Novel silicon carbide porcelain boat

A technology of silicon carbide and porous silicon carbide, which is applied to chemical instruments and methods, laboratory containers, furnaces, etc., can solve the problems of polluting tube furnace tube porcelain boats, affecting yield, scattered porcelain boats, etc., and achieve thermal expansion The coefficient is small, the effect of improving product quality and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementations of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific implementation manners described herein are only used to illustrate and explain the embodiments of the present invention, and are not used to limit the embodiments of the present invention.

[0020] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with exemplary embodiments.

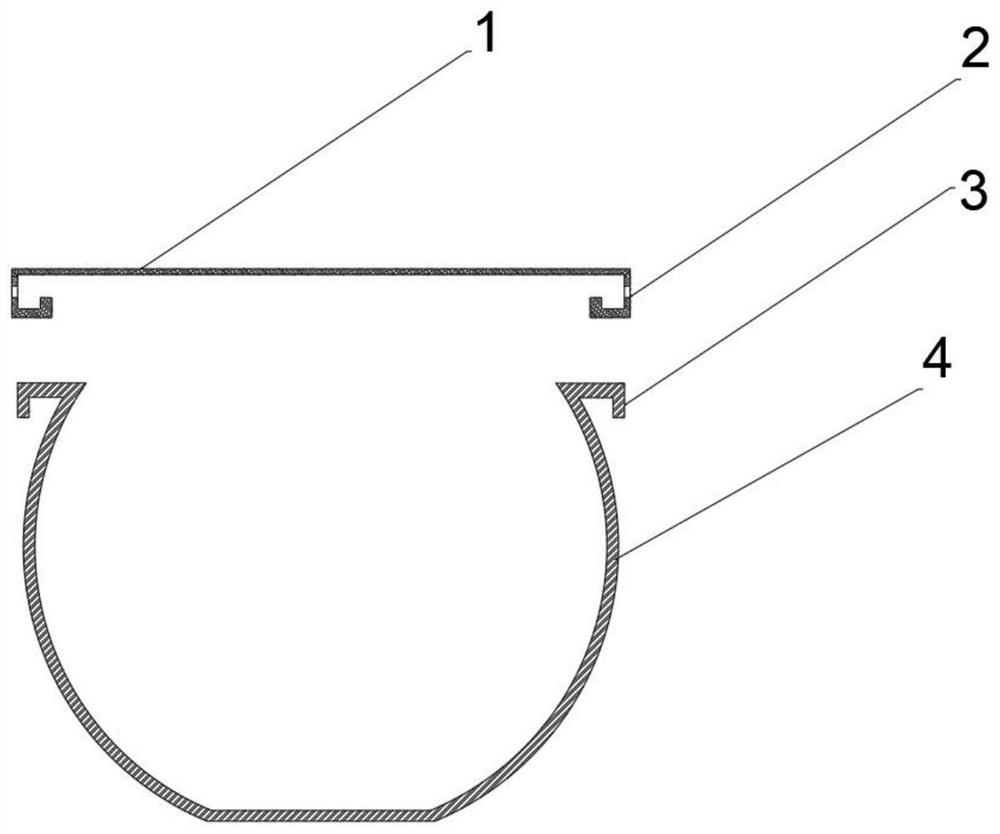

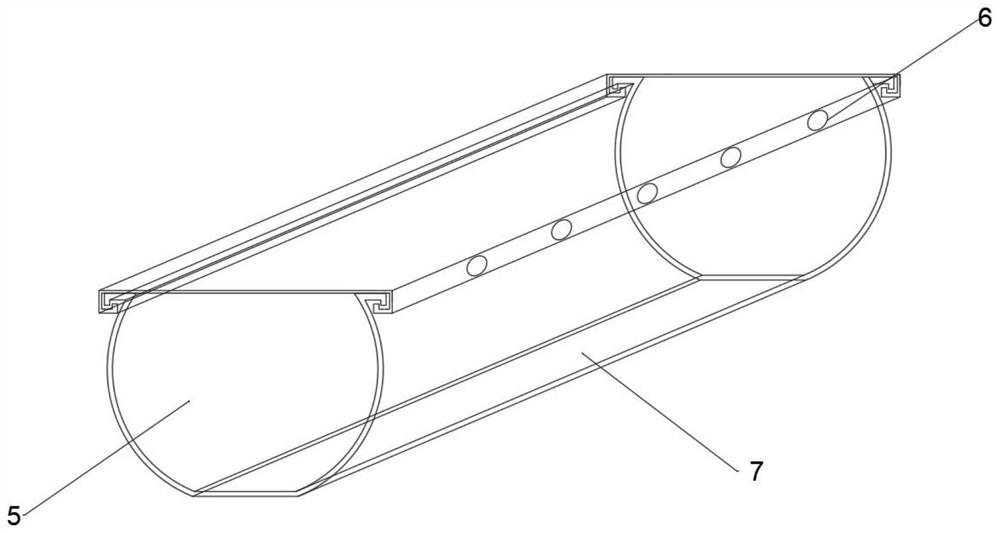

[0022] The novel silicon carbide ceramic boat of the present invention includes a bottom surface 7 and side walls surrounding the bottom surface, the bottom surface 7 and the side walls form a cavity with an opening, and the side walls are two oppositely arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com