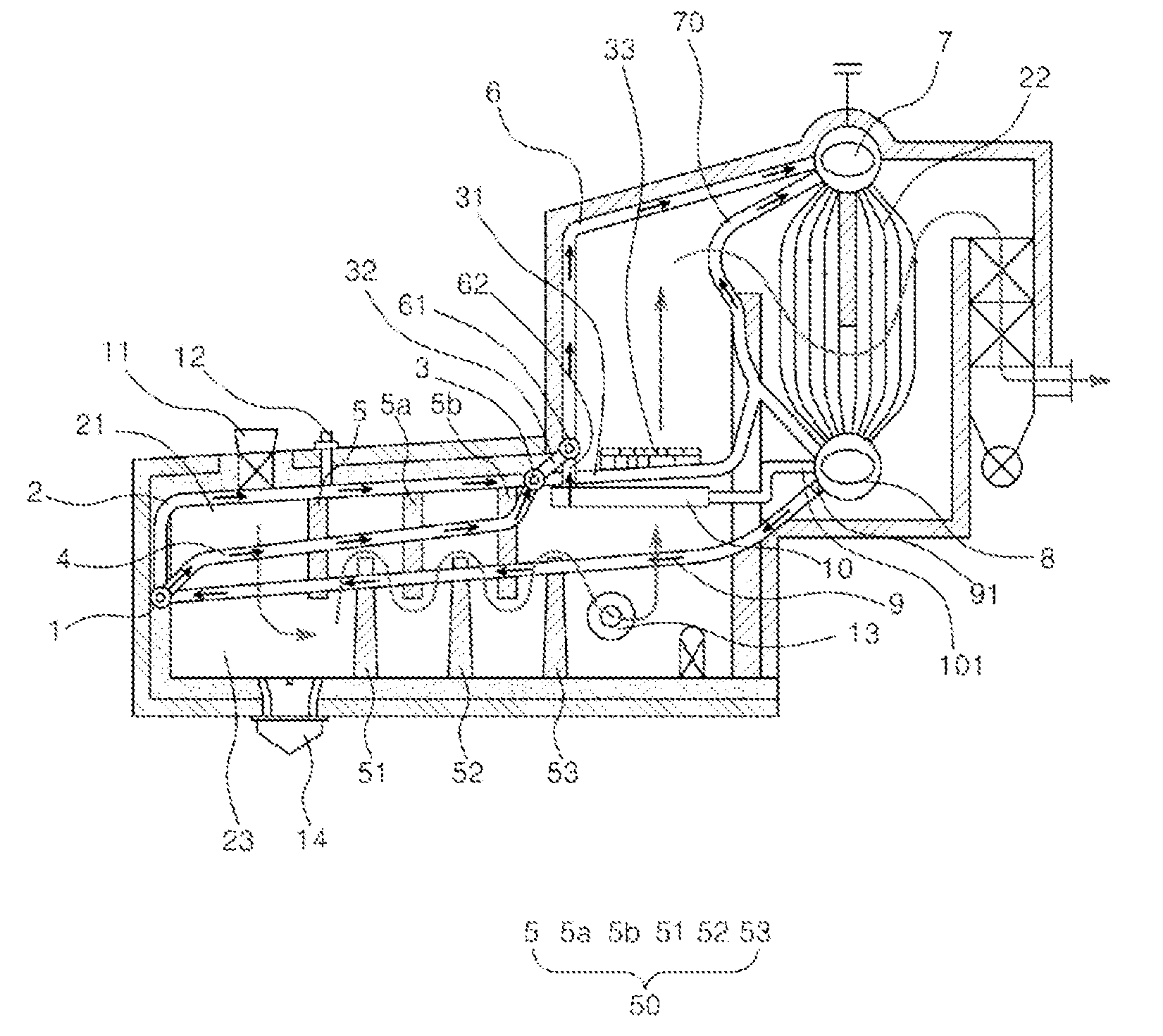

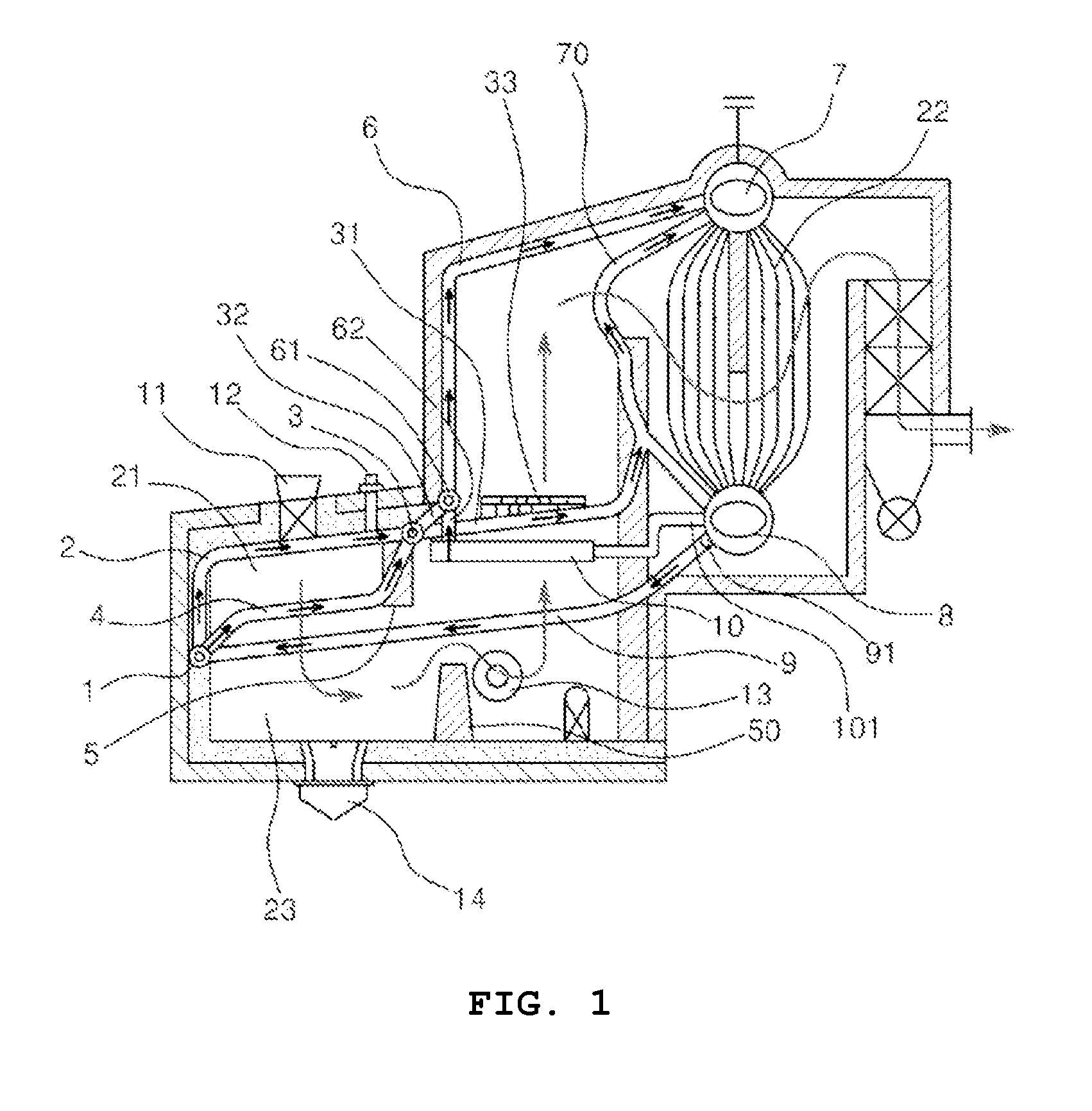

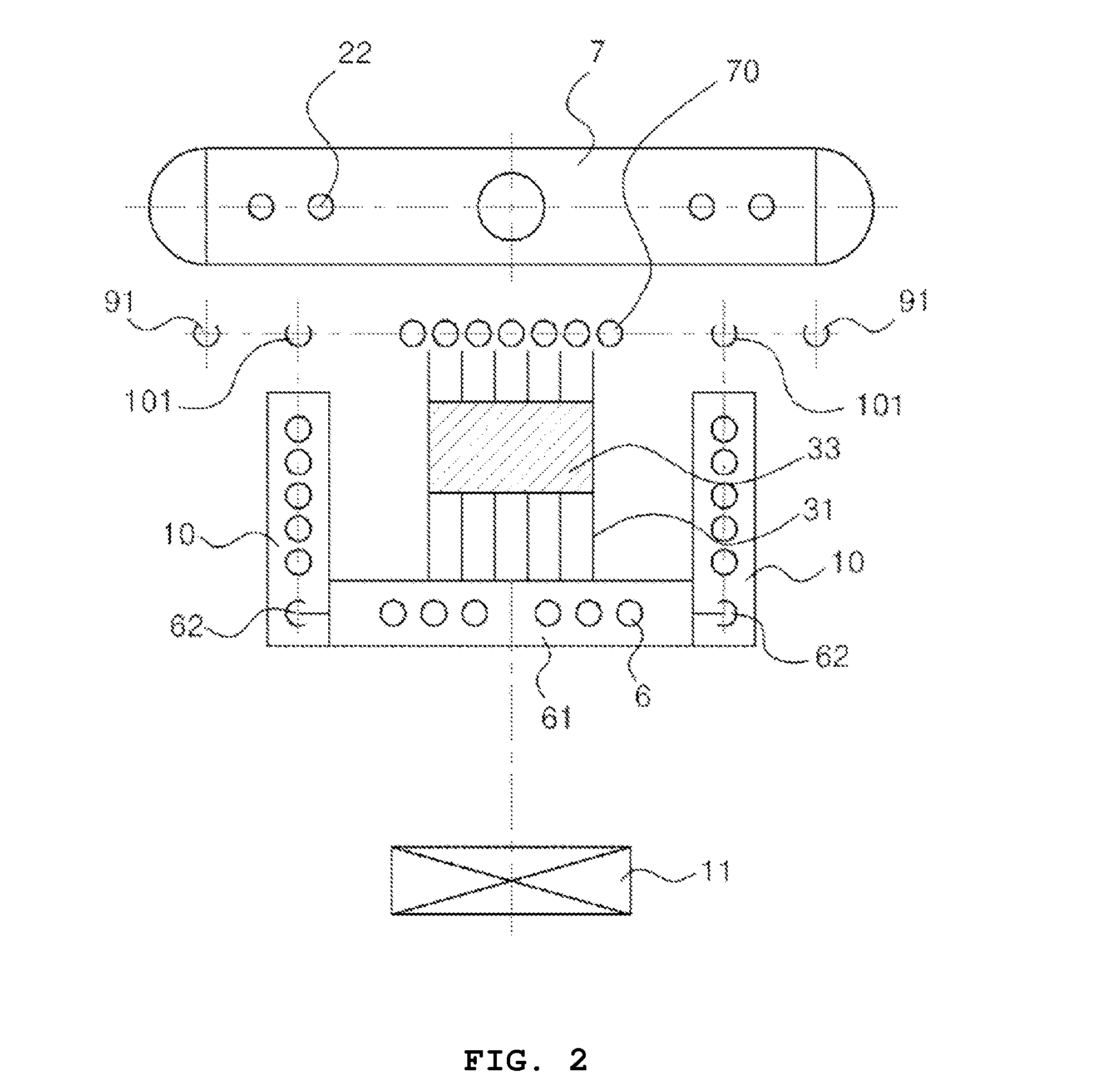

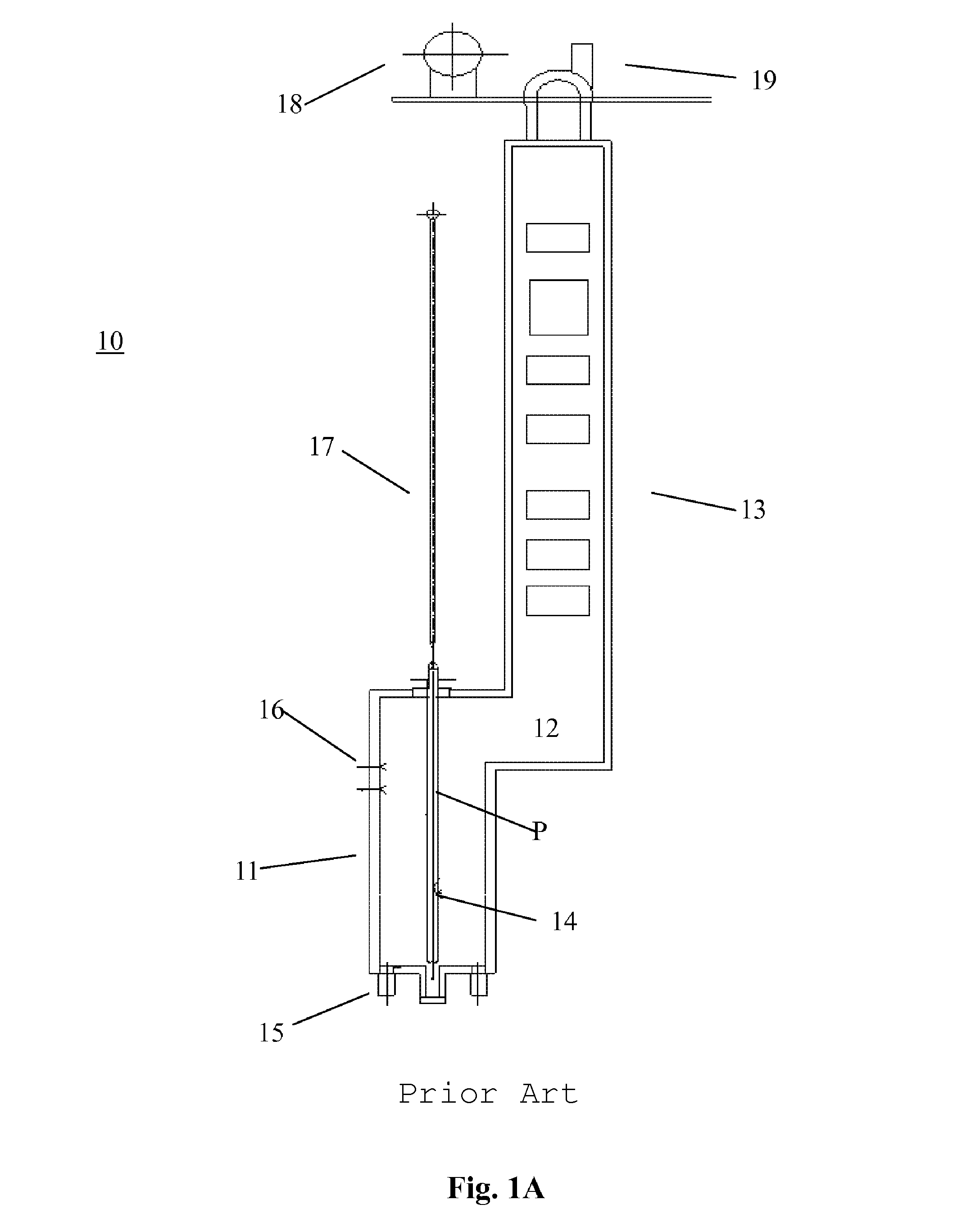

Suspended combustion type power steam generator capable of rapid and high-temperature pyrolysis using frdf for extending residence time of high-temperature gas

