Solar photovoltaic photo-thermal coupling drying box

A solar photovoltaic, photothermal coupling technology, applied in the direction of solar heat storage, solar thermal energy, solar thermal power generation, etc., can solve the problems of obvious intermittent and uninterrupted utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

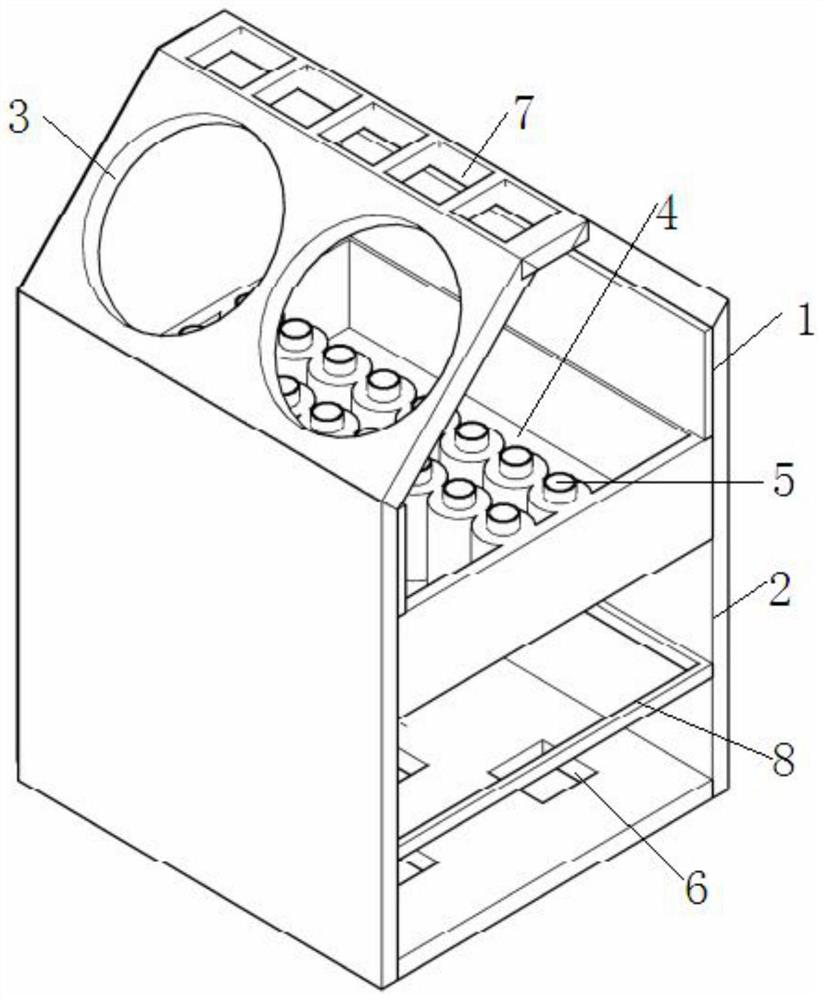

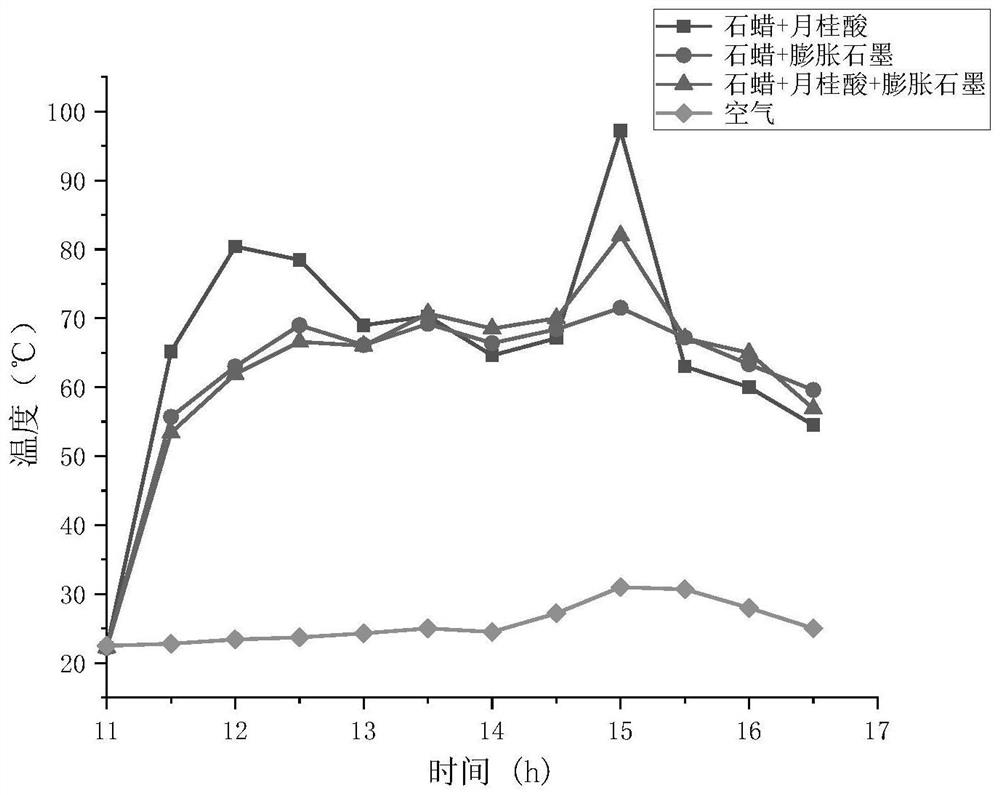

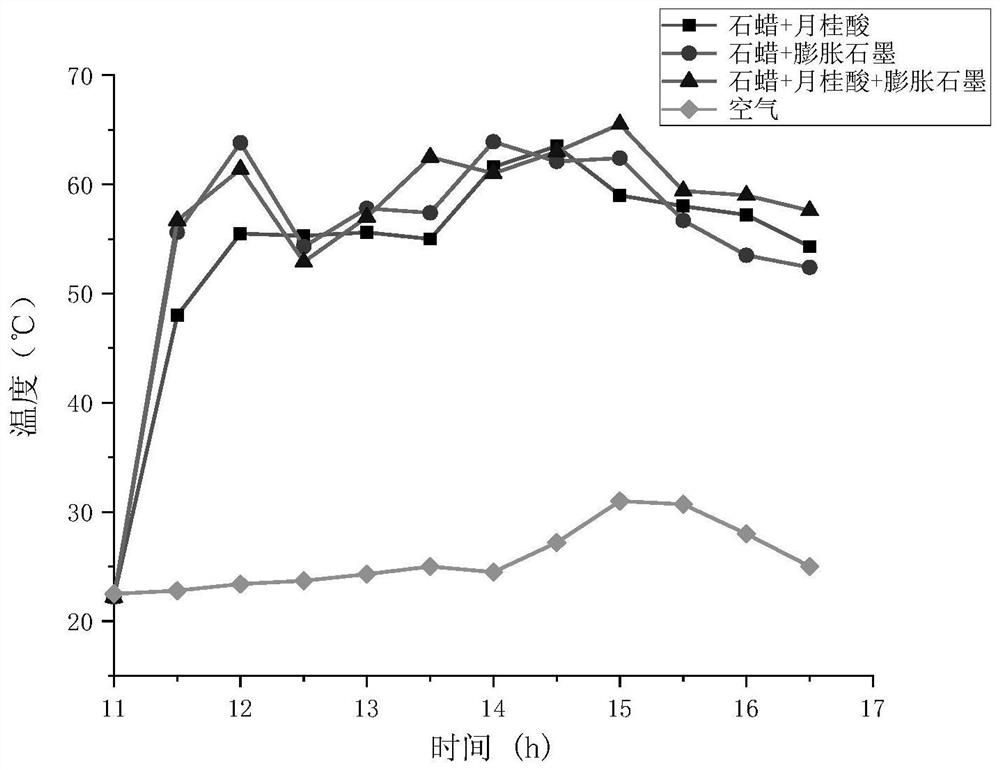

[0017] Embodiment 1: as Figure 1-Figure 4 As shown, a solar photovoltaic photothermal coupling drying box includes a heat storage layer 1 and a drying layer 2. The heat storage layer 1 is an inverted V-shaped structure and is arranged above the drying layer 2. The Neel lens 3 is provided with a composite medium layer 4 of paraffin, lauric acid and expanded graphite inside, and the heat storage layer 1 and the drying layer 2 are connected through a plurality of ventilation copper pipes 5, and the upper end of the ventilation copper pipe 5 is placed on the composite medium layer 4 (paraffin wax (80%) + lauric acid (10%) + expanded graphite (10%)), the top of the heat storage layer 1 and the bottom of the drying layer 2 are respectively provided with five induction fans 7 and five exhaust fans 6, the induction fans 7 and the exhaust fan 6 are connected to the battery, and the battery is connected to the photovoltaic panel through the charging module. dry.

[0018] The paraffin...

Embodiment 2

[0023] Example 2: The preparation method of the composite medium layer 4 is as follows: when preparing the composite medium layer, the paraffin wax as the main heat storage material is heated in the container, and 10% expanded graphite is added when the paraffin wax is completely melted. As a good heat-conducting material, the addition of graphite will greatly improve the heat-conducting efficiency of paraffin, so that heat can be stored in paraffin more efficiently. And because the 80-mesh expanded graphite is selected for use, the solubility of graphite in paraffin wax is further enhanced, making it difficult to precipitate in paraffin wax solution. In order to mix the two evenly and avoid uneven heat conduction, sufficient stirring is required during the mixing process. After the two are mixed evenly, cool and maintain the temperature of the heat storage medium to 65 degrees. At this time, add 10% lauric acid. The choice of 65 degrees is because when the temperature is lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com