A tobacco material for smoking and its preparation method

A technology of tobacco and heat-conducting material is applied in the field of tobacco to achieve the effects of increasing smoke concentration, improving distribution uniformity, and uniform smoke release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

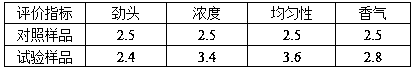

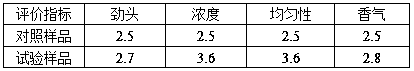

Image

Examples

Embodiment 1

[0029] The tobacco materials suitable for smoking provided in this embodiment are calculated in parts by mass, and the specific dosage of each material is: 20 parts of tobacco stem powder, 30 parts of tobacco water extract, 30 parts of glycerin, and 2 parts of aluminum oxide powder , 2.5 parts of polyethylene glycol (molecular weight 2000), 3 parts of sodium carboxymethyl cellulose;

[0030] The tobacco stem powder is the tobacco stem in the cigarette production process, and the particle size is 40 mesh;

[0031] The alumina powder has a particle size of 100 mesh;

[0032] The tobacco water extract can be prepared by using specific similar commercially available products, or it can be prepared by referring to the following method: take the waste tobacco powder in the cigarette production process, add water after drying according to the ratio of material to liquid 1:3 (w / w) , After extraction at 90°C for 2 hours, the solid-liquid separation was performed, and the filtrate was ...

Embodiment 2

[0041] The tobacco material suitable for smoking provided by the present embodiment, in parts by mass, the specific consumption of each material is: 30 parts of tobacco powder, 40 parts of tobacco 70% ethanol extract, 20 parts of propylene glycol, 0.2 part of graphene powder , polyethylene glycol (molecular weight 3000) 2 parts, hydroxypropyl cellulose sodium 5 parts;

[0042] The tobacco powder is powder after crushing tobacco leaf fragments, and the particle size is 50 mesh;

[0043] The tobacco 70% ethanol extract can be prepared by using specific similar commercially available products, or it can be prepared by referring to the following method: take the waste tobacco powder in the cigarette production process, dry it according to the ratio of solid to liquid 1:5 (w / w) Add 70% ethanol, extract at 70°C for 5 hours, then separate the solid from the liquid, and concentrate the filtrate under reduced pressure to obtain a 70% ethanol extract of tobacco.

[0044]During preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com