ActiveUS20150059659A1Rapid and high-temperature pyrolysisExtended stayDrum steam boilersEnergy inputRefuse-derived fuelCombustion chamber

There is provided a suspended combustion type power steam generator capable of rapid and high-temperature pyrolysis using FRDF for extending residence time of high-temperature gas, and particularly the present invention improves the heating conditions of fluid in an arch water pipe, a heating water pipe and a down pipe by extending the residence time of high-temperature gas inside a combustion chamber. The present invention is an improvement of a power steam generator using fine refuse derived fuel (FRDF) which is an alternative energy source, and a flameless combustion device using fossil fuel capable of structuring a new additional facility so as to address the possibility of irregular raw material supply in the ethyl alcohol fuel operation for new renewable energy, that is, FRDF. Therefore, fuel conversion operations can be carried out and a circulation path is partially restructured so as to prevent the interruption of the natural convection function of boiler water regardless of FRDF operation or fossil fuel operations. The existing power steam generator is commonly used in 0.5 tons class and has the problem of having a short residence time of high-temperature gas according to the heating conditions of fluid in a large capacity power steam generator of 5 tons or higher. The present invention extends the residence time of high-temperature gas in the combustion chamber by installing a baffle plate portion so as to sufficiently satisfy the heating condition of fluid as the result.

Owner:KOREA INST OF ENERGY RES +1

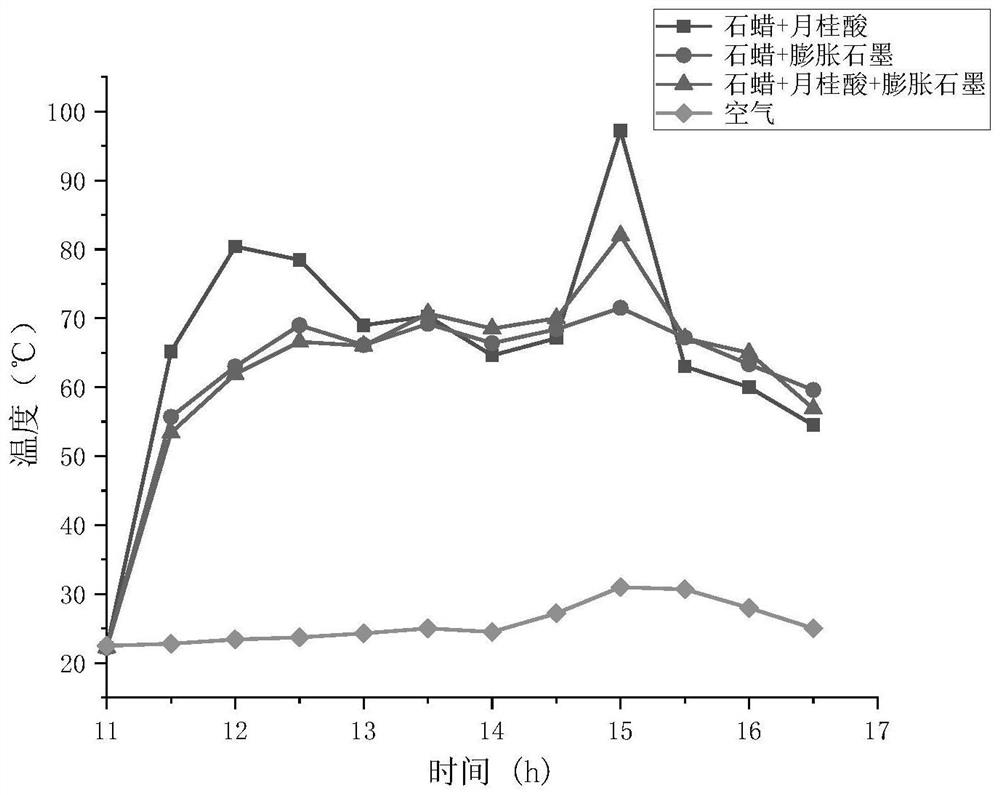

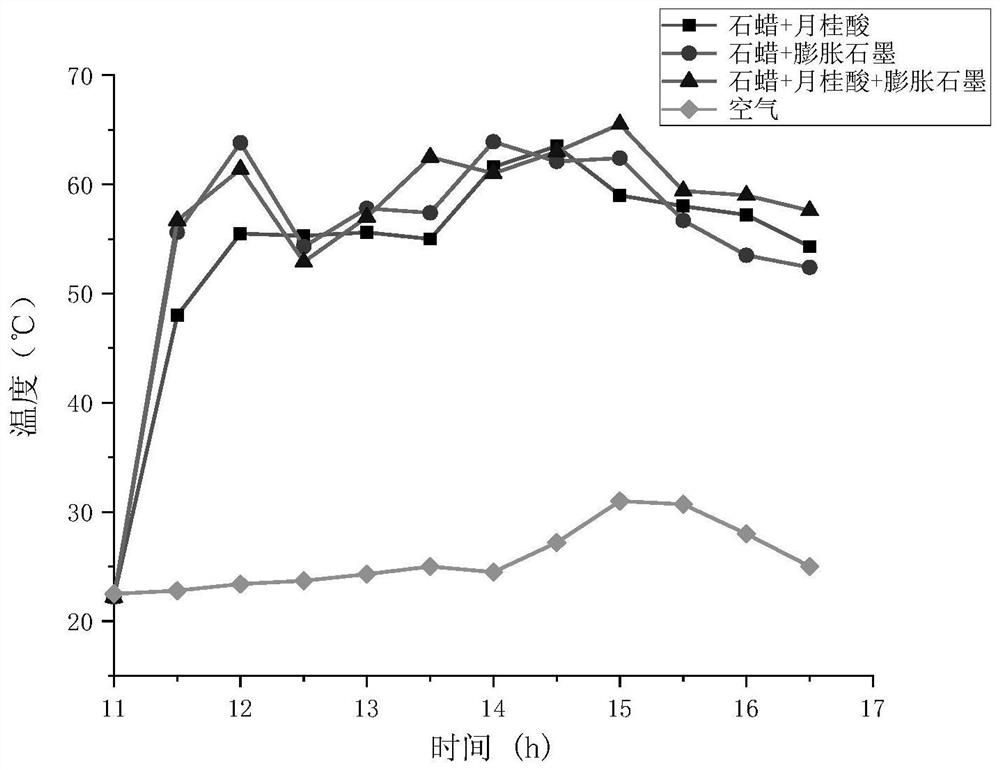

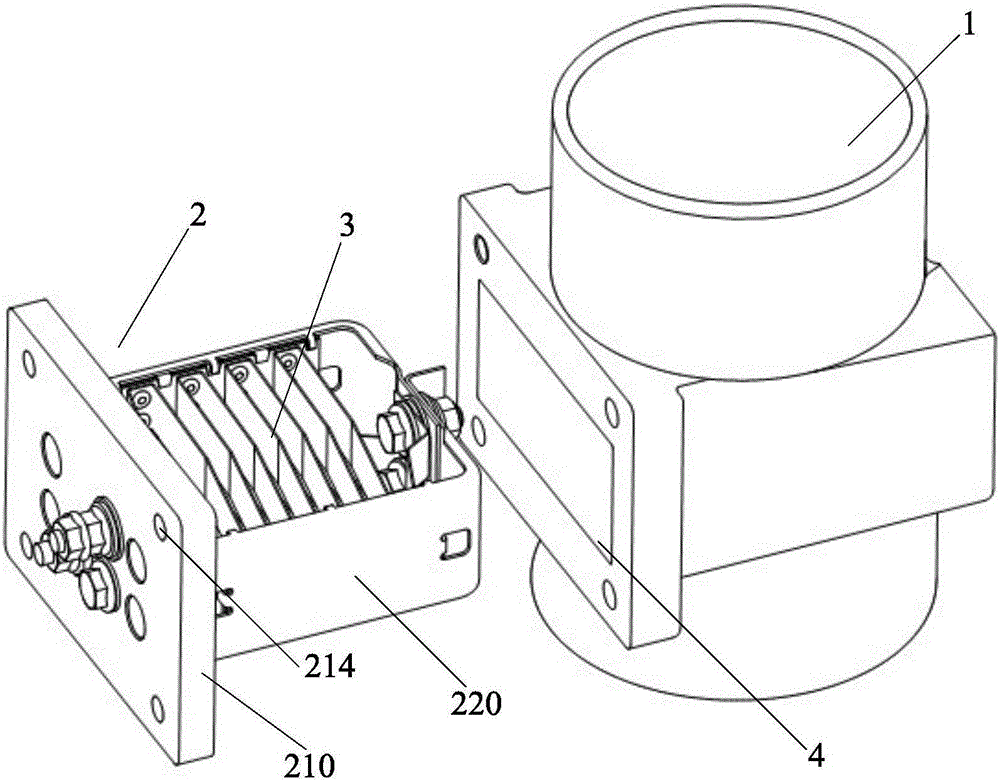

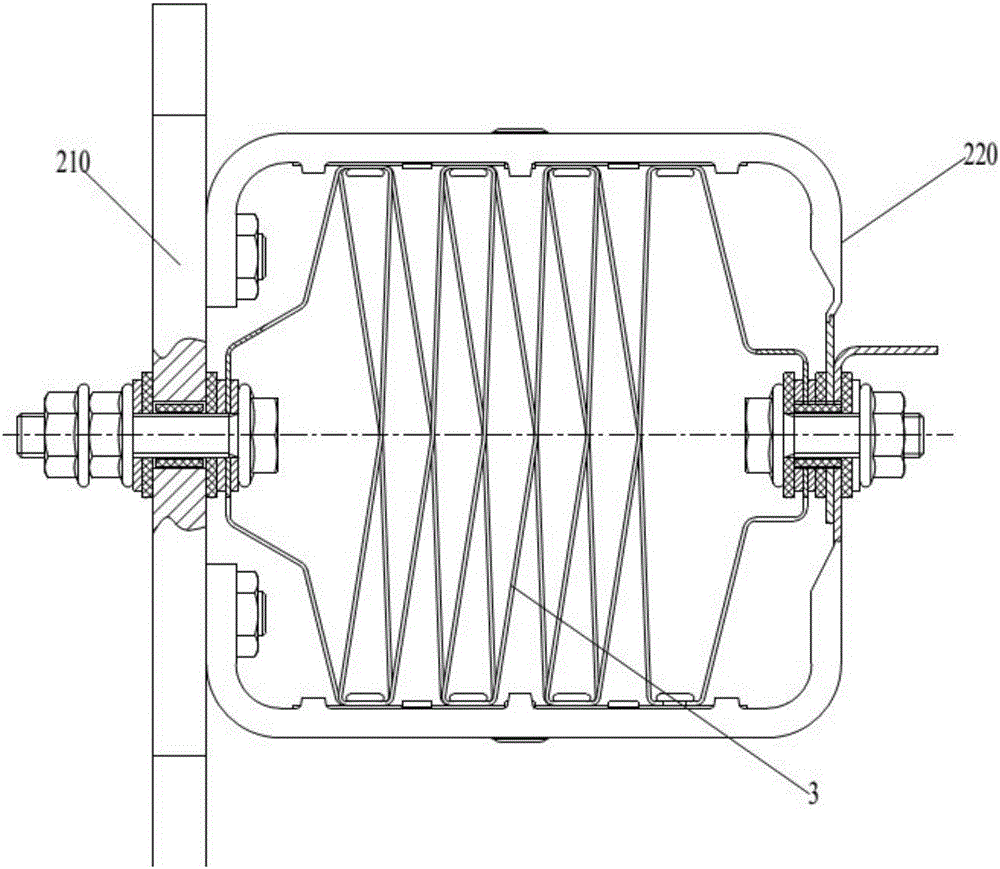

Solar photovoltaic photo-thermal coupling drying box

PendingCN114396765AImprove thermal conductivityHigh latent heat of vaporizationSolar heating energyBatteries circuit arrangementsFresnel lensComposite media

The invention discloses a solar photovoltaic photo-thermal coupling drying box which comprises a heat storage layer and a drying layer, the heat storage layer is of an inverted-V-shaped structure and is arranged above the drying layer, Fresnel lenses are arranged on the two slopes of the top of the heat storage layer, and a composite medium layer internally provided with paraffin, lauric acid and expanded graphite is arranged on the two slopes of the top of the heat storage layer. The heat storage layer and the drying layer are communicated through a plurality of ventilation copper pipes, the upper ends of the ventilation copper pipes are arranged in the composite dielectric layer, the top of the heat storage layer and the bottom of the drying layer are provided with an induced draft fan and an exhaust fan respectively, the induced draft fan and the exhaust fan are connected with a storage battery, the storage battery is connected to a photovoltaic panel through a charging module, and the photovoltaic panel is installed above the heat storage layer. The composite medium layer of the composite phase change material prepared by mixing graphite, lauric acid and paraffin is arranged in the heat storage layer, the expanded graphite improves the thermal conductivity of the paraffin, the lauric acid reduces the phase change temperature of the paraffin, the Fresnel lens improves the heating condition of the heat storage medium, the heat exchange efficiency of equipment is high, and the drying effect is better.

