Waste heat utilization device of multifunctional energy-saving stove

A multi-functional energy-saving stove and waste heat technology, which is applied to stoves/stoves with hot water devices, applications, household heating, etc., can solve the problem of partial fire in the combustion chamber, failure to recycle heat energy well, and affect cooking quality and other problems, to achieve the effect of uniform fire supply, good heating condition and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

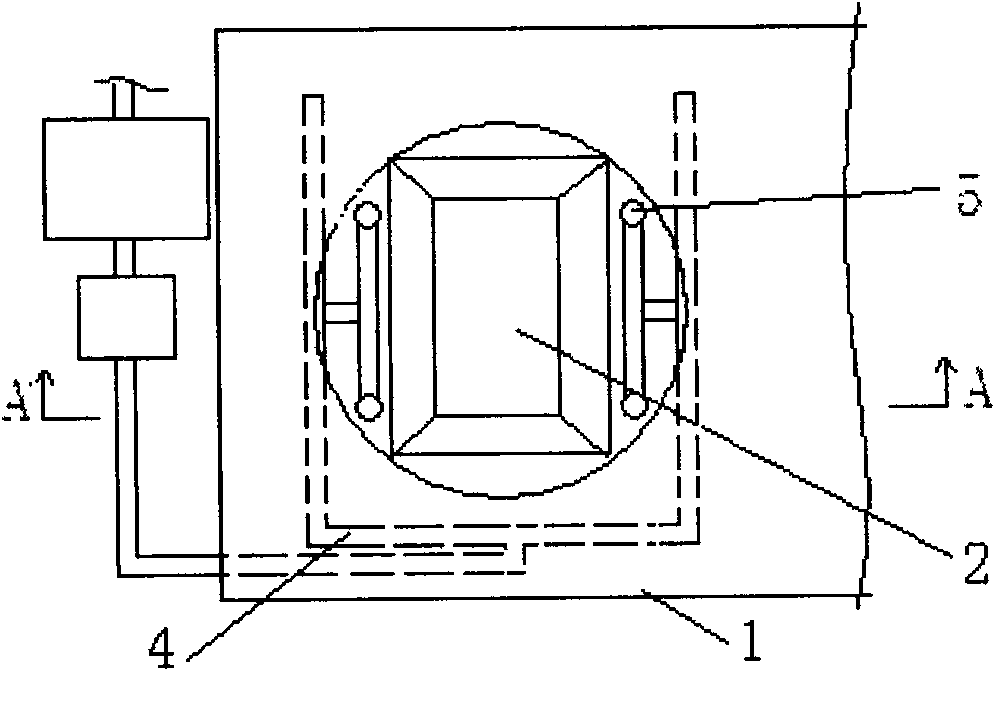

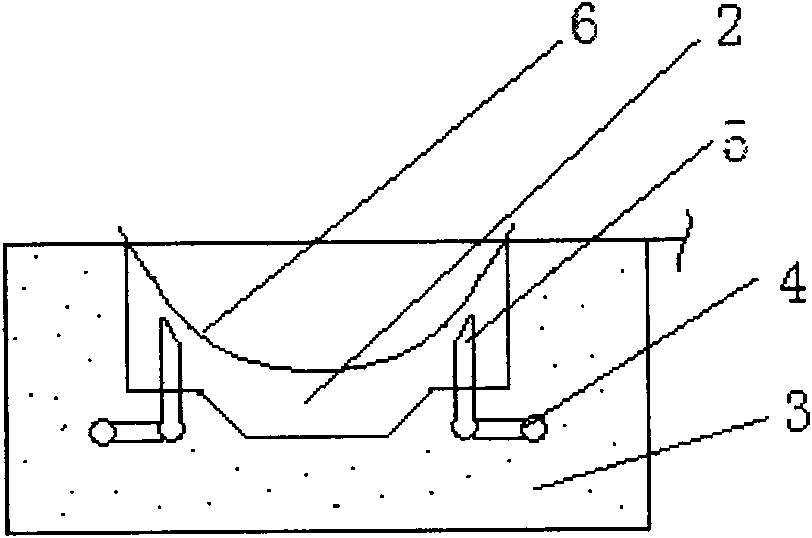

[0014] Such as figure 1 , 2 , 3, the present invention includes a body of furnace 1, a combustion chamber 2 in the body of furnace 1, a water jacket 3 arranged at the bottom of the combustion chamber 2 and a circumference thereof, and waste heat utilization pipes 4 in the water jacket 3. Such as figure 1 As shown, after the waste heat utilization pipeline 4 protrudes from the water jacket 3 on both sides of the combustion chamber 2, the top view projections are T-shaped respectively, and the symmetrical ends of each T-shaped are folded upwards and two suction nozzles are stretched to the distance from the boiler. The bottom of the pot surface 1cm place of 6, four suction nozzles 5 equal divisions are arranged on the circumference line concentric with pot 6. The suction pipe mouth 5 is a slope, which is consistent with the slope of the bottom of the pot.

Embodiment 2

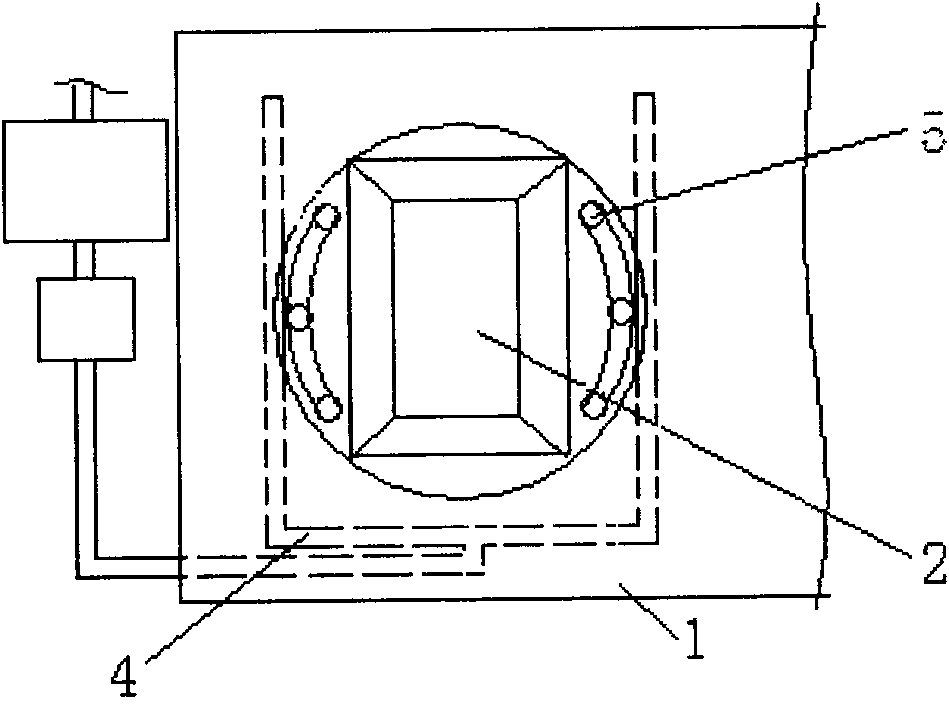

[0016] After the waste heat utilization pipeline 4 protrudes from the water jacket 3 on both sides of the combustion chamber 2, the top view projections are semicircular respectively. The semicircle is set at the same center as the pot. The suction pipe mouth 5. All the other implementations are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com