A baking mechanism used in a thousand-sheet wheel production line

A technology of production line and thousand-sheet wheel, which is applied to the device for coating liquid on the surface, pretreatment of the surface, coating, etc., can solve the problems of low output, waste of energy, etc., to increase production capacity, solve low output, and improve heating conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described below with reference to the accompanying drawings and examples.

[0020] Abrasive belt cylinder refers to a bundle of tubular abrasive belts bonded by a large number of abrasive belts, and its cross section is circular.

[0021] Abrasive belt roll refers to the abrasive belt cylinder whose inner cavity has undergone glue injection, baking and shaping processes, and its length is generally one meter.

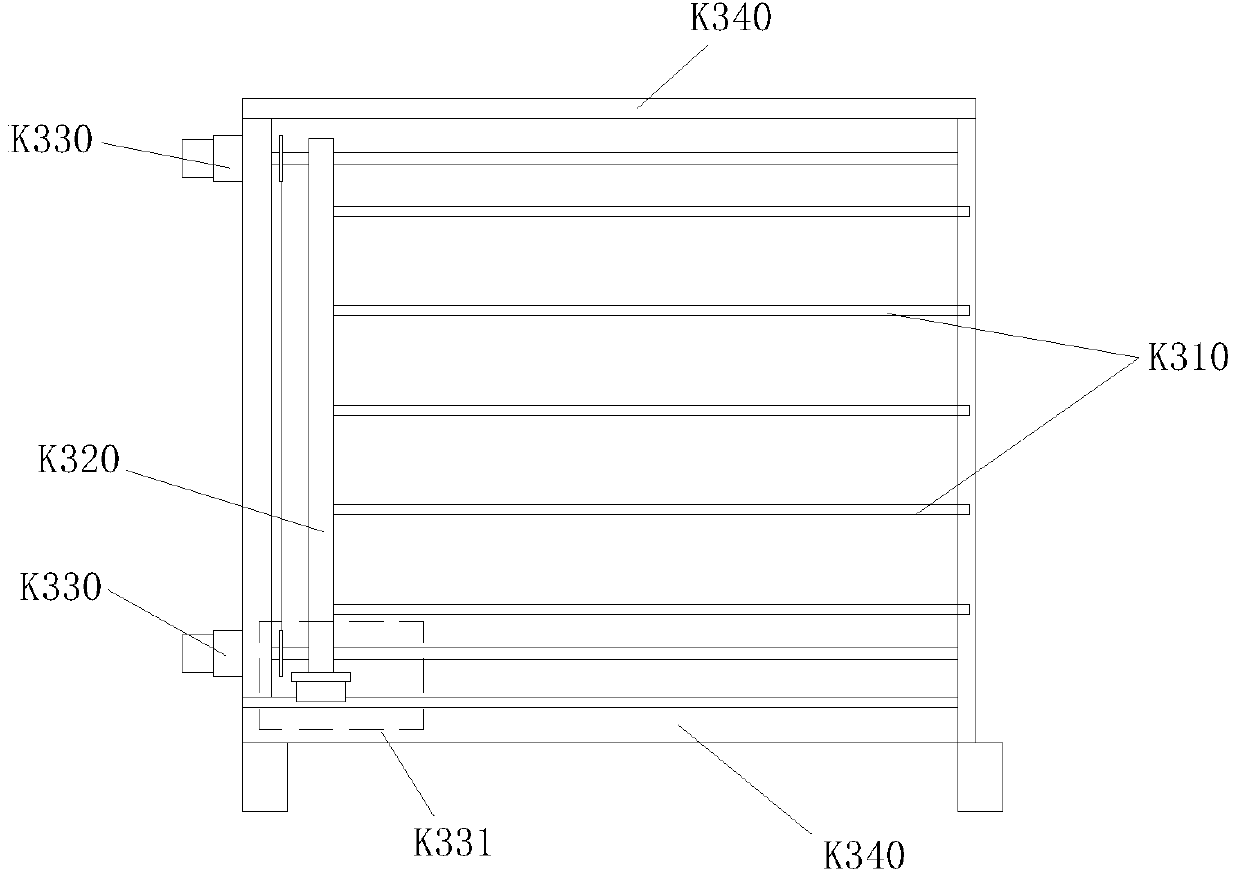

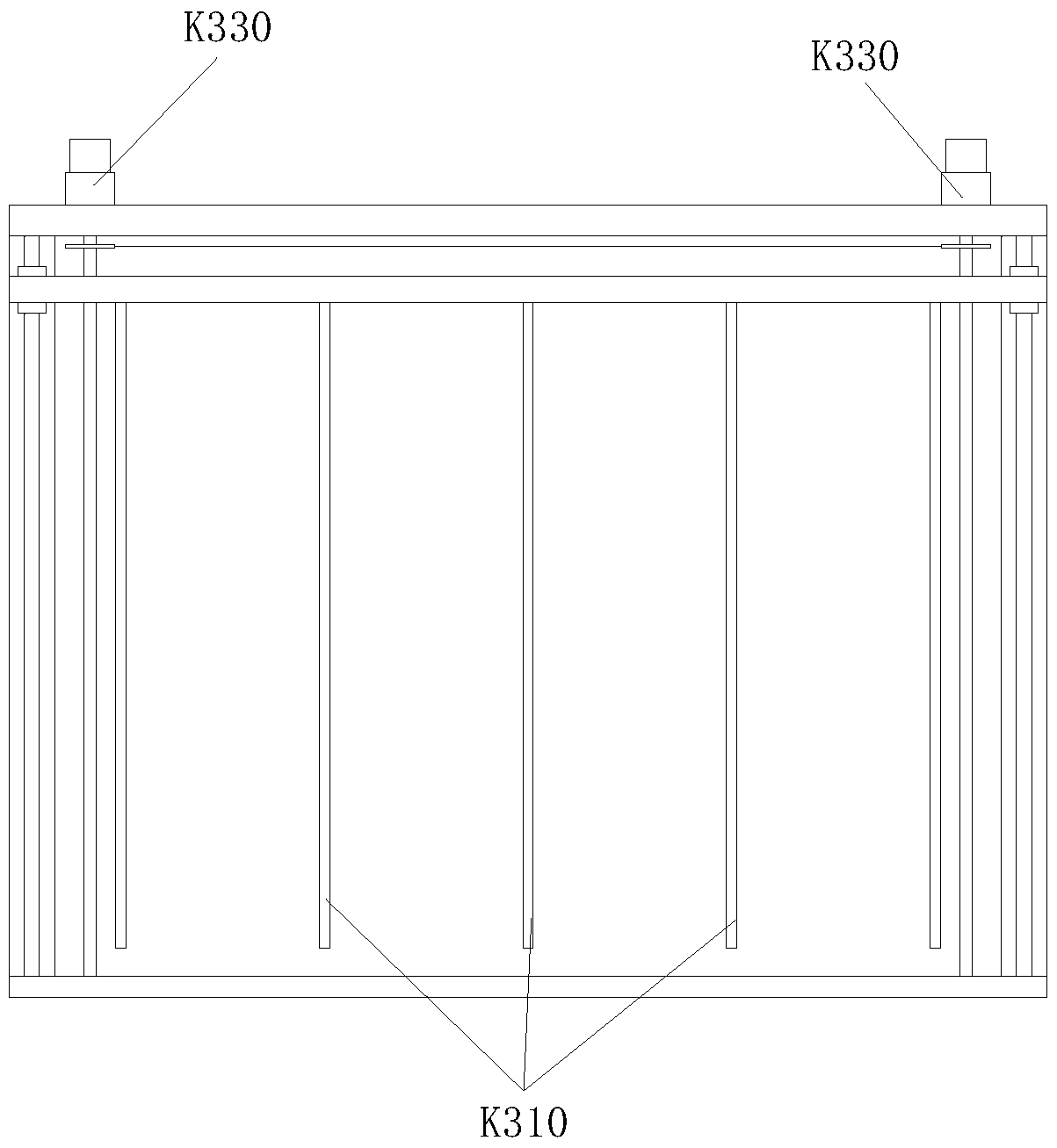

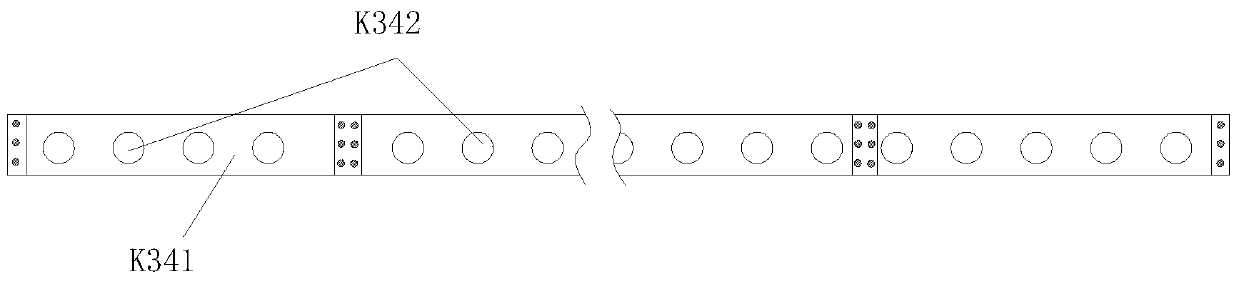

[0022] Such as figure 1 with figure 2 As shown, the invention discloses a baking mechanism used in a thousand-page wheel production line, and the baking mechanism is used for baking the blank roll of the abrasive belt after the glue injection is completed. It includes a heating tube K310 for heating and curing glue, a back plate K320 for fixing the heating tube K310, and a feeding unit K330 for controlling the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com