Owner:GUIZHOU UNIV

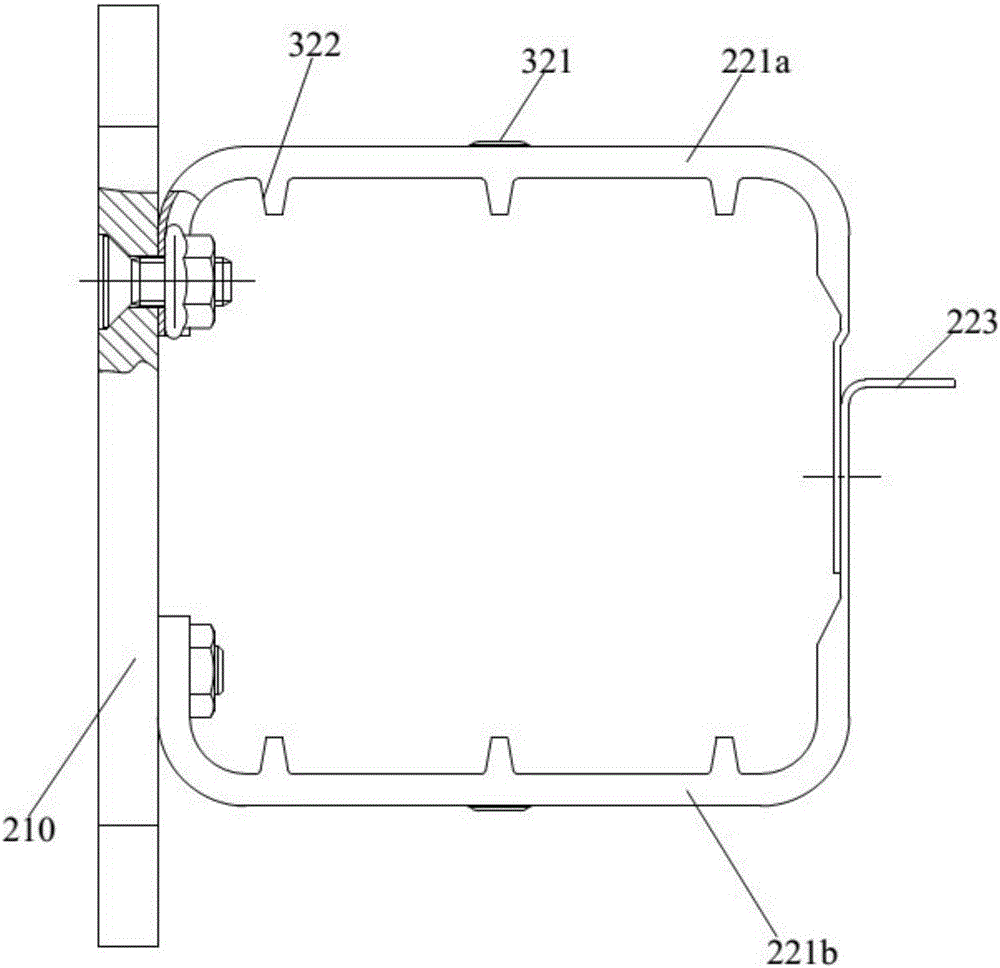

Air heater of diesel engine

InactiveCN105020065AAvoid thermal deformationAnti-damageMachines/enginesThermal treatment of fuelEngineeringDiesel engine

The invention discloses an air heater of a diesel engine. The air heater comprises a shell component and a heating body component, wherein the shell component is a frame having a center cavity, and comprises a mounting basal plate and a shell skeleton; one end of the shell skeleton is fixed on the mounting basal plate; the shell skeleton is manufactured by a heat resistant material; the heating body component is fixed in the center cavity of the shell component; the shell skeleton and the heating body component are both inserted into an air inlet pipe through an opening of the air inlet pipe; and the mounting basal plate is fixed outside the air inlet pipe, and closes the opening of the air inlet pipe. The mounting basal plate of the air heater is arranged outside the air inlet pipe, and the high-melting-point shell skeleton is arranged in the air inlet pipe, so that the fusion phenomenon caused by overhigh temperature of the shell component of the heater is solved.

Owner:北京奥博汽车电子电器有限公司

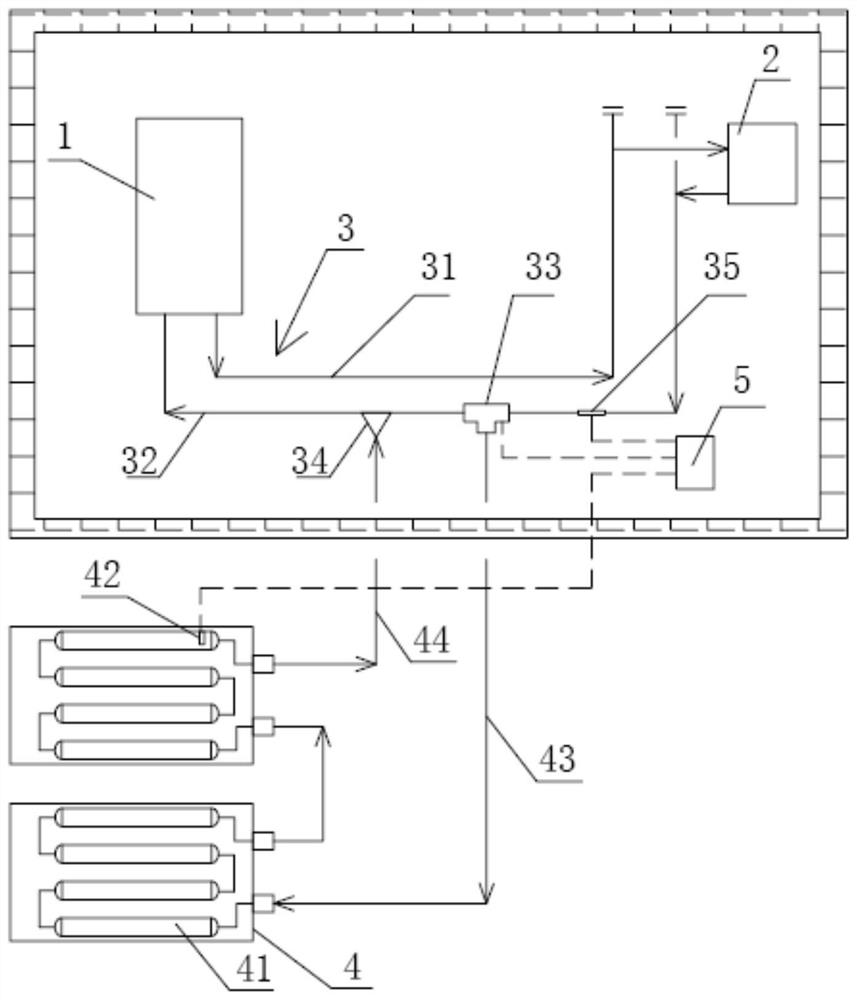

Heating system and method

PendingCN112377976AGuaranteed uptimeImprove heat collection and heat exchange efficiencySolar heating energySolar heat collector controllersSolar lightSolar water

The invention provides a heating system and method. The heating system comprises a heating device, a heat dissipation device and a circulating pipeline connected between the heating device and the heat dissipation device, wherein the circulating pipeline is connected with a solar water heater capable of bearing the operation pressure of the heating system through a pipeline; the solar water heatercomprises a hot water storage tank used for collecting and storing solar light and heat; and the circulating pipeline is provided with a three-way valve capable of enabling hot water to enter the hotwater storage tank, and the three-way valve is used for enabling the solar water heater to conduct auxiliary heating on the heating system. The hot water storage tank with the heat collection function is adopted, a heat collector of the solar water heater and the hot water storage tank are integrated, the occupied area of the device is effectively reduced, and the installation difficulty of equipment is lowered. The heat collection function and the water storage function are combined, the solar heat collection and exchange efficiency is improved, the heat loss of hot water transmitted in thesolar water heater is reduced, energy loss and waste are greatly reduced, and the heat utilization rate and the useful heat are increased.

Owner:BEIJING PIONEER RADIATOR

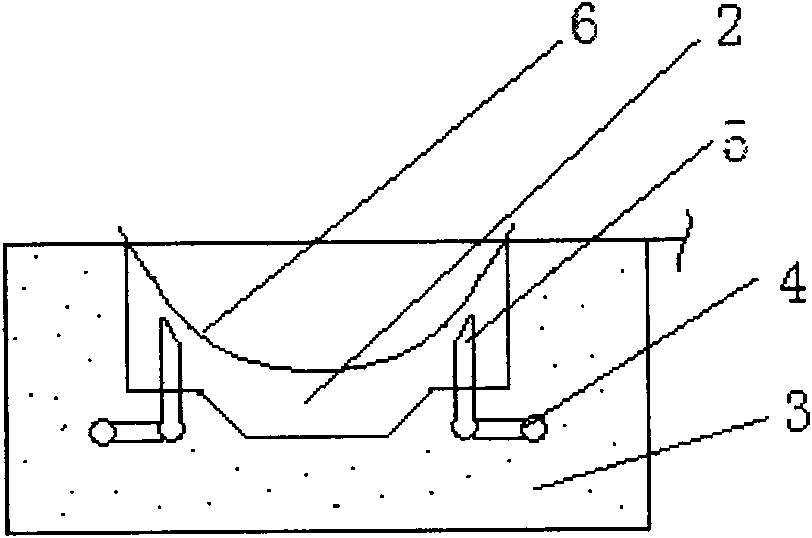

Waste heat utilization device of multifunctional energy-saving stove

InactiveCN102759127AEven fire supplyImprove heating conditionsLighting and heating apparatusStove/ranges for heating waterCombustion chamberHearth

The invention discloses a waste heat utilization device of a multifunctional energy-saving stove. The waste heat utilization device comprises a furnace body and a combustion chamber, and further comprises a water jacket and a waste heat utilization pipeline, wherein the combustion chamber is arranged in the furnace body; the water jacket is arranged at the bottom and on the circumference of the combustion chamber; the waste heat utilization pipeline is arranged inside the water jacket and extends out of the water jacket from the two sides of the combustion chamber to be folded upwards; and at least four air suction nozzles are folded upwards and are uniformly arranged on the circumference concentric with the furnace. Based on the granted patents of the applicant, the amount and location of the air suction nozzle of the waste heat utilization pipeline are improved in the invention, so that not only can the fire supply in the combustion chamber be uniform, the heated condition of the furnace is good, and the cooking quality is ensured, but also all the advantages of the multifunctional energy-saving furnace are kept.

Owner:冯素明

Ethylene cracking furnace with multi-pass radiant coil

ActiveUS8900522B2Improve mechanical propertiesIncrease on-line percentageThermal non-catalytic crackingHydrocarbon distillationCombustorThermal radiation

The invention relates to an ethylene cracking furnace having a multi-pass radiant coil, comprising at least one radiant section. In the radiant section there are provided with bottom burners and / or sidewall burners, and at least one set of multi-pass radiant coil longitudinally arranged in the radiant section. The multi-pass radiant coil is a four- to ten-pass type radiant coil. At least one tube of the multi-pass radiant coil is arranged to be spatially adjacent to a tube which is not consecutive to said at least one tube. With this arrangement, the thermal radiation influence between tubes with high temperature can be reduced, so that the tubes with low temperature can absorb the radiation heat from the tubes with high temperature. Therefore, the surface temperature of the tubes with high temperature can be reduced, thus extending the lifetime of the radiant coil and the operational cycle of the cracking furnace.

