Power station boiler hydraulic power soot blower

A technology of soot blowing device and power station boiler, which is applied in lighting and heating equipment, etc., can solve problems such as load limitation or even shutdown, affecting boiler economy and safety, and coking of furnace water walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

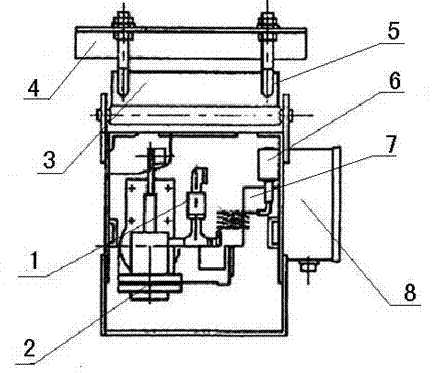

[0008] Depend on figure 1 As we know, the hydraulic soot blowing device of the power plant boiler is composed of a spray gun 1, a spray gun angle control system 2, a water pump 3, a valve 4, a semi-telescopic soot blower 5 and a control cabinet 6. The spray gun 1 is equipped with a one-way air valve 7, which is semi-telescopic. There is a valve 8 on the bottom side of the tail of the type soot blower, and the opening and closing mechanism of the valve is set on the valve 8. The opening and closing mechanism of the valve is connected with the one-way air valve 7. With cold water as the medium, it can clean the area of nearly 500m2 of the furnace at one time during work. When installing each hydraulic soot blower, it is only necessary to open a 0.4m square hole in the water cooling wall, and the water blowing trajectory is controlled by software design during soot blowing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com