Owner:CHINA PETROCHEMICAL CORP +2

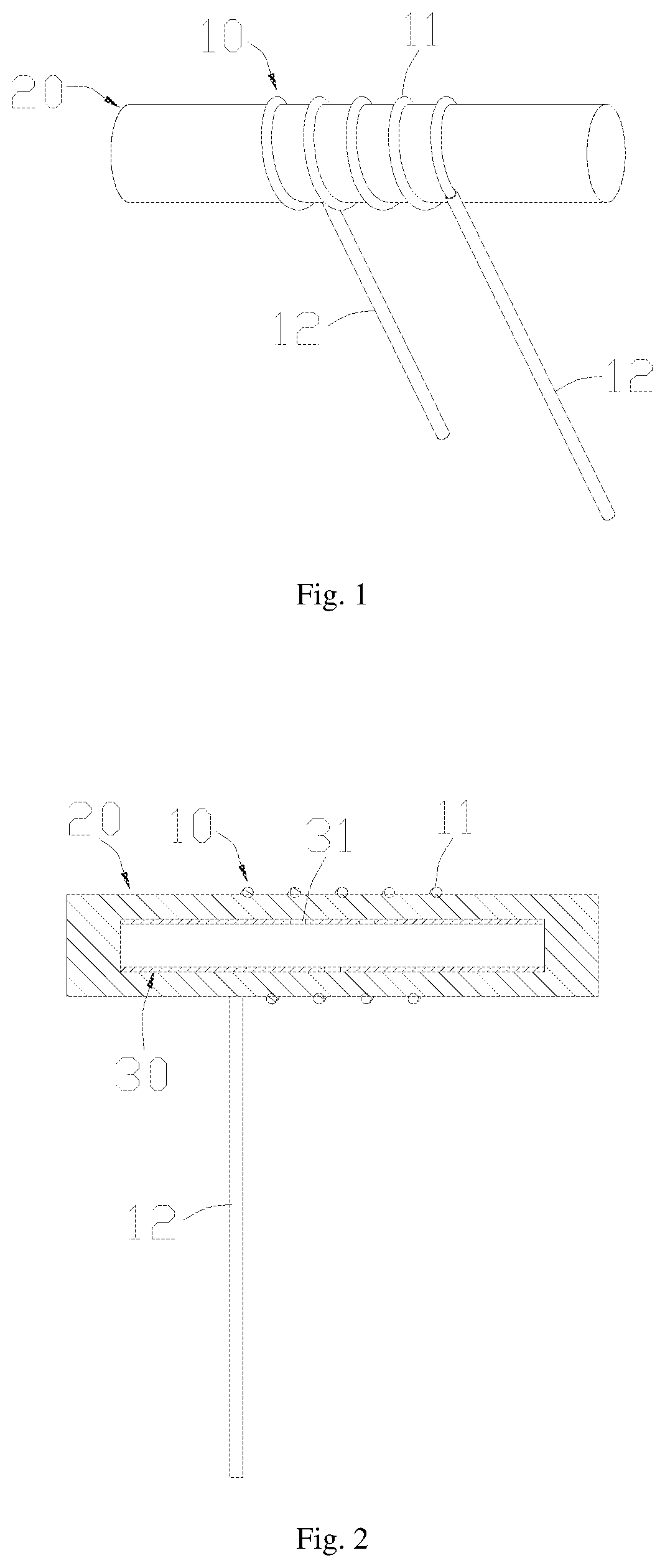

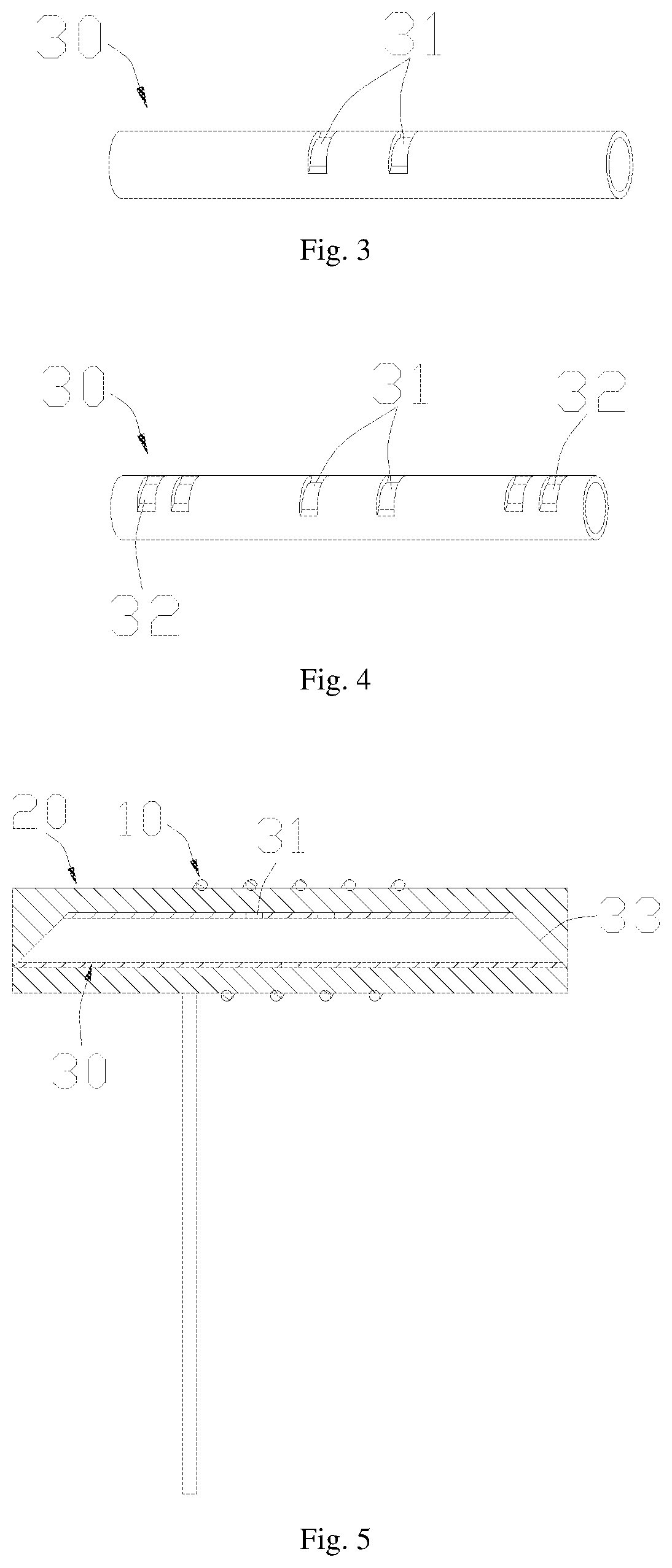

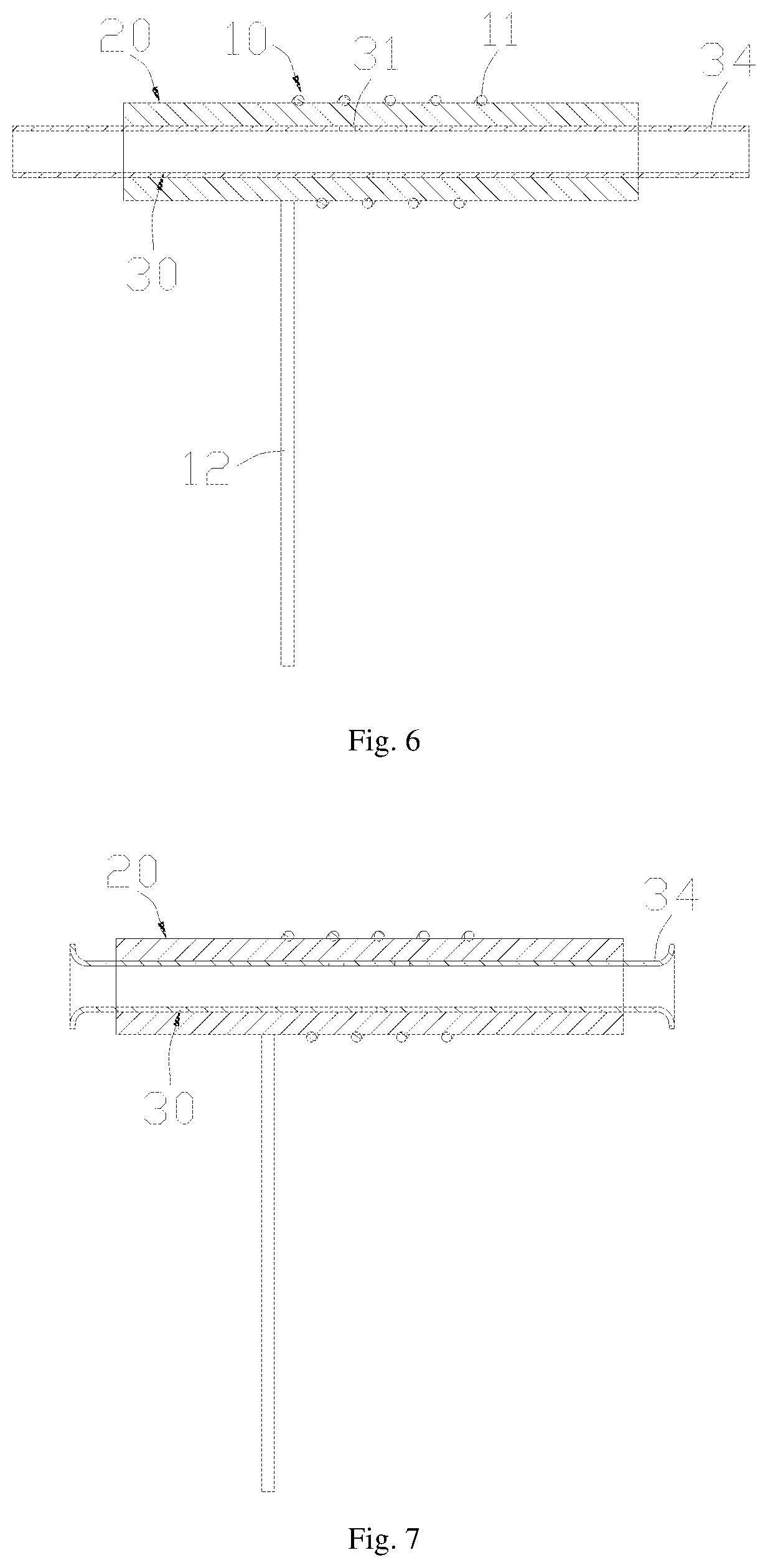

Liquid conducting cotton atomization unit

PendingUS20220346446A1Improve heating conditionsImprove structural strengthOhmic-resistance electrodesHeating element shapesComposite materialMechanical engineering

A liquid conducting cotton atomization unit, including a heating member, a liquid conducting cotton and at least one supporting tube. The liquid conducting cotton is axially inserted in the heating member. The supporting tube is inserted in the liquid conducting cotton parallel to an axial direction thereof. The heating member includes a heating portion and two electrode portions respectively connected to two ends of the heating portion, the supporting tube is provided with at least one liquid outlet hole communicated with the heating portion. Liquid is conducted via the supporting tube, and is guided to the heating portion-via the liquid outlet hole, to solve the problem of high temperature and insufficient service life caused by insufficient liquid supply in center of the heating member. Meanwhile, the supporting tube can expand the outer diameter of the liquid conducting cotton, making the liquid conducting cotton fully contact with the heating member.

Owner:SHENZHEN HUACHENGDA PRECISION IND CO LTD

High-yield sweet potato cultivation method

ActiveCN102498844BEarly seedling periodImprove heating conditionsClimate change adaptationGreenhouse cultivationTemperature differenceBiology

The invention provides a high-yield sweet potato cultivation method, composed of several links including seedling raising, transplanting and field management, characterized in that: the step of seedling raising is composed of electric heating sprouting and seedling raising, a plastic house covering small plastic sheds and electric blanket coverage are adopted in sprouting, and the rate of emergence reaches 80-90%; and in the process of field management, when potato vines fully cover the ground, vines are put in proper order ridge by ridge, potato vines on one side of a potato ridge are moved to the other side, and the potato vines of every two ridges are put into one furrow with the other furrow exposed, thus improving the heating condition of the potato ridges, enlarging day-and-night temperature difference, accelerating potato tuber enlargement, and achieving the purpose of high yield. Because two layers of plastic sheds and electric blanket coverage are adopted for seedling raisingby electric heating, the seedling raising time can be advanced from the first ten days of March to the first ten days of January (before the beginning of spring), and simultaneously the rate of emergence reaches 80-90%; and because vines are put in proper order ridge by ridge and the heating condition is improved, the yield per mu of sweet potato reaches 4000-4500 kilograms, and the yield is increased by more than 20% compared with traditional methods under the same growing environment and management.

Owner:HUBEI XIANGSHANG FOOD

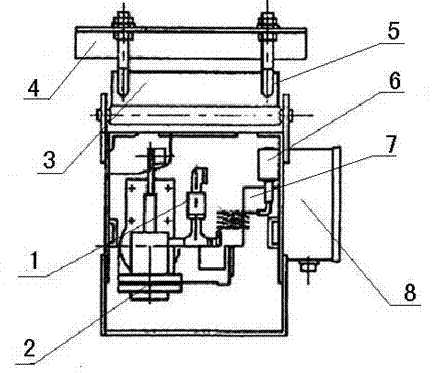

Power station boiler hydraulic power soot blower

InactiveCN103499099AOptimize structure layoutImprove bottom heatingLighting and heating apparatusPower stationControl system

The invention provides a power station boiler hydraulic power soot blower. The power station boiler hydraulic power soot blower comprises a spray gun, a spray gun angle control system, a water pump, a valve, a semi-retractable soot blower body, a control cabinet and the like. A one-way air valve is arranged in the spray gun, wherein the valve is arranged on the bottom side of the tail portion of the semi-retractable soot blower body, and a valve opening and closing mechanism is arranged on the valve and connected with the one-way air valve. The power station boiler hydraulic power soot blower is characterized in that cold water is used as a medium, and coke in an area which is nearly 500 m<2> of a hearth can be cleaned at a time when the power station boiler hydraulic power soot blower operates; when the power station boiler hydraulic power soot blower is installed, only a 0.4 m<2> hole needs to be formed in a water wall, and a waterflow sweeping trajectory at the time of soot blowing is designed and controlled through software. The power station boiler hydraulic power soot blower can realize trajectory control over a water column through control over water quantity, water column diameter, water column speed, water column vertical adjustment angles and water column horizontal adjustment angles.

Owner:单志贤

Heat treatment device for optical fiber reinforcing member, optical fiber fusion splicer provided with same heat treatment device, and method for heat treating optical fiber reinforcing member

ActiveUS9310557B2Improve heating conditionsElectric heatingCoupling light guidesFiberInstruction unit

A heating device for heating an optical fiber reinforcing member includes fiber holders to hold optical fibers covered with the reinforcing member at a fusion-spliced portion, a heater to heat the reinforcing member, a power supply unit to apply a voltage to the heater, and a controller to control the application of a voltage from the power supply unit to the heater. The controller includes a detecting unit that detects a parameter for determining the amount of heat generation of the heater, a storage unit that stores a plurality of heating conditions that vary depending on the parameter value, and a condition instruction unit that selects any of the plurality of heating conditions in accordance with the parameter value detected by the detecting unit and instructs the power supply unit to apply a voltage to the heater on the basis of the selected heating condition.

Owner:SEI OPTIFRONTIER CO LTD

Thermon structure and fabrication method for heat-activated miniature self-heating getter

ActiveCN105858587BControl thicknessControl lengthSolid-state devicesFluid speed measurementMetal coatingElectrical resistance and conductance

The invention relates to the field of vacuum packaging technologies for MEMS (micro-mechanical systems) sensors, in particular to a heater structure for heating and activating micro-miniature self-heating air suction agents and a method for manufacturing the heater structure. The heater structure comprises a ceramic body, metal slurry, metal coatings and metal leading wires. The inside of the ceramic body is divided into a plurality of layers, the metal slurry wraps each layer, metal slurry layers are communicated with one another in the up-down directions, the metal slurry on two end surfaces of the ceramic body is reserved to be exposed, the metal coatings are formed on two end surfaces of the ceramic body by means of chemical plating or electroplating, and the metal leading wires of heating electrodes are welded on the two end surfaces of the ceramic body after the metal coatings are formed. The heater structure and the method have the advantages that resistance of the metal slurry layers is controlled, so that the consistency of resistance values of different devices can be guaranteed; whether heating and activating temperatures reach ideal activating temperatures of air suction materials or not can be monitored by special circuits in an online manner and can be controlled, accordingly, the activated air suction agents can be assuredly in the optimal activated states, and the activated states of the air suction agents are consistent and stable on a large scale.

Owner:XINFOO SENSOR TECH CO LTD

A tobacco material for smoking and its preparation method

ActiveCN105433434BIncrease concentrationImprove utilization efficiencyTobacco treatmentTobacco devicesFlue gasPolyethylene glycol

The invention belongs to the technical field of tobacco, and in particular relates to a tobacco material for smoking and a preparation method thereof. The tobacco material is sheet-like or film-like, with a thickness of 0.1-2mm; it is made of tobacco powder, tobacco extract, aerosol generating agent, heat-conducting material, polyethylene glycol and adhesive; in parts by mass, each The specific dosage of materials is: 10~50 parts of tobacco powder, 20~50 parts of tobacco extract, 10~30 parts of aerosol generating agent, 0.1~5 parts of thermal conductive material, 1~5 parts of polyethylene glycol, 1 part of adhesive ~5 servings. The advantages of the present invention mainly include: the heating condition of the tobacco material is improved by loading the heat-conducting material in the tobacco material, and the smoke concentration is better improved; the heating uniformity of the tobacco material is improved by uniformly dispersing the heat-conducting material in the polyethylene glycol solution, The uniformity of smoke release is significantly improved; the range of tobacco materials is widely used.

Owner:CHINA TOBACCO HENAN IND +1

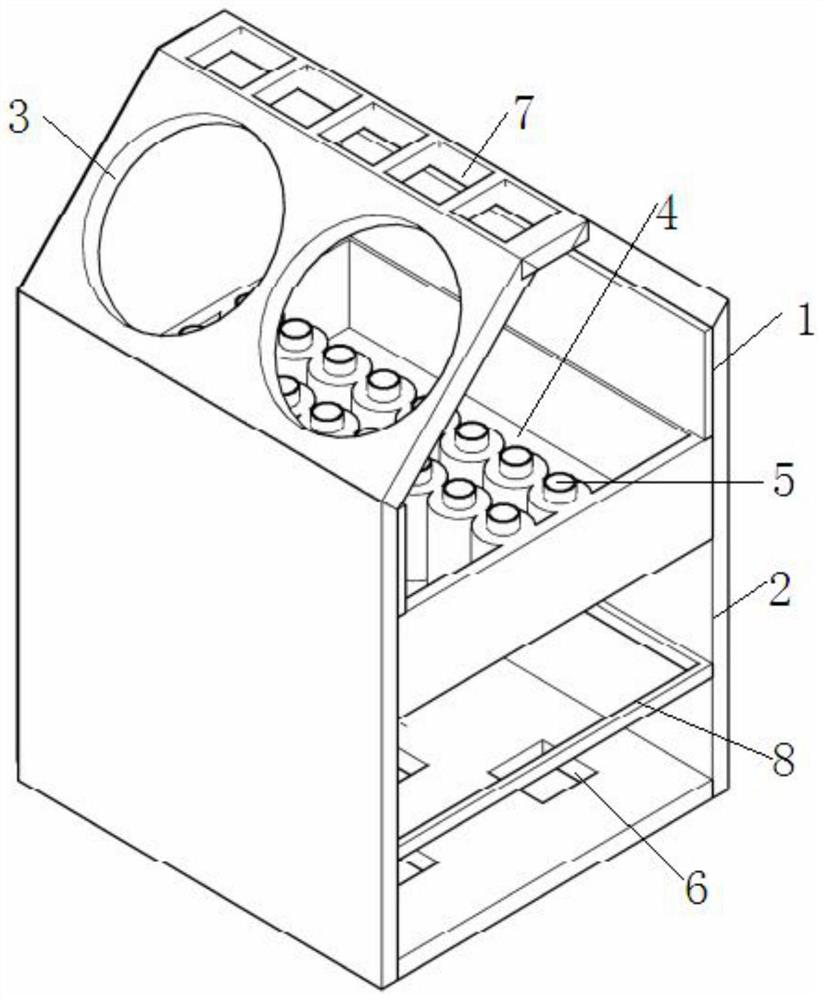

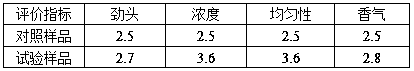

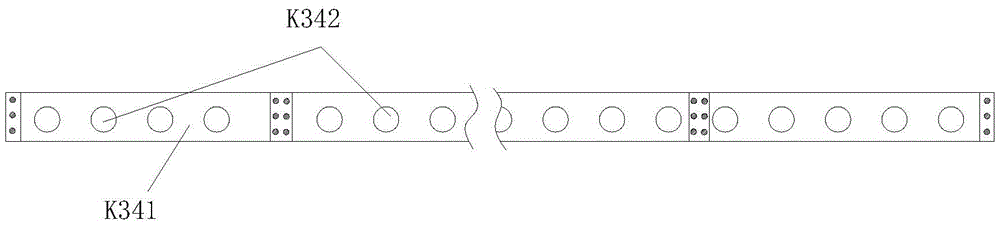

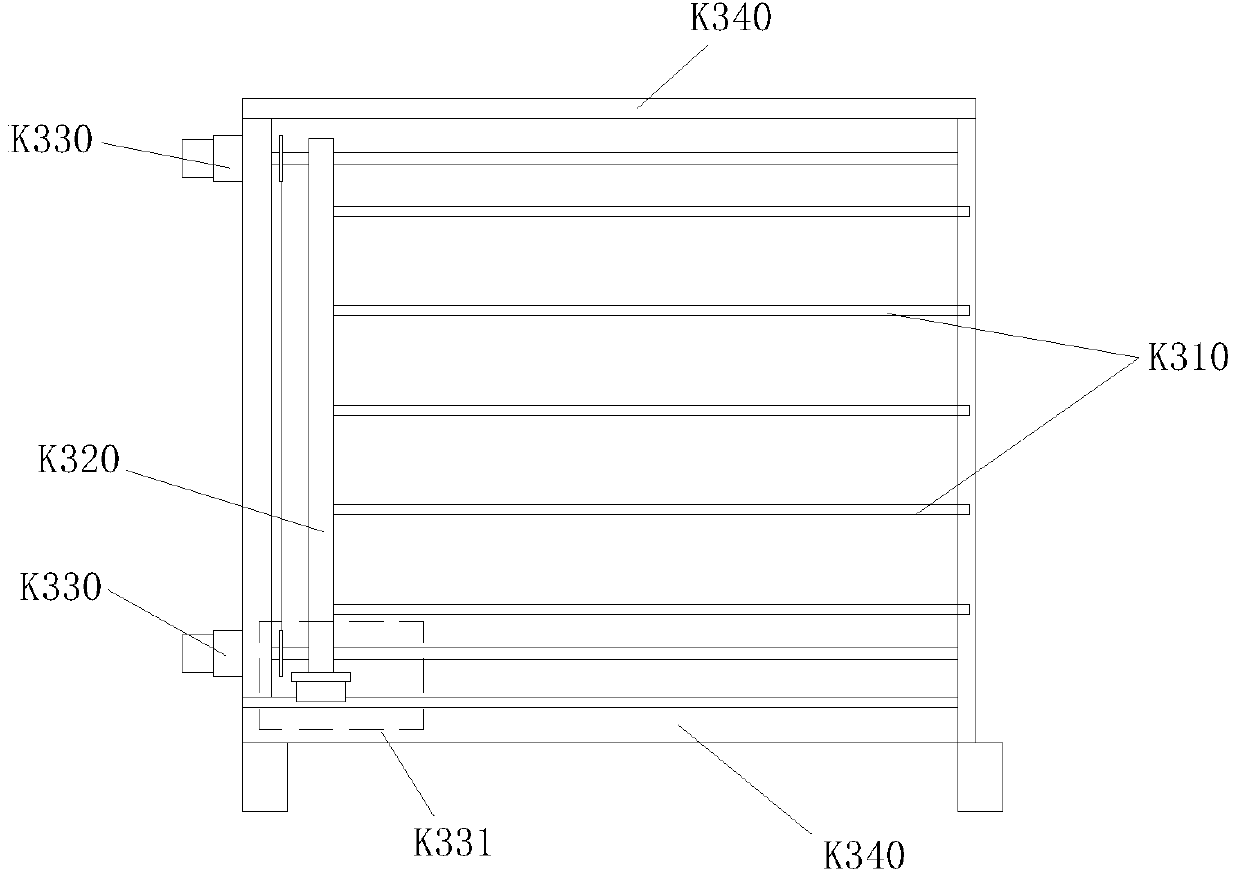

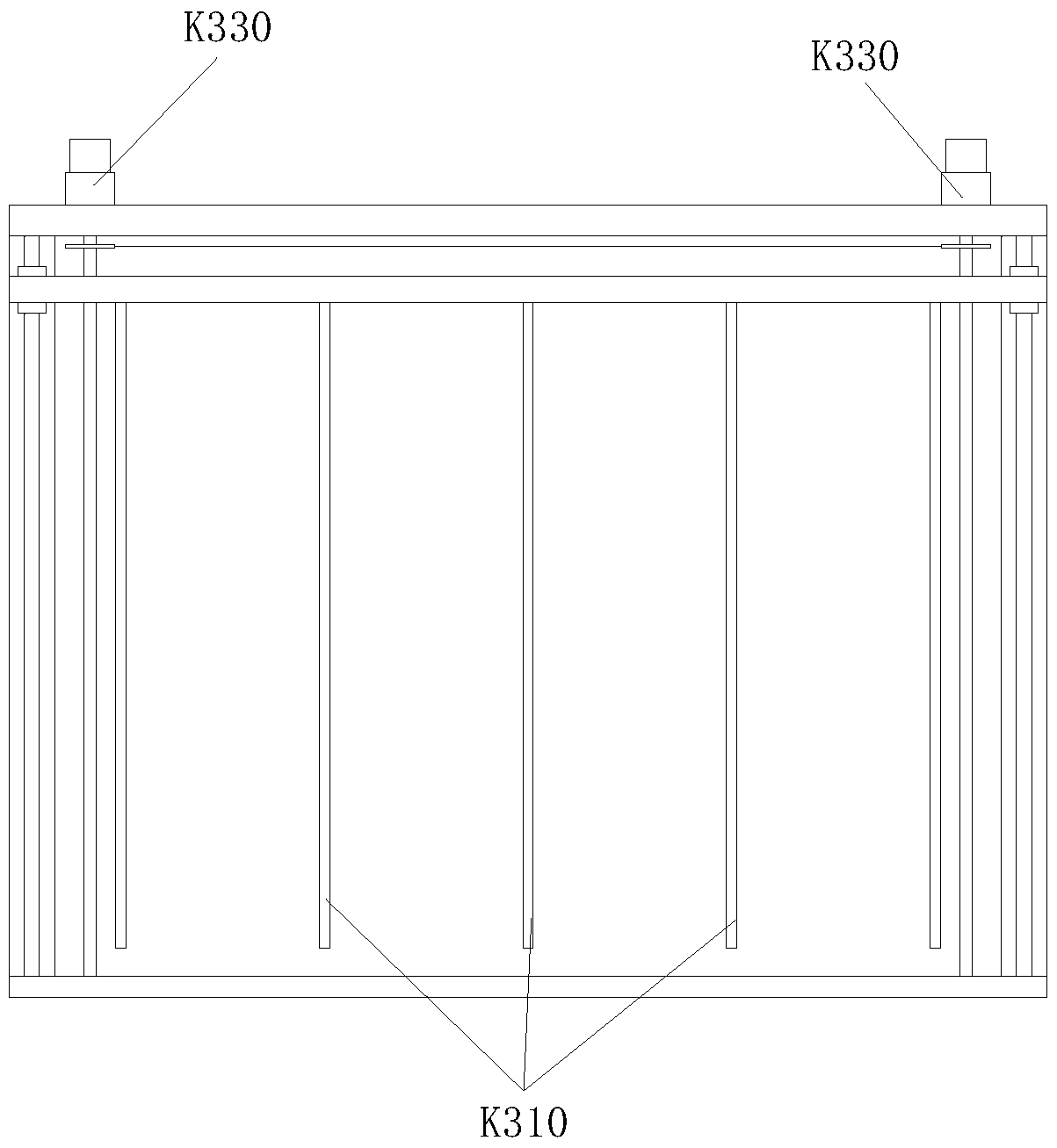

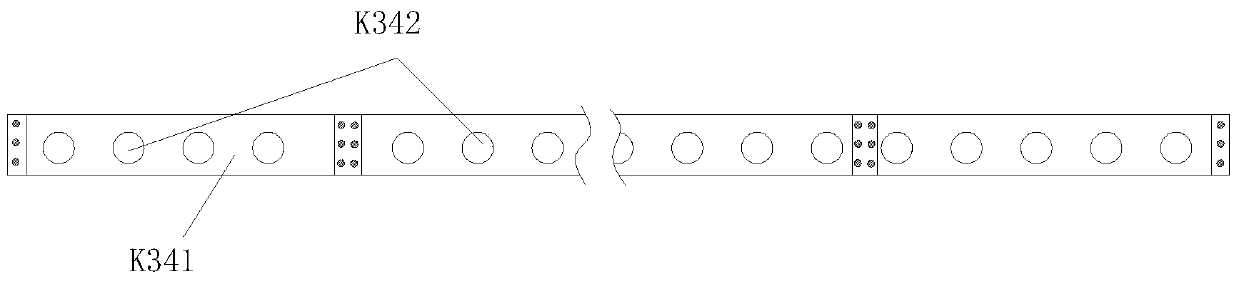

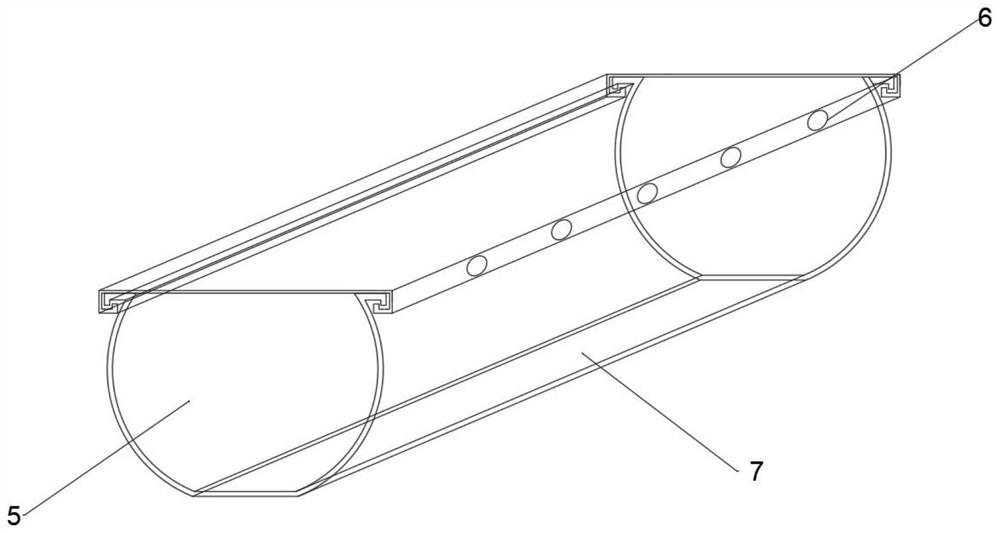

Baking mechanism used on flap wheel production line

ActiveCN105457864AImprove heating conditionsConducive to solidificationPretreated surfacesCoatingsProduction lineThermal energy

The invention discloses a baking mechanism used on a flap wheel production line. The baking mechanism comprises heating pipes used for heating and solidifying glue, a back plate used for fixing the heating pipes, and feeding units controlling the heating pipes to enter and leave abrasive belt blank rolls. The heating pipes are perpendicularly arranged on the back plate. The back plate is arranged on the feeding units and is driven by the feeding units to move forwards and backwards. A technology different from the open type baking technology of the traditional process is adopted, only inner cavities of the blank rolls are heated so that heating force can uniformly permeate into glue, the heated situations of all parts of the glue are improved, solidification forming of the glue is facilitated, and consumed thermal energy is reduced. In addition, the multiple columns of heating pipes are arranged to bake more abrasive belt blank rolls at the same time, the production efficiency can be greatly improved, and productivity is improved. The technical problems that an existing flap wheel baking technology is low in yield and wastes energy are well solved.

Owner:南通市科脉电子科技有限公司

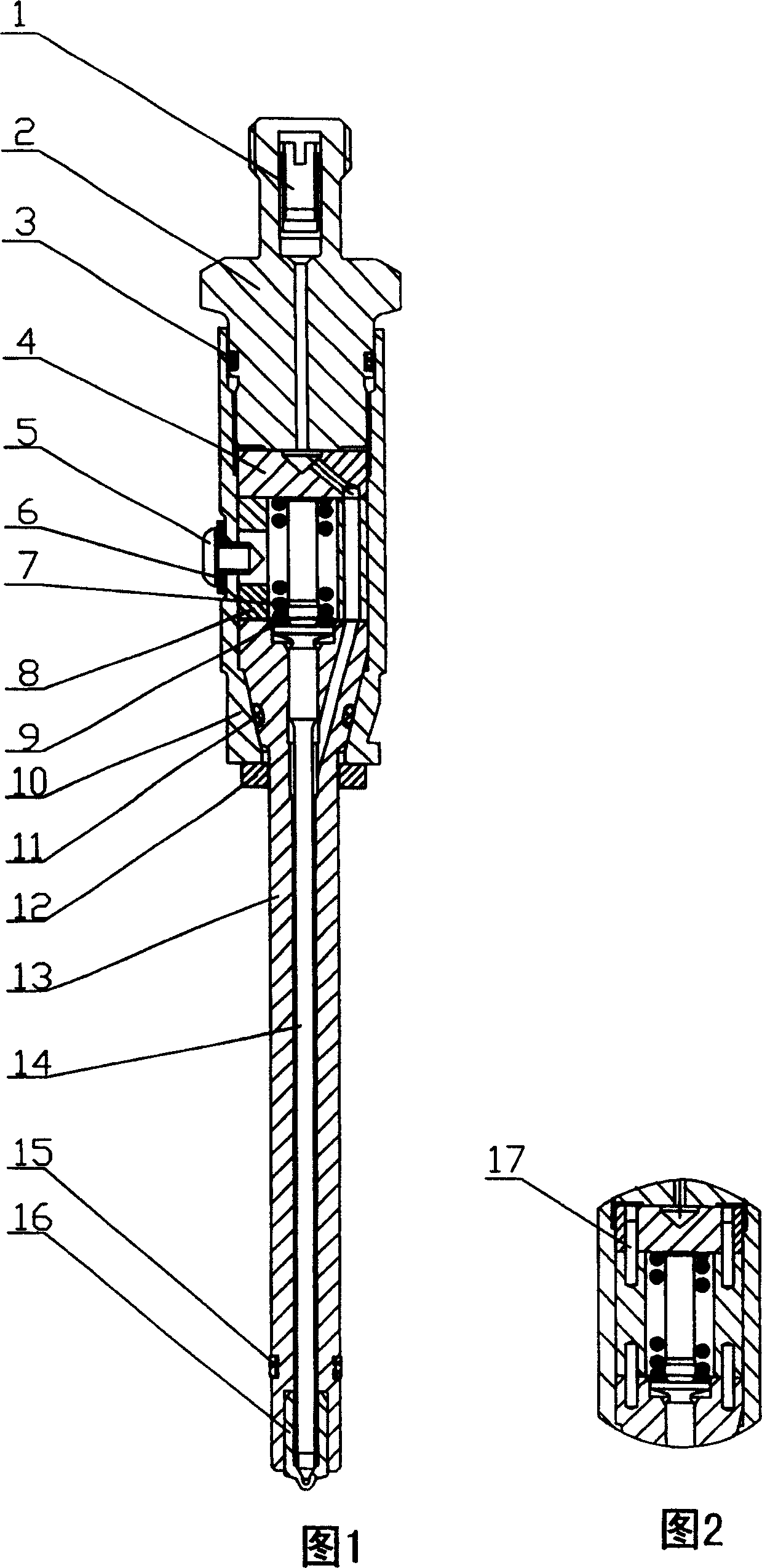

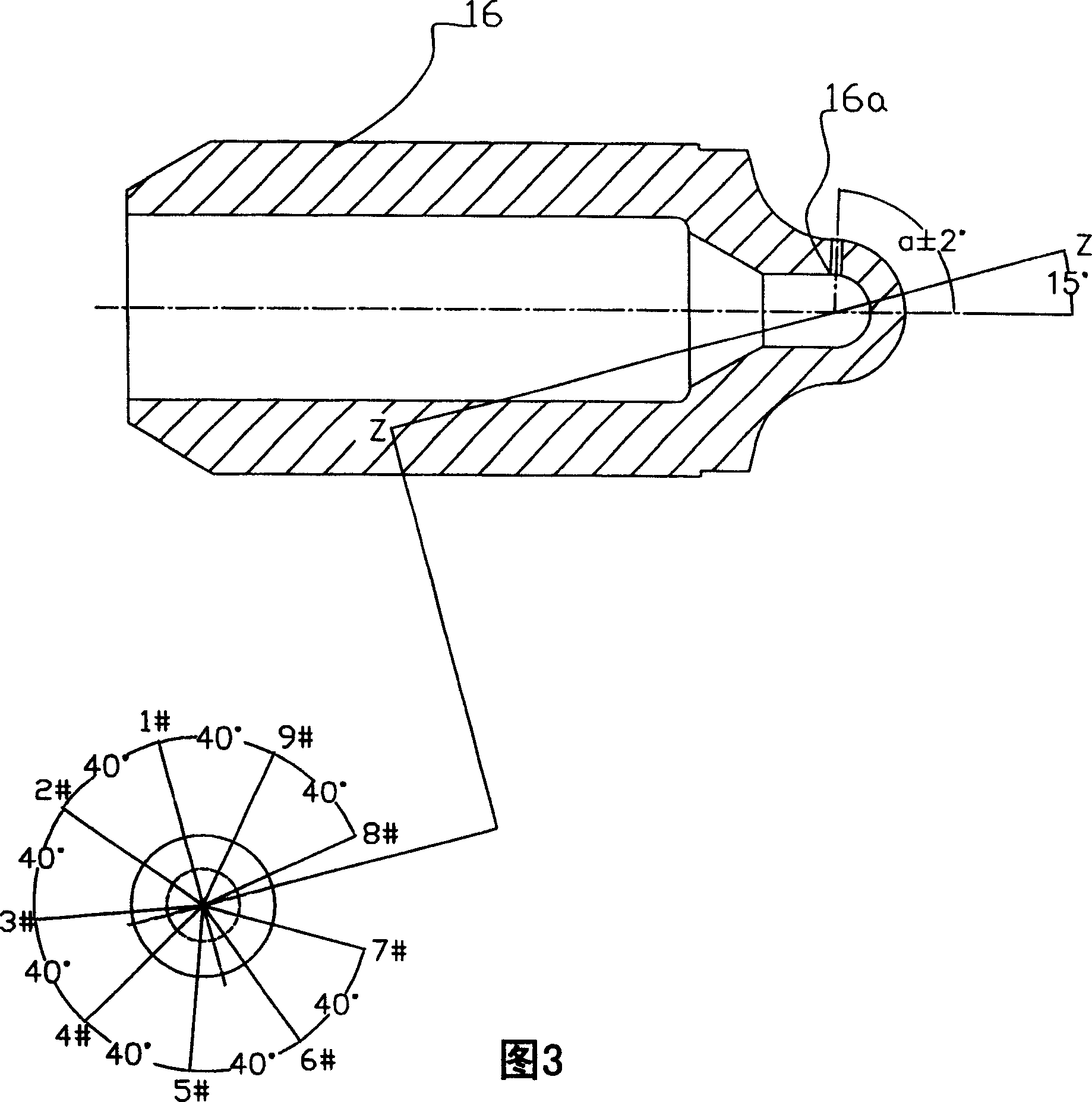

Multi-orifice pencil-style fuel injectors

InactiveCN100334344CSmall atomization qualityImprove atomization qualityFuel injection apparatusMachines/enginesEngineeringNeedle valve

A pencil like apparatus of multi oil spouts, includes an inside oil spray body, an oil inlet junction bolt with filter, a needle valve, an oil injector. The spray body has an O type gasket, the body is an acerose pencil like structure, wherein the spray body matches the acerose shank needle valve, wherein the oil injector is of multi mini spouts on the top of the spray body. The rear part of the spray body is locked in a tight cannula, wherein has pressure adjusting gasket, pressure adjusting spring, fixing bolt, middle bolt on the top of the cannula. Anti coking loops are embedded in the grooves on the outside top of the spray body. Screw the oil inlet in the tight cannular and contact against the needle valve blocker, wherein between there is an O type gasket.

Owner:宁波舜田良源油嘴油泵有限公司

A baking mechanism used in a thousand-sheet wheel production line

ActiveCN105457864BImprove heating conditionsConducive to solidificationPretreated surfacesCoatingsProduction lineThermal energy

The invention discloses a baking mechanism used on a flap wheel production line. The baking mechanism comprises heating pipes used for heating and solidifying glue, a back plate used for fixing the heating pipes, and feeding units controlling the heating pipes to enter and leave abrasive belt blank rolls. The heating pipes are perpendicularly arranged on the back plate. The back plate is arranged on the feeding units and is driven by the feeding units to move forwards and backwards. A technology different from the open type baking technology of the traditional process is adopted, only inner cavities of the blank rolls are heated so that heating force can uniformly permeate into glue, the heated situations of all parts of the glue are improved, solidification forming of the glue is facilitated, and consumed thermal energy is reduced. In addition, the multiple columns of heating pipes are arranged to bake more abrasive belt blank rolls at the same time, the production efficiency can be greatly improved, and productivity is improved. The technical problems that an existing flap wheel baking technology is low in yield and wastes energy are well solved.

Owner:南通市科脉电子科技有限公司

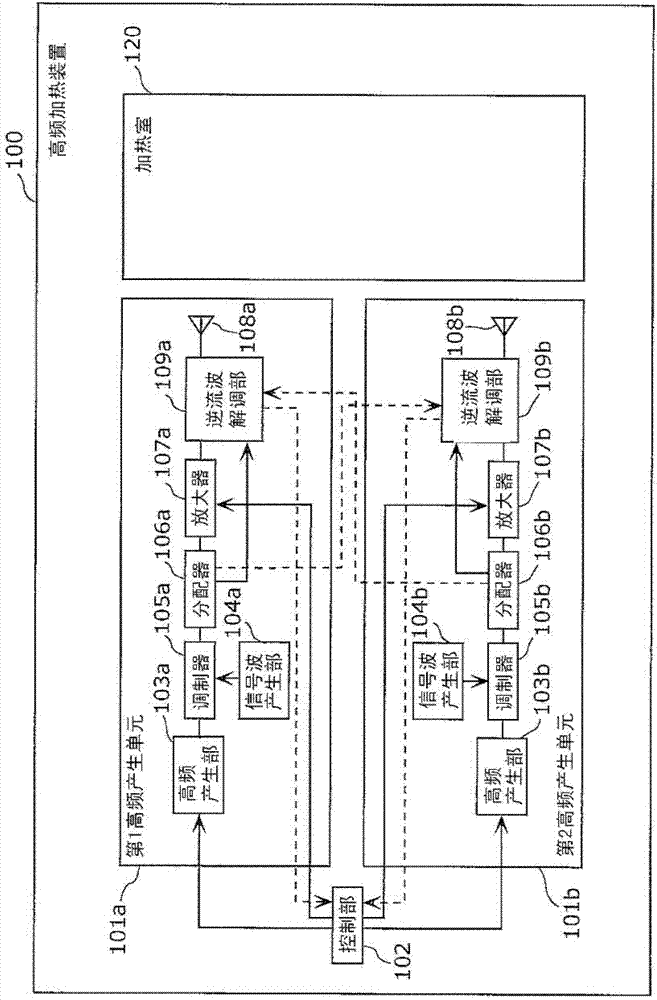

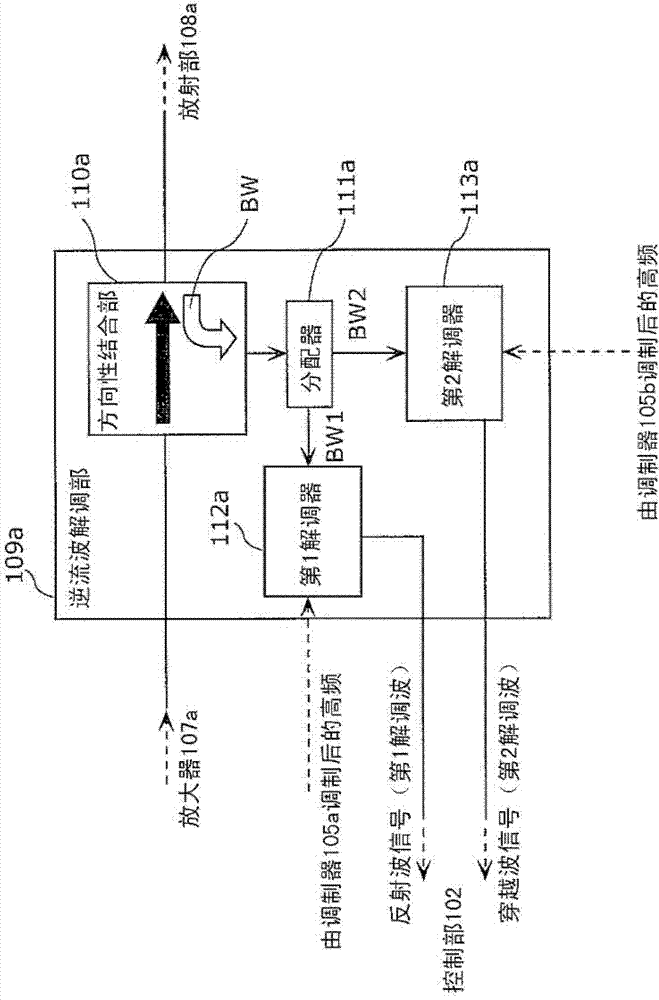

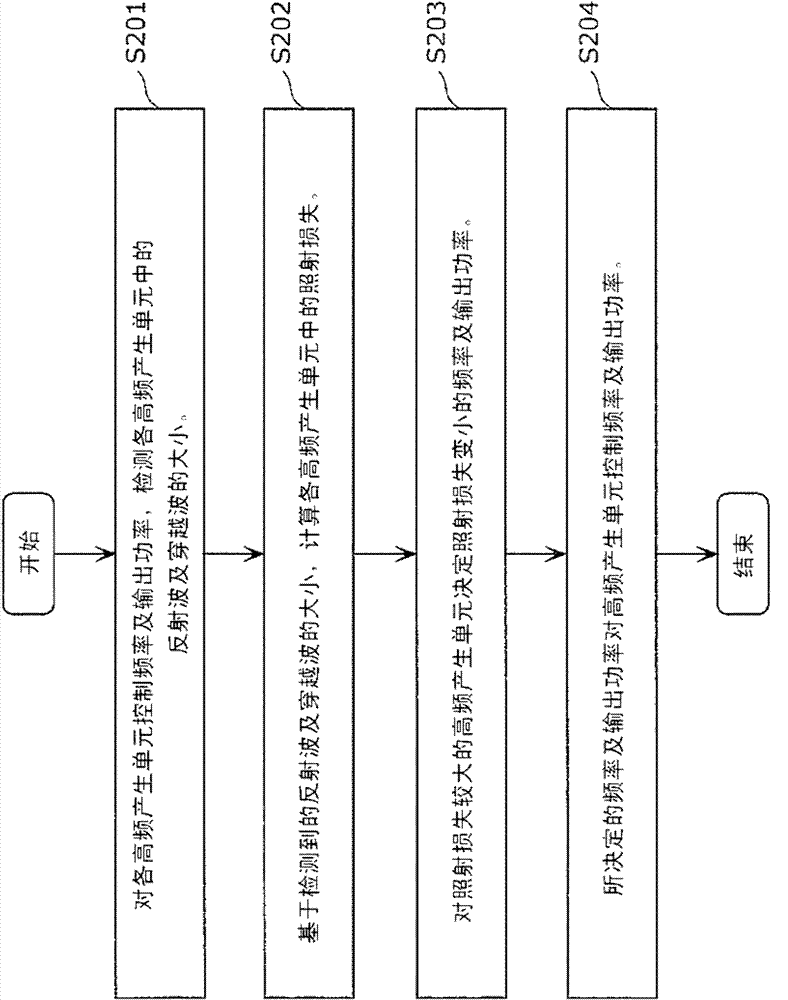

High-frequency radiation heating device

ActiveCN102187734BSuppression of radiation lossImprove low efficiencyMicrowave heatingReflected wavesRadio frequency

A radio-frequency heating apparatus includes a heating chamber, first and second radio-frequency wave generation devices from which radio-frequency waves are radiated, and a control unit that controls the first and second radio-frequency wave generation devices. Each of the first and second radio-frequency wave generation devices includes: a radiation unit that radiates radio-frequency waves into the heating chamber; and a backward wave demodulation unit that demodulates backward waves entering from the heating chamber. The backward wave demodulation unit of the first radio-frequency wave generation device detects reflected waves that are radio-frequency waves radiated from the radiation unit and reflected back into the radiation unit, and through waves that are radio-frequency waves radiated from another radiation unit and enter the radiation unit. The control unit controls the first and second radio-frequency wave generation devices based on the detected reflected waves and through waves.

Owner:PANASONIC CORP

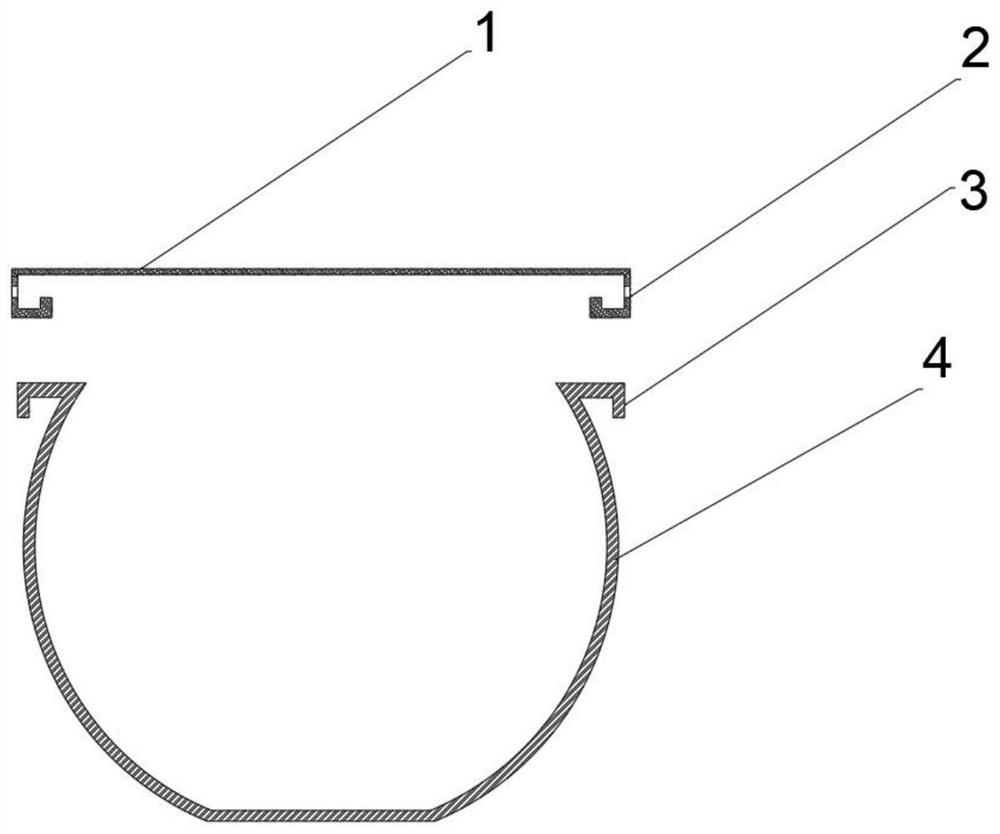

Novel silicon carbide porcelain boat

PendingCN114768902AHigh temperature resistantCorrosion resistanceCharge supportsLaboratory glasswaresCarbide siliconMetallurgy

The novel silicon carbide porcelain boat comprises a bottom surface and side walls surrounding the bottom surface, a cavity with an opening is defined by the bottom surface and the side walls, the side walls are two arc-shaped side walls which are oppositely arranged, end faces are arranged at the two ends of the two arc-shaped side walls respectively, and the end faces are arranged on the bottom surface. The two arc-shaped side walls, the two end faces and the bottom face jointly define the cavity. A porous silicon carbide top cover is arranged above the opening, the lower ends of the two side edges of the porous silicon carbide top cover are bent inwards to form clamping grooves, the upper edges of the two arc-shaped side walls are bent outwards to form clamping hooks, and the clamping grooves and the clamping hooks are matched to be used for connecting the porous silicon carbide top cover and the arc-shaped side walls; pressure relief millimeter holes are formed in the side edge of the porous silicon carbide top cover in the length direction at intervals. According to the invention, gas can enter and exit from the interior of the porcelain boat through the micron or nano pores, and solid samples in the porcelain boat cannot be dissipated out of the porcelain boat, so that the yield of products is improved.

Owner:ZHEJIANG UNIV OF TECH

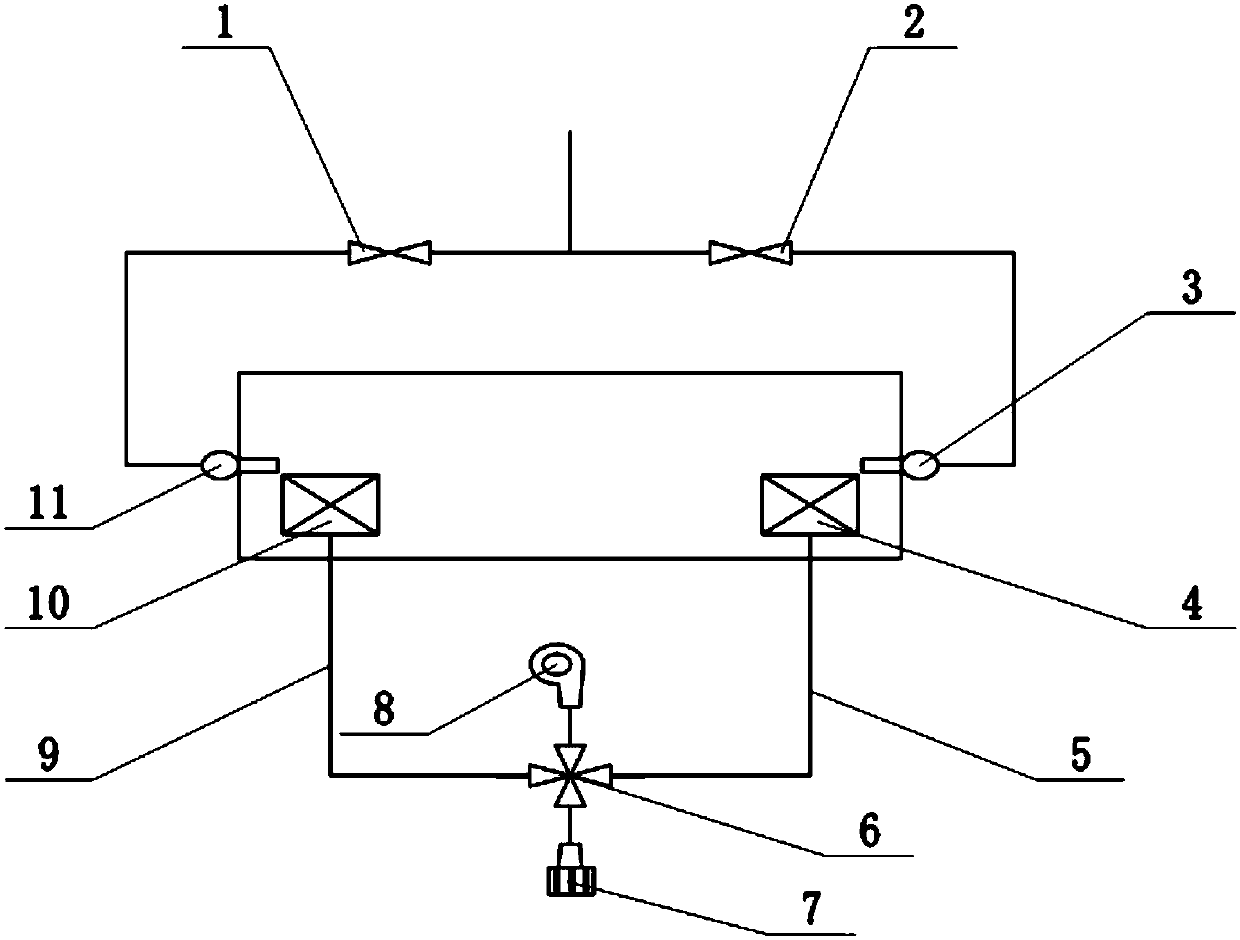

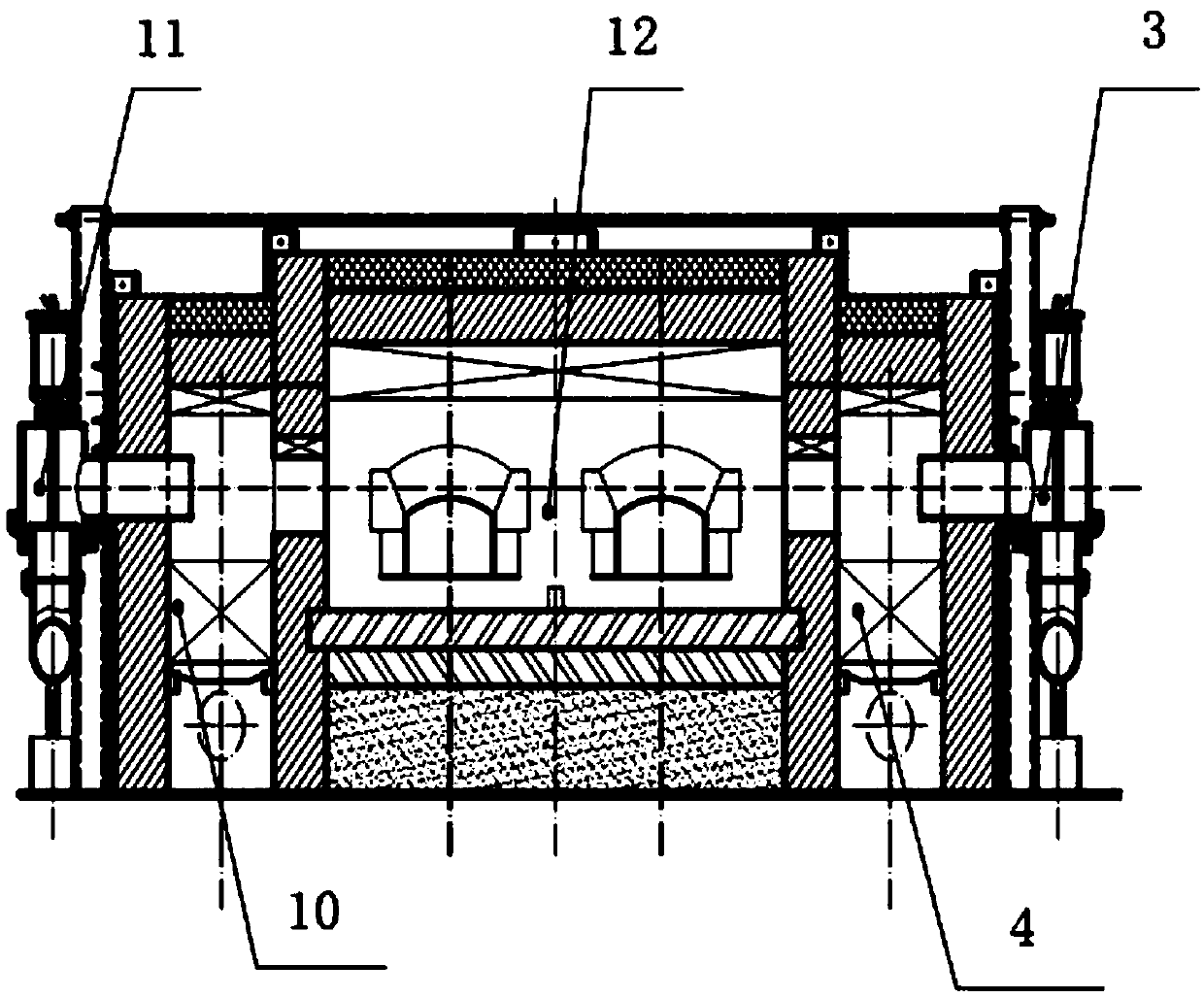

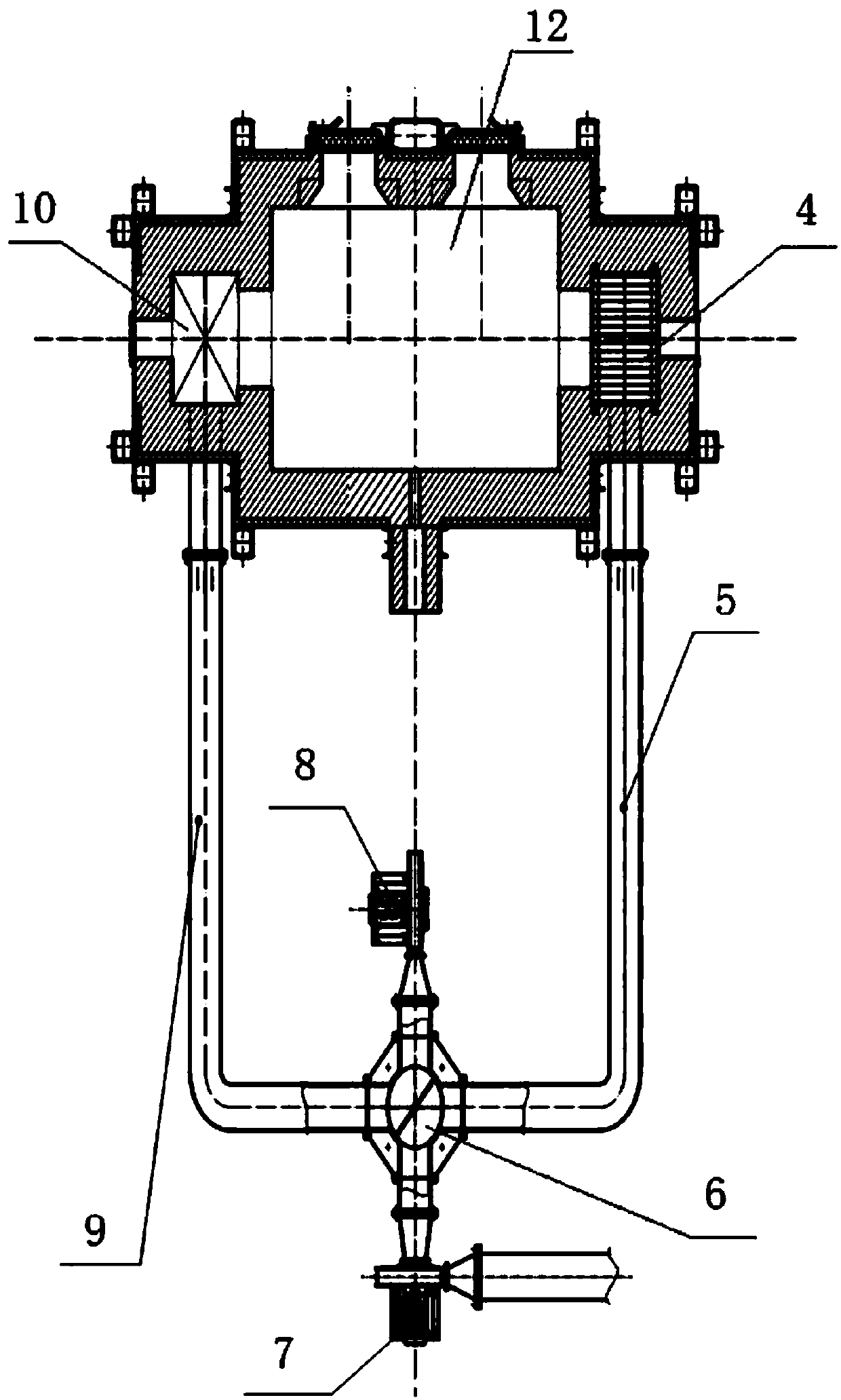

Regenerative combustion V2O5 melting furnace

InactiveCN108120280AImprove heating conditionsFast heatingCharge treatment typeCrucible furnacesProcess engineeringFlue gas

The invention belongs to the field of metallurgy, and particularly relates to a regenerative combustion V2O5 melting furnace. The technical scheme includes that the melting furnace comprises a meltingfurnace body, a regenerative air heat exchanging device A, a regenerative air heat exchanging device B, a combustor A, a combustor B, an air-flue gas pipeline A, an air-flue gas pipeline B, an electric control multi-directional valve, an induced draft fan and a supply fan, the regenerative air heat exchanging device A and the regenerative air heat exchanging device B are mounted on two sides of the melting furnace body, the combustor A is mounted on the regenerative air heat exchanging device A, the combustor B is mounted on the regenerative air heat exchanging device B, one end of the air-flue gas pipeline A is connected with the regenerative air heat exchanging device A, one end of the air-flue gas pipeline B is connected with the regenerative air heat exchanging device B, and the otherends of the air-flue gas pipeline A and the air-flue gas pipeline B, the induced draft fan and the supply fan are integrally connected with the electric control multi-directional valve. According tothe melting furnace, combustion-supporting air is preheated by the aid of high-temperature flue gas, and the heat efficiency of the furnace is improved.

Owner:NORTHEASTERN UNIV +1

Tobacco material suitable for heating non-combustion device and preparation method thereof

Owner:CHINA TOBACCO HENAN IND +1

Utilization device for residual heat of multi-functional energy-saving stove

InactiveCN104359135AEven fire supplyImprove heating conditionsLighting and heating apparatusWater heating stoves/rangesCombustion chamberEngineering

The invention discloses a utilization device for residual heat of a multi-functional energy-saving stove. The device comprises a stove body, a burning chamber in the stove body, a water clamp cover which is arranged at the bottom and the periphery of the burning chamber and residual heat utilizing pipelines in the water clamp cover, wherein the residual heat utilizing pipelines extend out the water clamp cover from both sides of the burning chamber to be folded up upwards, at least four air sucking pipe openings are folded up upwards, and the air sucking pipe openings are formed in a circumference line of which the circle center is same as a pot at equal intervals. On the basis of the authorized patent of an applicant for the device disclosed by the invention, the amount and the arranged positions of the air sucking pipe openings of the residual heat utilizing pipelines are improved, so that the fire supply for the burning chamber is uniform, the heated condition of the pot body is good, the cooking quality is ensured, and all of the advantages of the multi-functional energy-saving stove are maintained.

Owner:KUNSHAN FULING ENERGY USE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com